Patents

Literature

210 results about "Cup feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

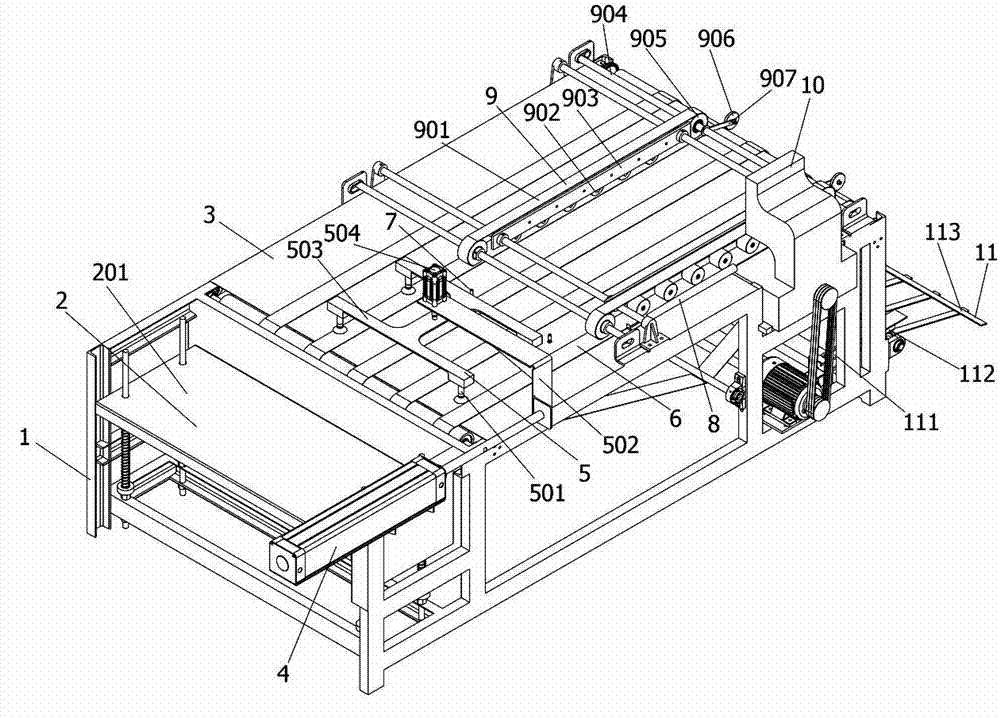

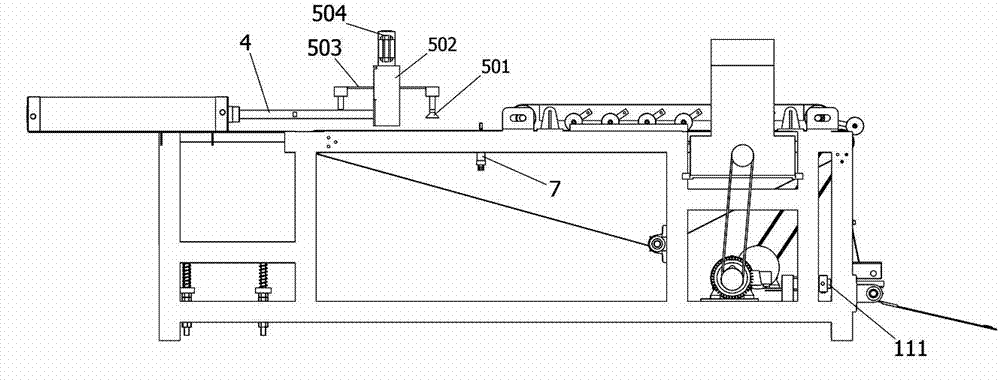

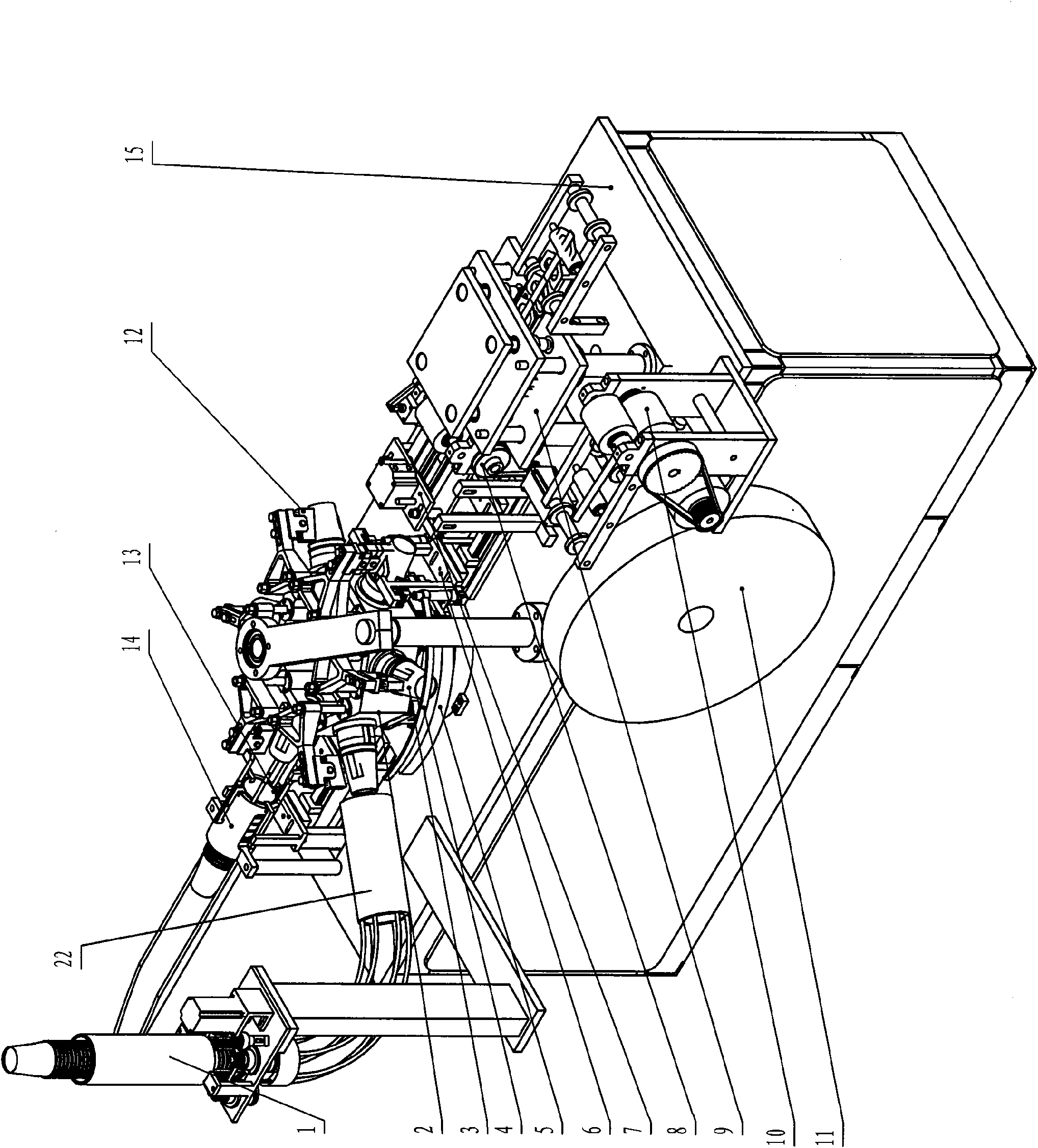

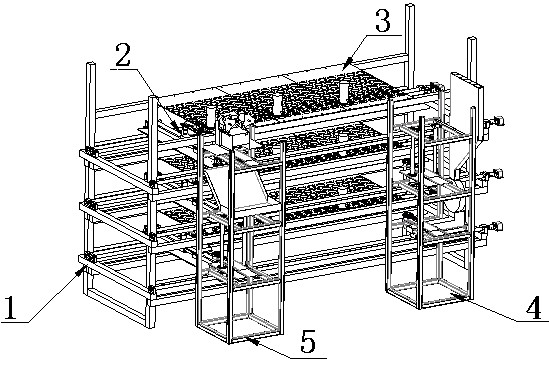

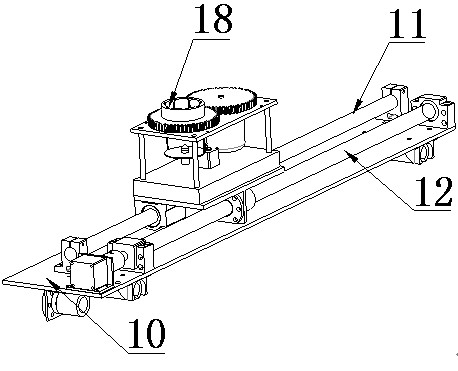

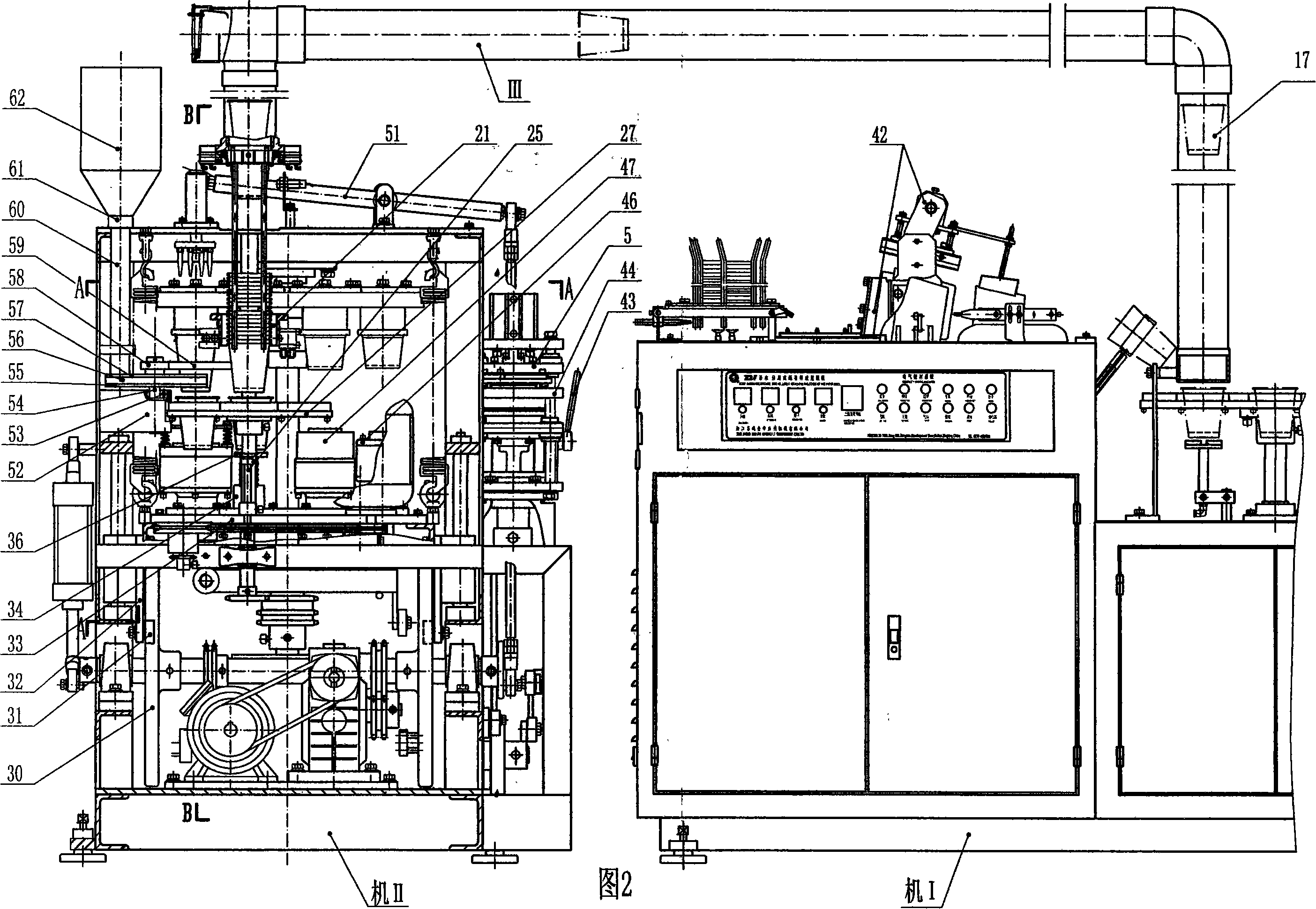

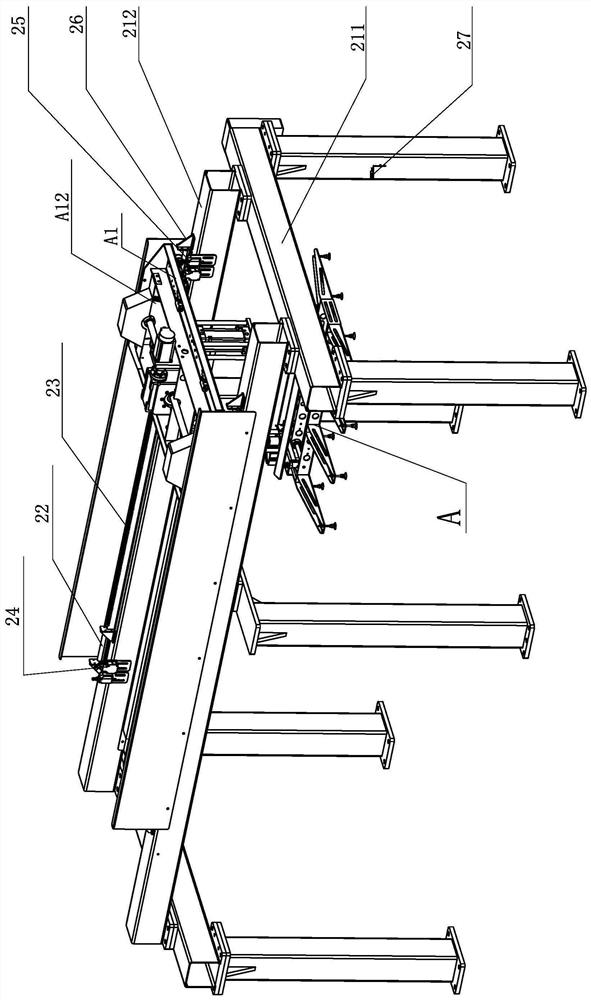

Automatic bag sewing machine

InactiveCN103882629AReduce labor costsShorten the lengthWork-feeding meansWork-collecting devicesReciprocating motionAutomation

The invention discloses an automatic bag sewing machine which comprises a rack assembly, a conveying assembly, a suction cup feeding assembly and a pressing wheel assembly. The rack assembly is located at the feeding end of the conveying assembly, and woven bags to be sewn are placed on the rack assembly. The suction cup feeding assembly is installed above the conveying assembly and the rack assembly and can reciprocate above the conveying assembly and the rack assembly so that the woven bags to be sewn can be moved from the rack assembly onto the conveying assembly. The pressing wheel assembly is installed on the conveying assembly so that the woven bags moving on the conveying assembly can be tightly attached to the conveying assembly to be flattened. A hemmer and a sewing machine body are installed on at least one side of the conveying assembly. The automatic bag sewing machine has the advantages of being simple and compact in structure, high in automation degree, good in consistency of sewn products, capable of reducing the labor cost and the like.

