Full-automatic production equipment for compressor copper pipes

A production equipment, fully automatic technology, applied in other manufacturing equipment/tools, metal processing, manufacturing tools, etc., can solve the problems of low processing rate of finished pipe fittings, limited processing accuracy, easy to generate waste, etc., to achieve effective control of processing costs , Improve processing efficiency and benefit production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

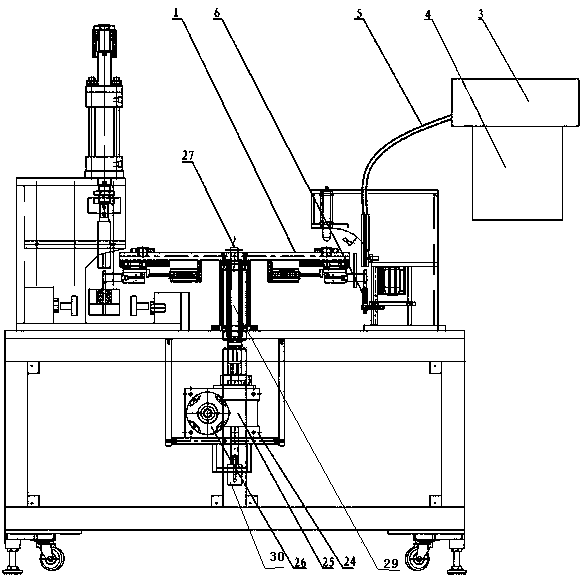

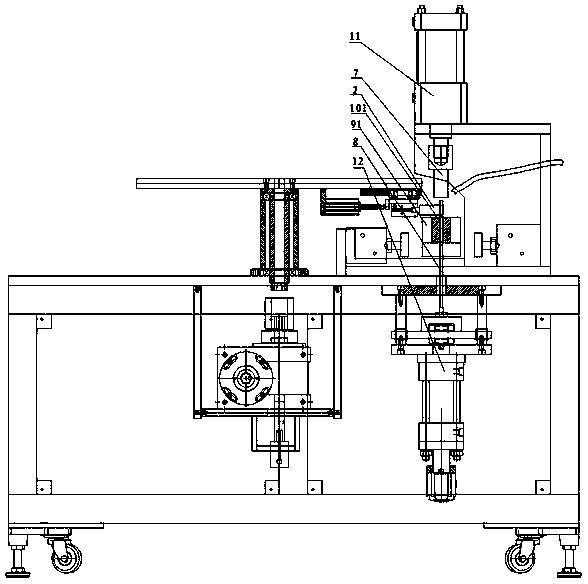

[0032] A kind of fully automatic production equipment of copper tube of compressor in this embodiment, combines figure 1 , including feeding station, flaring station, bunching station, discharging station and turntable 1, the feeding station, flaring station, bunching station and discharging station are installed on turntable 1 in sequence On the side, the bottom of the turntable 1 is equipped with a manipulator 2, which is used to move the pipe to be processed from the previous station to the next station, wherein:

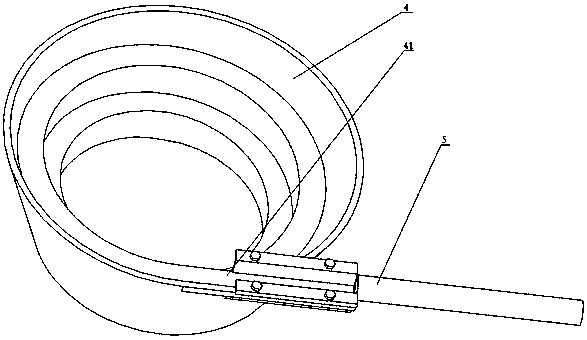

[0033] combine figure 2 , the feeding station includes a vibrating plate 3, a spiral progressive trough 4, a metal hose 5, and an accommodating sleeve 6. The spiral progressive trough 4 is located above the vibrating plate 3, and is driven by the vibrating plate 3 to vibrate. The opening 41 of the progressive trough 4 communicates with the upper end of the metal hose 5, the lower end of the metal hose 5 is located directly above the accommodating sleeve 6, the ...

Embodiment 2

[0043] The setting and working principle of this embodiment are the same as that of Embodiment 1, the difference is that the left mold 15 and the right mold 16 are composed of a mandrel 19 with high rigidity and an outer mold 20 with little rigidity, and the mandrel 19 is installed in the outer mold 20 , the matching hole is opened on the mandrel 19, the mandrel 19 is different from the outer mold 20 in rigidity, the mandrel 19 is more rigid than the outer mold 20; the second accommodation hole 102 is a through hole.

[0044] The production equipment of this embodiment is used to process copper tubes of compressors. From the aspect of processing flow, the traditional discontinuous processing is transformed into continuous automatic processing; from the aspect of input cost, under the premise of meeting the processing needs, the maximum In terms of processing efficiency and processing accuracy, the fully automated continuous production ensures the improvement of processing effic...

Embodiment 3

[0046] The arrangement and working principle of this embodiment are the same as those of Embodiment 2, the difference is that the second accommodating hole 102 is a half-through hole, and its bottom is blocked.

[0047] The production equipment of this embodiment is used to process copper tubes of compressors. From the aspect of processing flow, the traditional discontinuous processing is transformed into continuous automatic processing; from the aspect of input cost, under the premise of meeting the processing needs, the maximum In terms of processing efficiency and processing accuracy, the fully automated continuous production ensures the improvement of processing efficiency, and the cooperation of each processing station with the positioning mechanism, manipulator 2 and various power sources ensures the processing accuracy. It not only improves the qualified rate of finished products, but also reduces the scrap rate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com