Semitrailer grillage-shaped beam welding tooling and welding process thereof

A semi-trailer and tic-tac-toe technology is applied in the field of aluminum alloy welding to achieve the effect of ensuring position accuracy, eliminating the influence of welding operations, and improving the quality of welding seams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

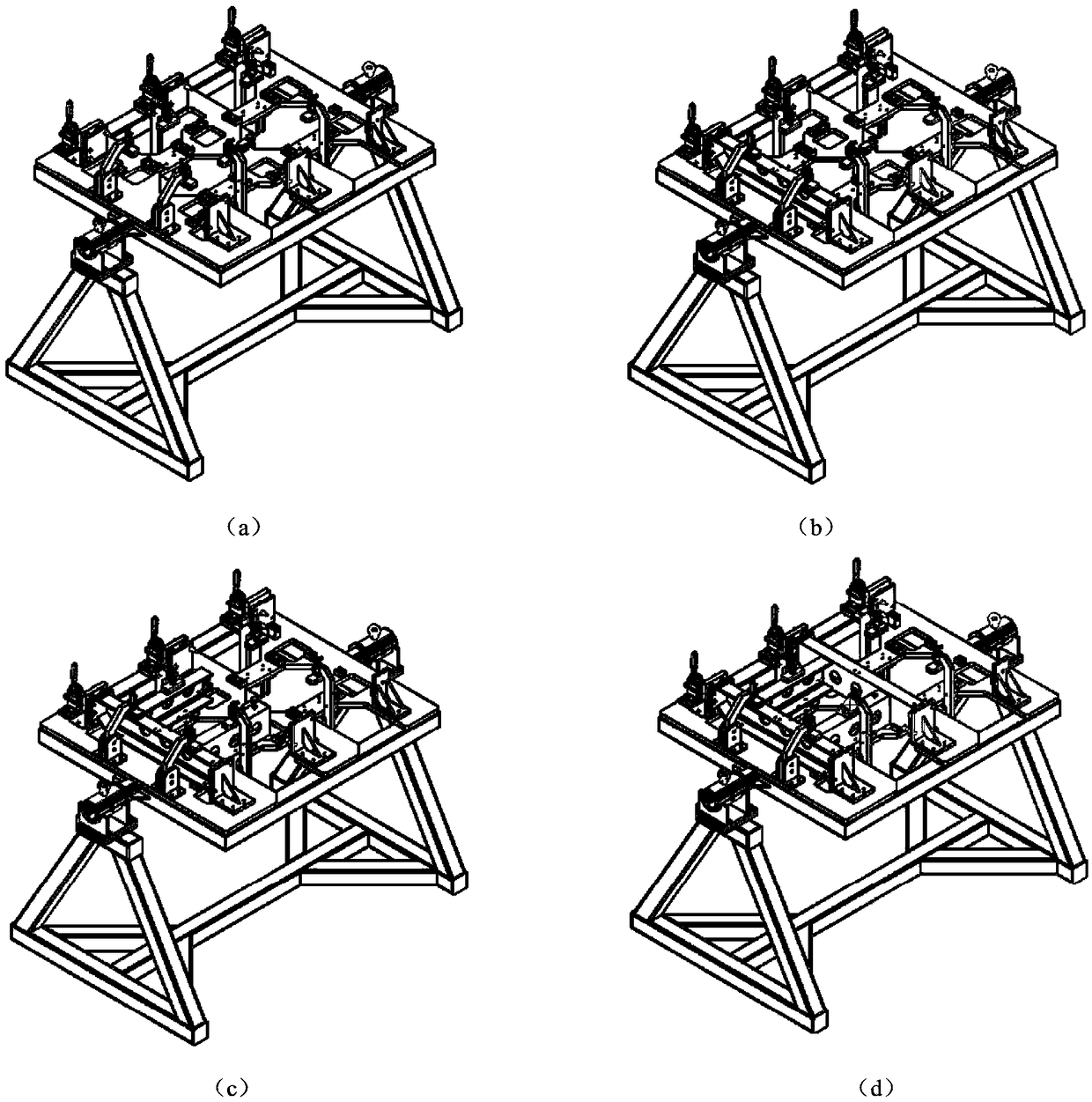

[0035] Preferred embodiments of the present invention will be described in detail below.