Owner:重庆市巨恒塑料有限公司

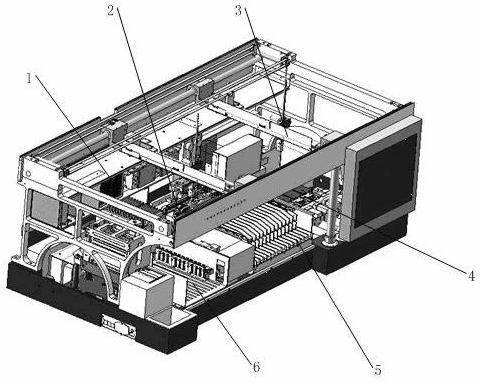

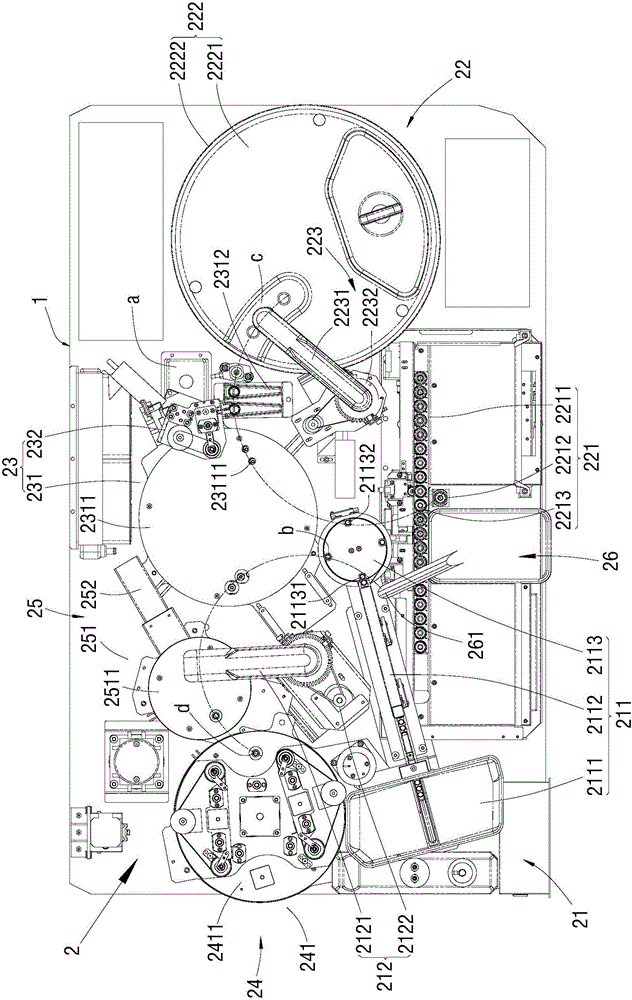

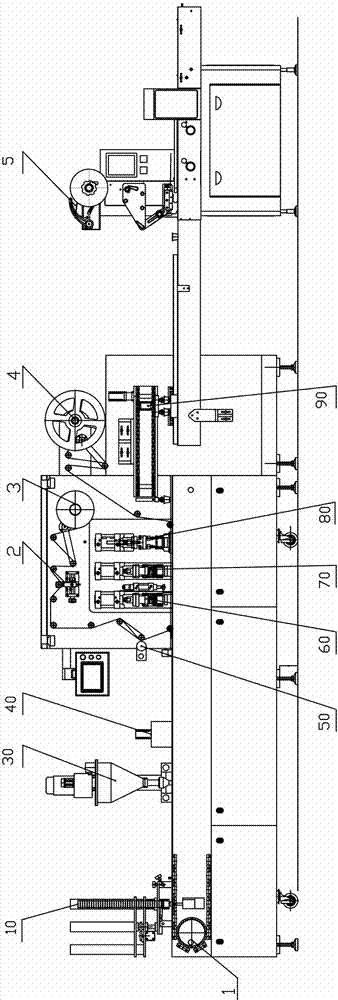

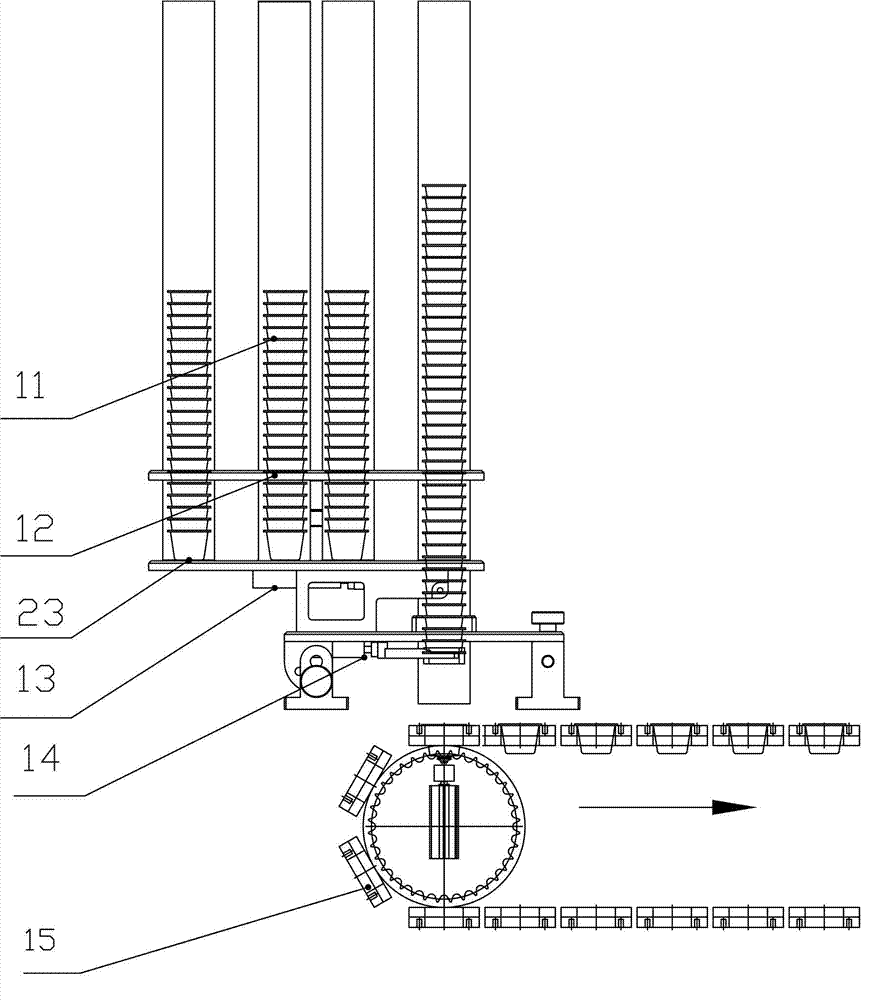

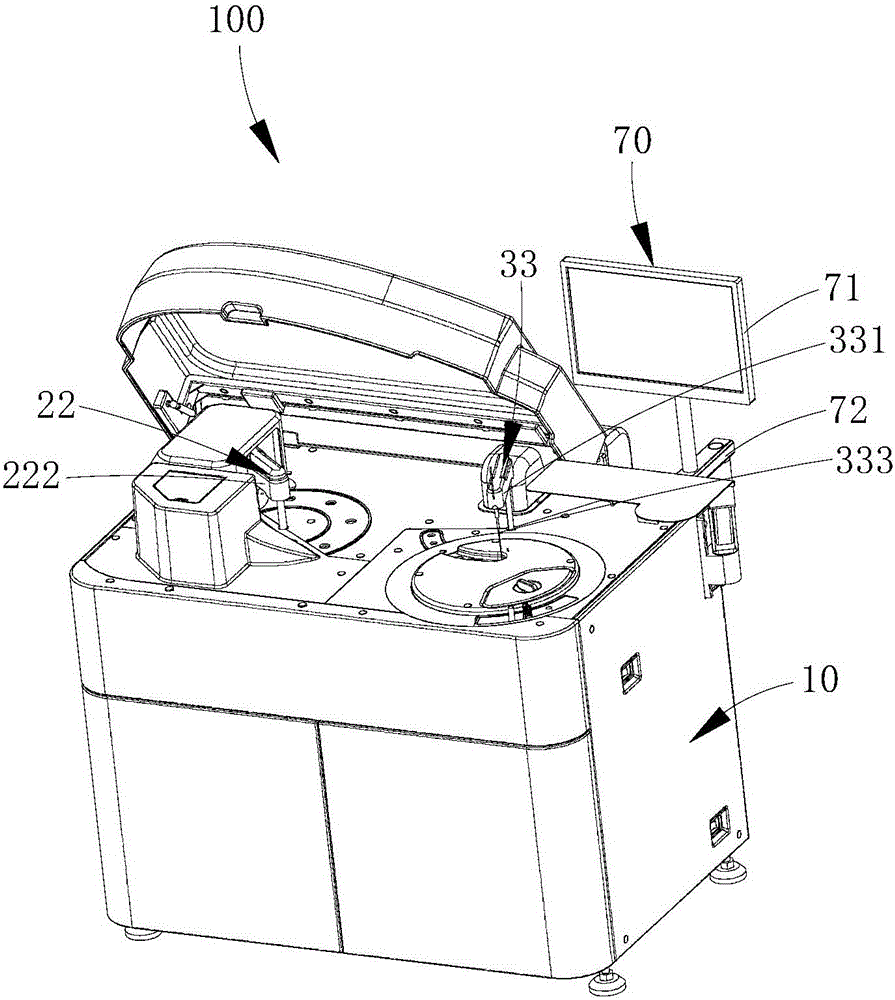

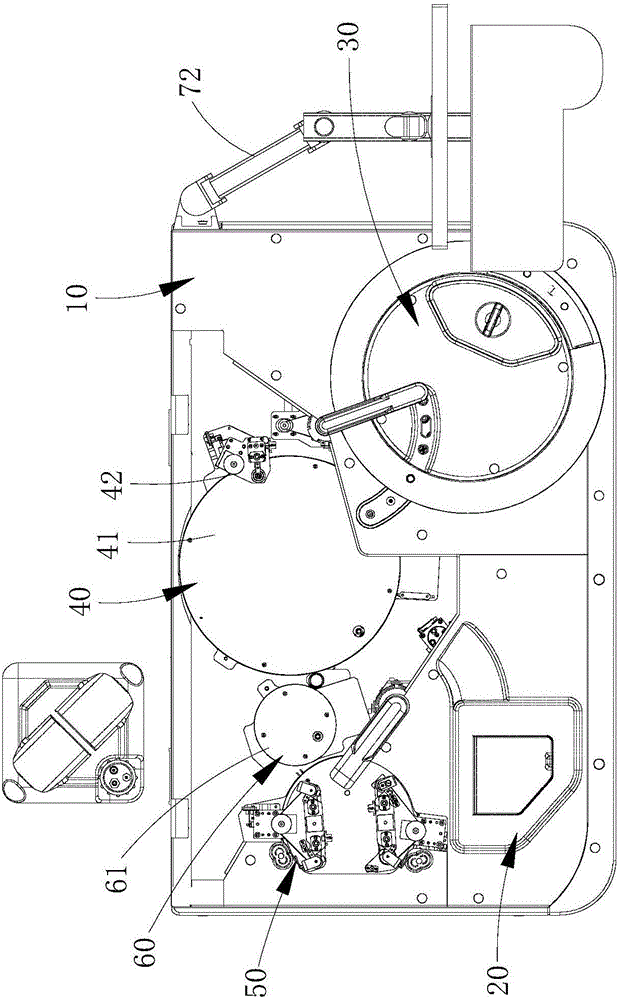

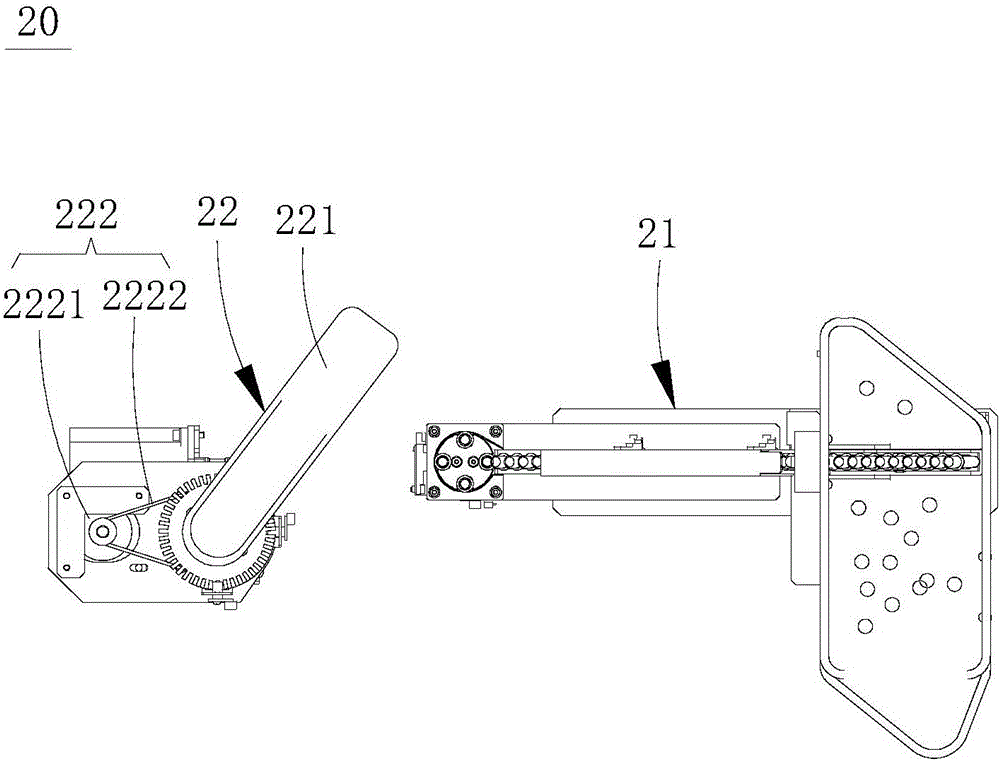

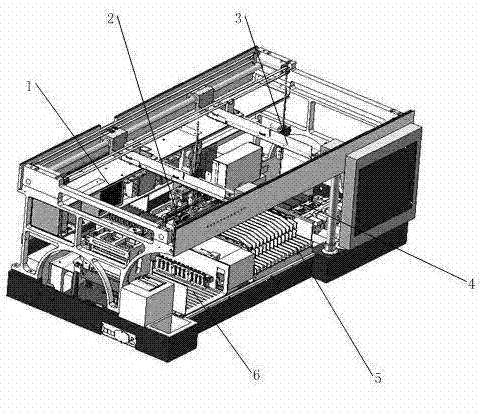

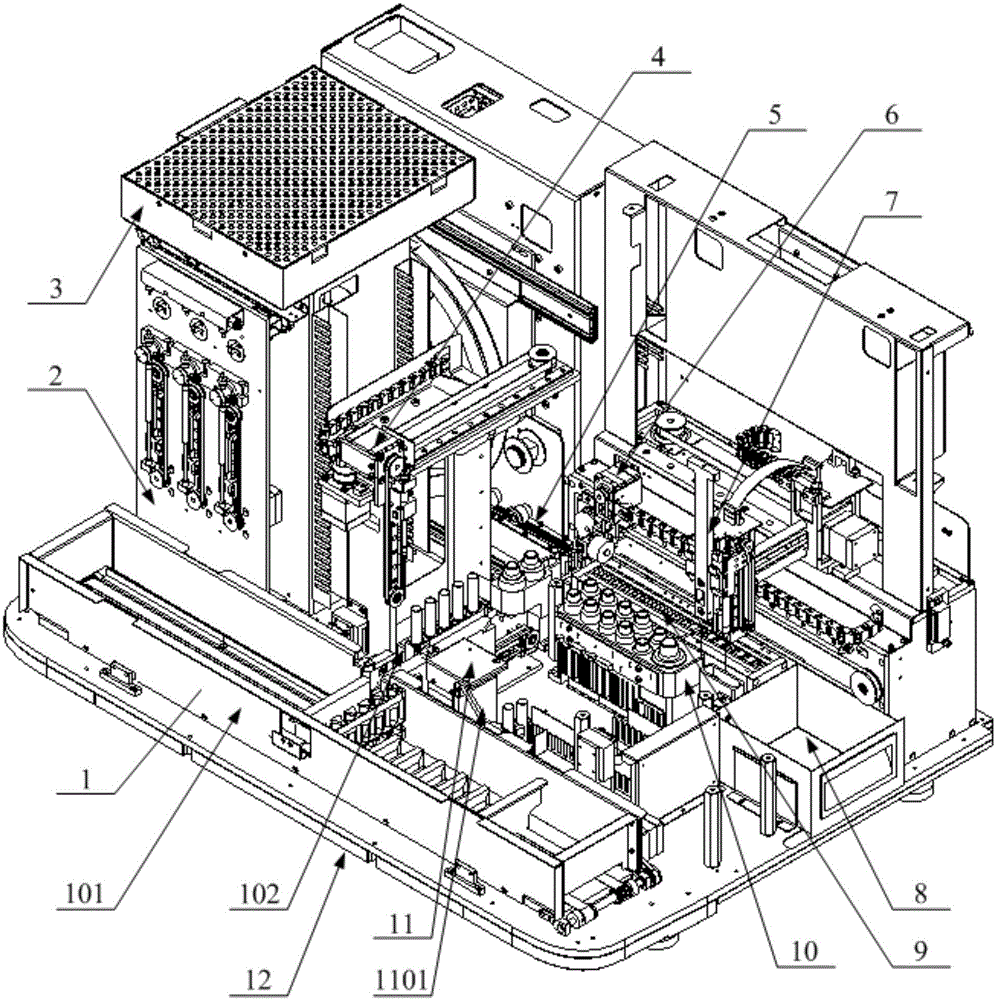

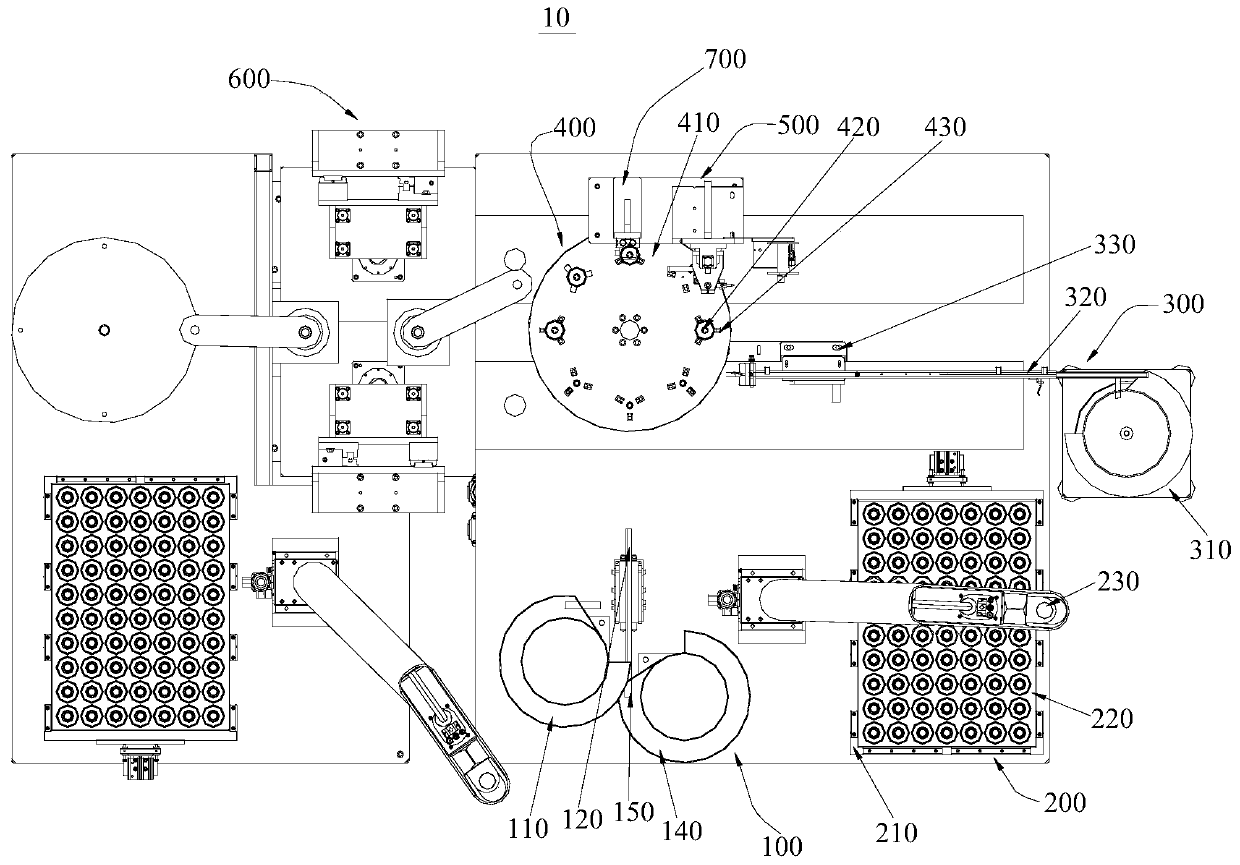

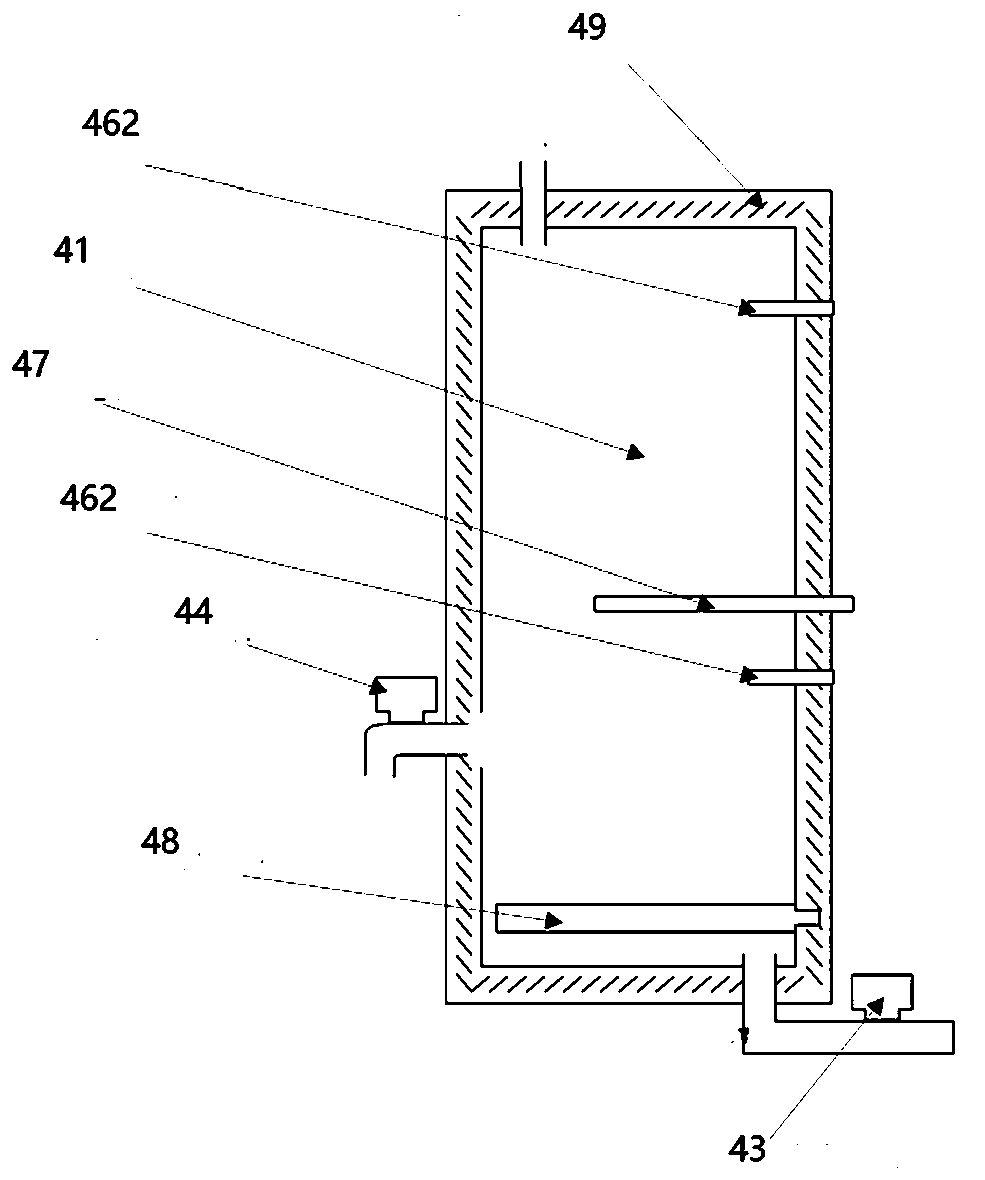

