Patents

Literature

41results about How to "Reduce the difficulty of welding operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Welding method of low alloy steel plate and ship plate

ActiveCN104646803AReduce distortionReduce the difficulty of welding operationArc welding apparatusWelding/soldering/cutting articlesProduction rateSheet steel

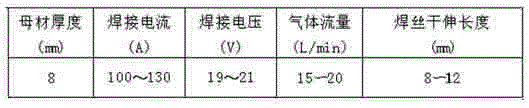

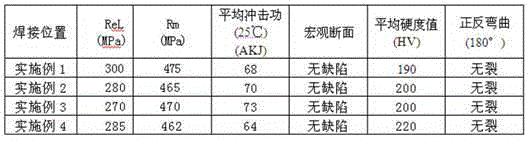

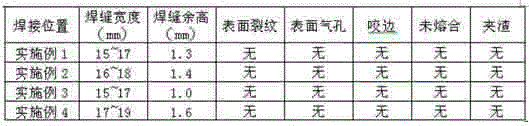

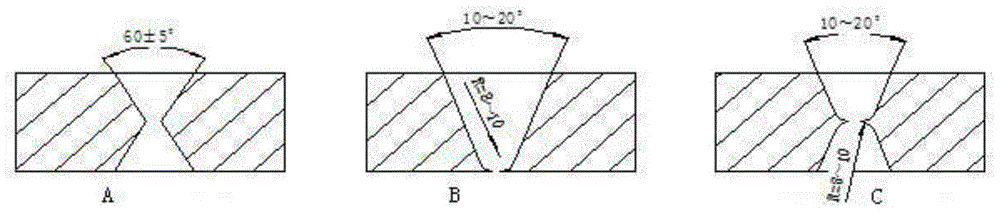

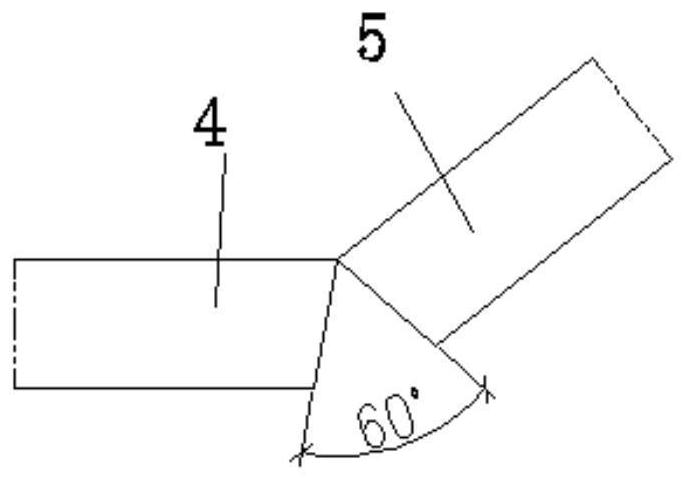

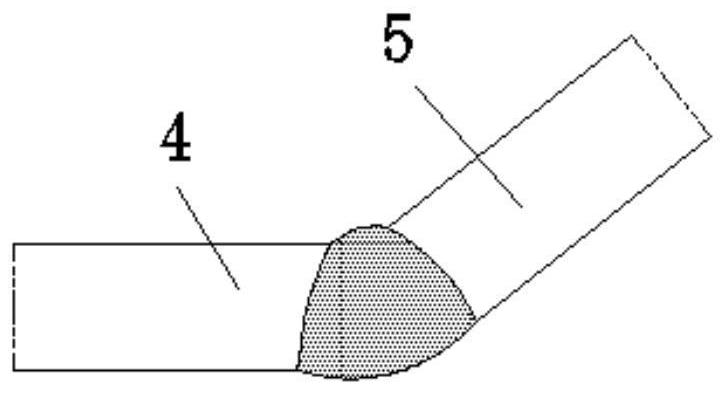

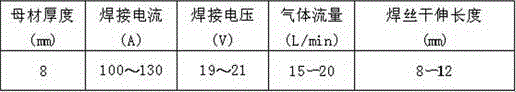

The invention discloses a welding method of a low alloy steel plate and a ship plate and relates to the technical field of welding. According to the welding method, through analysis and experiment, stipulates that grooves and surfaces of welding materials are subjected to dust cleaning before the two dissimilar steel boards are welded, wherein a weld width between the steel boards is less than 1mm; the back face of a slab joint is subjected to positioned welding with gas shielded welding, so that the positions of striking arc are full and arc suppression positions are filled with arc craters; welding is carried out with small specifications, multi-layer and multi-pass welding can be realized, and weld joints on each face are subjected to backing welding and cosmetic welding; for the slab joint, carbon arc gouging is adopted to machine the grooves, and the angle of the grooves is 60-70 degrees; the grooves are ground; a welding part and the both sides of the welding part are baked for dehumidification through a cutting torch before welding; the temperature of a weld joint layer and the inter-pass temperature are controlled to be below 100 DEG C. With the adoption of the welding method, the problems that by the conventional welding method for low alloy steel plates and ship steel plates, the welding production rate is low, the whole weld is poor in quality, and a welding structure is large in transformation can be solved.

Owner:中船桂江造船有限公司

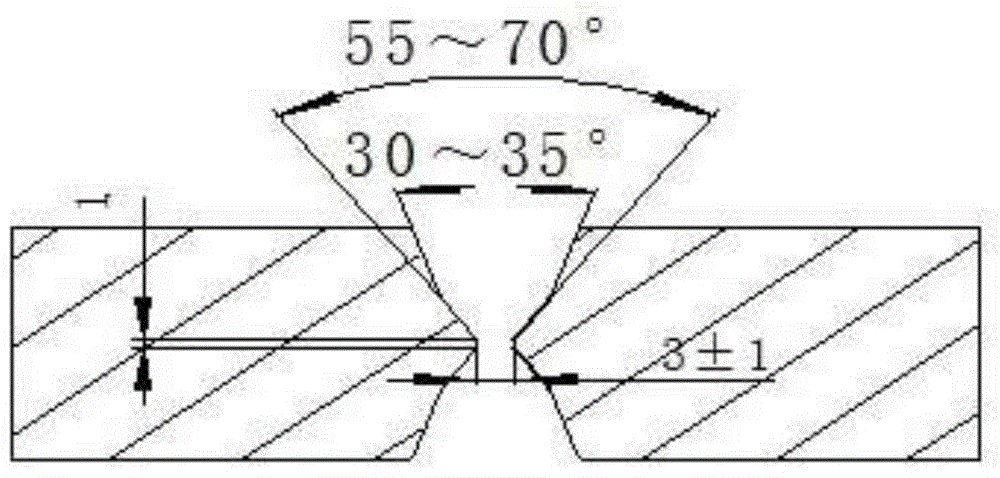

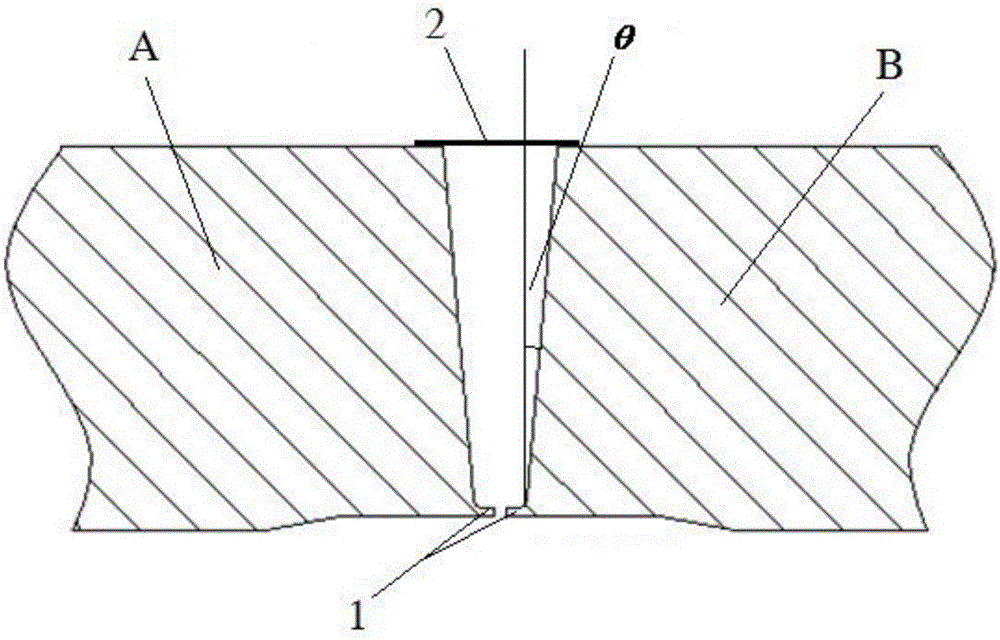

Welding technology for manual argon arc welding of thick plate titanium material

InactiveCN104057185AReduce the difficulty of welding operationGuarantee welding qualityArc welding apparatusWelding/soldering/cutting articlesTitaniumEngineering

The invention discloses a welding technology for manual argon arc welding of a thick plate titanium material. The welding technology comprises the following steps: 1) cleaning welding wires, the surface of a groove and two sides of the groove; 2) adopting a double V-shaped groove, setting the angle of the lower section of the groove to be 55-70 degrees, and setting the angle of the upper section of the groove to be 30-35 degrees; 3) determining welding parameters, and welding. The application range of welding technology for manual argon arc welding of the titanium material is enabled to be further enlarged, and is particularly suitable for welding the titanium material of more than or equal to 20mm. The angle of the lower section of the groove is 55-70 degrees, so that a sufficient welding operation space is ensured, the defects of incomplete fusion, incomplete penetration and the like are prevented from being generated, and the welding quality is guaranteed; the angle of the upper section of the groove is 30-35 degrees, so that the metal filling volume is effectively reduced, and the difficulty requirements of improved groove processing technology is greatly reduced compared with U-shaped and double U-shaped grooves.

Owner:LUXI IND EQUIP

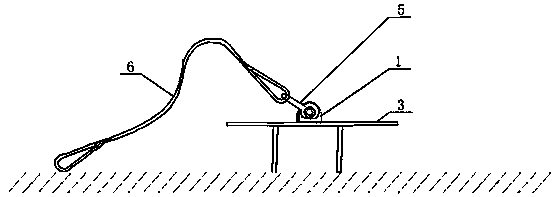

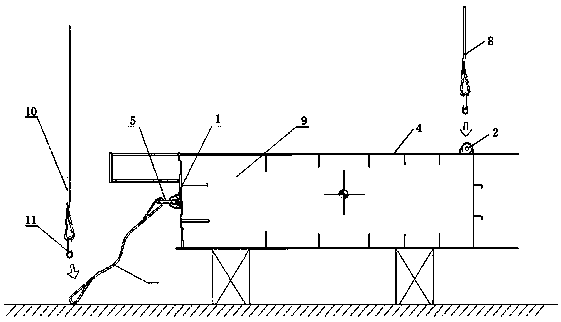

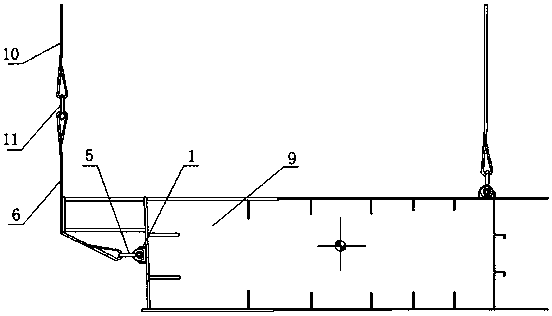

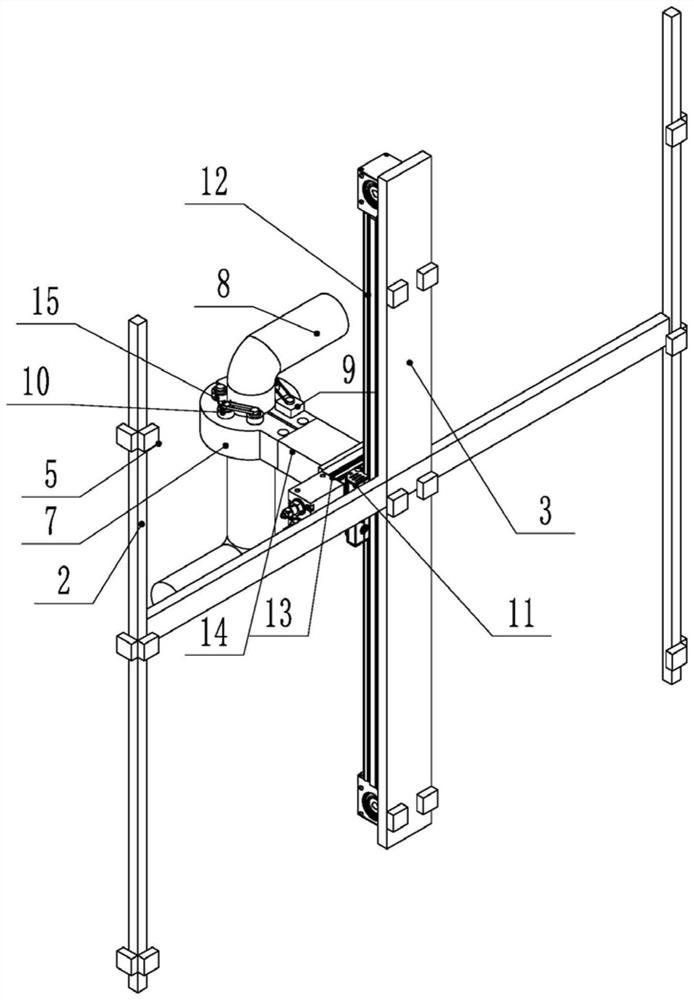

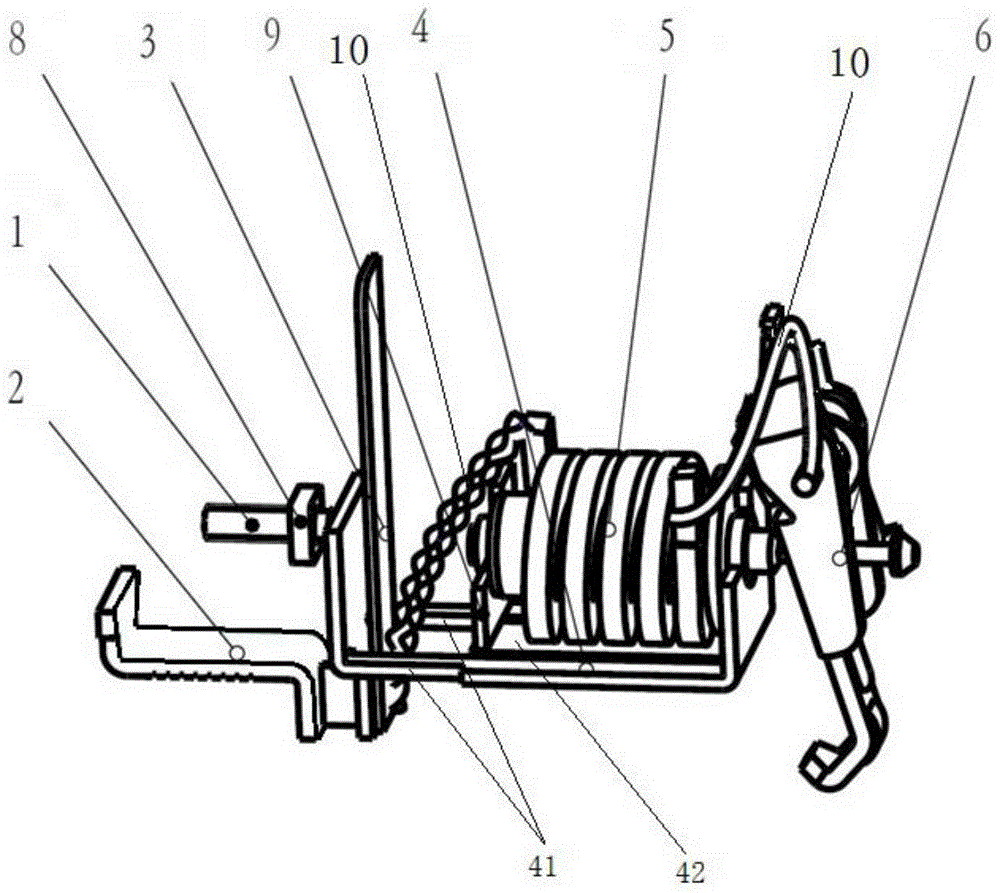

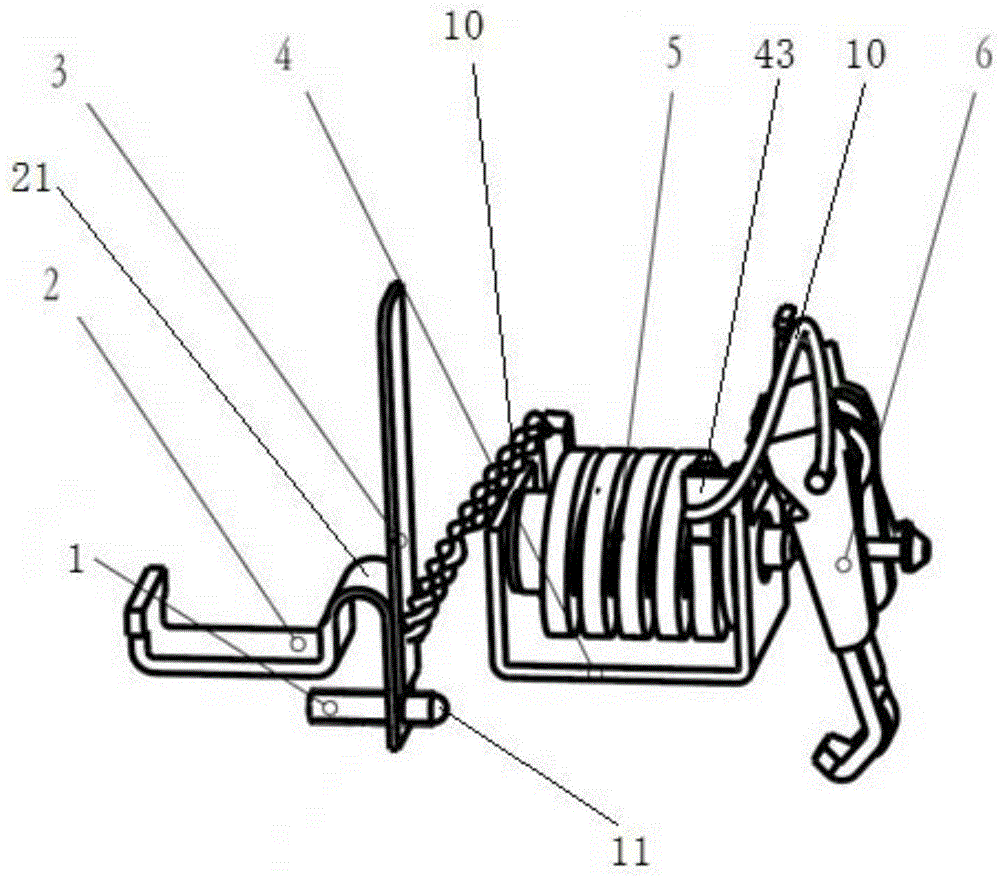

Segmental lifting method for ship body provided with hatch coaming

InactiveCN108163694AReduce installation difficultyReduce the difficulty of welding operationLoad-engaging elementsMarine engineeringMaterial resources

The invention discloses a segmental lifting method for a ship body provided with a hatch coaming. The segmental lifting method comprises the following specific steps that a main hook lifting ring andan auxiliary hook lifting ring are installed in the small assembly stage; a first shackle is installed on the main hook lifting ring, a first steel wire rope is fixed to the first shackle, and a second steel wire rope is fixed to the auxiliary hook lifting ring; a deck assembly and other assemblies of the ship body are assembled into ship body segments; the first steel wire rope is connected witha second shackle on a crane; the ship body segments are lifted; and the first shackle and the first steel wire rope are disassembled. According to the segmental lifting method, the lifting rings are installed in the small assembly stage, jacking push operation is converted into plane operation, the lifting rings can be installed without adopting auxiliary jacking push tools, the installing difficulty of the lifting rings is greatly lowered, the installing quality of the lifting rings is greatly improved, the operation difficulty is lowered, quick installing of the lifting rings and the steel wire ropes is achieved, a lot of manpower and material resources are saved, and the production efficiency is improved.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

