Manufacturing method of vehicle traction beam, vehicle traction beam and rail vehicle

A vehicle traction and manufacturing method technology, applied in the field of vehicle traction beams, can solve problems such as low machining accuracy and complicated manufacturing methods of traction beams, and achieve the effects of ensuring welding quality, reducing mold opening costs, and reducing the number of molds to be opened

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

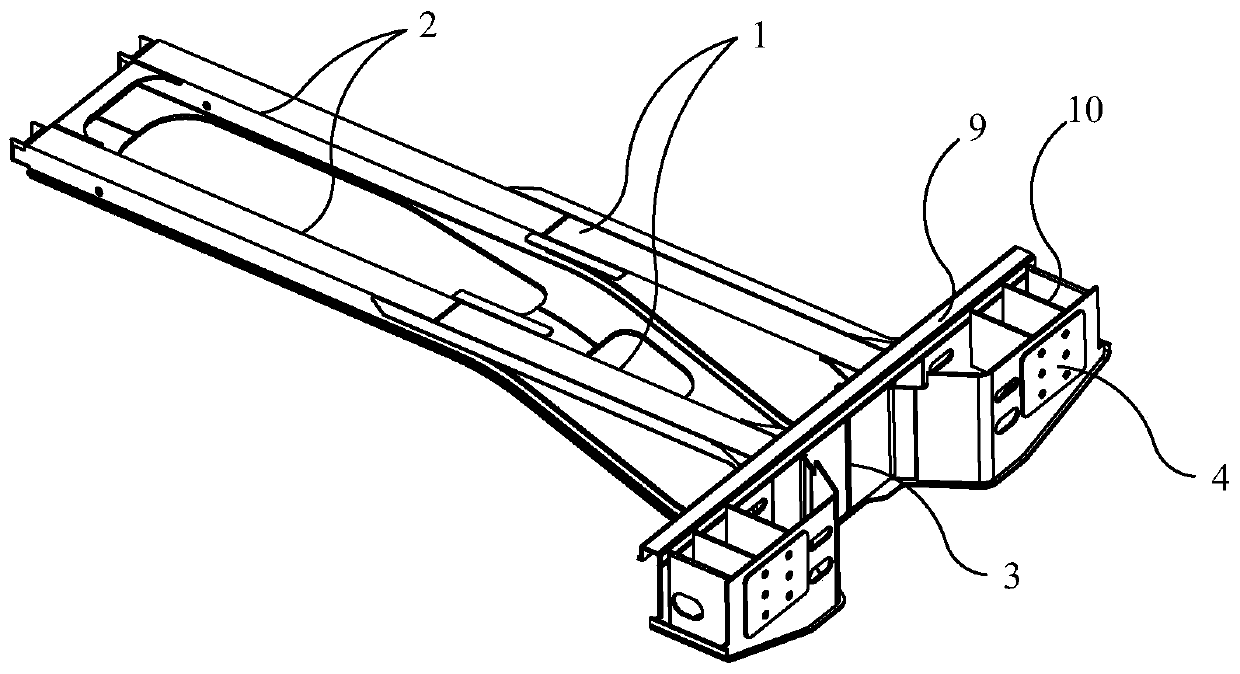

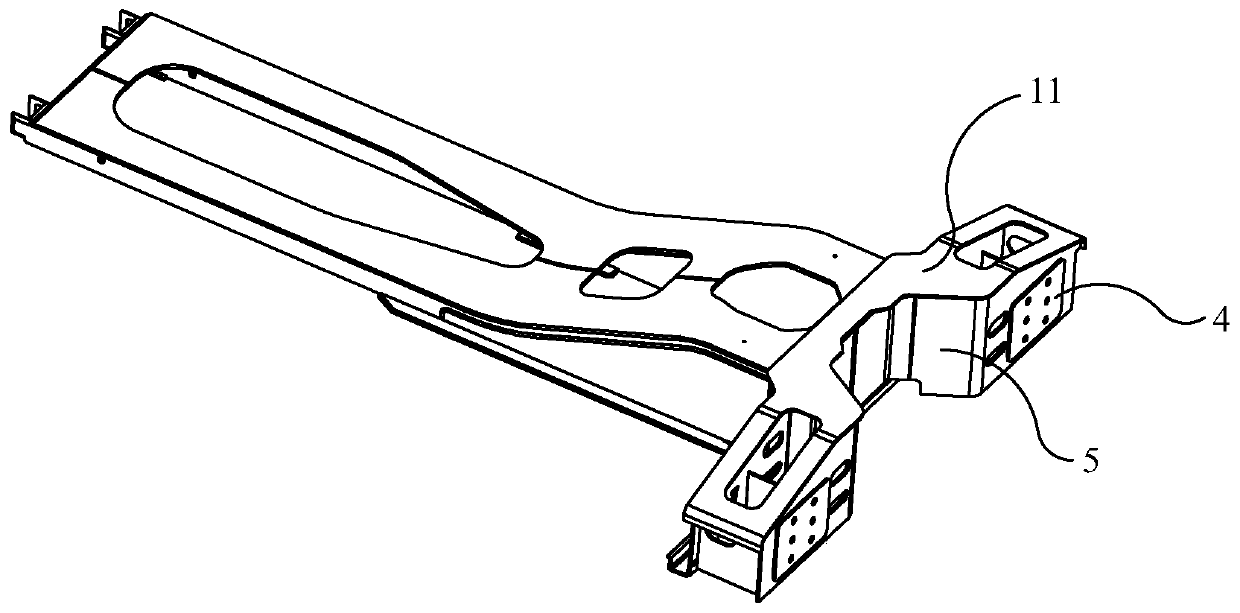

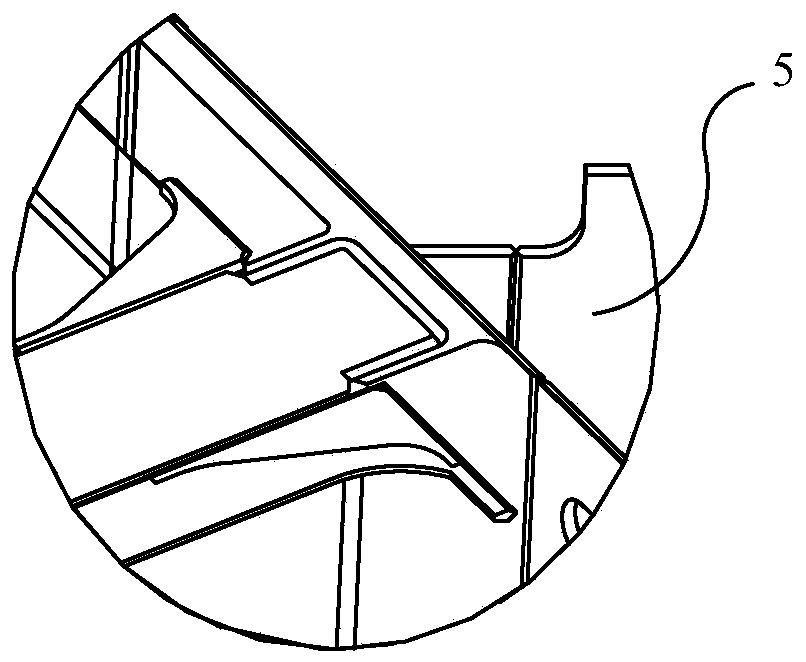

[0040] see in conjunction Figure 1 to Figure 8 , the manufacturing method of the vehicle traction beam includes the following steps: forming two traction beam webs 1 through a single profile; the traction beam web 1 and the lower cover plate 2 are spliced to form a V-shaped groove and butt-welded to form the vehicle traction beam main body The main body of the vehicle traction beam is docked with the coupler mounting seat 3 to form a Y-shaped groove and welded; the curved surface mounting plate 5 is welded between the anti-climbing energy-absorbing device mounting seat 4 and the coupler mounting seat 3 .

[0041] The manufacturing method of the vehicle traction beam provided by the present invention and the vehicle traction beam form two traction beam webs 1 by using a single profile, so that the profile sections of the traction beam web 1 are unified, the number of molds is reduced, and the cost of mold opening is reduced. At the same time, the utilization rate of the prof...

Embodiment 2