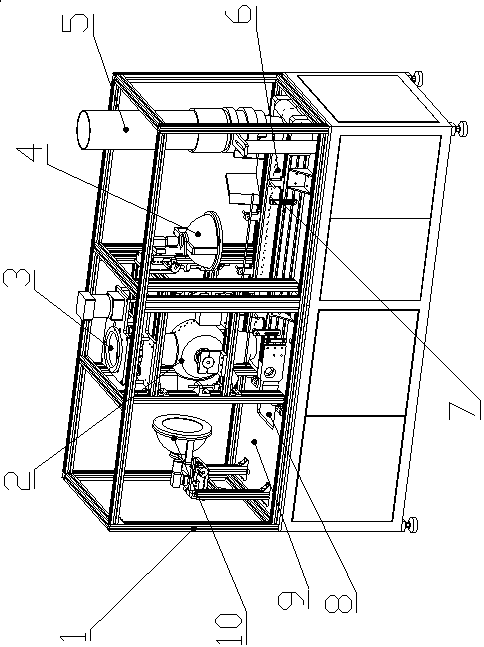

Full-automatic chemiluminescence immunity analyzer

ActiveCN102183639ACompact and reasonable structureHigh degree of automationMaterial analysisTransfer systemControl system

The invention relates to a full-automatic chemiluminescence immunity analyzer, which consists of a reaction cup feeding system, a three-dimensional mobile sample adding module, a sample area, a reagent area, a pump set and a control system. The reaction cup feeding system comprises a stacking module, a transfer module, an incubation module, a washing module and a measuring chamber, wherein the stacking module is positioned at the leftmost end; reaction cup transfer passages of the modules are positioned on the same height; the reaction cup location exit of the incubation module can be alignedwith the transfer groove outlet of the transfer module and the transfer groove inlet of the washing module; the transfer passage exits of the rest modules are aligned; and the three-dimensional mobile sample adding module is positioned above the rest modules. When the system works, a three-dimensional mobile arm automatically distributes sample solution and reagent solution to a reaction cup, thereaction cup sequentially passes through the modules of the transfer system, and operations of incubation, washing, detection and the like are completed. The analyzer has compact and reasonable structure, high automation degree and quick and accurate detection, and is suitable to be used in various hospitals.

