Thermal bending/diffusion bonding technology method for three-layer corrugated structure of TiAl base alloy

A technology of diffusion bonding and process method, applied in the field of TiAl-based alloy three-layer corrugated structure thermal bending/diffusion bonding process, can solve the problems of high energy consumption, low production efficiency, long process time, etc., to reduce energy consumption and improve efficiency , the effect of reducing heat exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

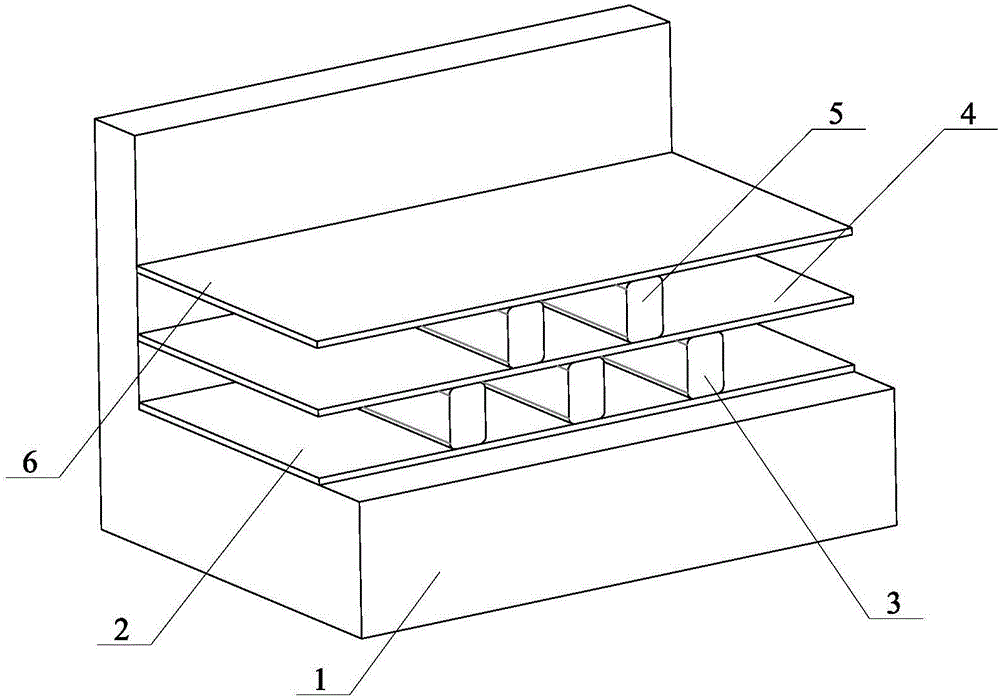

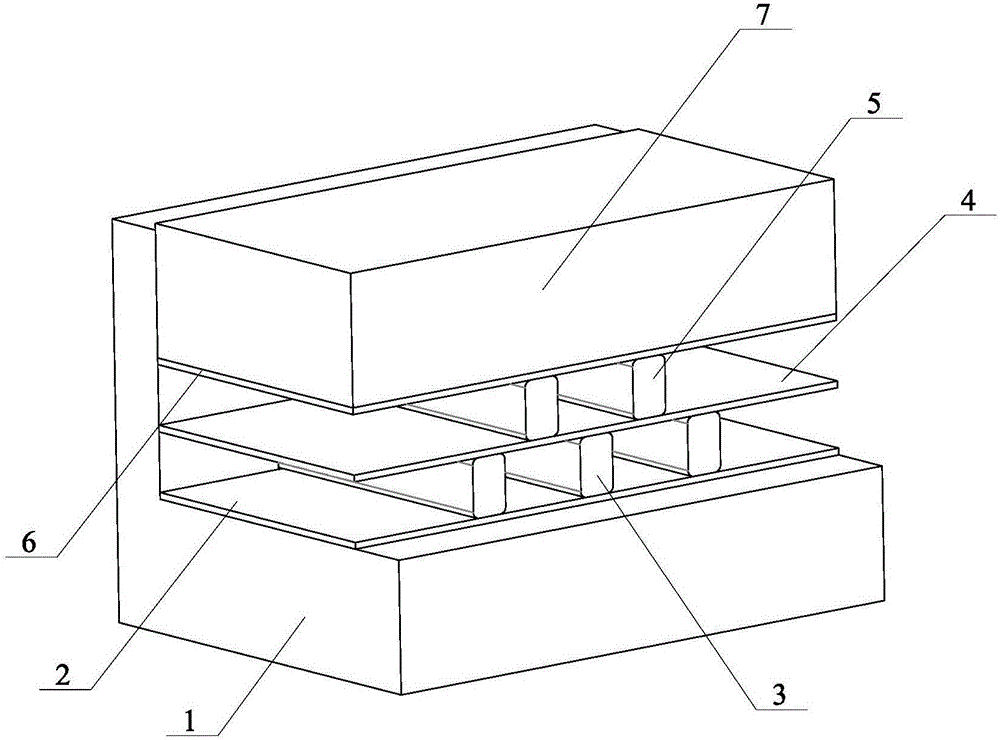

[0017] Specific implementation mode one: combine Figure 1 to Figure 3 To illustrate this embodiment, a TiAl-based alloy three-layer corrugated structure thermal bending / diffusion bonding process method in this embodiment includes the following steps:

[0018] Step 1: Surface treatment:

[0019] The method of combining mechanical cleaning and chemical cleaning is used to remove the surface oxide layer and oil stains, and to clean the surface of the sheet to ensure that the surface is free from pollution;

[0020] Step 2: Arranging the three-layer corrugated structure;

[0021] Lay the lower panel 2 on the lower pressure head 1, set three strip-shaped lower pads 3 side by side on the lower panel 2, lay the core board 4 horizontally on the three strip-shaped lower pads 3, and arrange two upper pads 5 side by side on the core board 4 above, and the two upper pads 5 are located above the two adjacent strip-shaped lower pads 3 among the three strip-shaped lower pads 3, and the up...

specific Embodiment approach 2

[0024] Specific implementation mode two: combination Figure 1 to Figure 3 This embodiment will be described. In this embodiment, the upper panel 6 , the core panel 4 and the lower panel 2 are all rectangular plates. The dimensions of the upper panel 6 and the lower panel 2 in the length direction are equal to or smaller than the length of the core panel 4 . Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

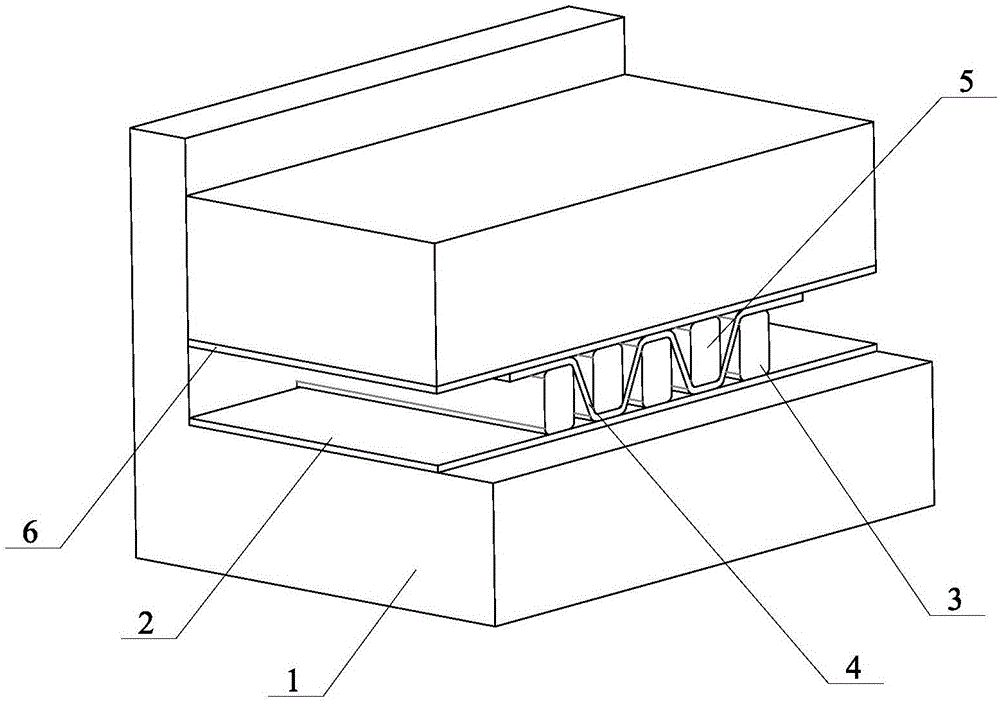

[0025] Specific implementation mode three: combination Figure 1 to Figure 3 To illustrate this embodiment, after the corrugated core plate is formed in Step 3 of this embodiment, the pressure continues to increase at a rate of 2-3 MPa per minute until the pressure between the core plate and the panel reaches about 20 MPa. Under the pressure and constant temperature conditions, keep it for 2-3 hours to realize the diffusion connection between the upper panel 6 and the core panel 4 and the lower panel 2 and the core panel 4 . Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

[0026] In order to be able to press the best corrugated core plate, the best thermal bending temperature is 1050°C. For diffusion connection, in order to form an excellent diffusion connection interface, the pressure should reach 12MPa, and the connection time is 3h. At this time, it can be formed Defect-free connection interface with high interface strength.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com