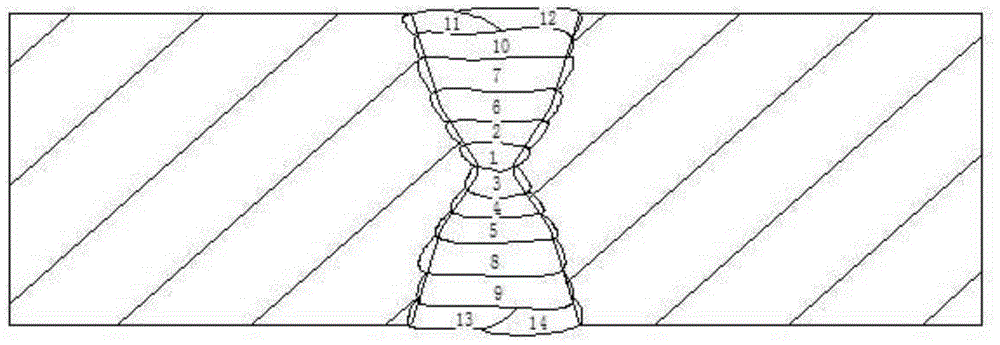

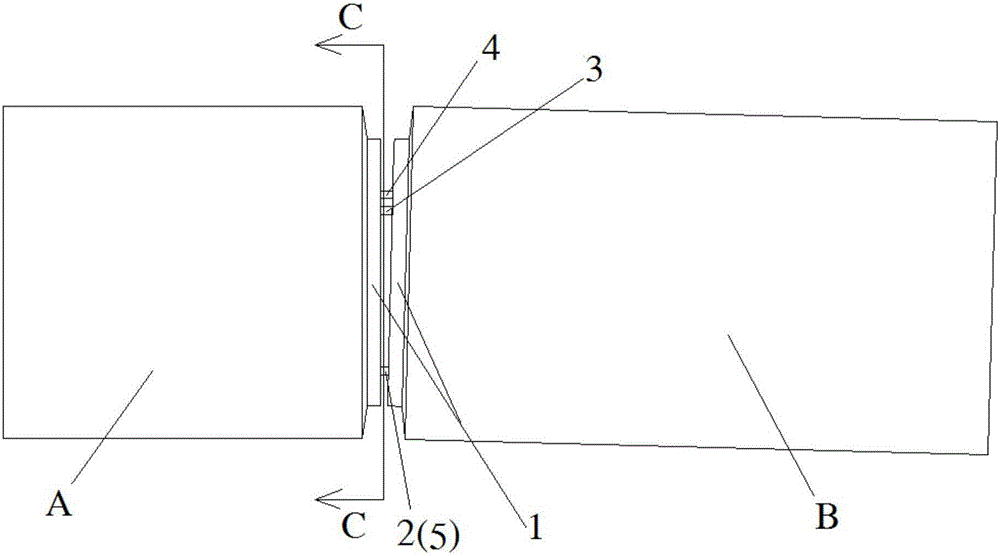

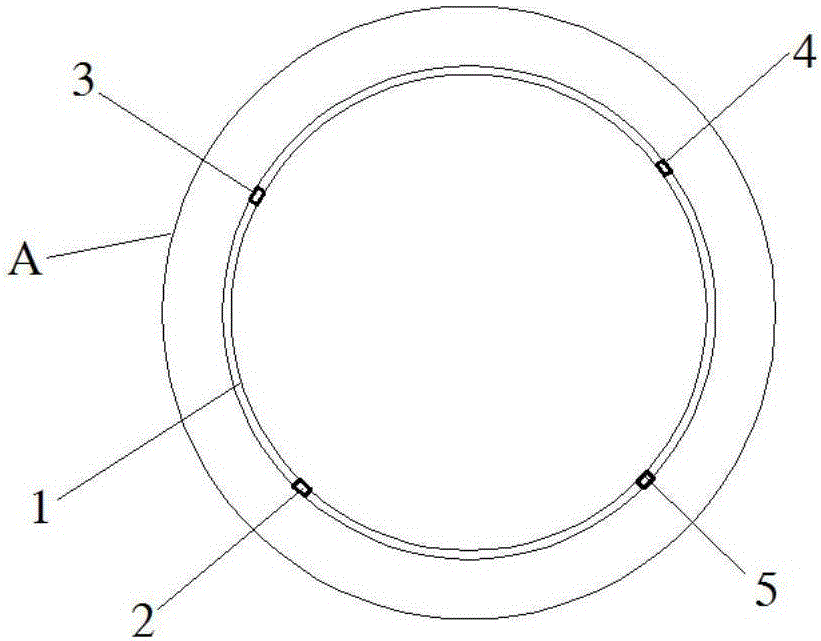

Method for welding butt joint of large thick wall pipelines in nuclear power station

InactiveCN105149744AReduced precision requirementsPrevent breakdownArc welding apparatusNuclear powerButt joint

The invention relates to the field of building of nuclear power stations, in particular to a method for welding a butt joint formed by assembling large thick wall pipelines in a nuclear power station, and provides a method for welding a butt joint of large thick wall pipelines of a nuclear power station to lower welding difficulty and improve the welding efficiency and effect. The outer diameter of the large thick wall pipelines ranges from 450 mm to 1,100 mm, the pipe wall thickness ranges from 30 mm to 100 mm, and the pipelines are assembled to form an assembling clearance gradually increased from the 0-degree position of the butt joint to the 180-degree position of the butt joint. Back argon shielding is carried out in the welding process. Melt welding is carried out to form a penetration weld bead, and welding current is gradually increased. Support welding is carried out to form a plurality of supporting weld beads, and bottoming welding is completed. Filling welding is carried out, and when the root width of weld seams is smaller than or equal to 10 mm, single-layer and single-weld-bead welding is adopted. When the root width of the weld seams is larger than 10 mm, single-layer and multi-weld-bead welding is adopted till filling welding is completed. Covering welding is carried out to form a covering weld bead, and welding is finished. The welding method is low in operation difficulty, good in welding effect and high in efficiency.

Owner:CHINA NUCLEAR IND 23 CONSTR

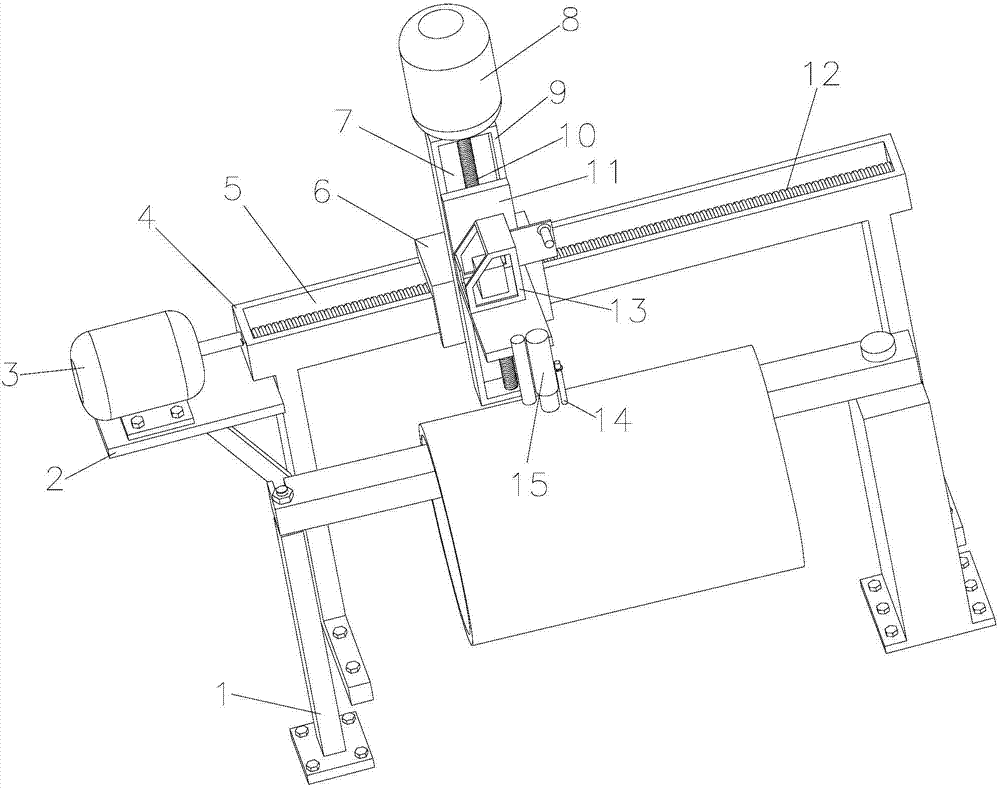

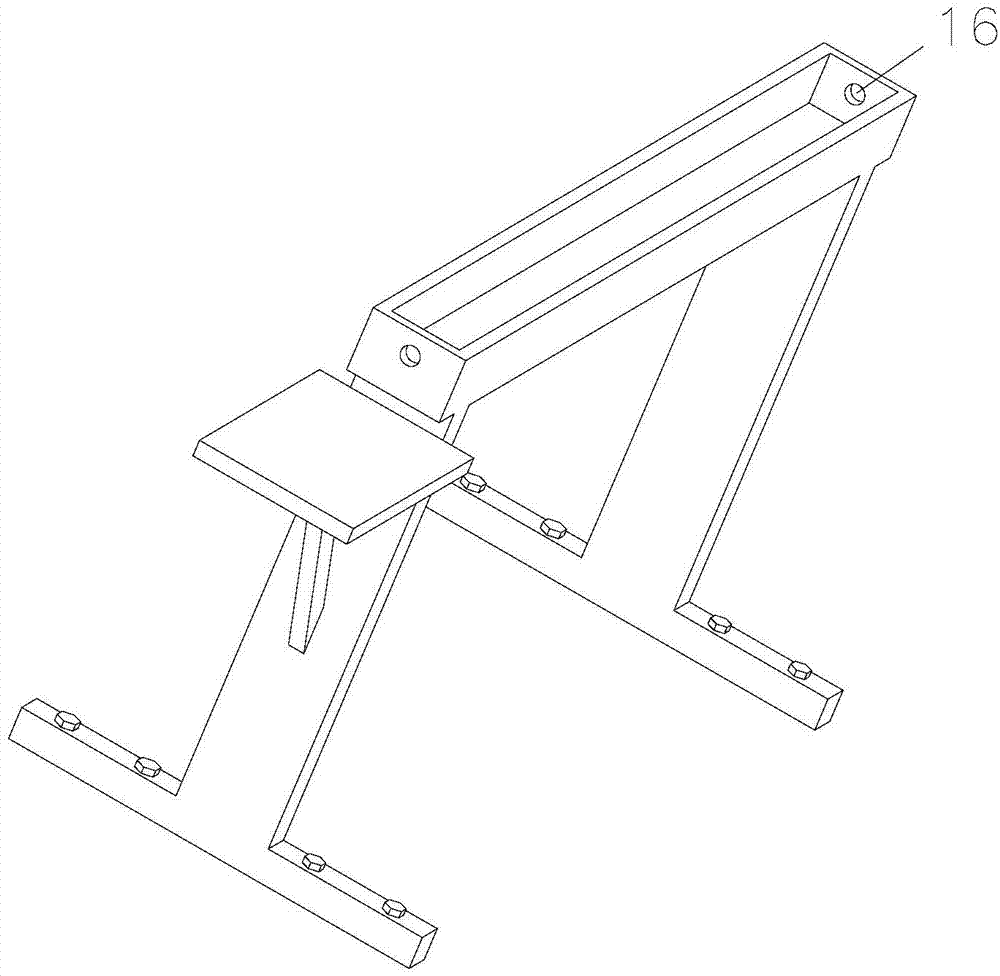

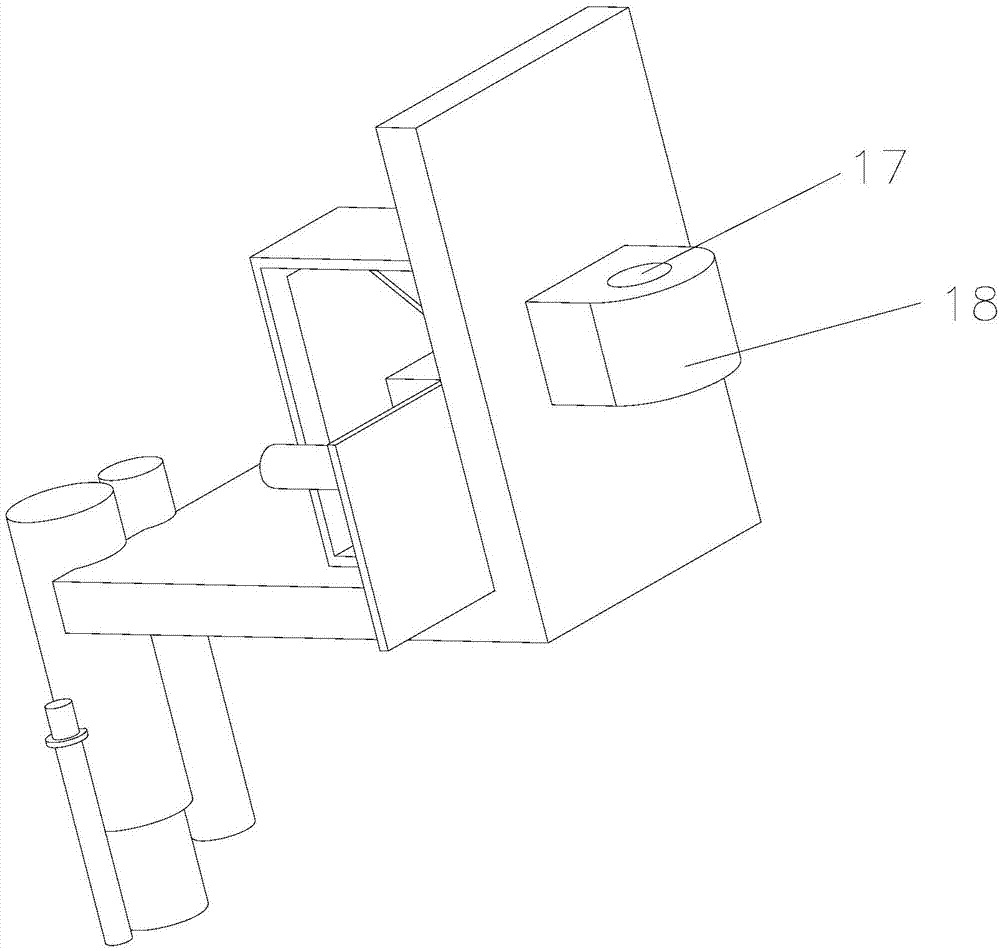

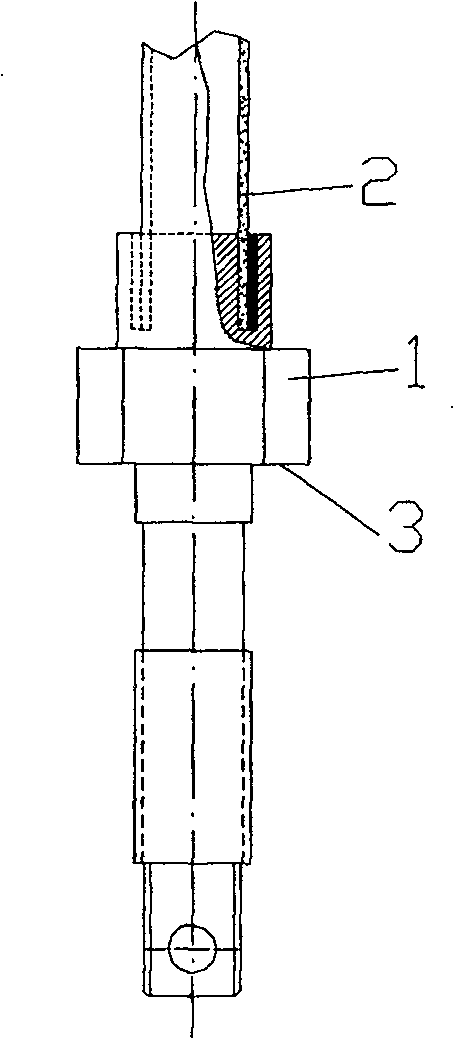

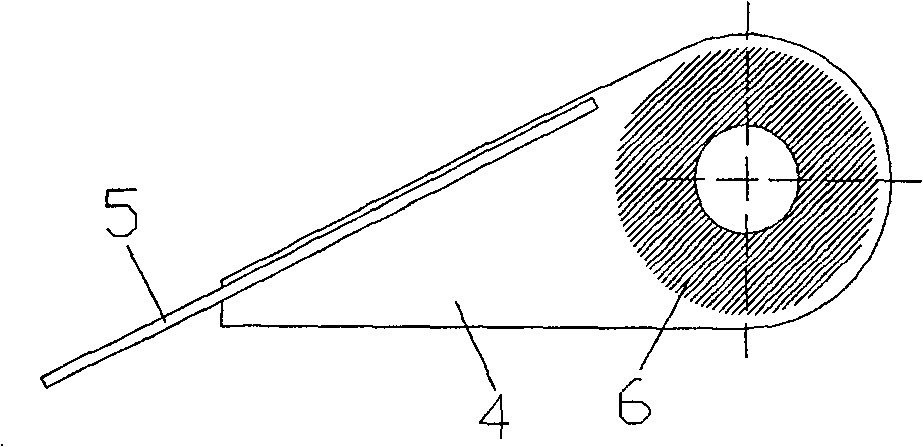

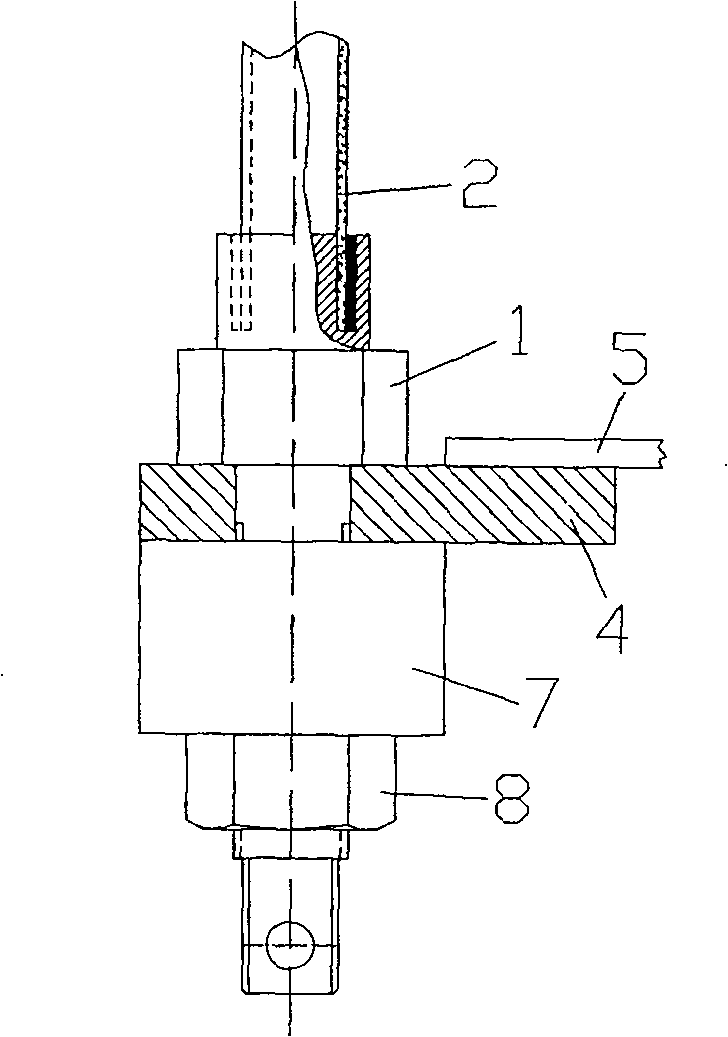

Infrared alignment pipe welding equipment

ActiveCN104493328AReduce the difficulty of welding operationImprove welding qualityPlasma welding apparatusMetal working apparatusPipe supportMost Times

The invention relates to infrared alignment pipe welding equipment which is characterized by comprising a transverse feeding mechanism, a longitudinal feeding mechanism, a welding mechanism and a pipe support frame, wherein the welding mechanism is arranged on the longitudinal feeding mechanism in a sliding way; the longitudinal feeding mechanism is arranged on the transverse feeding mechanism in the sliding way; the pipe support frame is arranged in parallel in front of the transverse feeding mechanism. According to the equipment, infrared rays are used for calibrating a pipe, a welder can regulate a welding head to move leftwards and rightwards directly by watching an infrared point in most time, and such a manner is more accurate than alignment by watching a plasma arc, so that difficulty in welding operation is reduced; the straightness of a weld can be monitored at any time by virtue infrared light, so that welding quality is improved.

Owner:JIANGSU WUJIN STAINLESS STEEL PIPE GRP

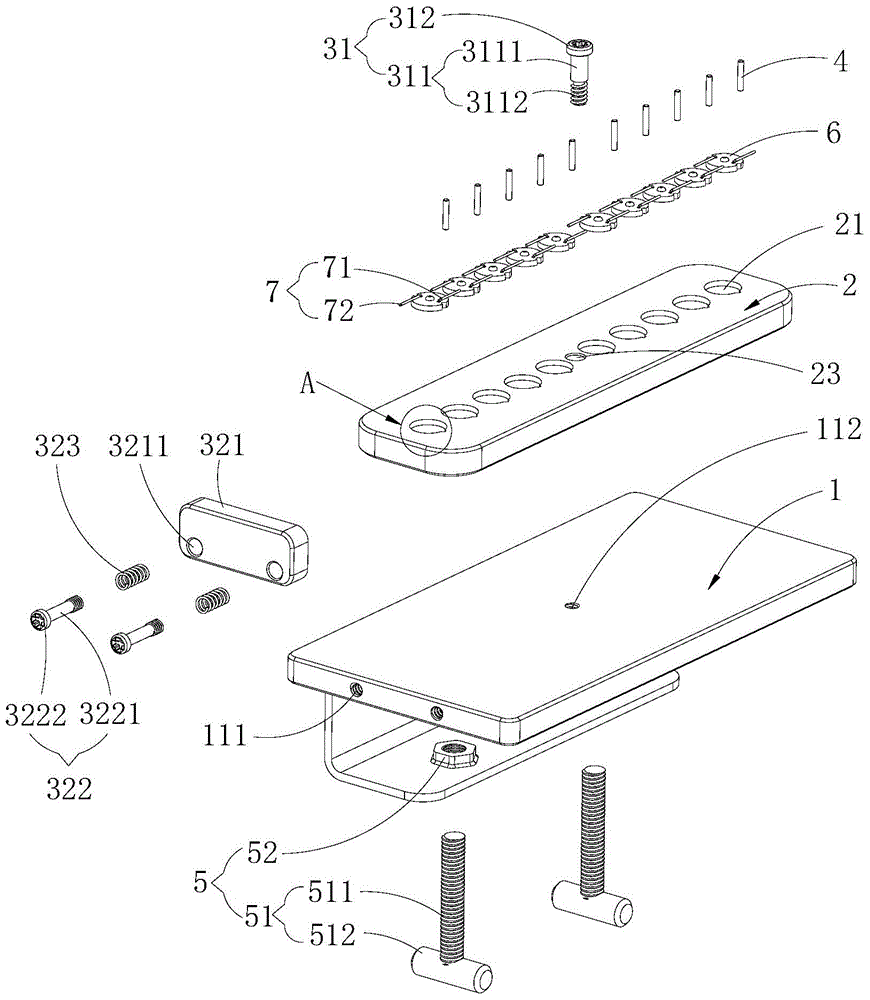

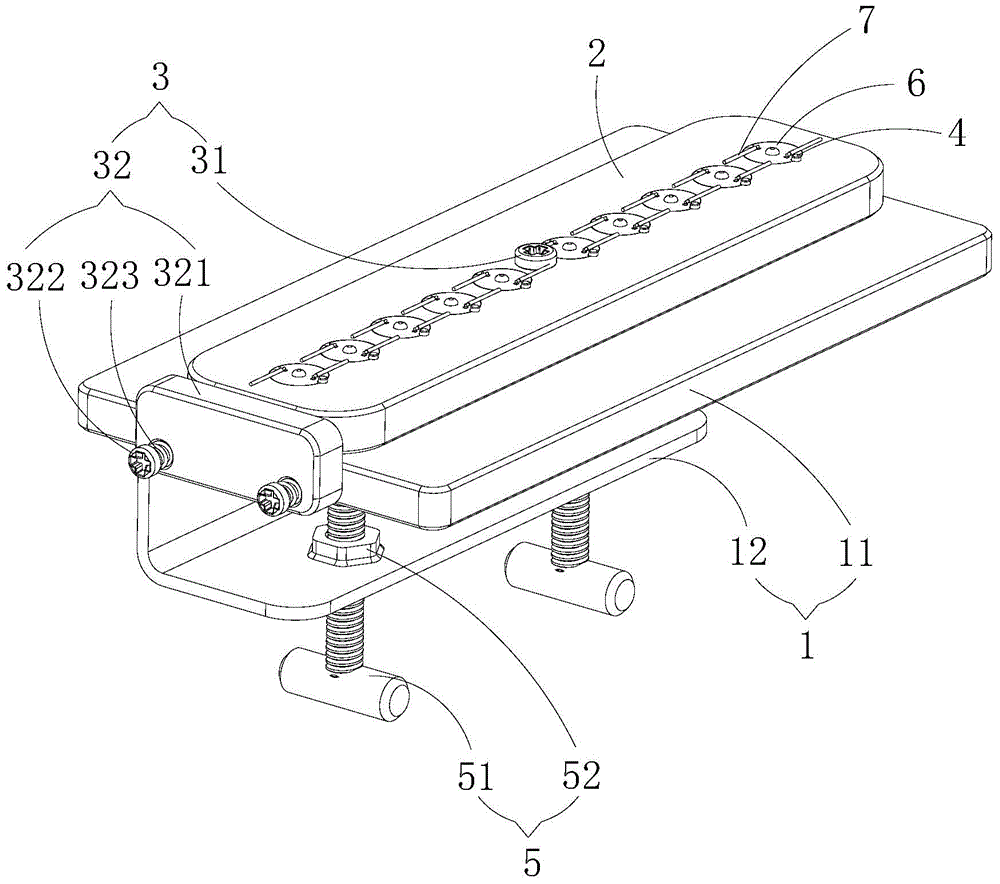

Machining locating device for LED light-emitting plates

InactiveCN104439817ARealize the installation and fixationEffective installation and fixationWelding/cutting auxillary devicesAuxillary welding devicesEngineeringLED lamp

