Automatic rust removal device and method for surface of steel plate

A steel plate, automatic technology, applied in the direction of grinding feed movement, workpiece feed movement control, image data processing, etc., can solve the problems of slow speed and low efficiency, improve work efficiency, save labor, reduce rust removal cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to make the purpose and realization method of the present invention clearer, the present invention will be further described in detail in conjunction with the accompanying drawings. This description introduces specific implementations consistent with the principles of the present invention by way of example, and aims to enable those skilled in the art to reproduce the present invention, and can use it without departing from the scope and spirit of the present invention. Other embodiments may change and / or replace the structure of the various elements. Accordingly, the following detailed description should not be read in a limiting sense.

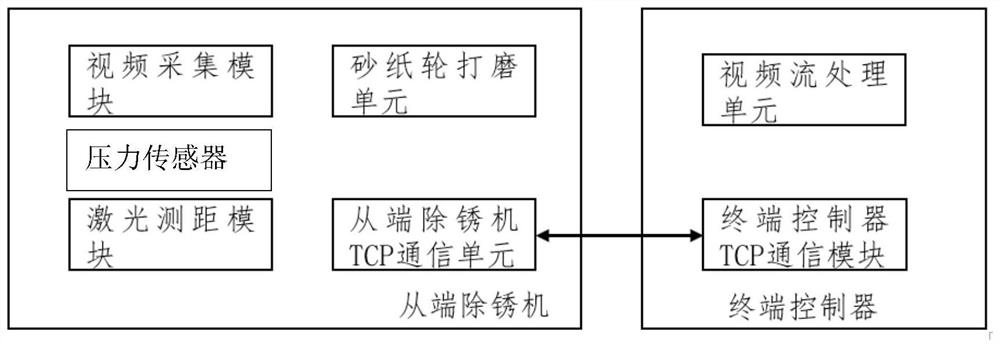

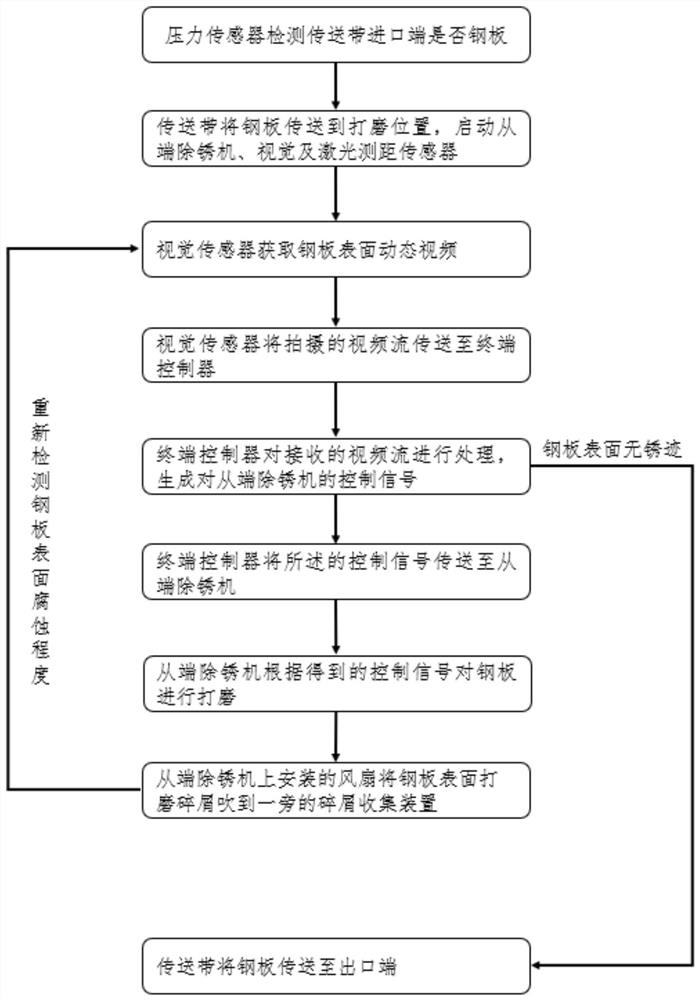

[0053] like figure 1 As shown, the specific implementation of the device includes a conveyor belt, a terminal controller, and a slave-end derusting machine. The terminal controller includes a video stream processing unit, a terminal controller TCP communication module, and the slave-end derusting machine is set near the conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com