Full-automatic optical fiber cutting knife

A cutting knife, fully automatic technology, applied in the coupling of optical waveguide, metal processing, etc., can solve the problem of not having a fully automatic optical fiber cutting knife

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

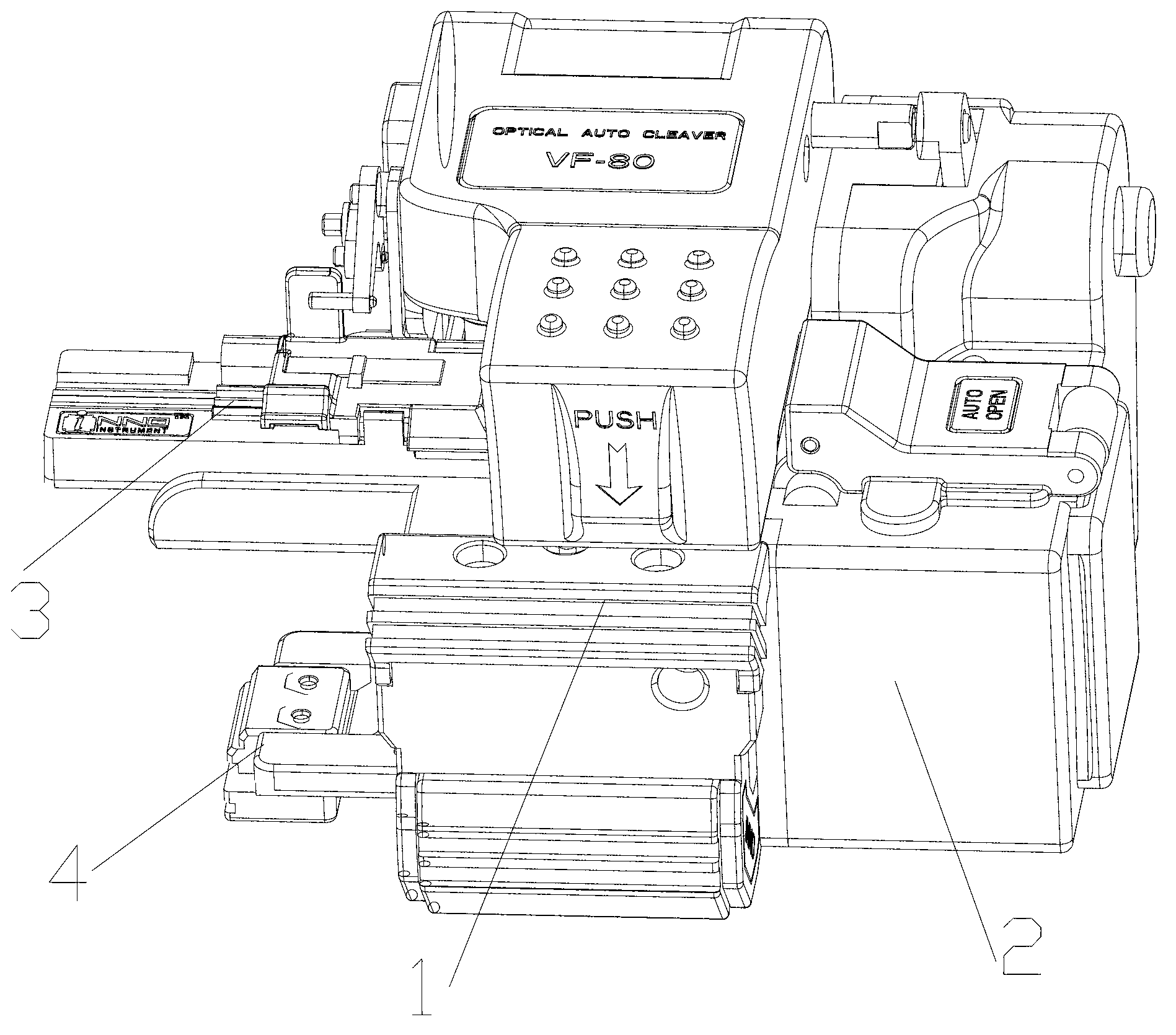

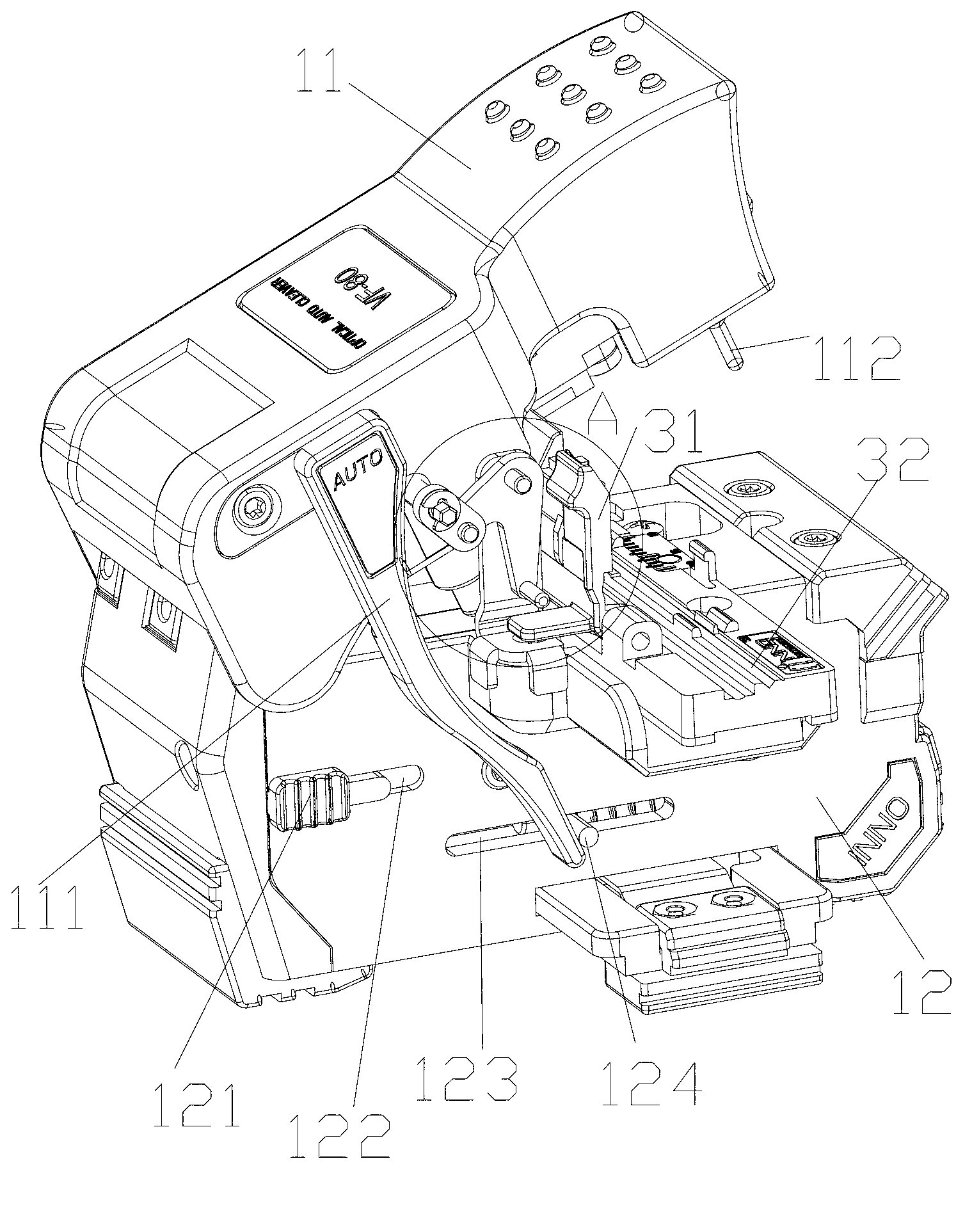

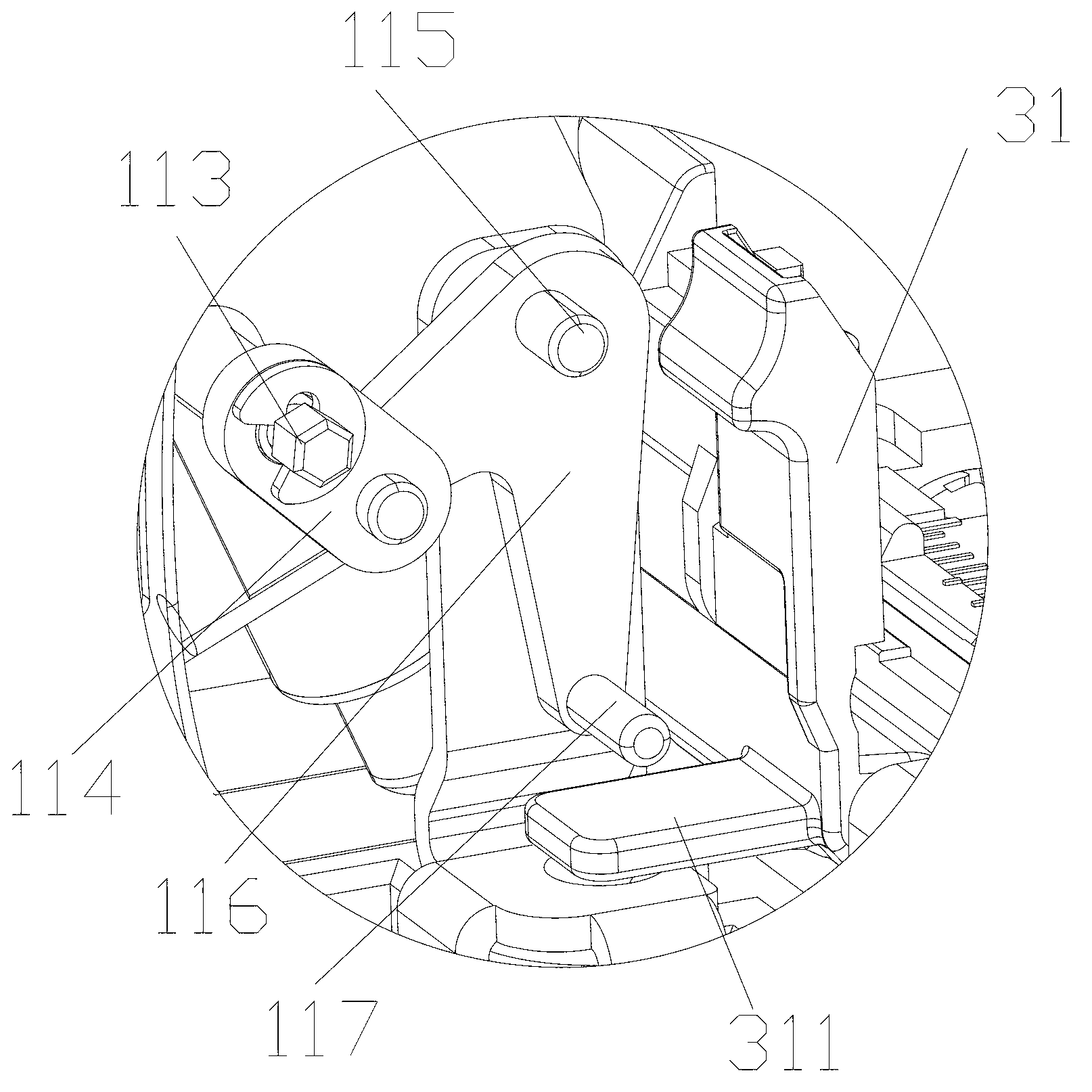

[0085]The present invention provides a fully automatic optical fiber cutter, which includes an optical fiber cutter body, an optical fiber clamp and a recoverer, the optical fiber clamp and the recoverer are respectively detachably arranged on the optical fiber cutter body, and the optical fiber cutter body includes a cutter cover and a cutter The main body, the cover of the cutter and the main body of the cutter are pivotally connected at the end, and a blade fixing seat is movably arranged in the main body of the cutter, and a blade for cutting optical fibers is arranged on the blade fixing seat; The clamp includes a clamp cover and a clamp main body, the clamp cover is pivotally connected to the clamp main body; the recoverer includes a recoverer body and a recoverer cover, and the open end of the recoverer body and the recoverer cover is provided with a fiber winding assembly corresponding to the fiber winding The component controls the fiber winding through a transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com