The invention is suitable for the field of LED lamp production equipment and discloses a machining locating device for LED light-emitting plates. The machining locating device is used for locking and locating the LED light-emitting plates with first limiting grooves formed in the outer side walls in a protruding mode during machining. The machining locating device comprises a base, a locating plate, a locking assembly and limiting posts, wherein the base is used for being connected with a workbench, the locating plate is arranged on the base, the locking assembly is used for locking and fixing the locating plate to the base, and the limiting posts are used for locking the LED light-emitting plates to the locating plate; at least one locating hole used for containing the LED light-emitting plates is formed in the locating plate in a spaced mode, the inner side wall of each locating hole is provided with a second limiting groove in a protruding mode, each second limiting groove and the corresponding first limiting groove are used for forming a limiting hole in an enclosed mode, and the limiting posts are fixed in the limiting holes in an inserted mode. When a wire welding sequence is conducted, the machining locating device is adopted for locking and locating the LED light-emitting plates, so the work fatigue degree of production staff can be lowered, wire welding efficiency is improved, and welding quality of wires on the LED light-emitting plates is guaranteed.

Owner:OCEANKING DONGGUAN LIGHTING TECH +2

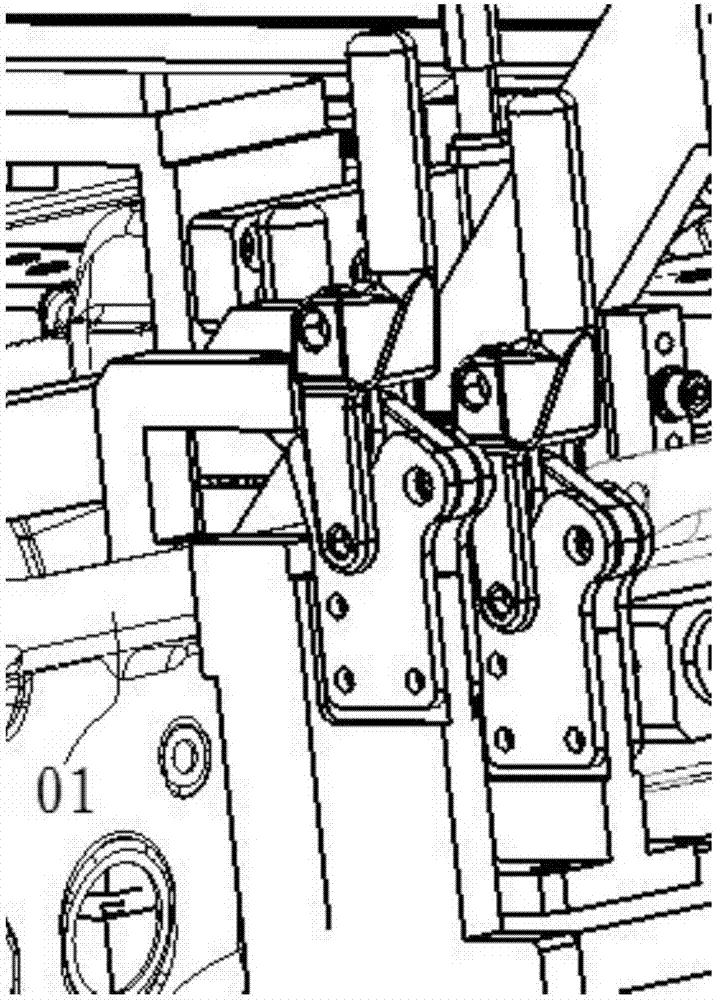

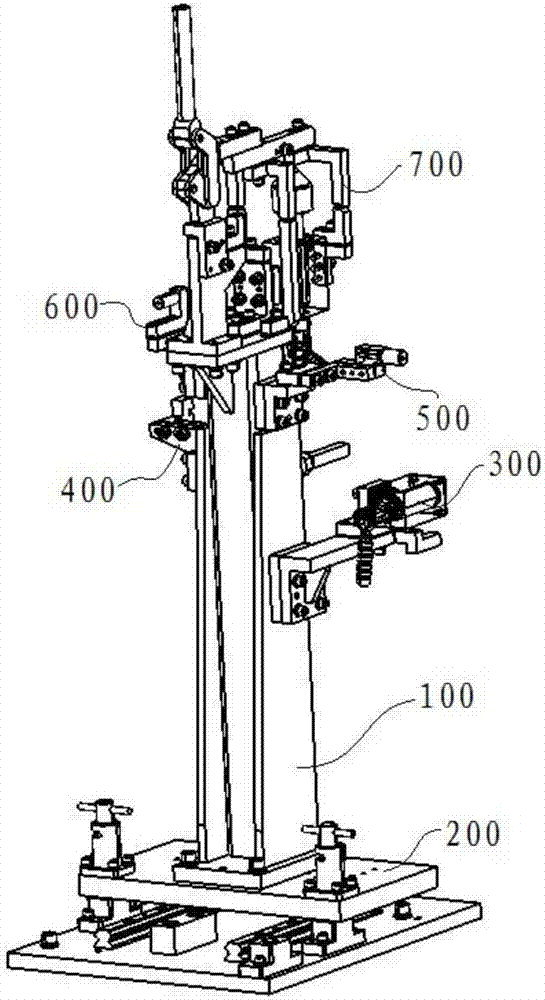

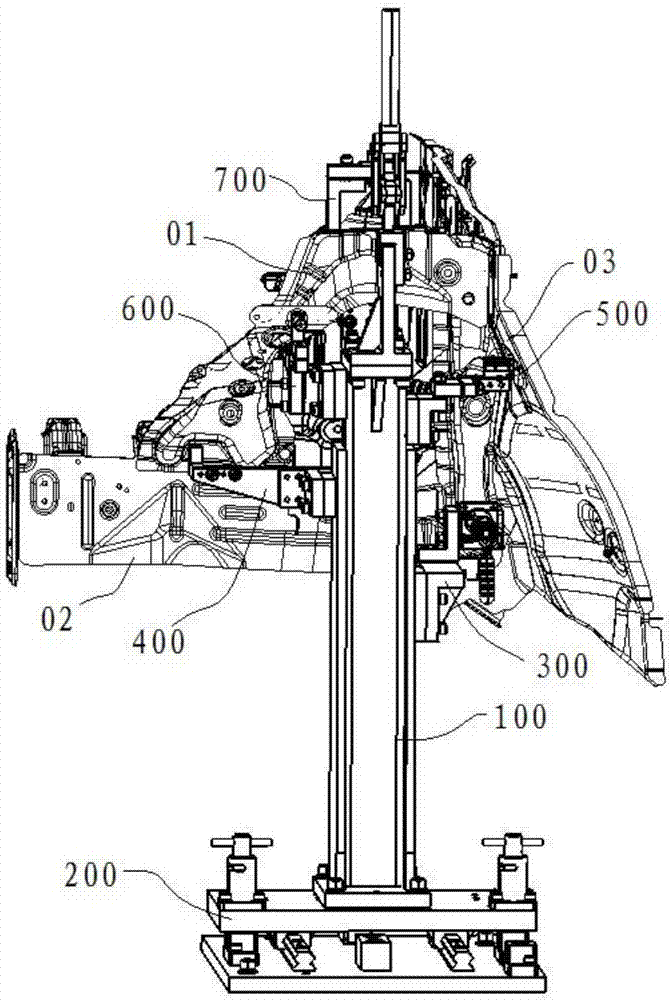

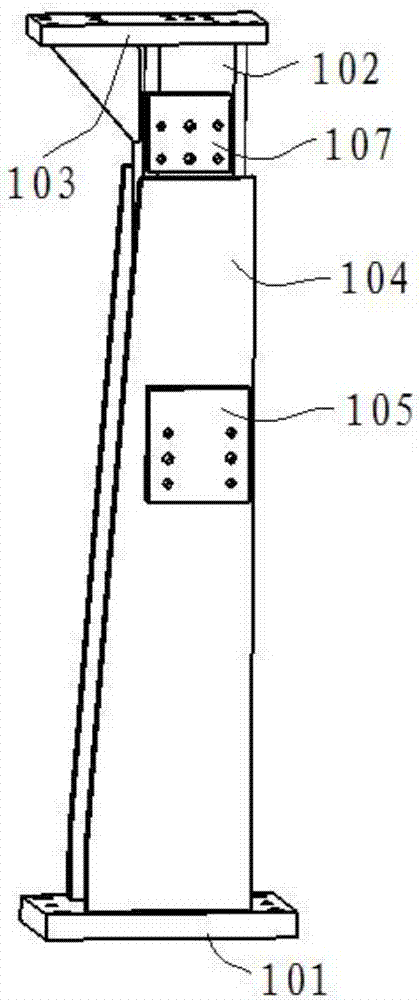

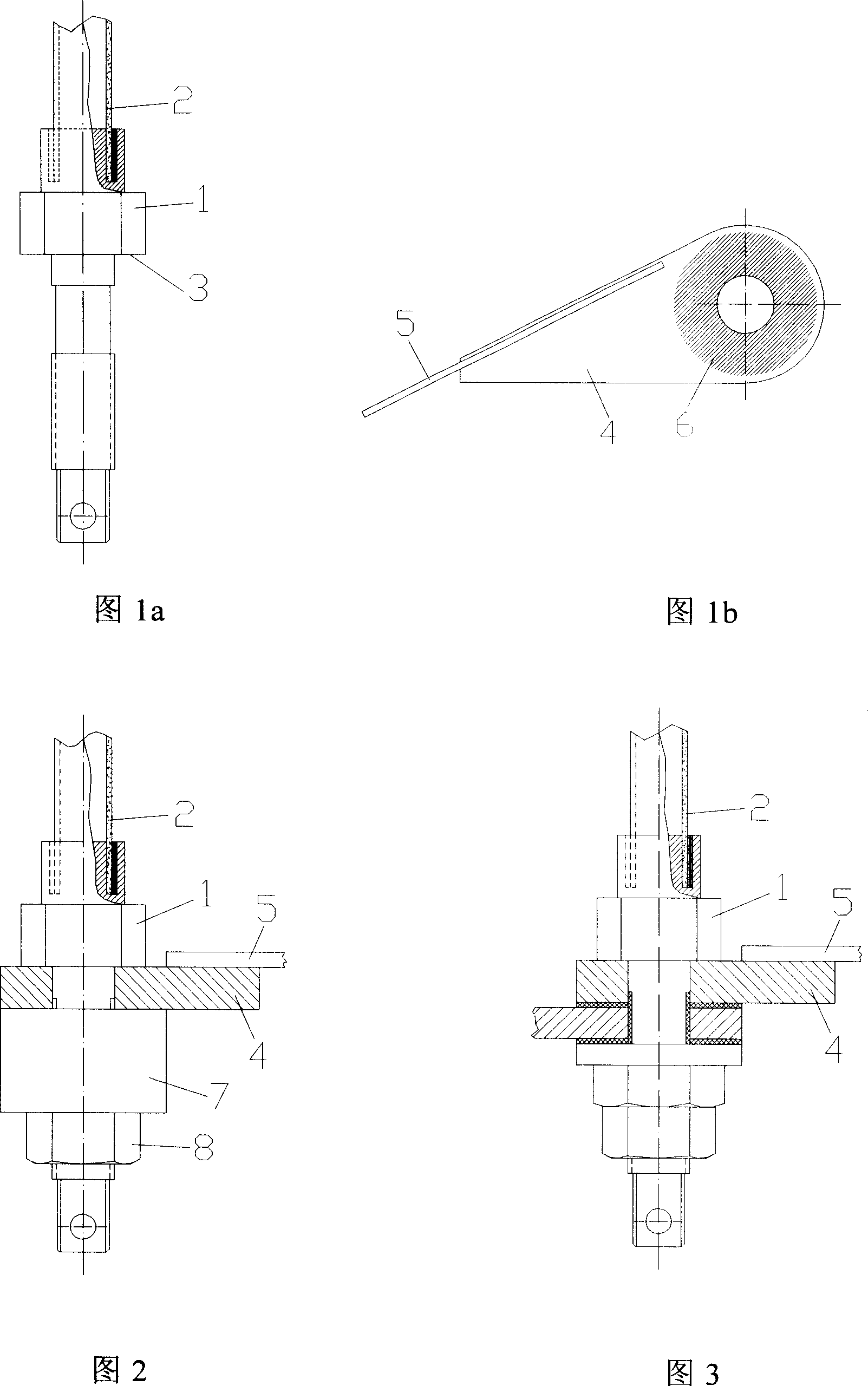

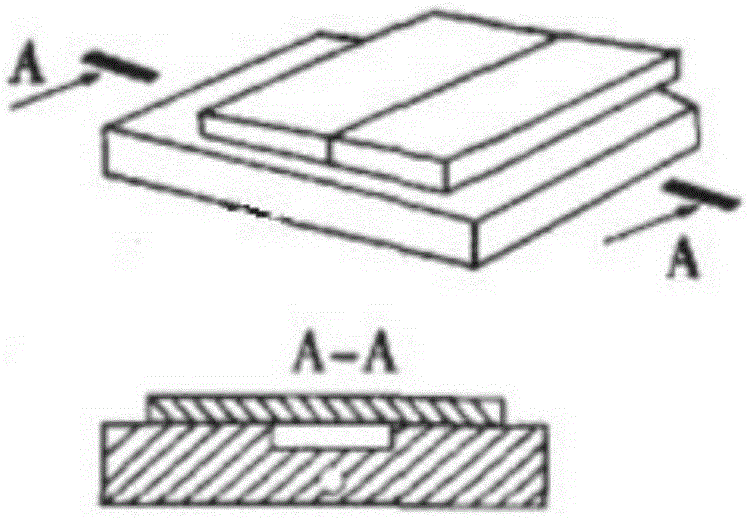

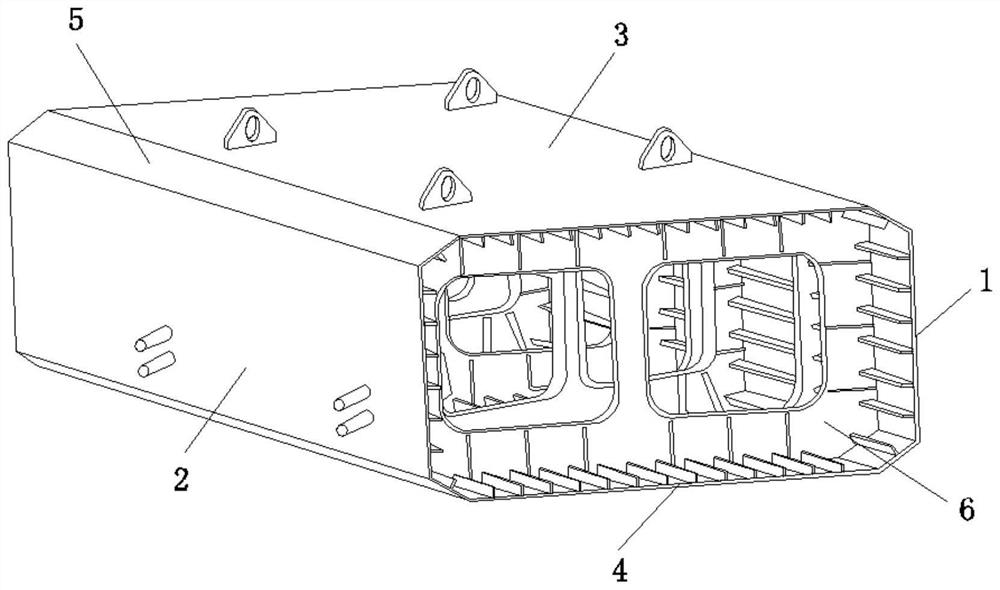

Doorsill type workpiece welding fixture

InactiveCN106984934AEffectively fixedImprove welding stabilityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention discloses a doorsill type workpiece welding fixture. The doorsill type workpiece welding fixture comprises a base, a first rotating arm and a second rotating arm, wherein a first pressing head is fixed to the base; the first rotating arm is pivoted to the base, and a first support block, a second support block and a third support block are fixed to the inner side of the first rotating arm in sequence from bottom to top; and the second rotating arm is pivoted to one end, which is far from the base, of the first rotating arm, and a second pressing head, a third pressing head, a fourth pressing head and a fifth pressing head are fixed to the inner side of the second rotating arm. Compared with the prior art, the doorsill type workpiece welding fixture has the advantages that five pressing points are set, wherein three pressing points act on a doorsill, two pressing points act on a floor assembly, and a plurality of pressing points are realized on the welding fixture, so that the doorsill can be effectively fixed, additionally, the floor assembly is assisted to be pressed, the welding stability of the whole assembly is increased, the structure of the welding fixture is simple, and the welding space is enough, so that the welding operation difficulty of employees is greatly reduced.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