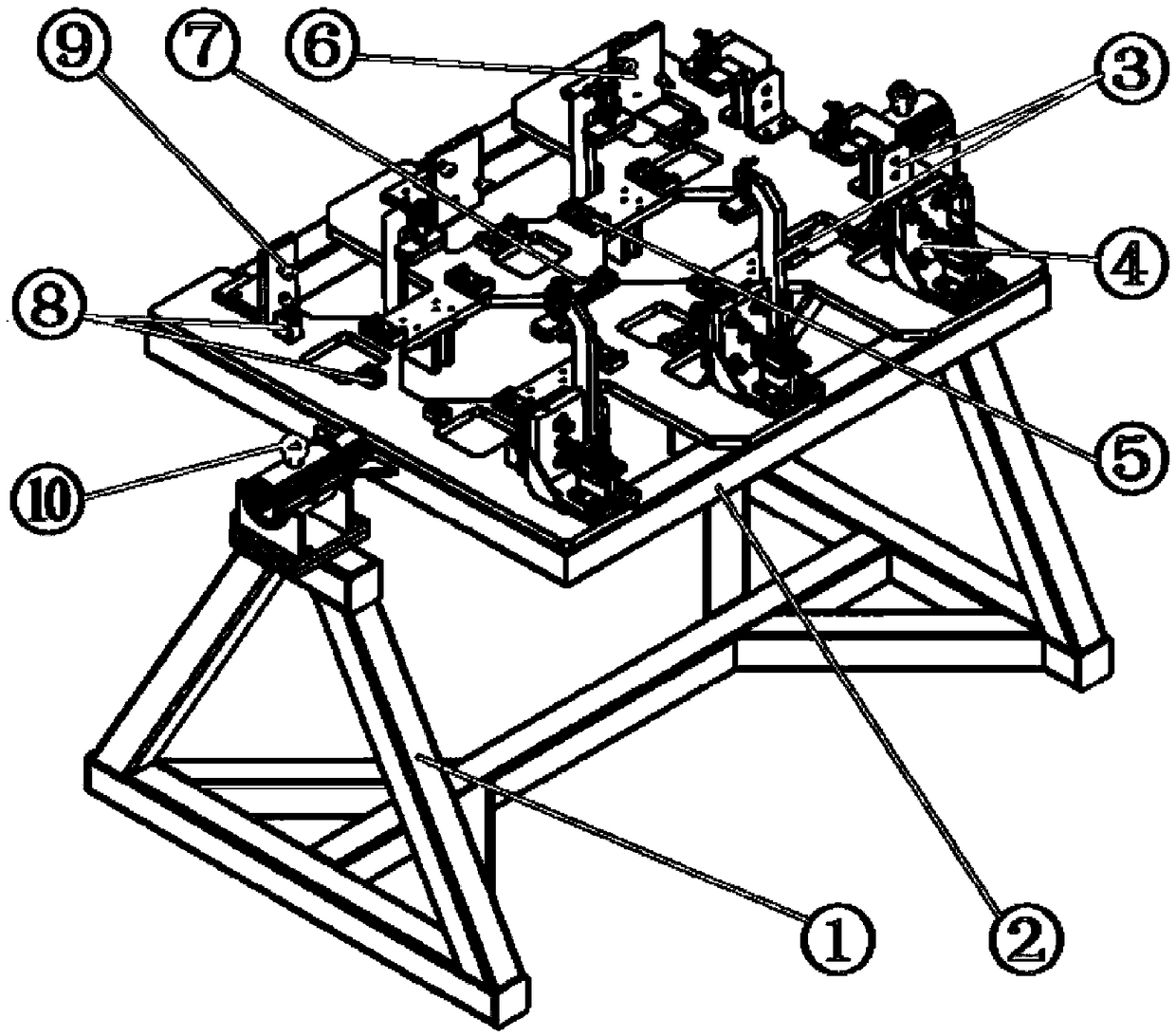

[0036] The reference signs in the accompanying drawings of the specification include:

