Fully-automatic plate-cutting apparatus

A fully automatic, sheet metal technology, used in shearing equipment, shearing devices, metal processing equipment, etc., can solve the problem of not being fully automatic.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

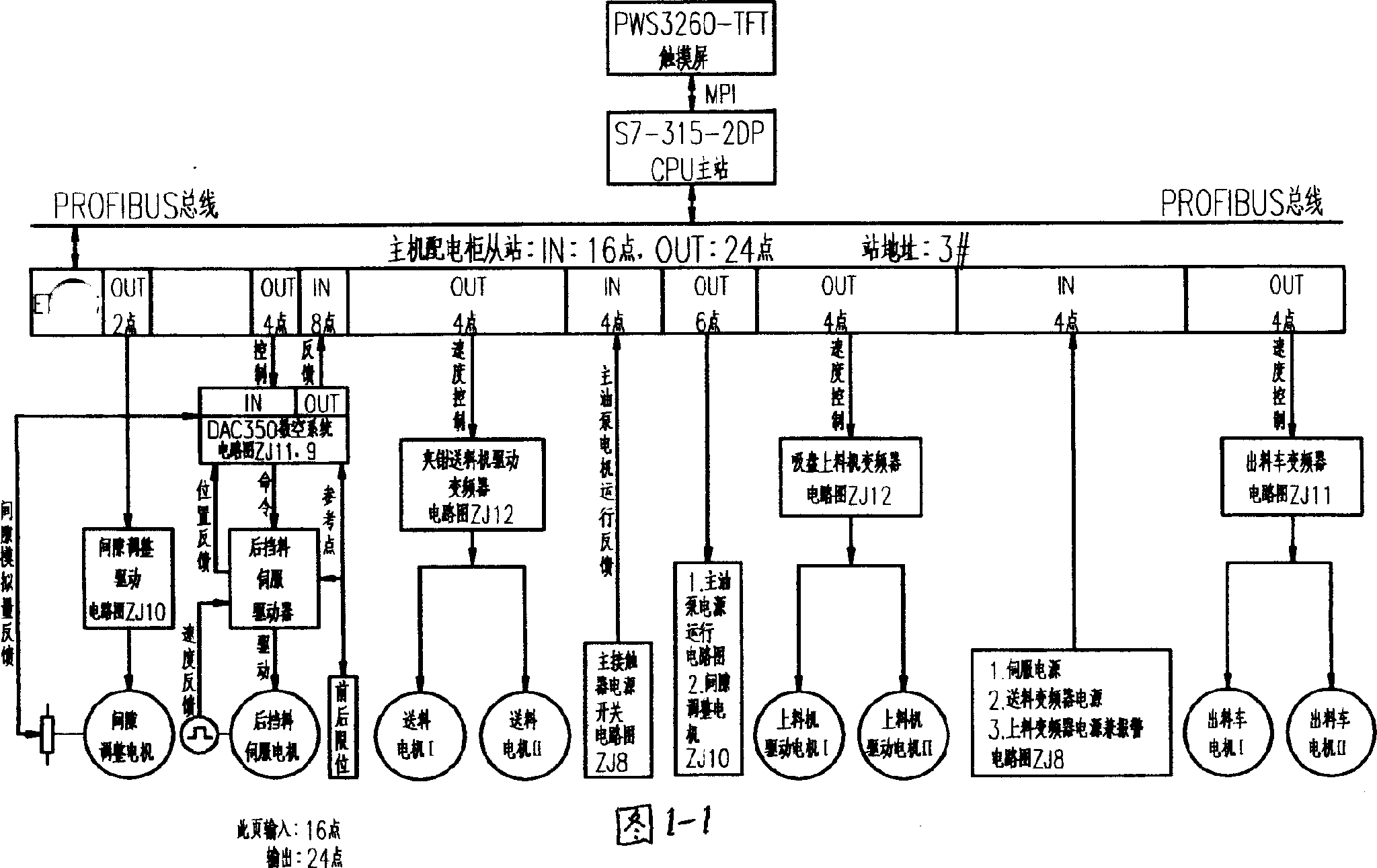

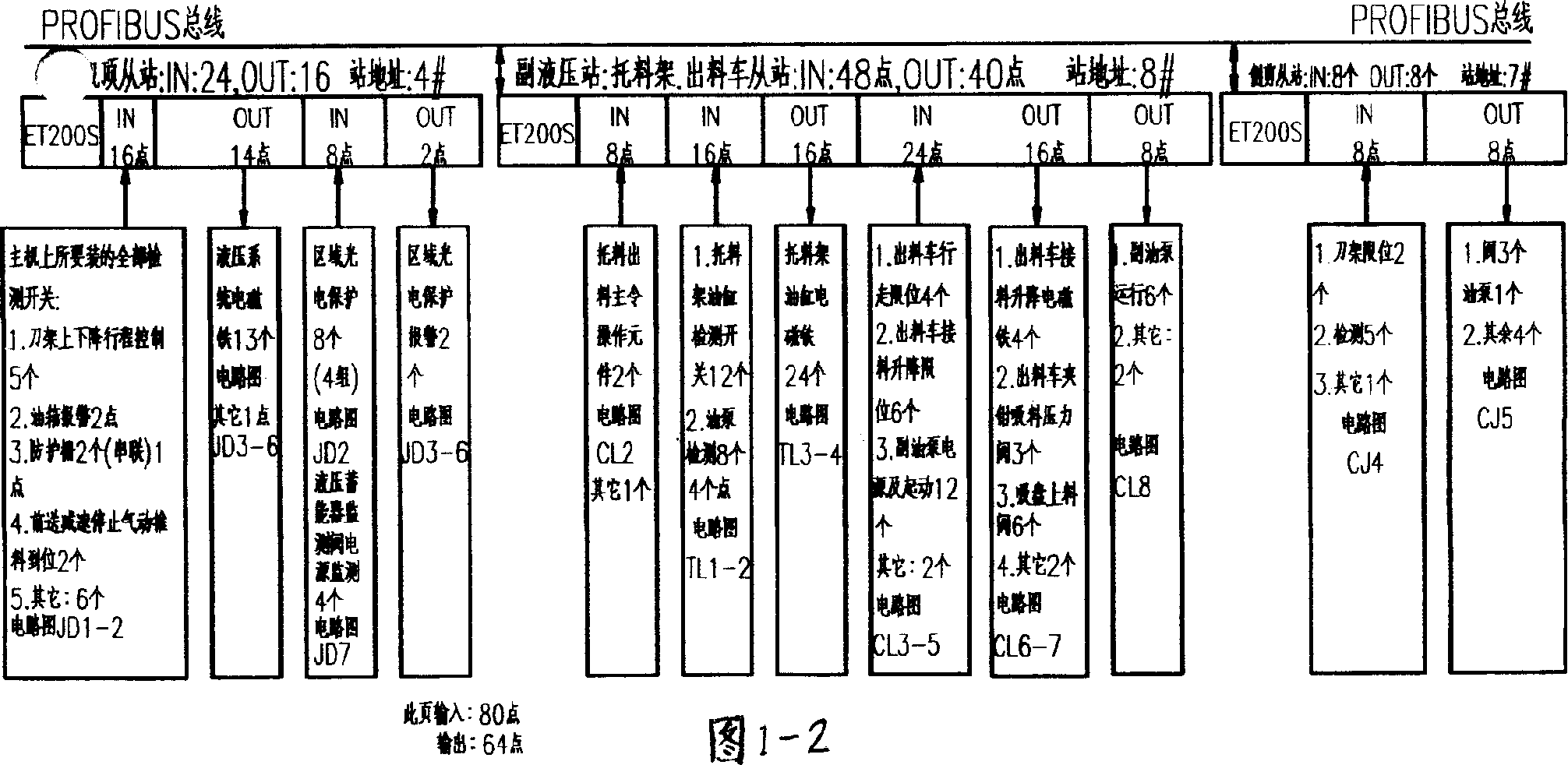

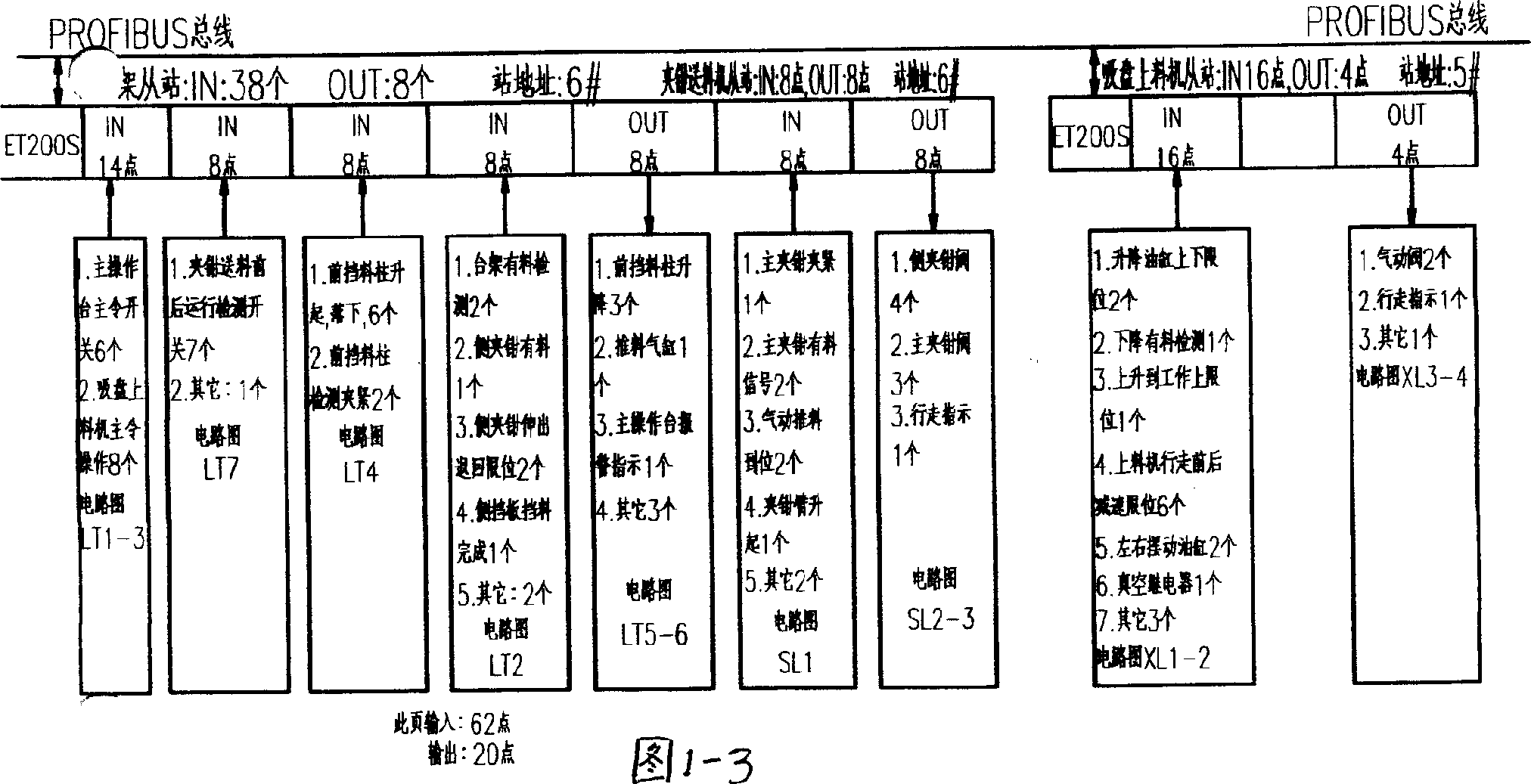

[0006] The CUP master station (S7-315-2DP) first realizes two-way data transmission and control with the touch screen (PWS3260-TFT), and then establishes a Profibus bus slave station (ET200S) through the Profibus bus to realize detection, drive, control, Protection, display (via touch screen). Specifically: 1. Host power distribution cabinet slave station: input 16 points, output 24 points, combined with DAC350 numerical control system to control the back gauge servo drive, clamp feeding drive frequency converter, suction cup feeding machine frequency converter, and discharge car frequency conversion 2. Machine-top slave station: input 24 points, output 16 points, sample the detection switch installed on the main engine, control the electromagnet of the hydraulic system, and the detection and alarm of the regional photoelectric protection unit; 3. Auxiliary hydraulic slave station (supporting material Frame slave station, material car slave station): input 48 points, output 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com