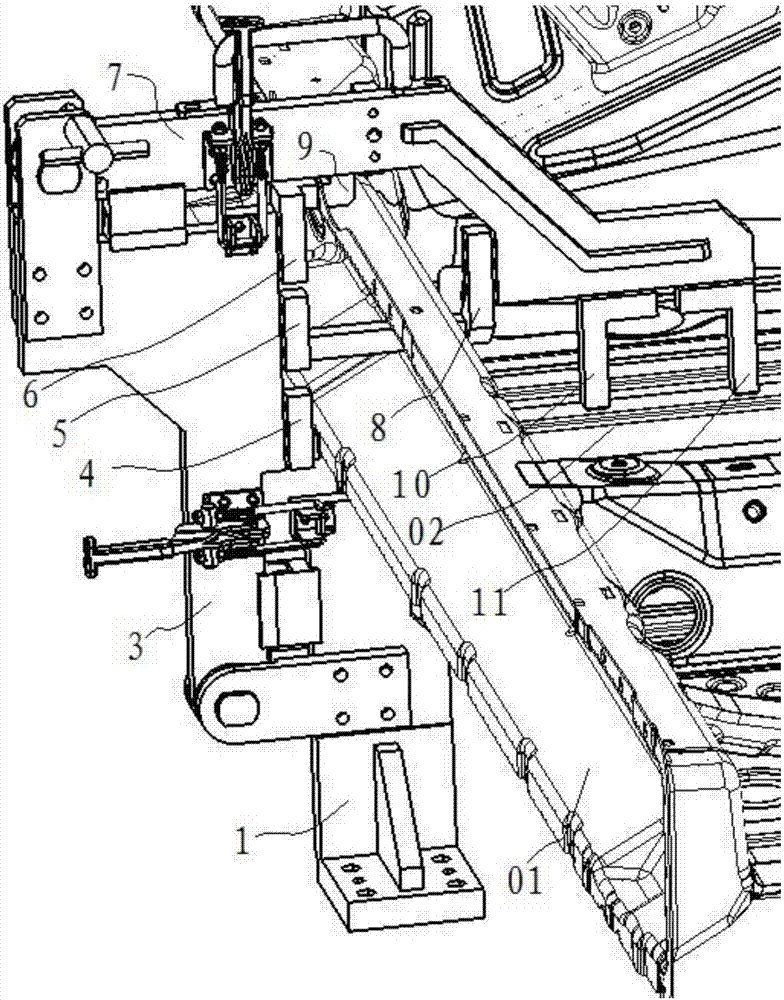

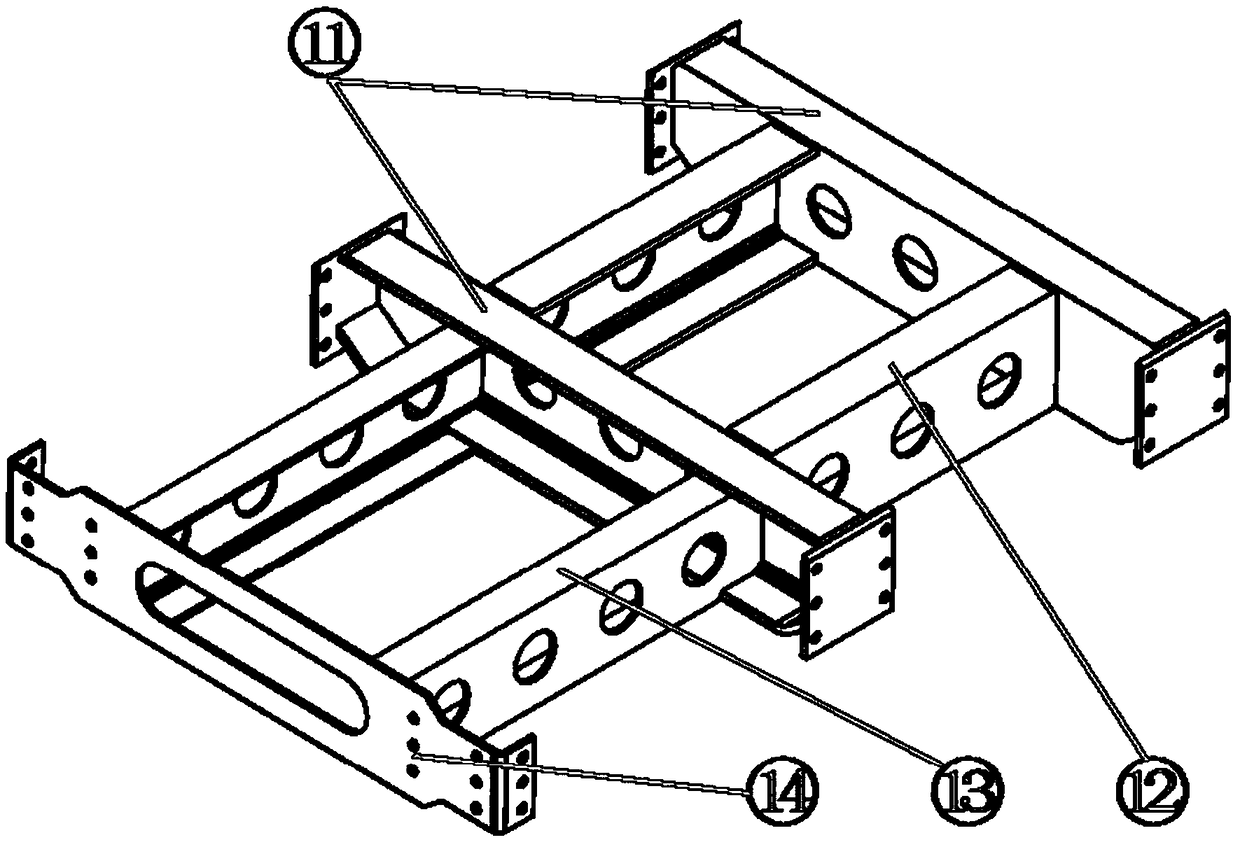

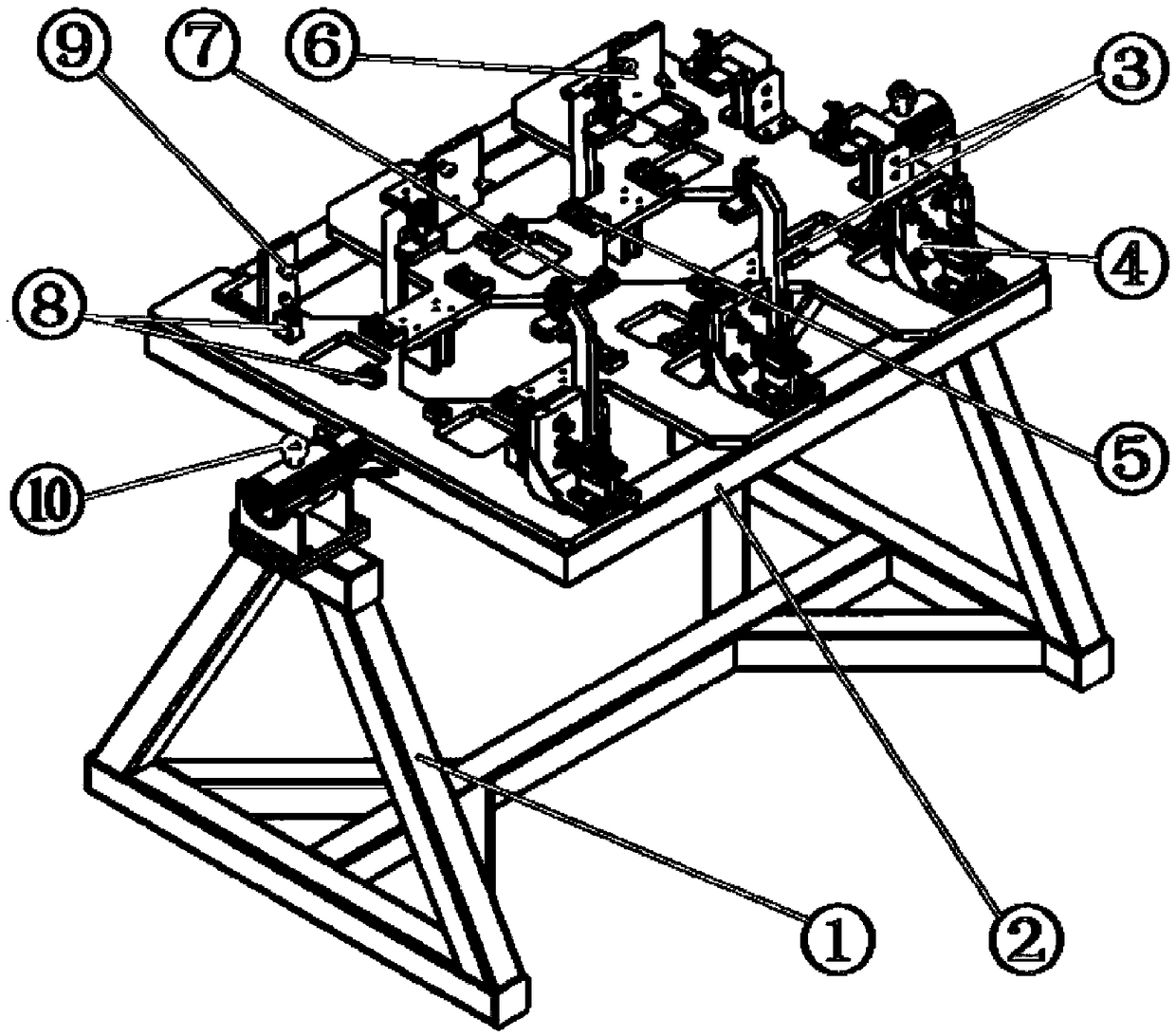

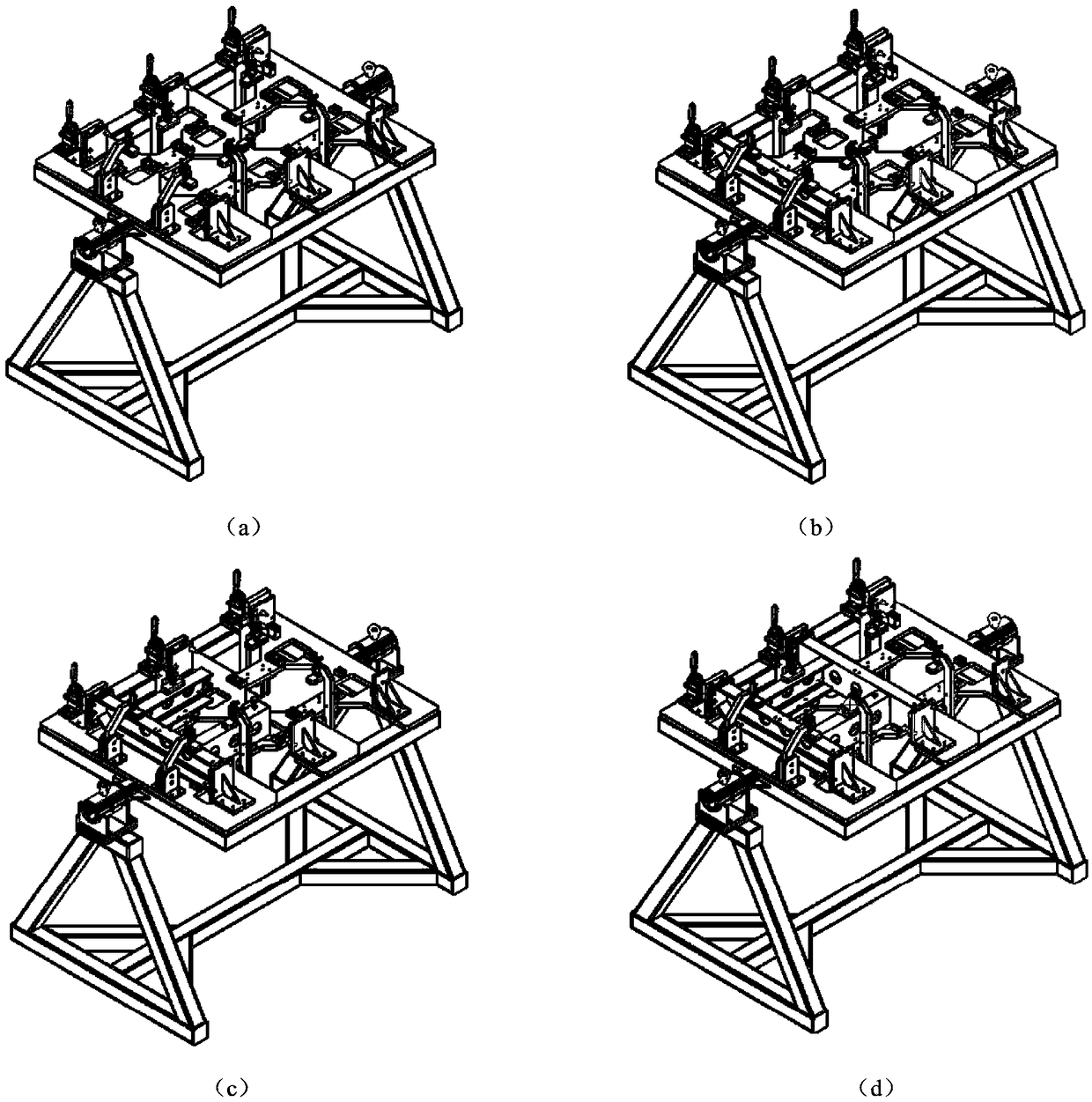

Semitrailer grillage-shaped beam welding tooling and welding process thereof

PendingCN109366032AEliminate the effects ofEasy to adjustWelding/cutting auxillary devicesAuxillary welding devicesShaped beamMobile end

The invention belongs to the technical field of aluminum alloy welding and relates to a semitrailer grillage-shaped beam welding tooling and a welding process for the semitrailer grillage-shaped beamwelding tooling. The semitrailer grillage-shaped beam welding tooling comprises a base and a main body frame rotatably installed on the base, wherein the left side and the right side of the main bodyframe are provided with three fixed end position-limiting blocks and moving end position-limiting blocks correspondingly, the outer sides of the fixed end position-limiting blocks and the moving end position-limiting blocks are fixedly provided with corresponding two sets of traction pin plate longitudinal beam compressing devices and a set of front end locking horizontal beam compressing devicescorrespondingly, the part, between the front end locking horizontal beam compressing devices, of the main body frame is evenly and fixedly provided with a plurality of front end locking horizontal beam connection angle part position-limiting grooves, and the part, between the traction pin plate longitudinal beam compressing devices, of the main body frame is evenly and fixedly provided with a plurality of traction pin plate position-limiting grooves used for clamping traction pin plate workpieces. By means of the welding tooling, the welding position is conveniently and efficiently adjusted toeliminate influence of the narrow and small space on welding operations, and by means of the position-limiting blocks and the compressing devices, the group matching accuracy is guaranteed to controlwelding deformation in the welding process.

Owner:LIAONING ZHONGWANG SPECIAL VEHICLE MFG

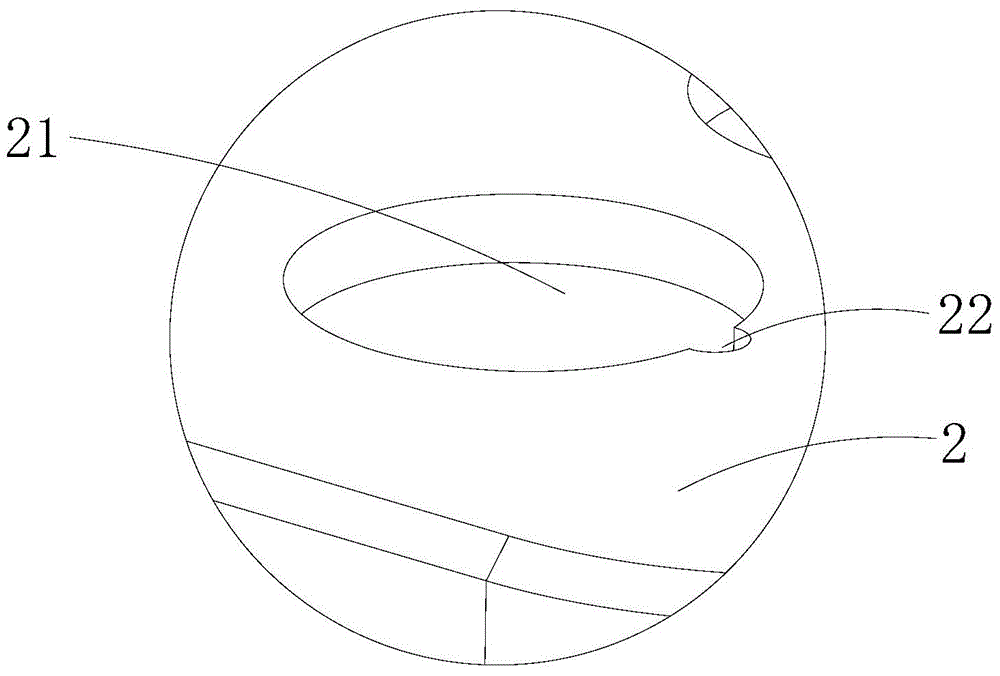

Wheel cover assembly clamp

InactiveCN107009075AAvoid direct connectionSolve the lack of spaceWelding/cutting auxillary devicesAuxillary welding devicesLap jointEngineering

The invention discloses a wheel cover assembly clamp which comprises a support, a lower portion positioning unit, a side face pressing unit, a rear portion pressing unit, a front end positioning unit and a main positioning unit. The support is connected with a sliding unit, wherein the sliding unit is used for guiding the support to move towards or away from a wheel cover assembly. The lower portion positioning unit is used for positioning and pressing the lower portion of the wheel cover assembly. The side face pressing unit is used for pressing the lap joint part of the wheel cover assembly and a longitudinal assembly. The rear portion pressing unit is used for positioning and pressing a front surrounding plate when the front surrounding plate is in lap joint with the wheel cover assembly. The front end positioning unit is used for positioning the front end of the wheel cover assembly. The main positioning unit is used for positioning a body of the wheel cover assembly. Compared with the prior art, multiple clamp basic units are integrated on the support to form a large unit, the problem that excessive clamp basic units are directly connected with a base plate, and consequently the space of the base plate is not sufficient is avoided, large welding space is reserved, and the welding operation difficulty is lowered.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

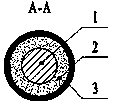

Superconductive current lead welding method

InactiveCN1981967AReduce the difficulty of welding operationReduce the temperatureSoldering apparatusElectrical conductorCopper

A method for welding the leading superconductor wire includes such steps as soldering a superconductor onto a transition copper block while applying a thin tin layer to another surface of said copper block to be soldered and soldering between two transition copper blocks by use of the solder with low smelting point.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

