Welding method of low alloy steel plate and ship plate

A technology of marine steel plate and welding method, which is applied in welding equipment, welding/welding/cutting items, metal processing, etc., can solve the problems of poor overall quality of welding seam, low welding productivity, and large deformation of welding structure, and achieve overall welding quality. Guarantee, improve production efficiency, reduce the effect of welding structure deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Flat butt welding of 903 low-alloy steel plate + CCSB marine steel plate

[0028] Horizontal position requirements: the inclination angle of the weld seam is 0°~5°, the rotation angle of the weld seam is 0°~10°,

[0029] Welding equipment: YD-350GM welding machine is equipped with YW-35KB wire feeder, air-cooled automatic welding torch,

[0030] Welding wire: Supercored71 (flux-cored welding wire produced by Hyundai, Korea) Ф1.2

[0031] Gas: 99.9% CO 2 gas.

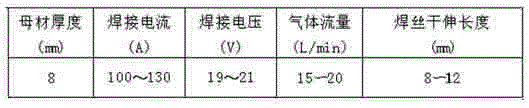

[0032] Process parameters: Table 1

[0033]

[0034] Follow this for flat position structural welding.

Embodiment 2

[0035] Example 2: Horizontal butt welding of 903 low alloy steel plate + CCSB marine steel plate

[0036] Horizontal position requirements: weld inclination angle is 0°~5°, weld seam rotation angle is 0°~90°,

[0037] Welding equipment: YD-350GM welding machine is equipped with YW-35KB wire feeder, air-cooled automatic welding torch,

[0038] Welding wire: ER309L (stainless steel welding wire) Ф1.2

[0039] Gas: 99.9% CO 2 gas.

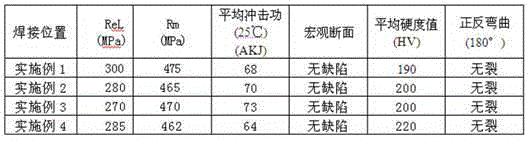

[0040] Process parameters: Table 2

[0041]

[0042] Carry out transverse position structural welding according to this.

Embodiment 3

[0043] Example 3: Butt welding of 903 low-alloy steel plate + CCSB marine steel plate

[0044] Requirements for the supine position: the inclination angle of the weld seam is 0°~15°, the rotation angle of the weld seam is 165°~180°,

[0045] Welding equipment: YD-350GM welding machine is equipped with YW-35KB wire feeder, air-cooled automatic welding torch,

[0046] Welding wire: Supercored71 (flux-cored welding wire produced by Hyundai, Korea) Ф1.2

[0047] Gas: 99.9% CO 2 gas.

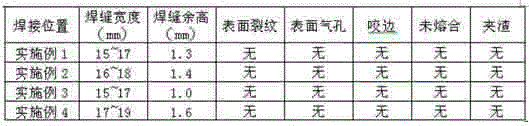

[0048] Process parameters: Table 3

[0049]

[0050] Perform structural welding in supine position according to this.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com