Owner:HARBIN INST OF TECH AT WEIHAI

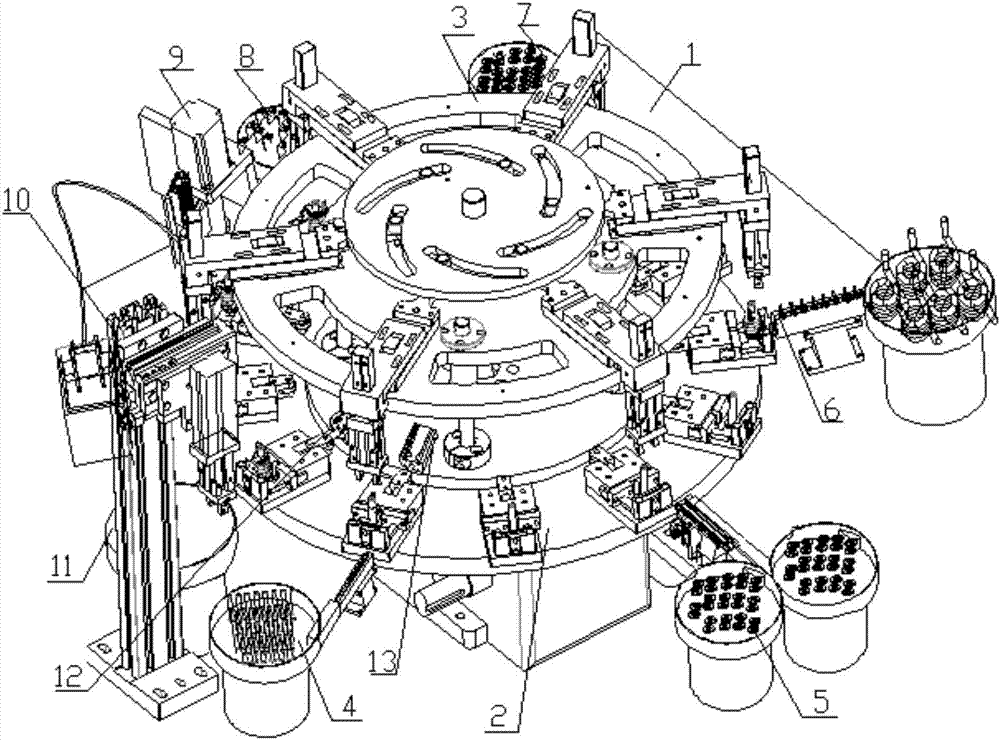

LED (Light-Emitting Diode) lamp assembling equipment

InactiveCN103707049AImprove assembly efficiencyEasy to operate manuallyAssembly machinesMetal working apparatusInductorCopper

The invention discloses LED (Light-Emitting Diode) lamp assembling equipment which comprises an eight-station intermittent-type rotating disc, wherein a constant current power supply, a plastic lamp cup feeding device, a copper screw feeding device, a copper screw tightening device, a power line winding pressing device, a nut cap feeding device, a nut cap on-site detection device, a qualified plastic lamp cup assembly withdrawing device and a disqualified assembly withdrawing device are sequentially arranged around the eight-station intermittent-type rotating disc according to successive procedures; the constant current power supply and the plastic lamp cup feeding device mainly comprise the constant current power supply and the human hand assembly station, conveying belt and mechanical hand of a plastic lamp cup; the lateral side of the intermittent-type conveying belt is sequentially provided with an LED assembly assembling and feeding device, an LED lamp assembly and the human hand assembly station, screw screwing device and human hand welding station of a plastic lamp cup assembly along the moving direction of the intermittent-type conveying belt. The LED lamp assembling equipment disclosed by the invention realizes the automatic assembly by controlling machines and mechanisms through various inductors and electric elements, thereby increasing the assembling efficiency and simplifying the manual operation.

