Three-stage light gas gun based on hydrogen and oxygen mixed detonation driving

A light gas gun, hydrogen-oxygen technology, applied in compressed air guns, weapons without explosives, weapon types, etc., can solve the strict requirements of the production process of the first-level target chamber of the third-level gun, and increase the difficulty and workload of cleaning the gun barrel. , increase the experimental cost and other issues, to achieve the effect of reducing the difficulty of the manufacturing process, reducing the risk of unsafe and unstable, and reducing unenvironmental factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

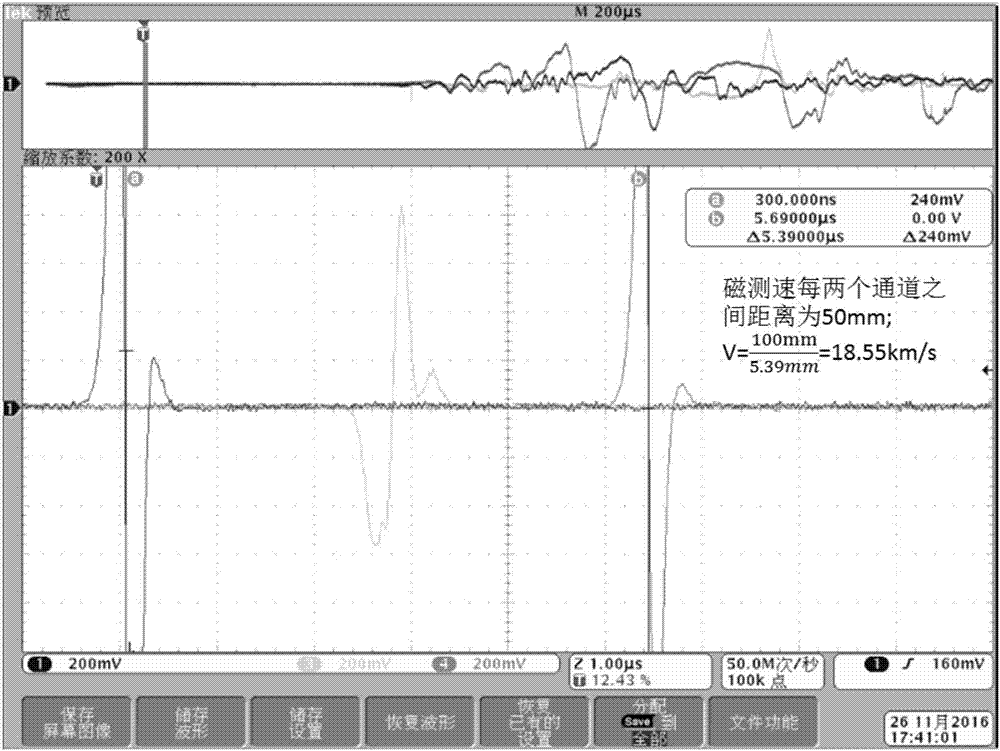

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with reference to the accompanying drawings and examples.

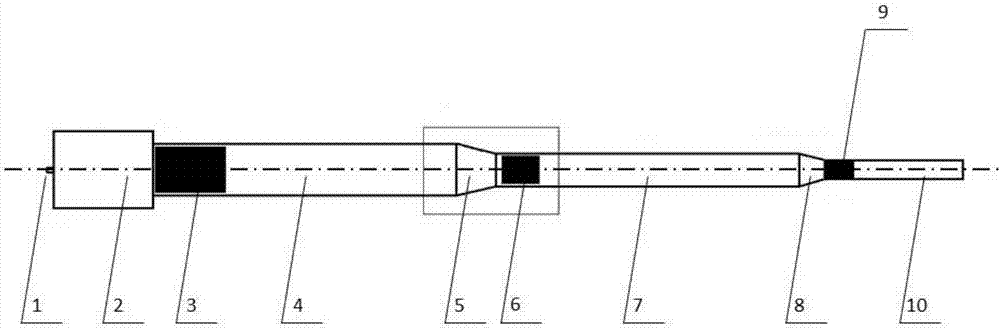

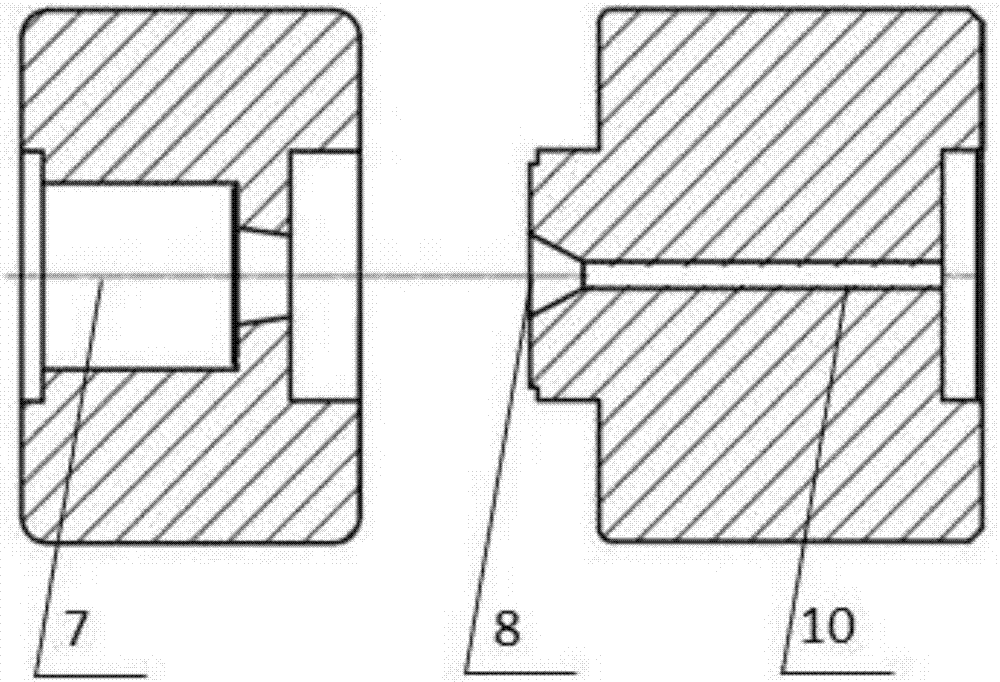

[0019] See attached figure 1 , a three-stage light gas gun driven by hydrogen-oxygen mixed detonation, which includes: a combustion chamber 2 with an ignition device 1 at the tail, a primary pump pipe 4 connected to the combustion chamber 2, and a primary pump pipe 4 connected between the combustion chamber 2 and the primary pump The first-stage diaphragm at the junction of the tube 4; the first high-pressure cone section 5 connecting the first-stage pump tube 4 and the second-stage pump tube 7; sheet; the second high-pressure cone section 8 connecting the secondary pump tube 7 and the launch tube 10; the tertiary diaphragm arranged at the junction of the second high-pressure cone section 8 and the launch tube 10;

[0020] The first-stage piston 3 is arranged at the end where the first-stage diaphragm is located in the first-stage pump tube 4, the second-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com