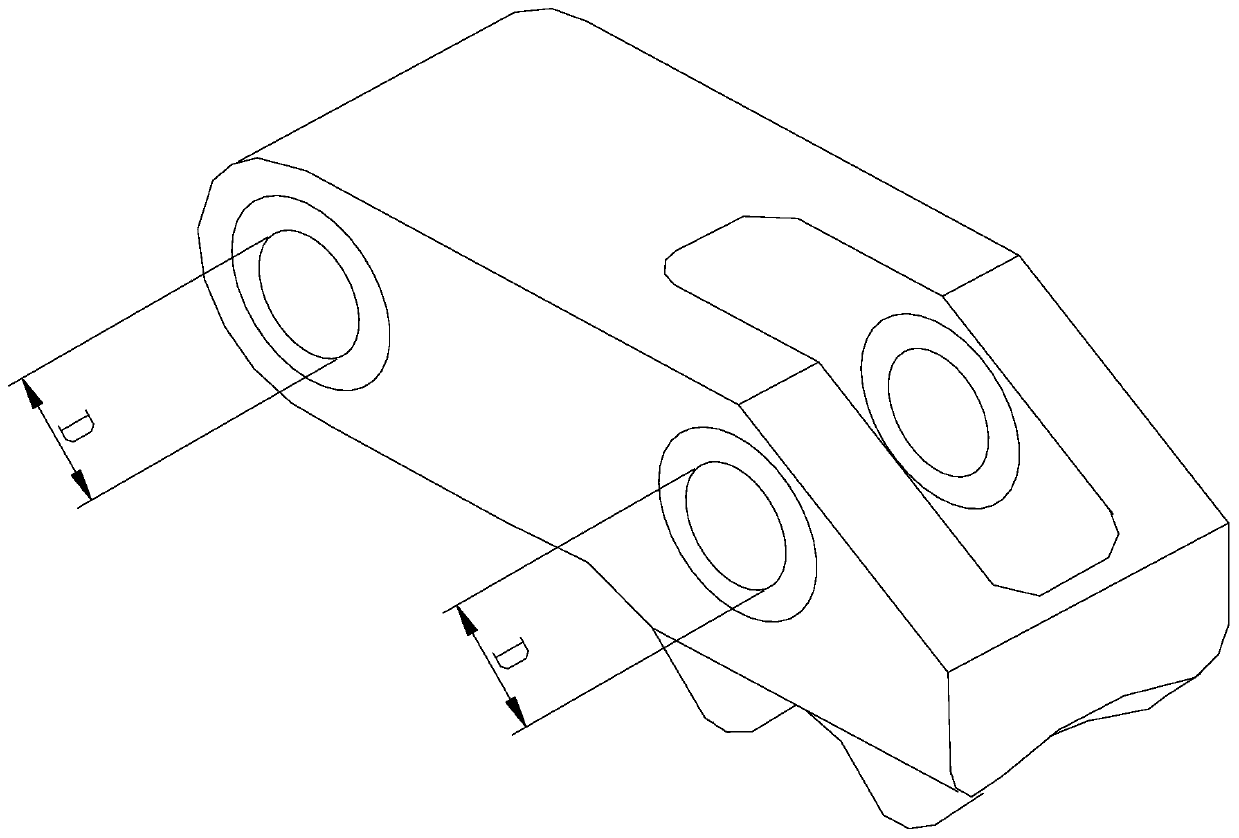

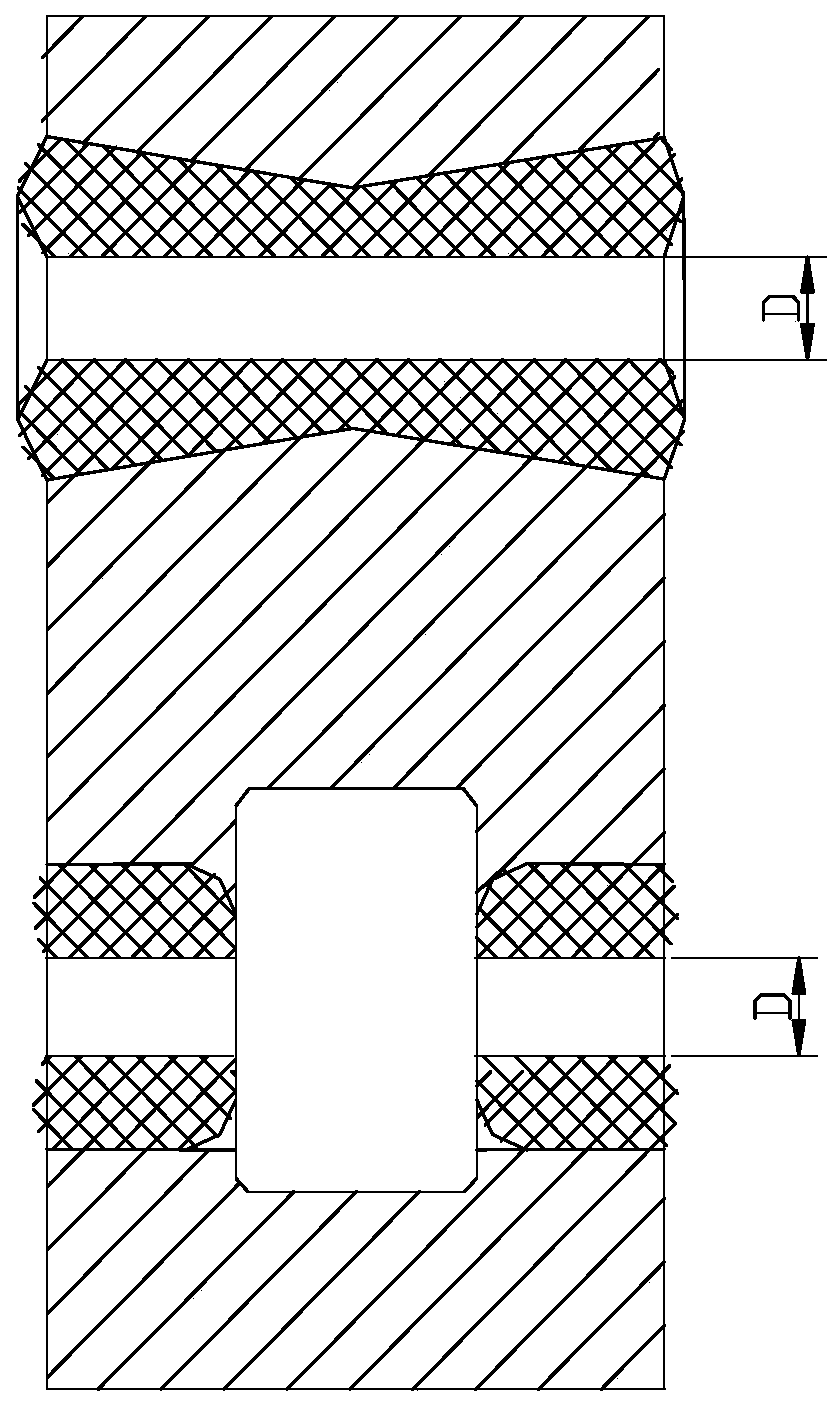

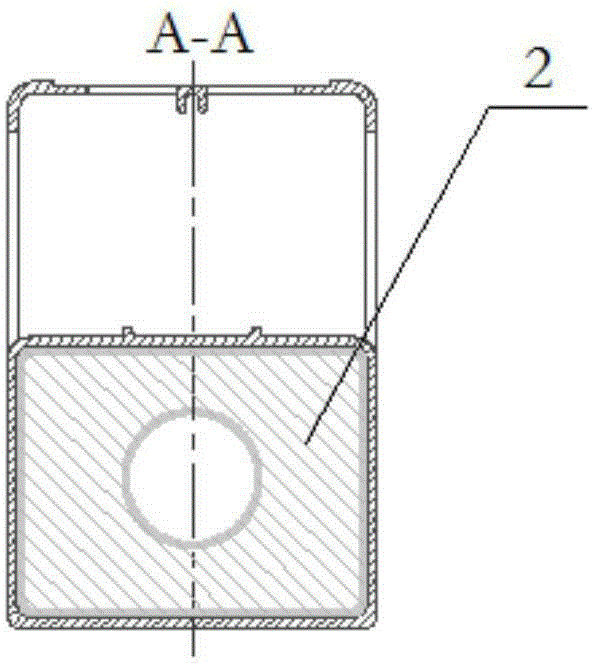

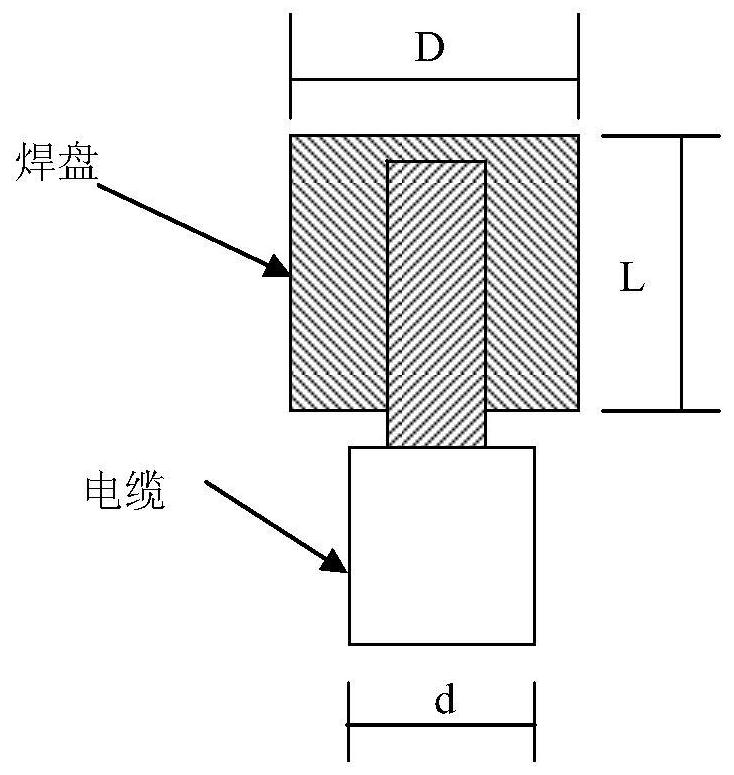

Hole inner wall wear-resistant layer preparation method capable of increasing product percent of pass

PendingCN110369980AImprove production efficiencyReduce the difficulty of welding operationNuclear energy generationReactors manufactureWear resistantMaterials science

The invention discloses a hole inner wall wear-resistant layer preparation method capable of increasing the product percent of pass. The method is used for obtaining a wear-resistant layer on the surface of a part pre-formed hole and finally obtaining a hole, having the inner diameter D and comprising the hole wall wear-resistant layer, on a part. The hole inner wall wear-resistant layer preparation method includes the following steps that S1, the pre-formed hole with the inner diameter D1 is drilled on the part, wherein D1 is larger than D; a filling core rod used for welding is obtained, andthe outer diameter of the filling core rod is smaller than D1 and larger than D; S2, the filling core rod is embedded in the pre-formed hole, and the gap between the filling core rod and the pre-formed hole is filled up through filling welding or self-fluxing welding; S3, a hole with the hole diameter D is obtained on the filling core rod, the filling core rod provides the whole hole wall for thehole with the hole diameter D, and the material of the filling core rod is the material of the wear-resistant layer. Due to the adoption of the method, the build-up welding difficulty of a hole innerwall build-up welding layer can be effectively lowered, and the aims of ensuring the build-up welding quality of the build-up welding layer and increasing the product percent of pass are achieved.

Owner:喻杰

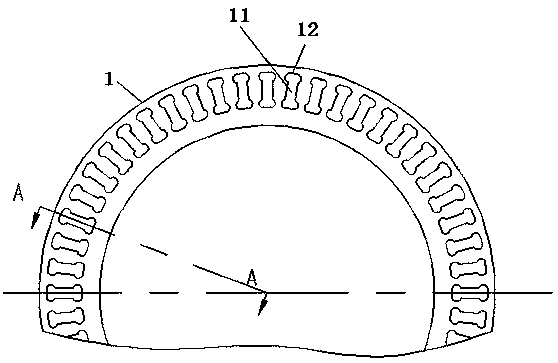

Welding method and structure for motor end ring and conducting bars

InactiveCN109352111AReduce dosageGuaranteed vertical accuracyMagnetic circuit rotating partsSoldering apparatusSolderingFiller metal

The invention discloses a welding method and structure for a motor end ring and conducting bars. The welding structure comprises the end ring and the conducting bars. The welding structure is characterized in that grooves which are in one-to-one correspondence to the conducting bars are processed in the end surface of the end ring according to the dimensions of the end parts of the conducting bars, wherein the conducting bars and the grooves are correspondingly welded on the end ring. The welding structure reduces area of grooves in the end ring, and welding flux is limited in a single grooveduring welding, so that melting and curing of the welding flux in a welding process are guaranteed to be always limited in single groove, dosage of sliver brazing filler metal and soldering flux can be effectively reduced, welding cost is reduced, the conducting bars are guaranteed to be uniformly spaced and distributed in the peripheral direction of the end ring, the welding positions of the conducting bars are positioned simply and clearly, distance regulating does not need to be manually performed, welding operation difficulty is effectively reduced, and welding efficiency and welding quality for the end ring and the conducting bars is improved.

Owner:CSR ZHUZHOU ELECTRIC CO LTD

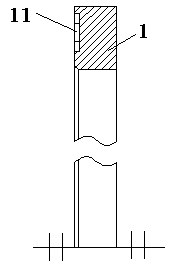

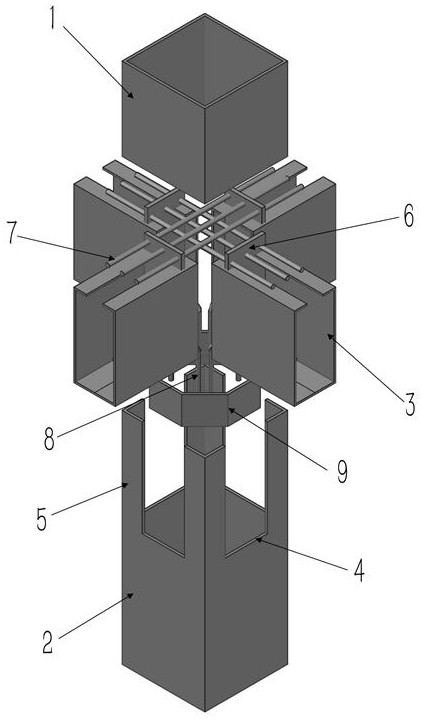

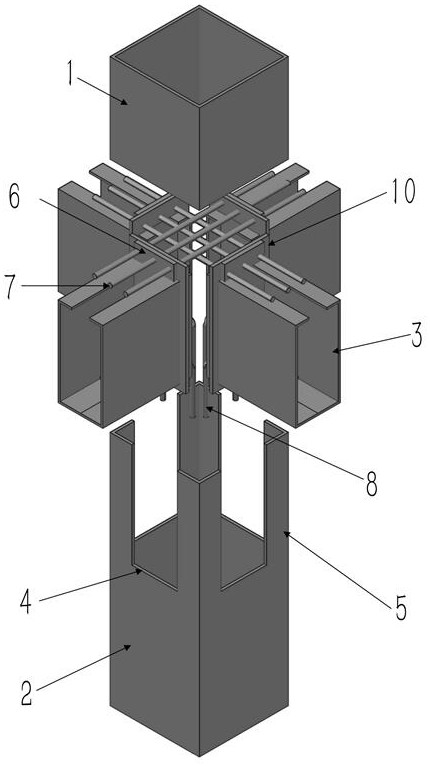

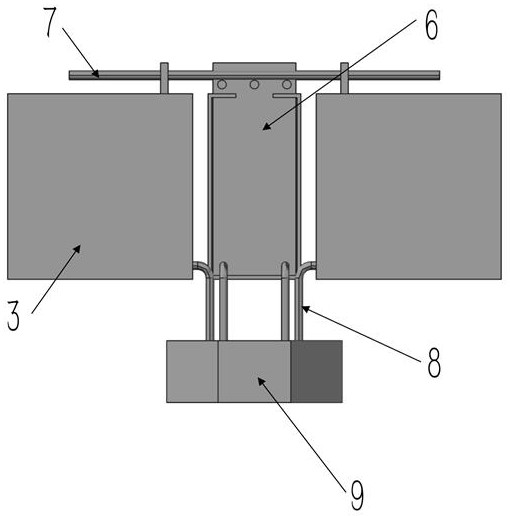

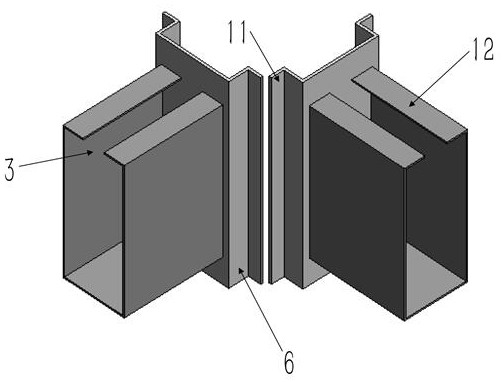

Joint of concrete filled steel tubular column

ActiveCN113006292AGood reinforcing effectImprove securityBuilding constructionsMechanical engineeringJoint (building)

The invention discloses a joint of a concrete filled steel tubular column. The joint comprises an upper steel pipe column and a lower steel pipe column which are vertically arranged, a U-shaped steel beam is horizontally arranged on the side wall of the lower steel pipe column, an open groove is formed in the side wall of the lower steel pipe column and corresponds to the steel beam, the open groove extends downwards from the upper end of the lower steel pipe column, the two sides of the open groove respectively form a connecting end, one end of the steel beam penetrates through the open groove, extends into the lower steel pipe column and is fixedly connected with the lower steel pipe column; a connecting plate is vertically arranged in the steel beam, and the connecting plate is fixedly connected with the steel beam; and the lower end of the upper steel pipe column is fixedly connected with the upper end of the upper steel pipe column. According to the joint, the joint of the steel pipe column and the steel beam is reinforced from the inside through the connecting plate, so that the appearance of the junction of the steel pipe column and the steel beam is smooth; and a standardized component inner sleeving process is adopted, adopted components, the steel pipe column and the steel beam can be installed in a factory, the production process and the installation process are convenient and fast, and a new thought is provided for the development direction of prefabricated buildings.

Owner:渝建建筑科技集团有限公司

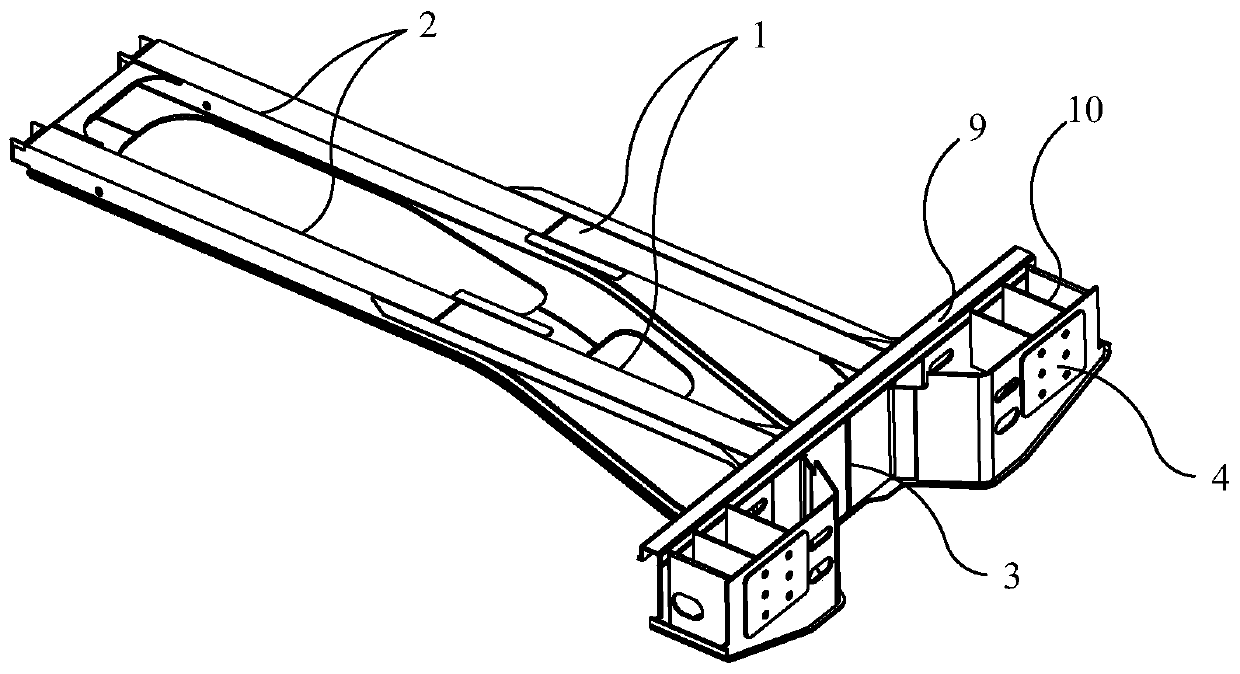

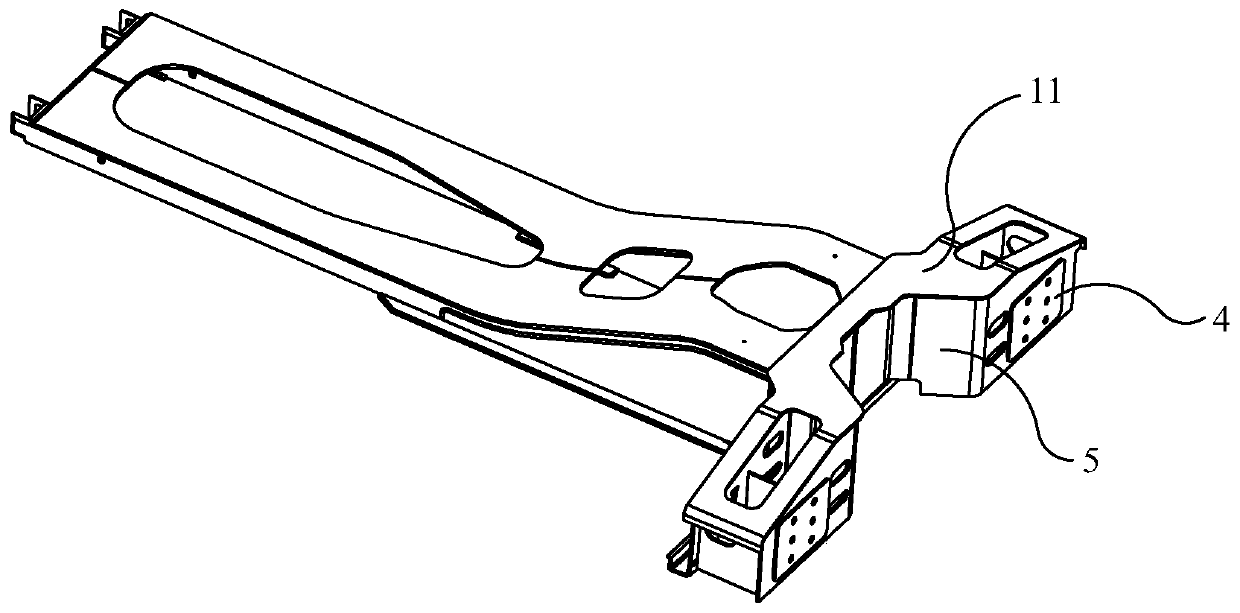

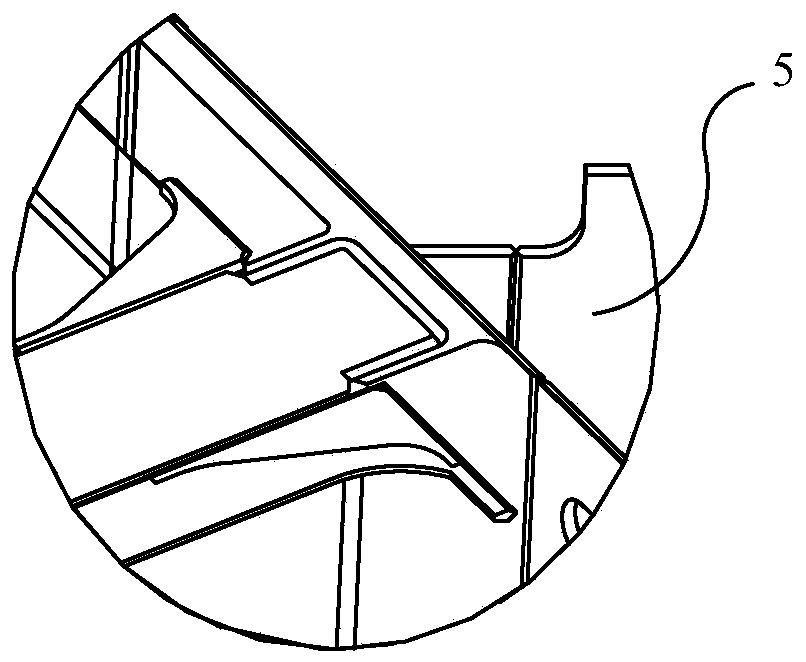

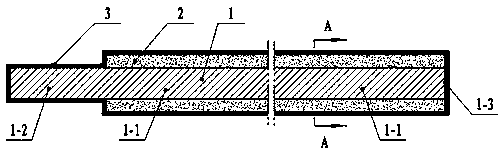

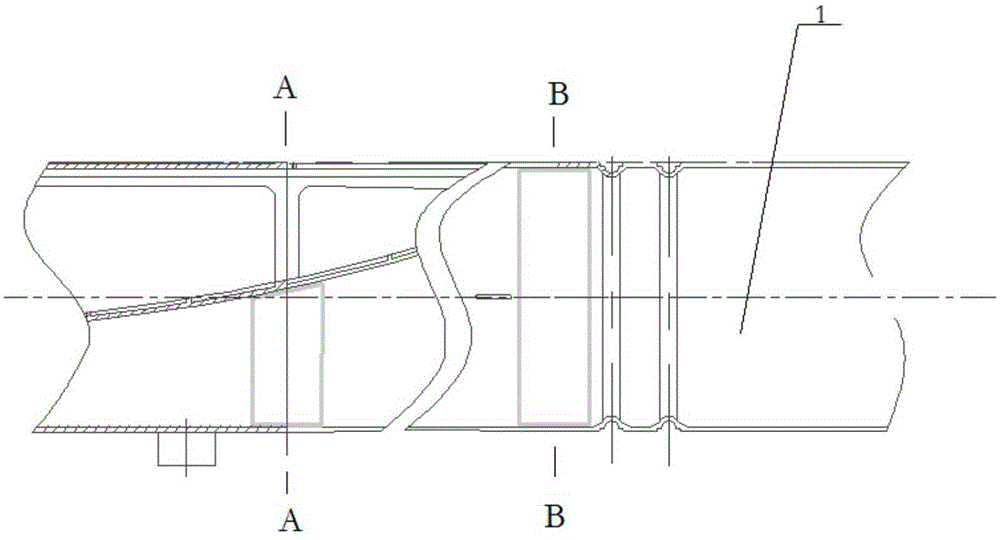

Manufacturing method of vehicle traction beam, vehicle traction beam and rail vehicle

ActiveCN110480266AReduce the difficulty of manufacturing processGuarantee the difficulty of manufacturing processVehicle componentsWelding apparatusButt weldingButt joint

The invention provides a manufacturing method of a vehicle traction beam, the vehicle traction beam and a rail vehicle. The manufacturing method of the vehicle traction beam comprises the steps: forming two traction beam webs by using a single sectional material; splicing the traction beam webs and a lower cover plate to form a V-shaped groove, and carrying out butt welding to form a vehicle traction beam body; enabling the vehicle traction beam body to be in butt joint with a vehicle coupler mounting seat to form a Y-shaped groove, and then carrying out butt welding; and welding a curved surface mounting plate between an anti-climbing energy absorption device mounting seat and the vehicle coupler mounting seat. According to the manufacturing method of the vehicle traction beam and the vehicle traction beam, the single sectional material is used for forming the two traction beam webs, so that the machining efficiency is improved; the V-shaped groove is formed in the spliced position ofthe traction beam webs and the lower cover plate; the Y-shaped groove is formed in the spliced position of the vehicle traction beam and the vehicle coupler mounting seat, so that the welding operation difficulty is reduced, and the welding quality is ensured; and the curved surface mounting plate is welded to the position between the anti-climbing energy absorption device mounting seat and the vehicle coupler mounting seat, so that a long enough gap is reserved between a vehicle coupler and the vehicle coupler mounting seat.

