Assessing test machine for tribological properties of high polymer compound material

A composite material and tribology technology, applied in the field of machinery, can solve the problems of long experiment time, complicated process, difficult to guarantee the bonding quality, etc., and achieve the effects of easy standardization, high experiment efficiency, and convenient disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

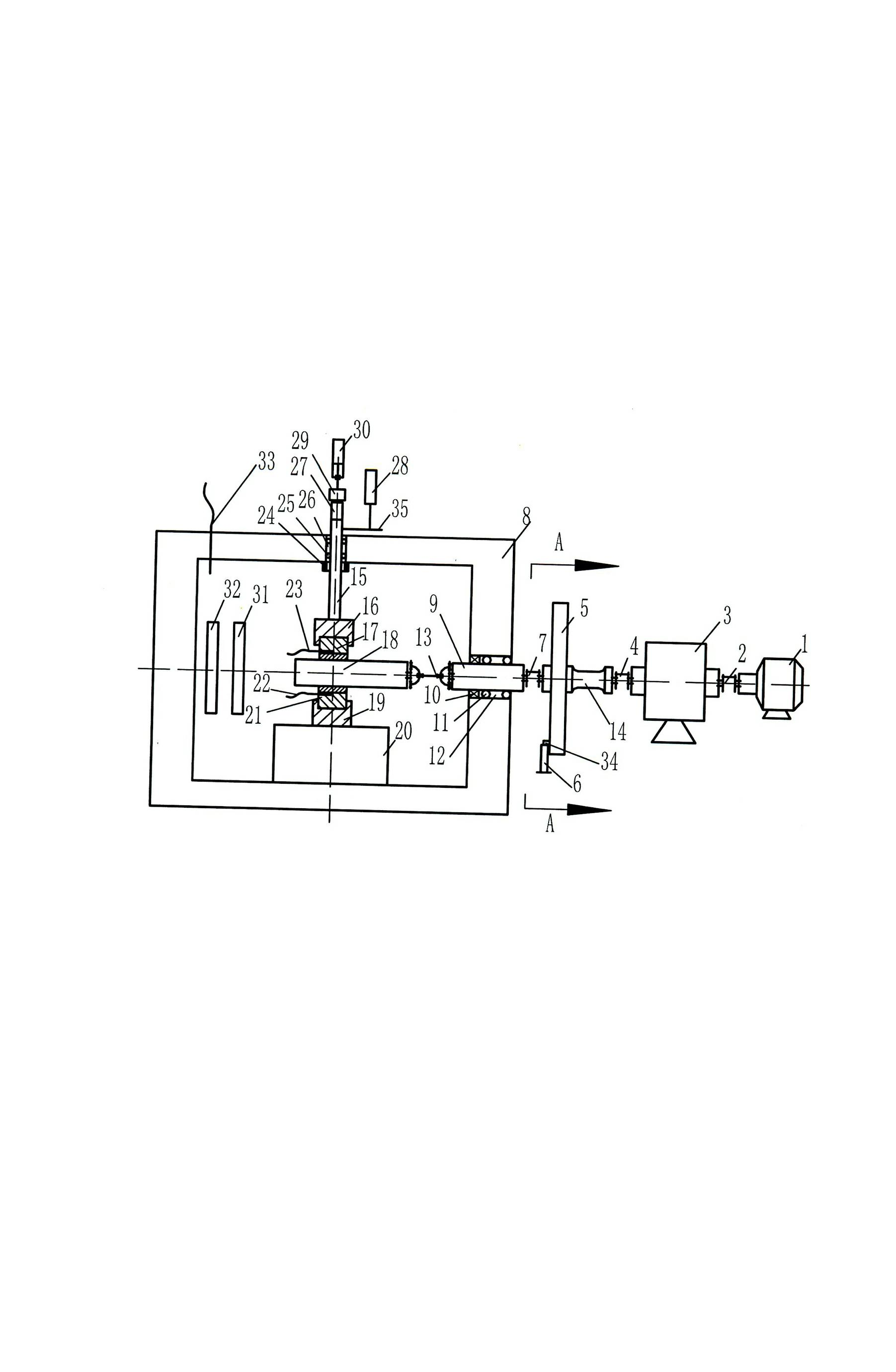

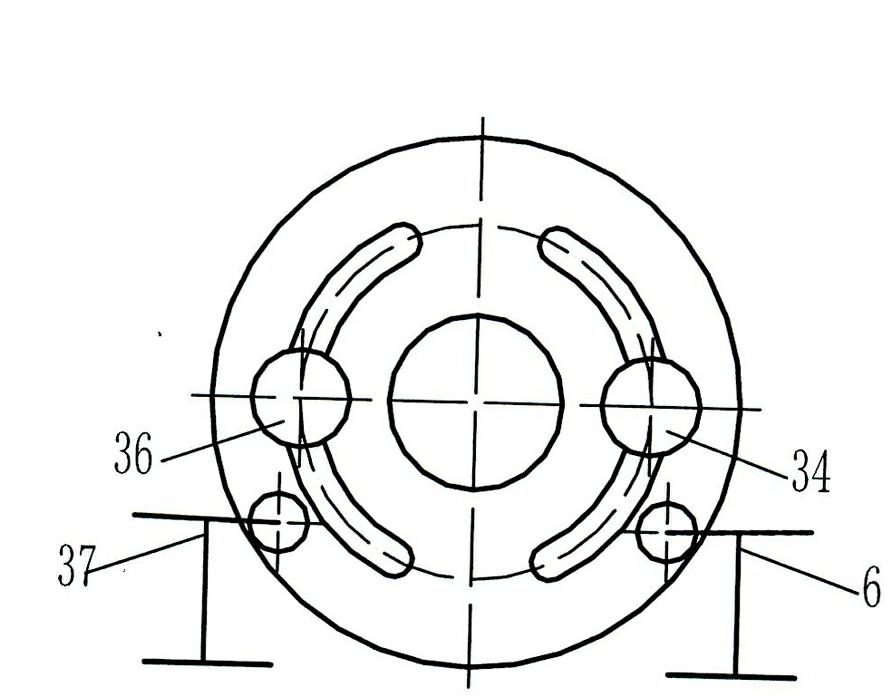

[0016] figure 1 , figure 2 and image 3 It is an embodiment disclosed by the present invention, and two holes are opened on the airtight box body 8: the first box body hole 11 and the second box body hole 26 . The axes of the first box hole 11 and the second box hole 26 are located in a plane and are perpendicular to each other. The first box hole 11 supports the transmission shaft 9 through the first bearing group 12, and one end of the transmission shaft 9 extends outside the airtight box 8, and the end of the extended end of the transmission shaft 9 is connected to the safety shaft through the third coupling 7. 14 is connected to the output end, the input end of the safety shaft 14 is connected to the output shaft of the torque meter 3 through the second coupling 4, and the input shaft of the torque meter 3 is connected to the output shaft of the servo motor 1 through the first coupling 2. The rotation angle disc 5 is installed and fixedly connected to the output end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com