Doorsill type workpiece welding fixture

A welding fixture and threshold technology, applied in the field of auto parts processing, to achieve the effect of ample welding space, reducing the difficulty of welding operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

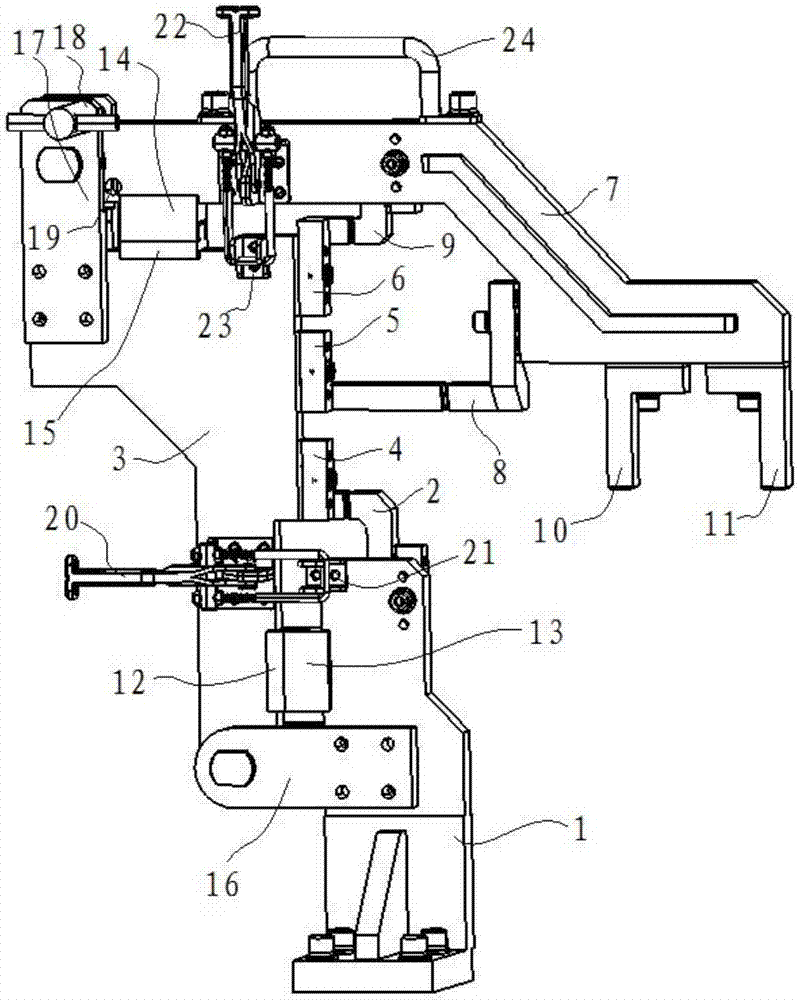

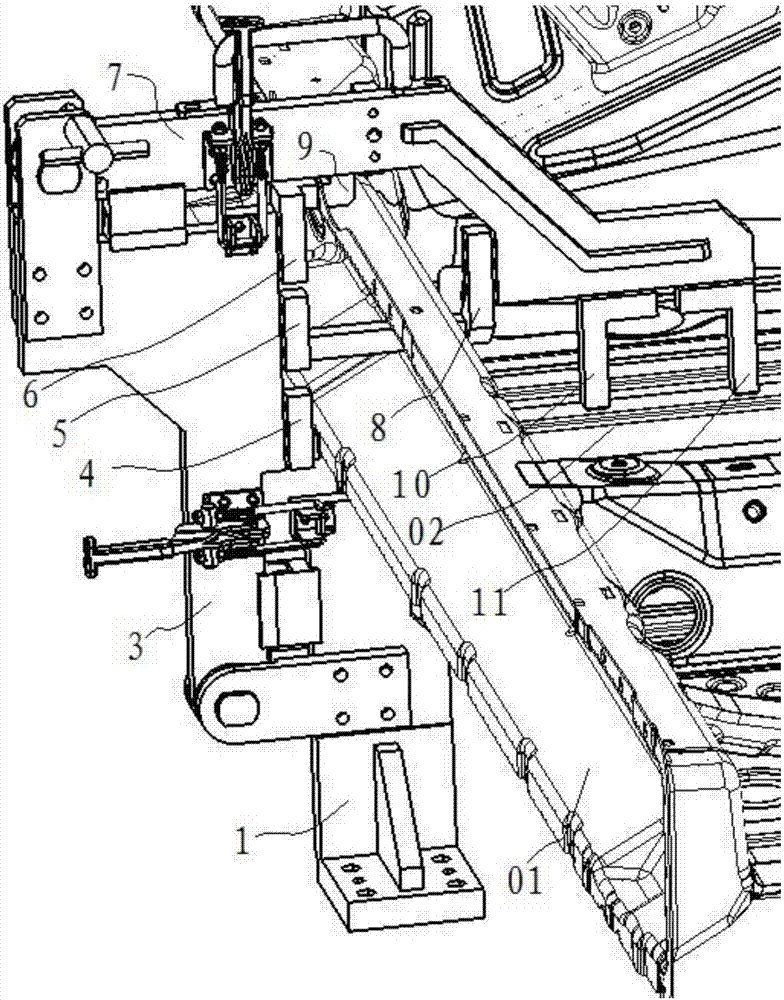

[0026] Embodiments of the present invention: as figure 2 As shown, the present invention provides a threshold type workpiece welding fixture, including:

[0027] Base 1, the base 1 is fixed with a first indenter 2, the first indenter 2 is fixed on the base 1 through an adapter block, and the bolts between the two are fixed and are provided with adjustable gaskets, which can be Adjust the supporting direction, the base 1 is an L-shaped body, the horizontal plate of the base 1 is fixed on the fixture base plate (not shown in the figure) by bolts, and the horizontal plate and the vertical plate of the base 1 are provided with Ribs, in order to ensure the stability and durability of the base 1, the ribs are connected to the base 1 by electric welding.

[0028] The first rotating arm 3, the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com