Owner:CRRC QINGDAO SIFANG CO LTD

Iron-based core flux-coated electrode free of pre-welding drying and easy to weld

ActiveCN110936056AWith moisture protectionSave energyWelding/cutting media/materialsSoldering mediaEpoxyFiber

Owner:ZHENGZHOU UNIV

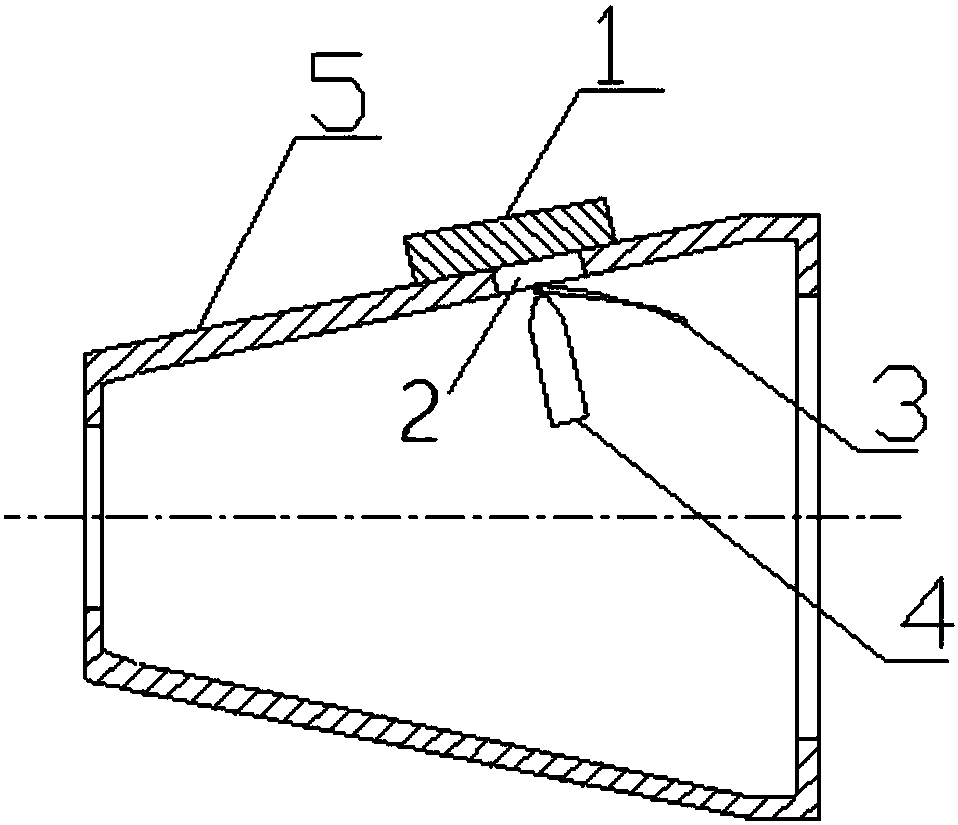

Welding process of titanium alloy graphite backing

InactiveCN105234526AFlat shapeUniform shapeArc welding apparatusWelding/soldering/cutting articlesGraphiteTitanium alloy

The invention discloses a welding process of a titanium alloy graphite backing. The welding process comprises a step 1 of designing and fabricating a graphite welding backing fixture according to a titanium alloy welded structure, a step 2 of performing drying and degassing treatments on the graphite welding backing fixture, a step 3 of assembling the graphite welding backing fixture in an inner cavity of titanium alloy welded structure part, a step 4 of carrying out welding, and a step 5 of crushing the graphite welding backing fixture after welding and taking out graphite fragments, and then finishing the welding process of the titanium alloy graphite backing. The welding process of the titanium alloy graphite backing is applicable to the welding of one side welding forced back shaping of complex and special-shaped titanium alloy structures, and capable of improving a back shaping effect.

Owner:BEIJING POWER MACHINERY INST

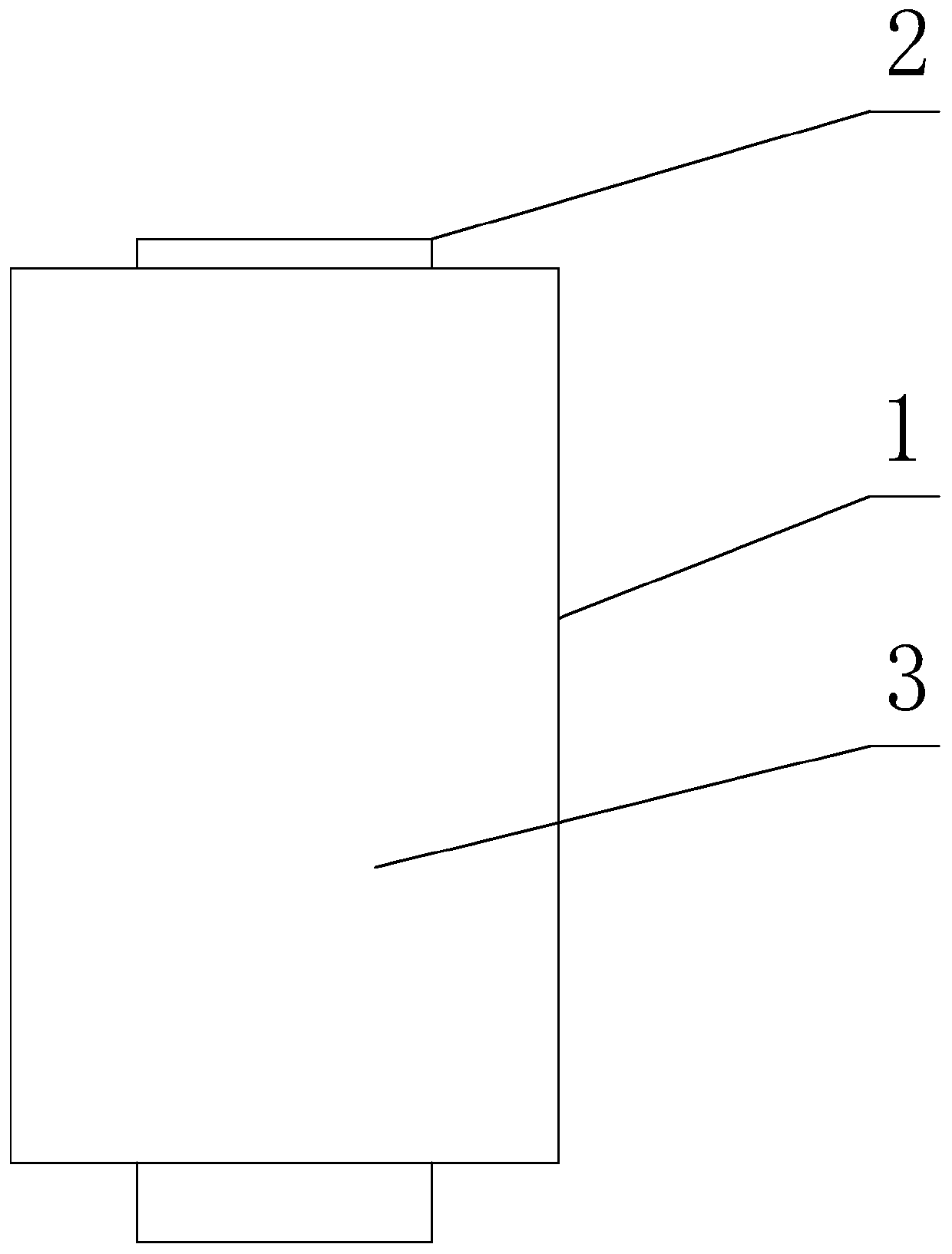

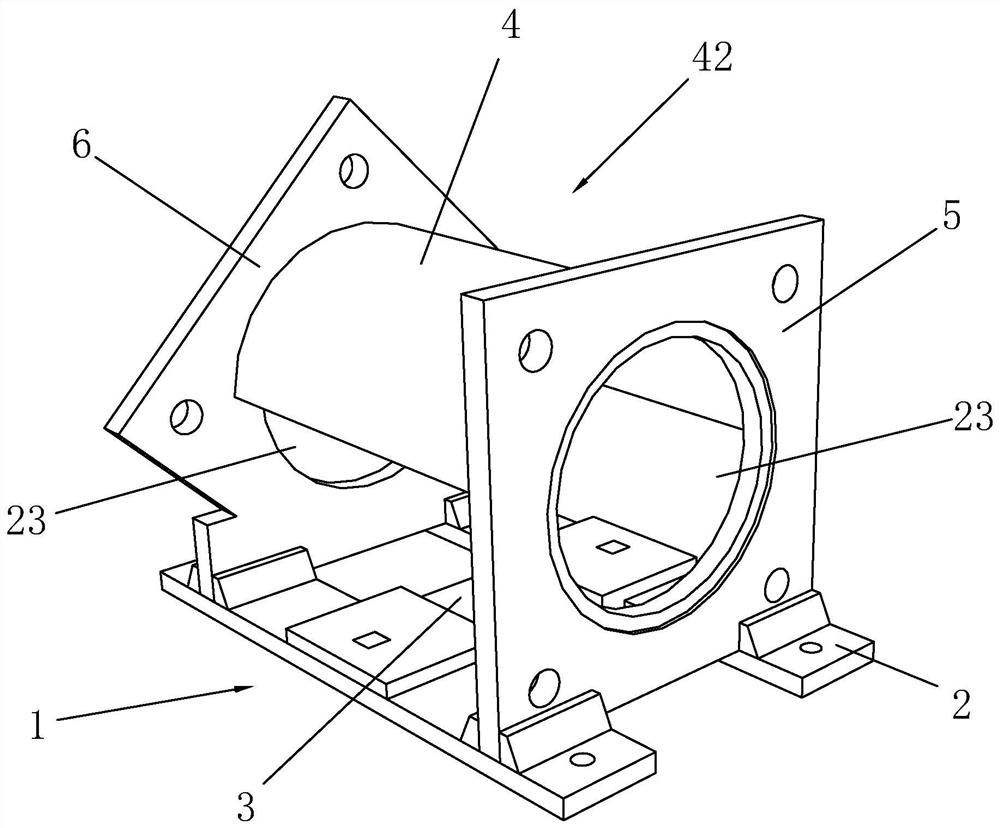

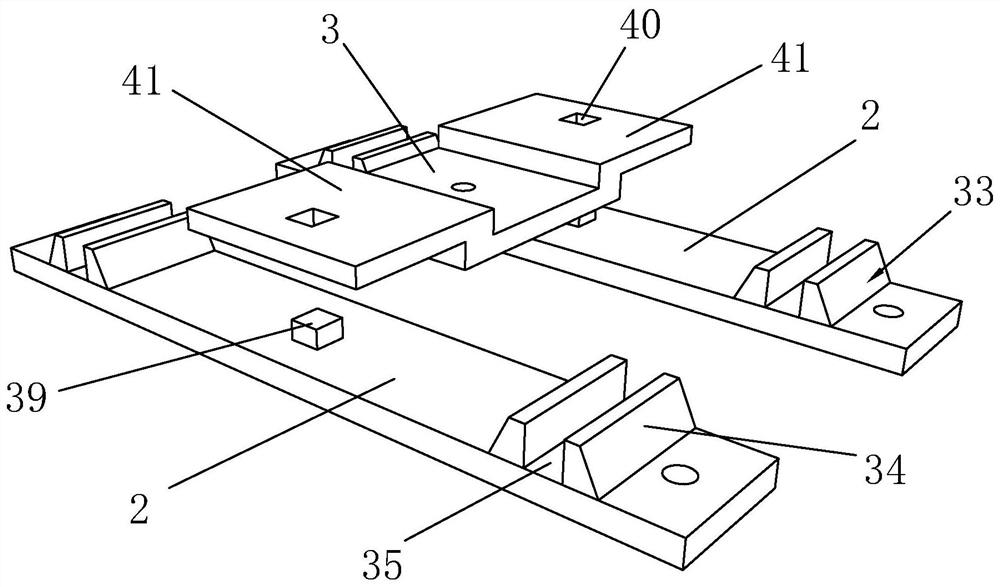

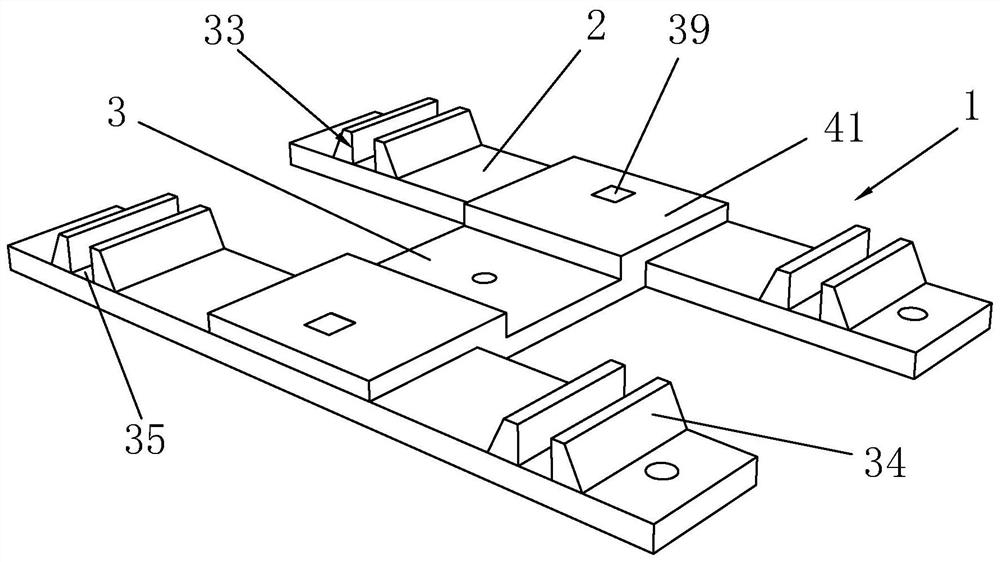

Method for manufacturing motor mounting bracket

ActiveCN112372170AImprove the strength of its own structureImprove installation stabilityWelding/cutting auxillary devicesAuxillary welding devicesElectric machineryStructural engineering

The invention discloses a method for manufacturing a motor mounting bracket. The method comprises the following steps of: 1) preparing a support bottom plate; 2) preparing a bracket; 3) assembling andfixing the bracket; 4) assembling and fixing the support bottom plate; and 5) assembling and fixing the support bottom plate and the bracket. The motor mounting bracket is firm and reliable in structure, and the stability of a motor after being mounted is effectively improved; the whole motor mounting bracket is assembled by the support bottom plate and the bracket, and auxiliary positioning welding is carried out for welding of all parts of the bracket by adopting an auxiliary device, so that accurate positioning adjustment between an arc-shaped plate and end plates at two sides is effectively guaranteed, and the actual welding accuracy and quality are improved; all components of the support bottom plate are accurately positioned through blocks and grooves and then welded and fixed in amatched manner, so that the structural strength of the support bottom plate is guaranteed; and finally the bracket and the support bottom plate are combined and welded, so that the structural stability of the whole motor mounting bracket is effectively ensured, and the use performance of the motor mounting bracket is better.

Owner:嵊州市龙凯机械加工厂

Novel steel pipe concrete column combined joint and construction method thereof

PendingCN112854483AGood reinforcing effectImprove securityBuilding constructionsArchitectural engineeringPipe

The invention discloses a novel steel pipe concrete column combined joint and a construction method thereof. The novel steel pipe concrete column combined joint comprises an upper steel pipe column, a lower steel pipe column and a plurality of U-shaped steel beams, wherein the upper steel pipe column and the lower steel pipe column are vertically arranged; an open groove is formed in the side wall of the lower steel pipe column and extends downwards from the upper end of the lower steel pipe column, and the two sides of the open groove form connecting ends correspondingly; one end of each steel beam penetrates through the open groove, then extends into the lower steel pipe column and is connected with a vertically-arranged end plate; the two sides of the end plate are fixedly connected with the connecting ends on the two sides of the open groove; the upper steel pipe column is located above the lower steel pipe column, and the lower end of the upper steel pipe column is fixedly connected with the upper end of the upper steel pipe column; and meanwhile, the upper steel pipe column is fixedly connected with the end plate. According to the novel steel pipe concrete column combined joint and the construction method thereof, the end plate is used for reinforcing the joint of the steel pipe columns and the steel beams from the interior, and a reinforcing component is arranged at the joint for further reinforcing, so that the appearance of the joint of the steel pipe columns and the steel beams is smooth, and redundant decoration construction is not needed; and meanwhile, the reinforcing effect of the reinforcing component on the joint is better, and the safety of the joint is higher.

Owner:渝建建筑科技集团有限公司

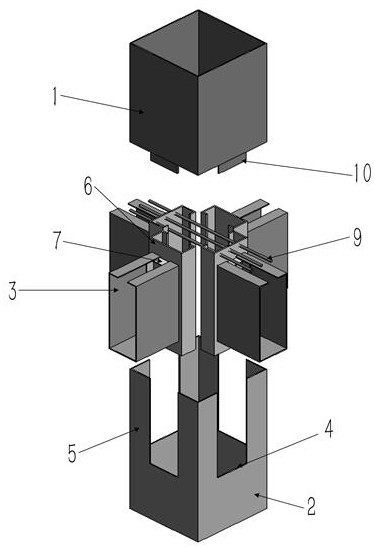

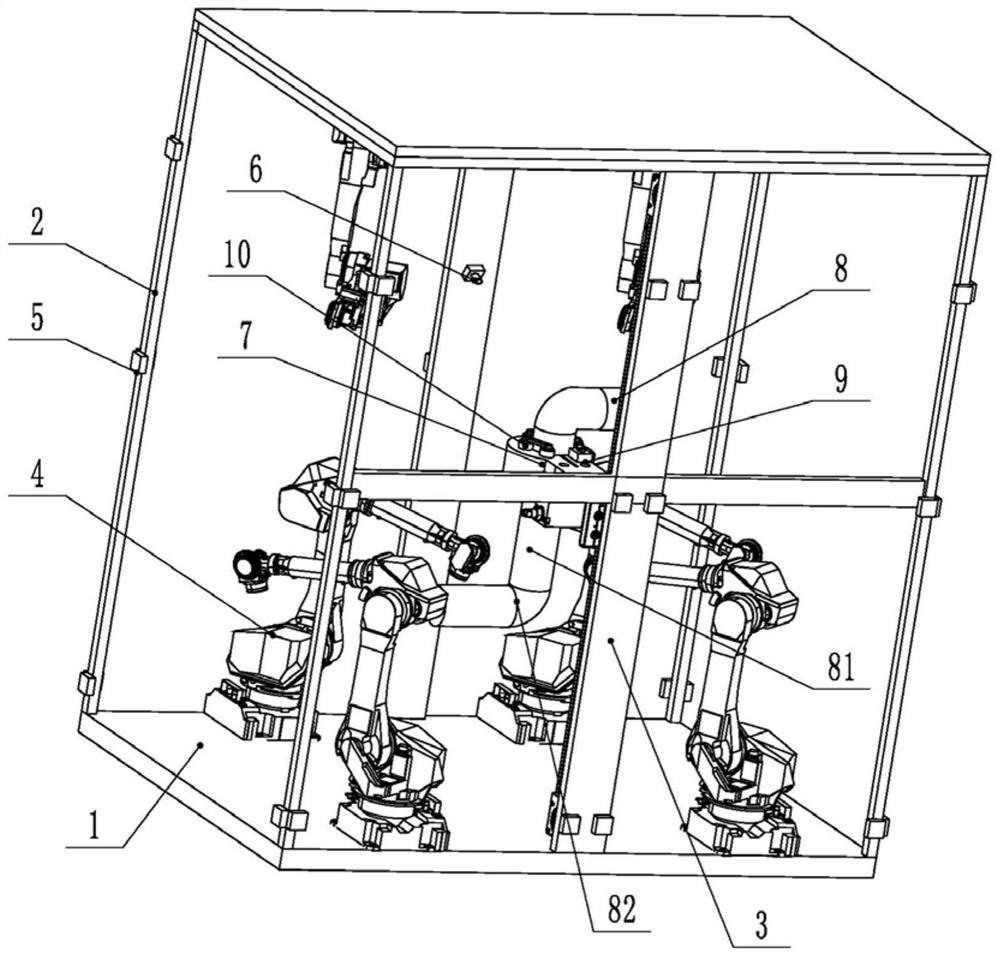

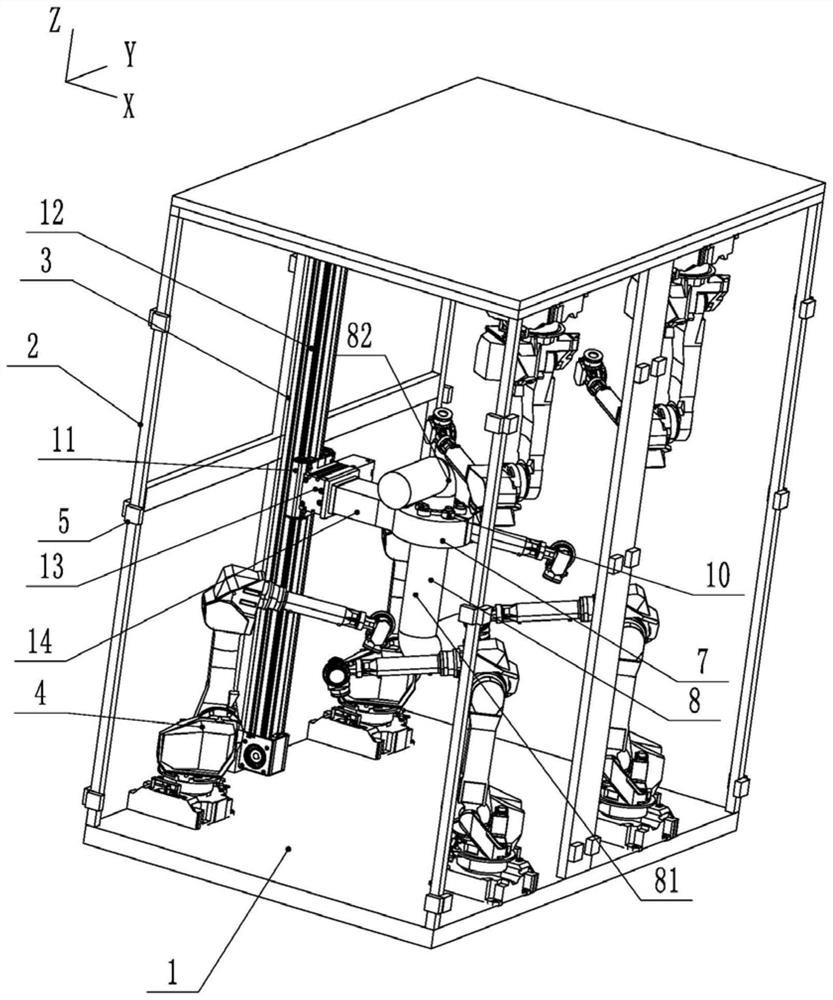

Chemical equipment modular manufacturing pipe section prefabrication welding method

ActiveCN113977129AHigh degree of automationReduce the difficulty of welding operationWelding/cutting auxillary devicesAuxillary welding devicesPipe fittingStraight tube

The invention discloses a chemical equipment modular manufacturing pipe section prefabrication welding method. The method comprises the following steps that: S1, preparation work is conducted: a straight pipeline and a pipe fitting are subjected to tack welding to form a pipe section; and a pipe section welding seam prefabrication welding device is provided; S2, the pipe section is clamped by a clamping jaw, the straight pipeline is clamped by the clamping jaw, and the clamping position is located at the gravity center of the pipe section; S3, the pipe section is driven to move to the middle of the rectangular frame; S4, a rotating base and an autorotation power device drive the pipe section to rotate around the X axis and the clamping center line, so that the welding seam is located at the flat welding position 1G or the horizontal welding position 2G; and S5, a welding seam recognition camera recognizes the serial number and the welding position of the welding seam, and the welding robot moves to the welding seam position to conduct welding operation according to the recognition result. According to the pipe section prefabrication welding method, the position of the prefabricated pipe section can be adjusted, the welding seam is located at the flat welding or horizontal welding position 2G, and a welding robot can conduct automatic welding conveniently.