[0059] According to another aspect of the present invention, the present invention provides a vehicle traction beam, including a lower cover plate 2, the vehicle traction beam is made by the manufacturing method of the vehicle traction beam in Embodiment 1; the outer edge of the lower cover plate 2 is provided with Traction beam patch 8. The overall structural strength of the lower cover plate 2 can be improved by providing the traction beam patch 8 , and further the overall structural strength of the vehicle traction beam can be further improved.

[0060] Further, the vehicle traction beam also includes a curved mounting plate 5 , and the two ends of the curved mounting plate 5 are respectively connected to the coupler mounting seat 3 and the anti-climbing energy-absorbing device mounting seat 4 .

[0061] The coupler mounting base 3 is fixedly connected to the traction beam. When the coupler mounting base 3 and the anti-climbing energy-absorbing device mounting base 4 are as...

Embodiment 3

[0063] According to another aspect of the present invention, the present invention provides a rail vehicle, including a buffer beam, a vehicle traction beam and a corbel, the buffer beam and the corbel are respectively connected to two ends of the vehicle traction beam, and the vehicle traction beam is the vehicle tow beam.

[0064] For other structures of the rail vehicle, reference may be made to the prior art, which will not be repeated herein. Since the vehicle traction beam has the above-mentioned technical effects, the rail vehicle including the vehicle traction beam also has corresponding technical effects, which will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com