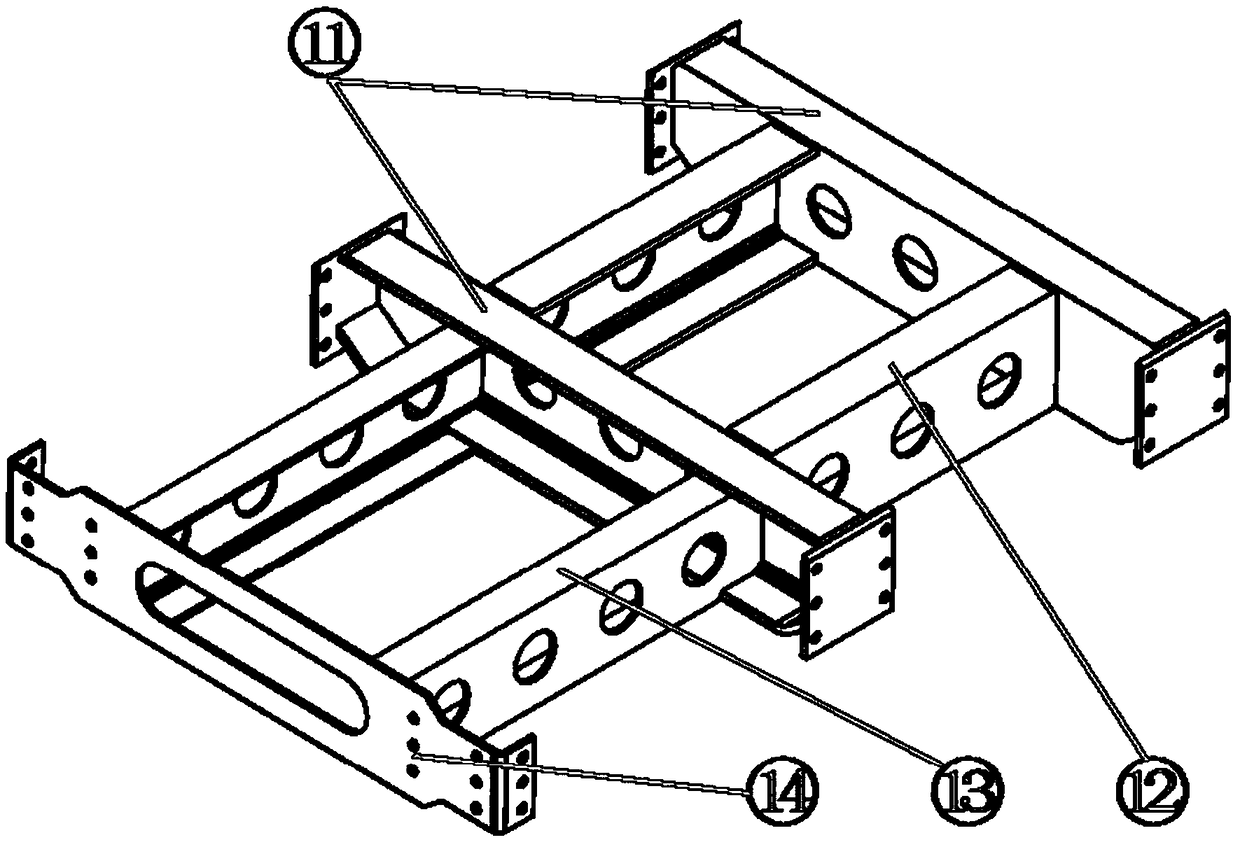

[0037] Base 1, main frame 2, front-end lock beam pressing device 3, moving end limit block 4, traction pin plate limit groove 5, fixed end limit block 6, traction pin plate longitudinal beam pressing device 7, front lock beam Limiting slot for connecting corner fittings 8, beam limiting pin 9, rotation limiting pin 10, traction pin plate beam 11, traction pin plate longitudinal beam rear section 12, traction pin plate longitudinal beam front section 13, front lock beam connecting corner piece 14 .

[0038] like figure 1 The well-shaped beam assembly in the prior art shown in the prior art includes the front lock beam connecting corner piece 14 and two traction pin plate beams 11, and two traction pin plate beams 11 are fixedly welded between the front end lock beam connecting corner piece 14 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com