Owner:江苏利柏特股份有限公司

Non-overturning welding method for steel arch box and non-overturning welding steel box arch

PendingCN113770581AReduce cost and increase efficiencyReduce security risksWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringWorkmanship

The invention provides a non-overturning welding method for a steel arch box and a non-overturning welding steel box arch. The non-overturning welding method comprises the following steps: formulating a scheme, designing a welding groove, testing a welding process, optimizing and perfecting the welding groove, welding and assembling the steel arch box, and inspecting the welding groove. Welding manufacturing of the steel box arch is achieved; meanwhile, the improved welding groove design is adopted, upward welding is changed into downward welding, and the technical problems that labor, time and labor are wasted, the safety risk is large, the site is limited, and the equipment investment is too large during steel box arch overturning welding are solved; and on-site overturning-free all-position welding operation of the steel box arch is achieved, and the purposes of reducing cost, improving efficiency, reducing safety risks, reducing welding difficulty and improving welding quality are achieved.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

Installation method of umbrella-shaped roof structure

ActiveCN113404199AShorten the construction periodImprove construction accuracyBuilding roofsStructural deformationSpatial structure

The invention provides an installation method of an umbrella-shaped roof structure, aims at solving the technical problems that an existing installation construction method is inconvenient due to the fact that the umbrella-shaped roof structure is complex in shape, large in component number, large in high-altitude splicing difficulty and high in precision requirement, and relates to the technical field of construction of large space structures of constructional engineering. An umbrella-shaped roof is divided into 20-30 umbrella-shaped unit structures, the adjacent umbrella-shaped unit structures are connected into a whole through long-strip-shaped wave-shaped roof steel beams, and the installation method comprises the following steps of (1) performing modular assembly on the ground; (2) installing a temporary support; (3) performing hoisting in units; and (4) dismantling the temporary support and monitoring structural deformation: unloading a sandbox support, dismantling the temporary support and monitoring the structural deformation. According to the installation method, the construction period is effectively shortened, the construction precision is improved, and meanwhile the installation quality of other related structures attached to the umbrella-shaped roof structure is improved.

Owner:CHINA RAILWAY CONSTR ENG GROUP

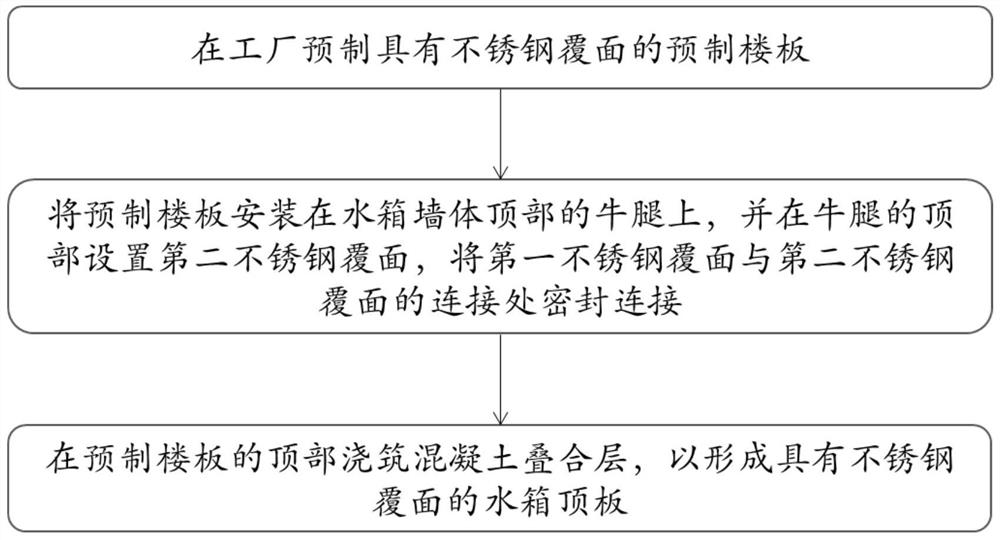

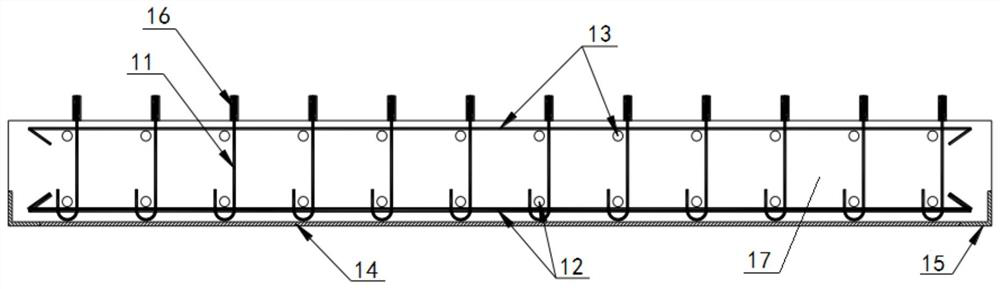

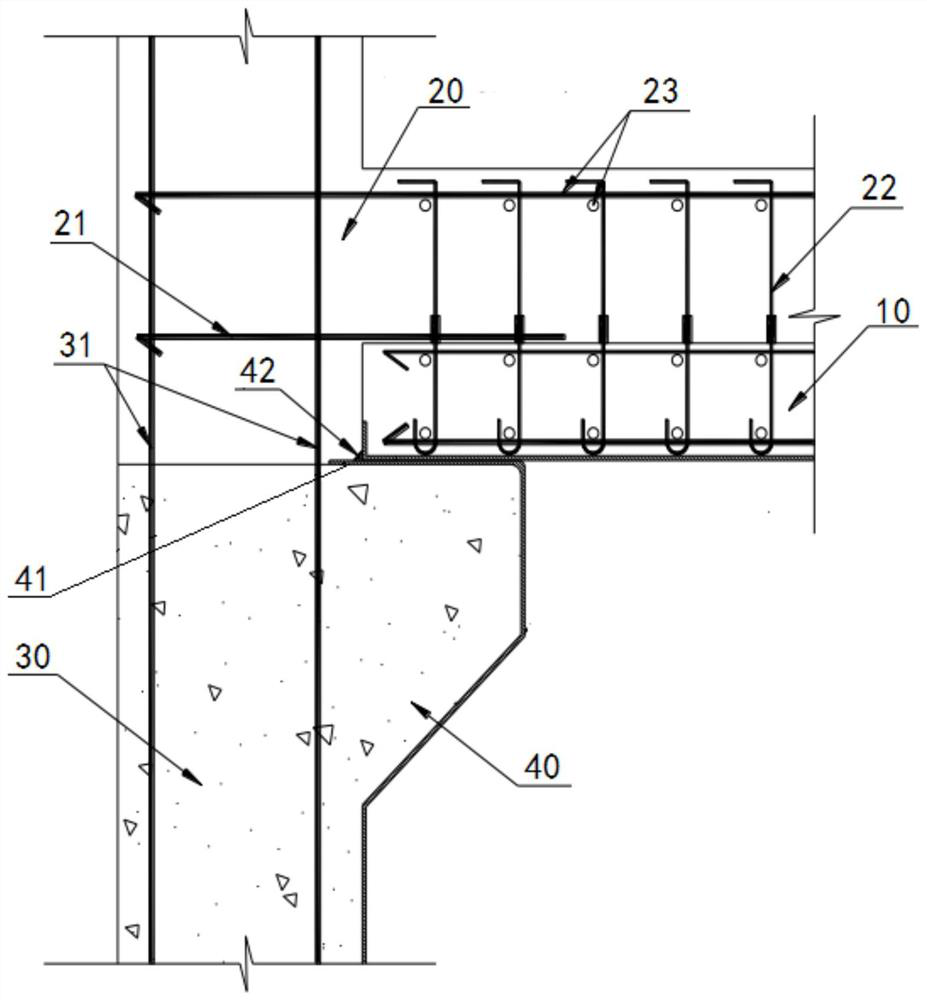

Construction method of stainless steel cladding top plate of building water tank and building water tank

InactiveCN113605497AReduce erectionAvoid double pouringWater supply tanksBuilding insulationsFloor slabArchitectural engineering

The invention discloses a construction method of a stainless steel cladding top plate of a building water tank. The construction method comprises the following steps that S1, a prefabricated floor slab with a stainless steel cladding is prefabricated in a factory; S2, the prefabricated floor slab is installed on a bracket at the top of the water tank wall, a second stainless steel covering face is arranged at the top of the bracket, and a first stainless steel covering face and the second stainless steel covering face are connected in a sealed mode; and S3, a concrete overlapping layer is poured at the top of the prefabricated floor slab, so that the water tank top plate with the stainless steel covering face is formed. The invention further discloses the building water tank. Construction is convenient, the construction workload is small, the cost is low, and the construction quality is guaranteed.

Owner:CHINA NUCLEAR POWER ENG CO LTD

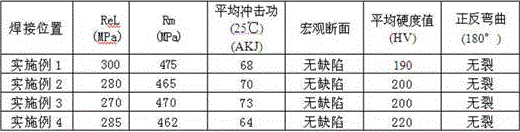

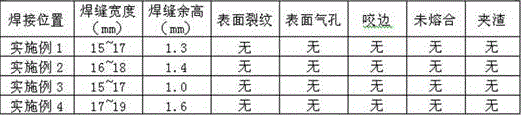

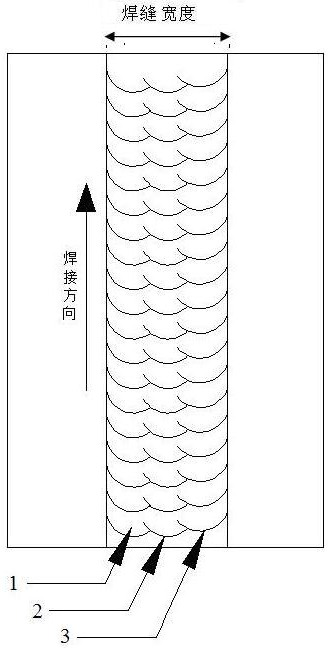

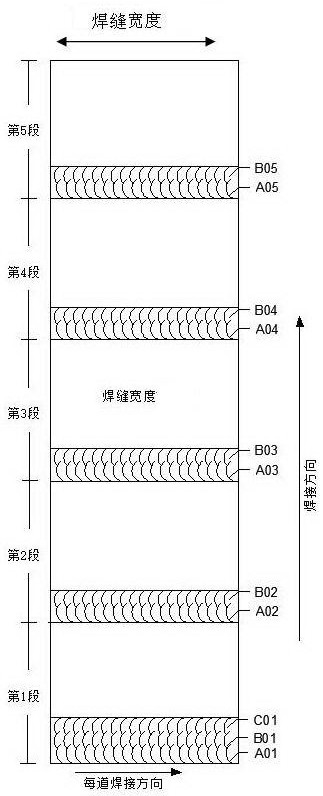

Welding method of low alloy steel plate and ship steel plate

ActiveCN104646803BReduce distortionReduce the difficulty of welding operationArc welding apparatusWelding/soldering/cutting articlesProduction rateTemperature control

The invention discloses a welding method of a low alloy steel plate and a ship plate and relates to the technical field of welding. According to the welding method, through analysis and experiment, stipulates that grooves and surfaces of welding materials are subjected to dust cleaning before the two dissimilar steel boards are welded, wherein a weld width between the steel boards is less than 1mm; the back face of a slab joint is subjected to positioned welding with gas shielded welding, so that the positions of striking arc are full and arc suppression positions are filled with arc craters; welding is carried out with small specifications, multi-layer and multi-pass welding can be realized, and weld joints on each face are subjected to backing welding and cosmetic welding; for the slab joint, carbon arc gouging is adopted to machine the grooves, and the angle of the grooves is 60-70 degrees; the grooves are ground; a welding part and the both sides of the welding part are baked for dehumidification through a cutting torch before welding; the temperature of a weld joint layer and the inter-pass temperature are controlled to be below 100 DEG C. With the adoption of the welding method, the problems that by the conventional welding method for low alloy steel plates and ship steel plates, the welding production rate is low, the whole weld is poor in quality, and a welding structure is large in transformation can be solved.

Owner:中船桂江造船有限公司

A welding operation method for transition layer and cladding layer of clad steel plate

ActiveCN110977098BIncrease employment rateReduce the difficulty of welding operationArc welding apparatusWelding/soldering/cutting articlesStructural engineeringWeld seam

Owner:中国石油天然气第一建设有限公司

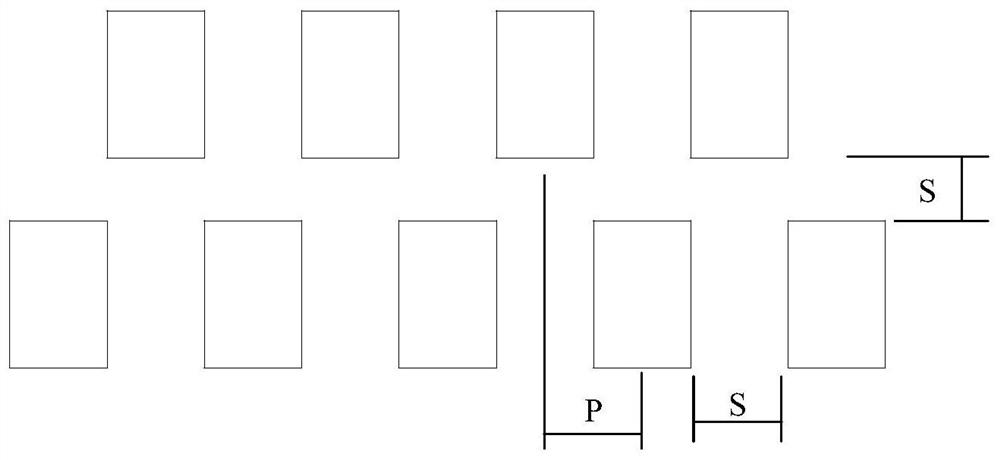

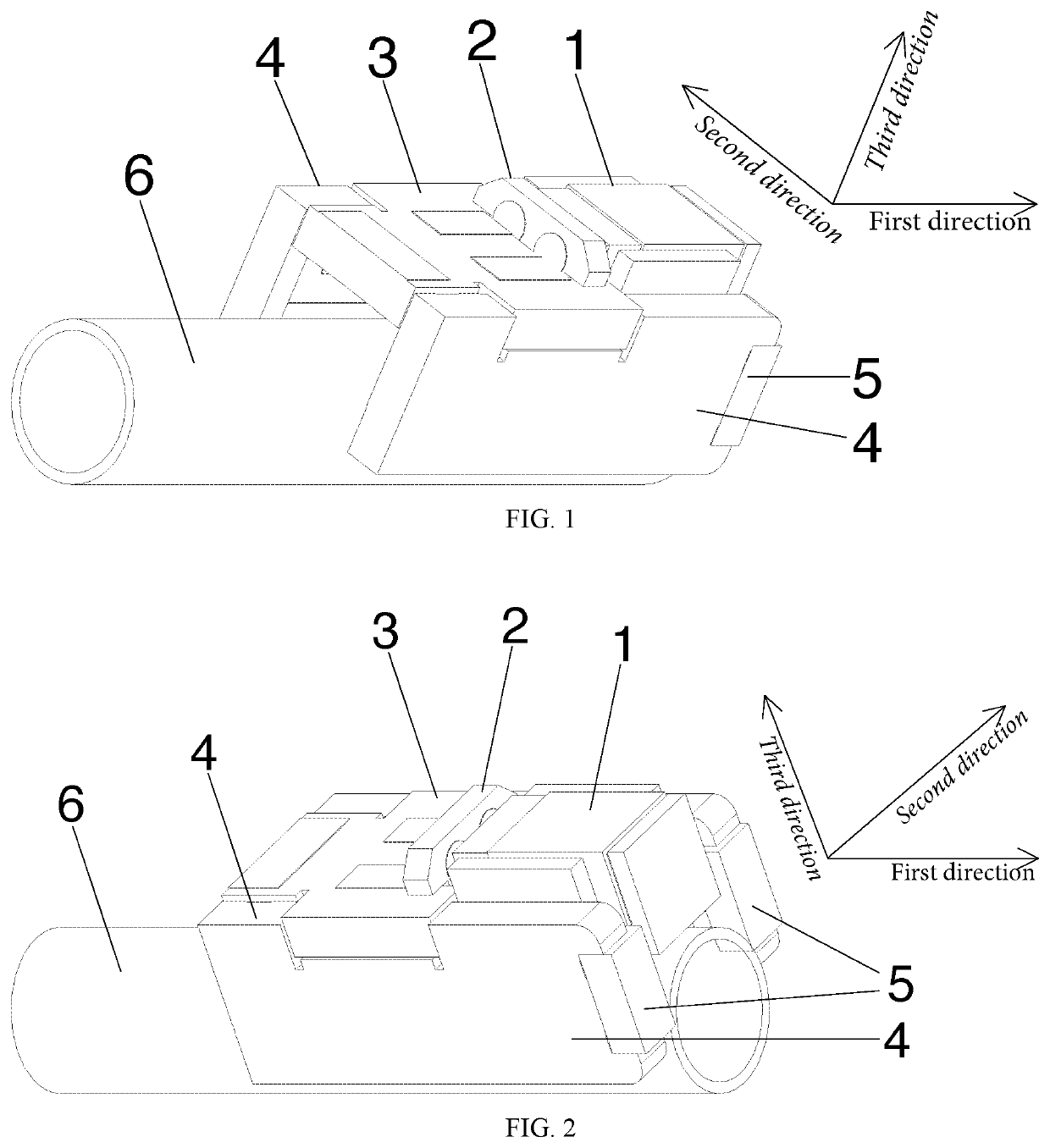

A method for electrical cascading of aerospace optical fiber inertial groups

ActiveCN113490334BLong and shortImprove aestheticsPrinted circuit assemblingSagnac effect gyrometersGyroscopeSurface mounting

The invention is an electrical cascading method of an aerospace optical fiber inertial group, which realizes the electrical connection between the circuit board, the electrical connector and the optical fiber gyroscope in the aerospace optical fiber inertial group by using a high-temperature ribbon cable with an anti-irradiation index; The ribbon cable wire ends are welded on the surface mount pads to realize the electrical connection between the ribbon cable and the circuit board; by using epoxy glue to fix the ribbon cable wire ends, the ribbon cable solder joints are not stressed under the mechanical environment purpose; by designing and manufacturing special-shaped ribbon cables to realize the electrical connection between electrical connectors, fiber optic gyroscopes and circuit boards; The sequential connection of cables greatly improves the correctness of assembly and inspection and production efficiency; by using surface mount pads to solder ribbon cable wire ends, the assembly difficulty of soldering wire ends in through-hole pads is effectively reduced. And less difficult to repair.

Owner:BEIJING AEROSPACE TIMES OPTICAL ELECTRONICS TECH

Flexible catheter-based in vivo detection device and system

PendingUS20210235978A1Reduce the difficulty of welding operationImprove reliabilitySurgeryPrinted circuit aspectsCatheterConductive materials

The present invention provides an in-vivo detection apparatus and system based on a flexible tube. The apparatus includes: a detection component, a main circuit board, a detection circuit board, an auxiliary circuit board, a cable, and an outer tube. A first conducting material is disposed on a first side surface of the detection circuit board, the detection component is connected to the first side surface of the detection circuit board, a wiring terminal of the detection component is welded to the first conducting material, a second conducting material is disposed on a second side surface of the detection circuit board, the second side surface of the detection circuit board is connected to a second edge of the main circuit board, and the second conducting material is perpendicularly welded to a conductive portion on a surface of the main circuit board. Each auxiliary circuit board is connected to one first edge, and a channel for at least a part of the instrument tube to pass through is formed between two auxiliary circuit boards. Based on the present invention, welding strength and reliability can be effectively improved when a packaging size is limited.

