Chemiluminescence micro-fluidic chip and analytical instrument containing chemiluminescence micro-fluidic chip

A microfluidic chip and chemiluminescent technology, applied in the field of microelectronics, can solve problems such as unguaranteed, low production efficiency, and poor quantitative accuracy, and achieve the effects of reducing the difficulty of the manufacturing process, improving production efficiency, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

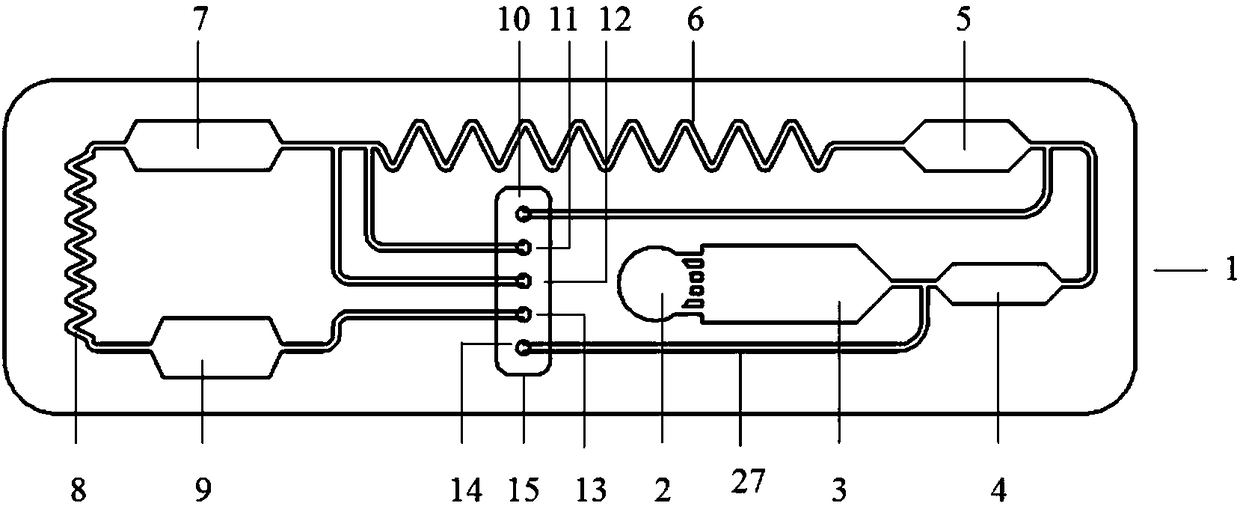

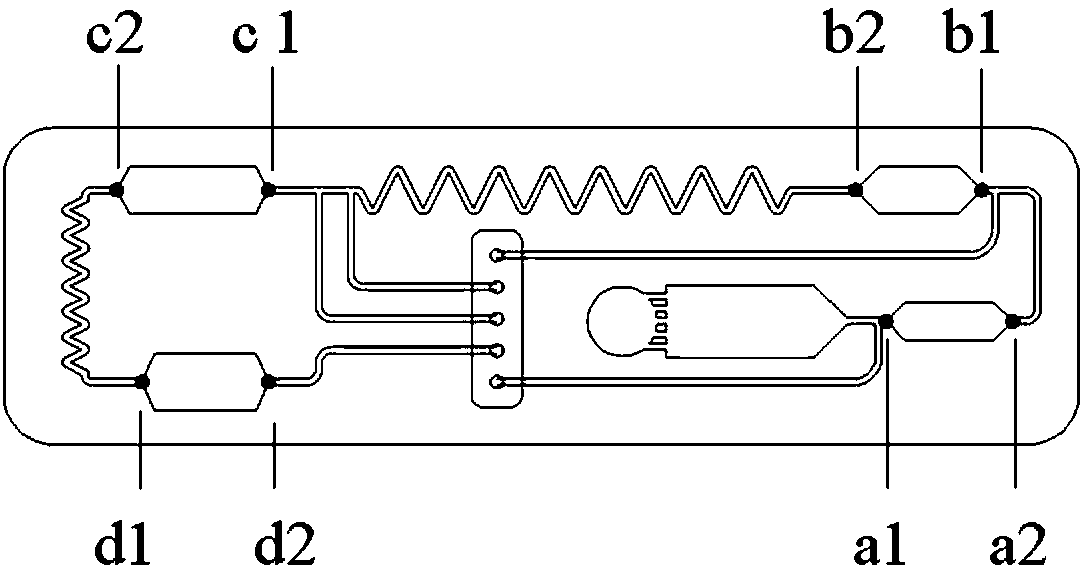

[0043] Please refer to Figure 1 to Figure 5 , this embodiment provides a chemiluminescent microfluidic chip, which includes a chip body, and a sample inlet 2, a liquid driving force inlet 13, a substrate luminescence liquid inlet 11, a cleaning solution inlet 12, Substrate luminescent liquid branch channel 17, cleaning liquid branch channel 18, main fluid channel and multiple functional areas; detailed description will be given below.

[0044] In this embodiment, the main fluid channel communicates with multiple functional areas to guide fluid flow between the functional areas.

[0045] The functional area includes an enzyme-labeled primary antibody embedding area 5 , a magnetic-labeled secondary antibody embedding area 7 and a chemiluminescent detection area 9 which are sequentially connected through the main fluid channel.

[0046] Among them, enzyme-labeled primary antibody embedding area 5 is embedded with enzyme-labeled primary antibody; magnetic-labeled secondary antib...

Embodiment 3

[0067] The description about the liquid quantification area in embodiment 3 is applicable to the description of the liquid quantification area (comprising magnetic label secondary antibody embedding area 7, enzyme-labeled primary antibody embedding area 5 and sample quantification area 4) in this embodiment, here No longer.

Embodiment 4

[0068] The description about the liquid identification site and the liquid identification device in Embodiment 4 is applicable to the description of the liquid identification site and the liquid identification device in this embodiment, and will not be repeated here.

[0069] Optionally, the connection between the other end of the substrate luminescent liquid branch channel 17 and the liquid inlet of the magnetic label secondary antibody embedding area 7 is located on the main fluid channel of the liquid inlet of the magnetic label secondary antibody embedding area 7; In one embodiment, "adjacent" here can generally be understood as "0.5-10 mm (preferably 0.5-2 mm) from the liquid inlet of the magnetic label secondary antibody embedding region 7".

[0070] Optionally, the cleaning liquid enters the magnetic label secondary antibody embedding area 7 through the cleaning liquid inlet 12 and the cleaning liquid branch channel 18 for quantification; the other end of the cleaning li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com