Owner:INNOVEX MEDICAL CO LTD

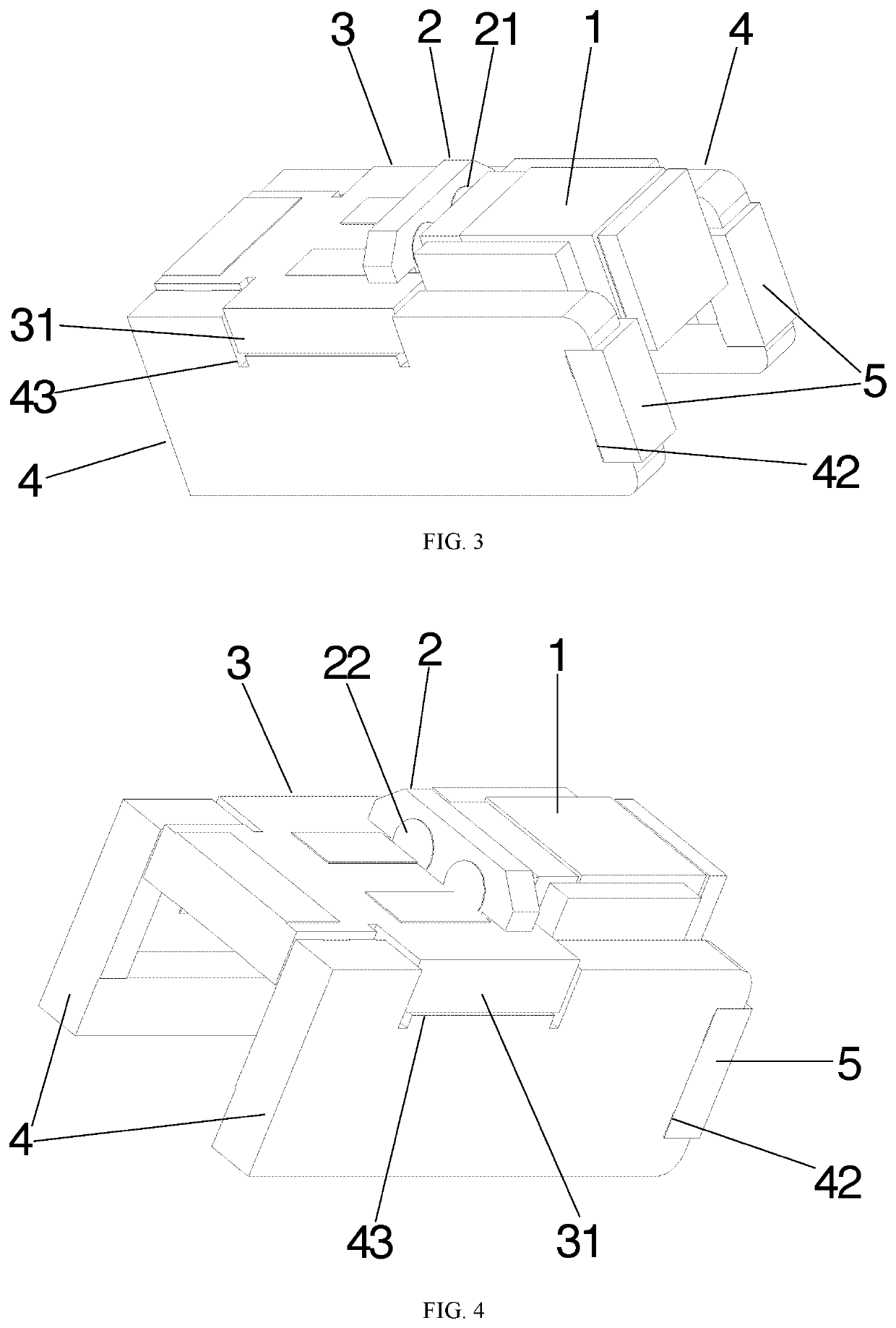

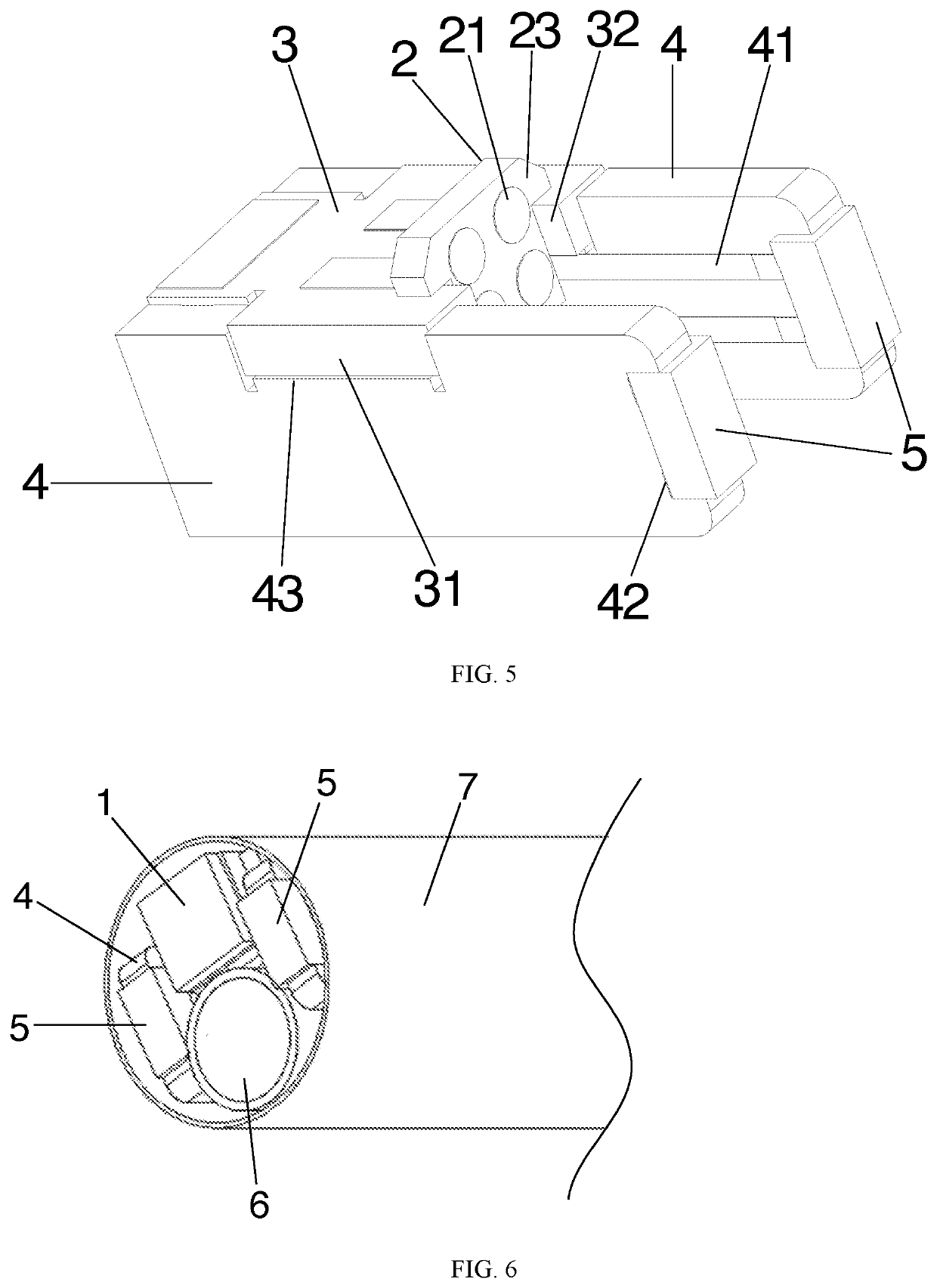

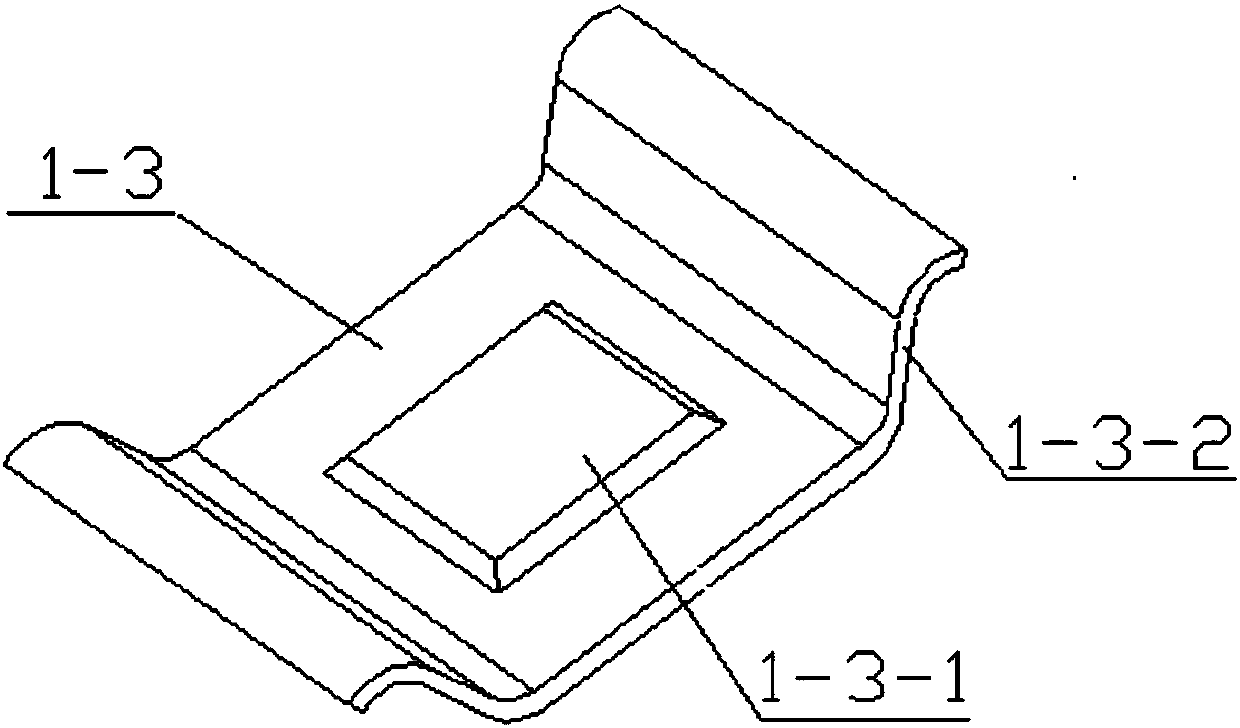

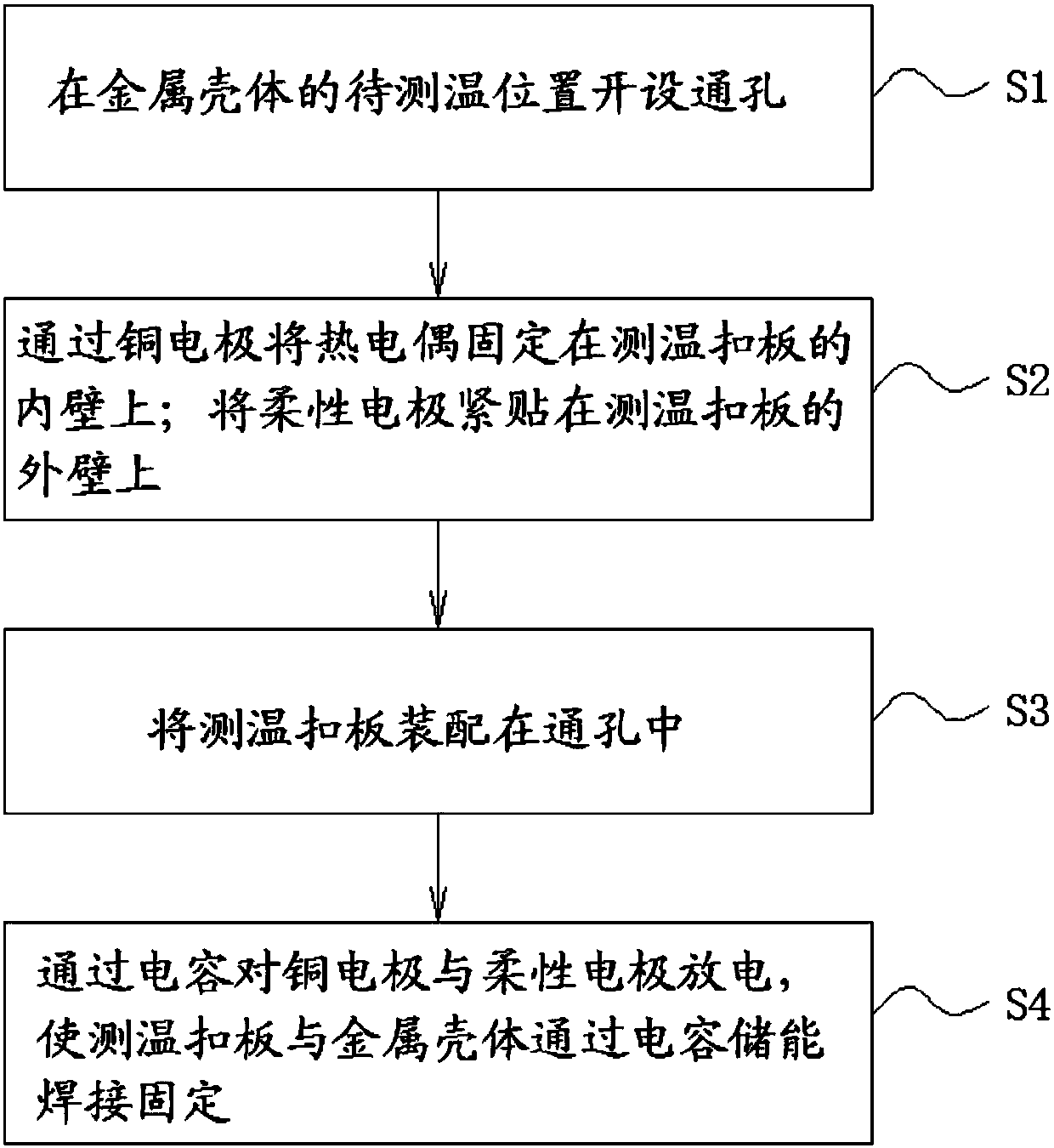

Capacitor energy storage welding forming method for cone metal shell and thermocouples

ActiveCN107584200AReduce the difficulty of operationAvoid high contact resistanceElectrode featuresStorage discharge weldingCapacitive energy storageCapacitance

The invention relates to a capacitor energy storage welding forming method for a cone metal shell and thermocouples. The method comprises the steps that a through hole is formed in a position, where the temperature is about to be measured, of the metal shell; the thermocouples are fixed to the inner wall of a temperature-measuring buckle plate through copper electrodes; flexible electrodes are closely attached to the outer wall of the temperature-measuring buckle plate, wherein the shape of the temperature-measuring buckle plate is matched with that of the through hole; the temperature-measuring buckle plate is assembled in the through hole; a capacitor discharges electricity to the copper electrodes and the flexible electrodes so that the temperature-measuring buckle plate and the metal shell can be fixed through capacitor energy storage welding. By means of the welding forming method, the operation difficulty of welding the thermocouples to the metal shell is reduced, and the weldingquality stability of multiple thermocouples on the inner surface of the metal shell is improved.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

A method for installing an umbrella-shaped roof structure

ActiveCN113404199BShorten the construction periodImprove construction accuracyBuilding roofsStructural deformationSpatial structure

The invention protects an installation method of an umbrella-shaped roof structure, aiming at the technical problems that the umbrella-shaped roof structure has complex shapes, a large number of components, difficulty in high-altitude assembly, and high precision requirements, which lead to inconvenience in the existing installation and construction methods. The construction technology field of large-scale space structures in construction engineering; the umbrella-shaped roof is divided into 20-30 umbrella-shaped unit structures, and the adjacent umbrella-shaped unit structures are connected by long strips of wavy roof steel beams. As a whole, the installation method includes the following steps: (1) Ground modular assembly; (2) Temporary support installation; (3) Sub-unit hoisting; (4) Temporary support removal and structural deformation monitoring: including sandbox support unloading, Temporary support removal and structural deformation monitoring. The installation method of the invention effectively shortens the construction period, improves the construction accuracy, and also improves the installation quality of other related structures attached to the umbrella roof structure.

Owner:CHINA RAILWAY CONSTR ENG GROUP

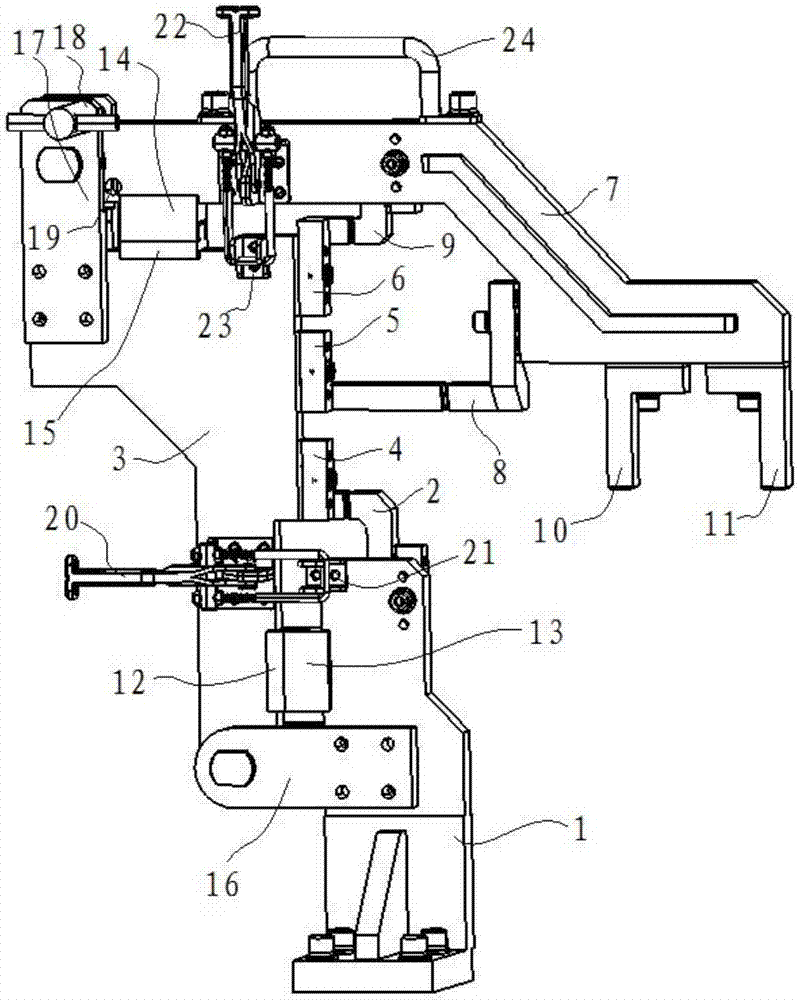

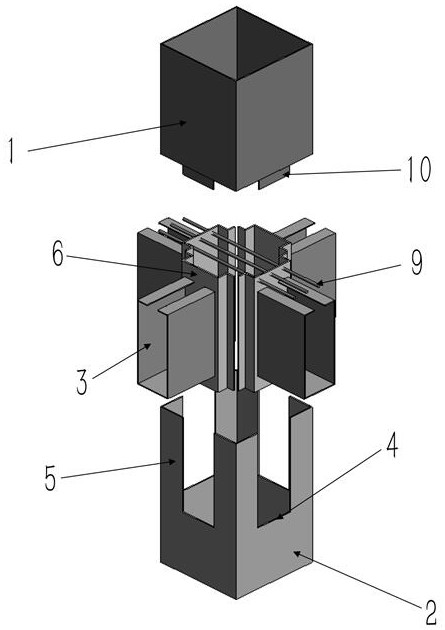

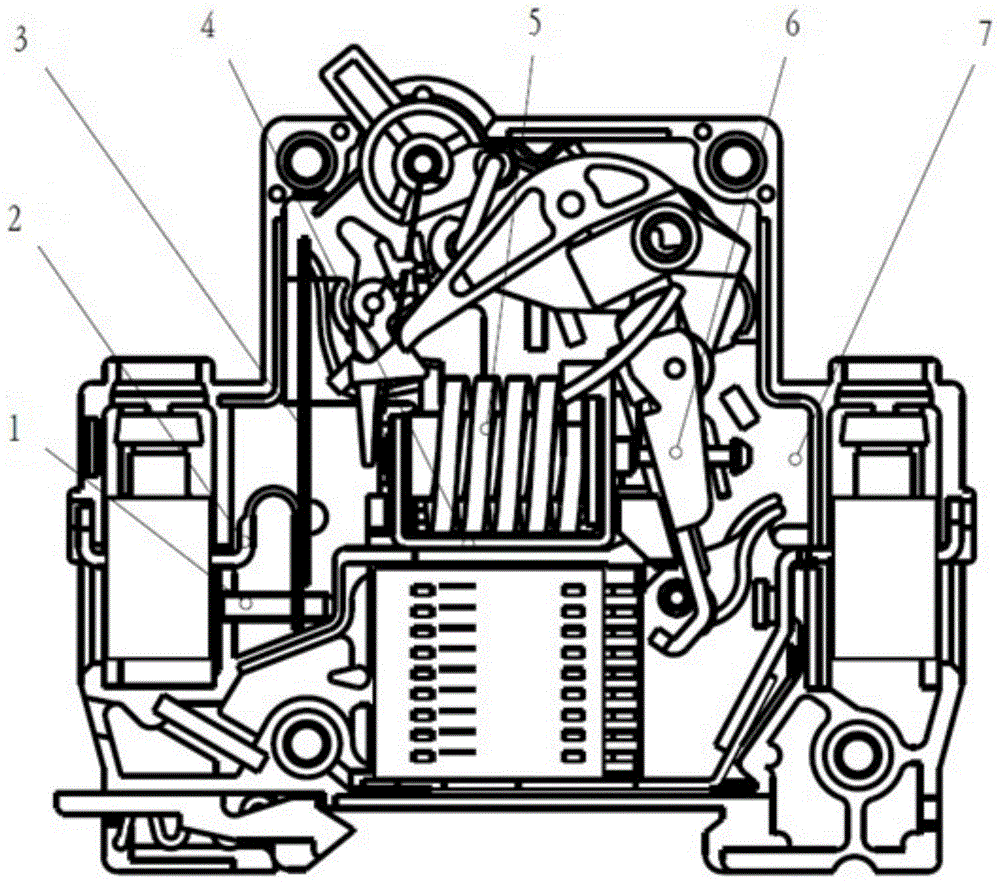

a small circuit breaker

ActiveCN103681146BConducive to extinguishingStrong arc blowing electromagnetic forceCircuit-breaking switch detailsElectricityEngineering

Owner:DELIXI ELECTRIC

Superconductive current lead welding method

InactiveCN100475403CReduce the difficulty of welding operationReduce heat exposureSoldering apparatusElectrical conductorCopper

A method for welding the leading superconductor wire includes such steps as soldering a superconductor onto a transition copper block while applying a thin tin layer to another surface of said copper block to be soldered and soldering between two transition copper blocks by use of the solder with low smelting point.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com