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

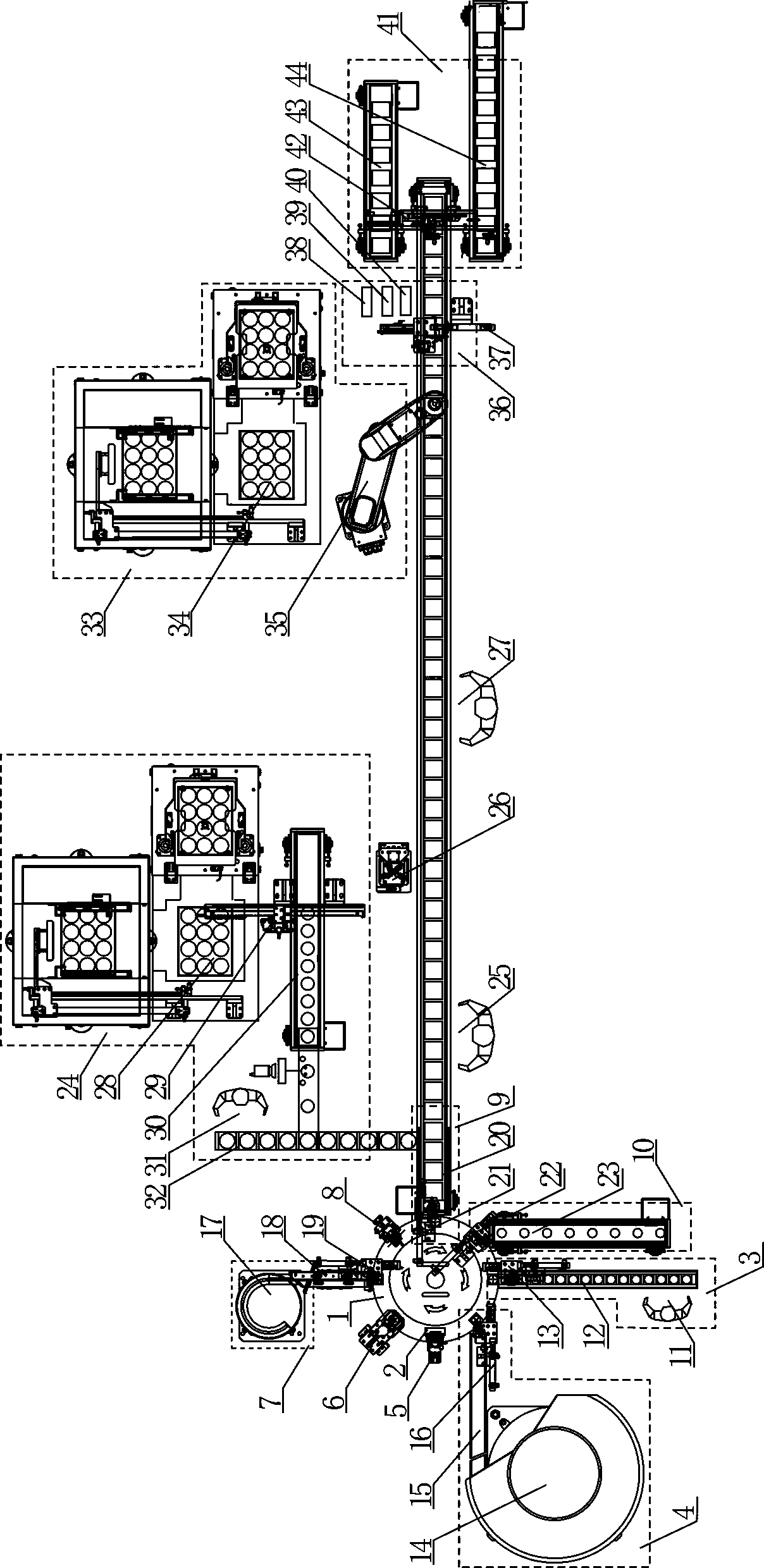

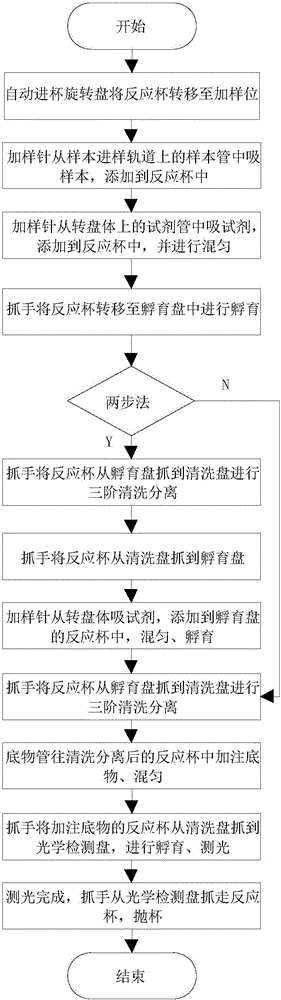

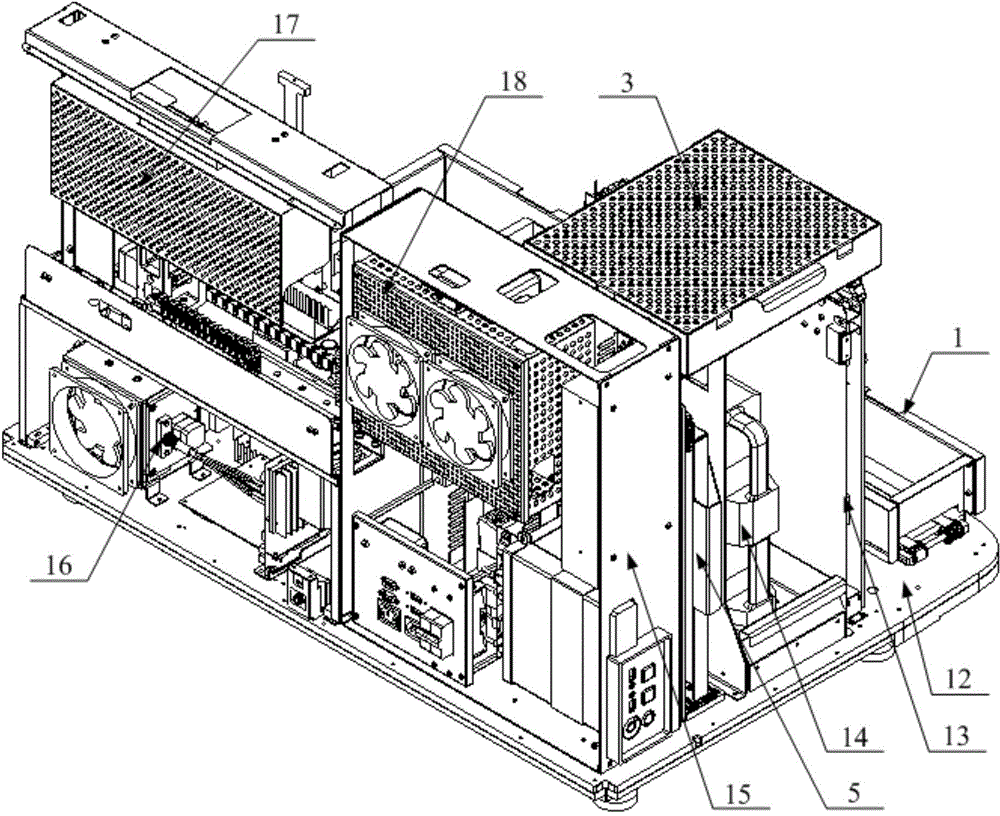

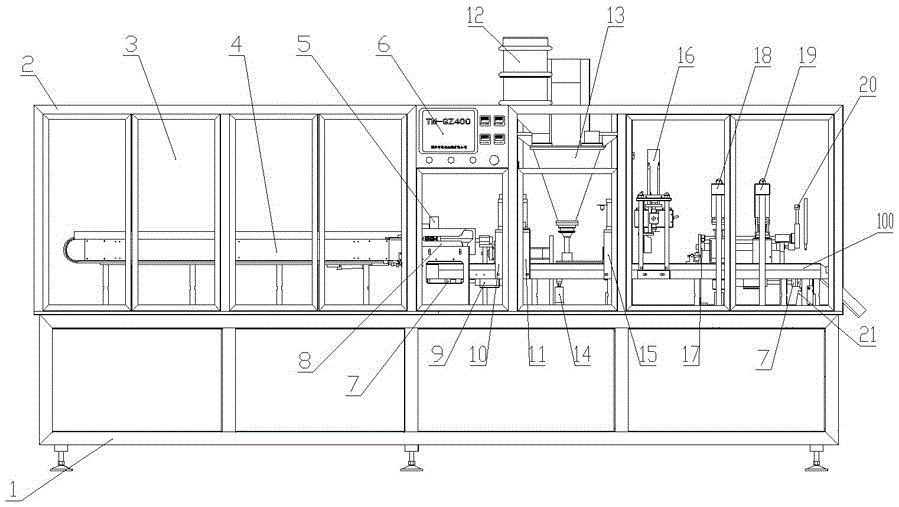

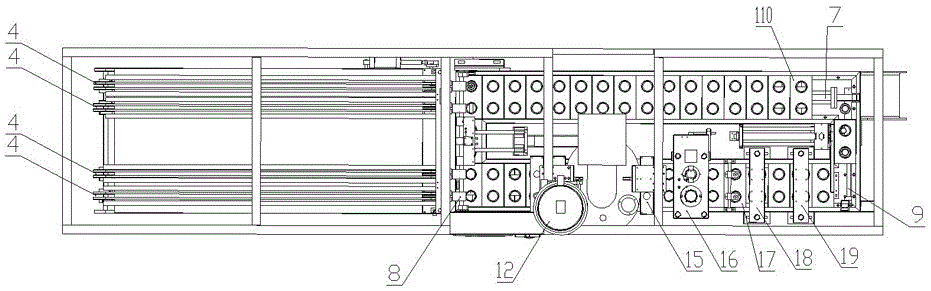

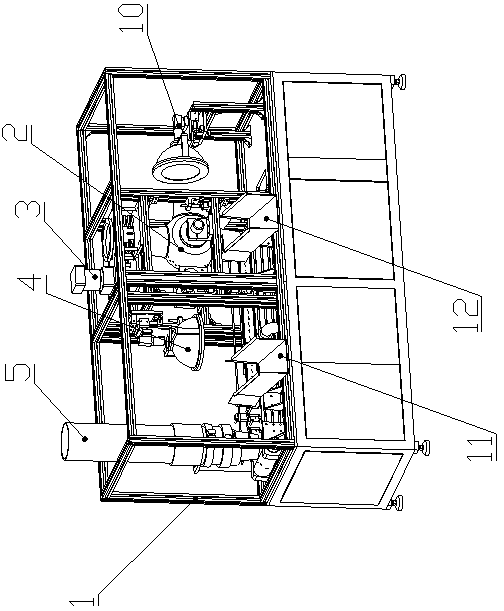

Full-automatic chemiluminescence immunity analyzer

ActiveCN106199026AAvoid individual differencesAvoid manual errorMaterial analysisBiochemical engineeringTransfer system

The invention relates to the technical field of automatic biochemical analysis equipment and discloses a full-automatic chemiluminescence immunity analyzer. The full-automatic chemiluminescence immunity analyzer comprises a rack, an analysis part and a control part, wherein the analysis part comprises a transferring system, a sampling system, an incubating system, a cleaning system and an optical detection system; the transferring system comprises an automatic cup feeding mechanism and a grabbing mechanism; the sampling system comprises a sample dispatching mechanism, a reagent disc mechanism and a sample adding mechanism; the incubating system comprises an incubating disc mechanism and a mixing mechanism; the cleaning system comprises a cleaning disc mechanism; the optical detection system comprises a light-detecting disc mechanism and a lighting mechanism. The full-automatic chemiluminescence immunity analyzer disclosed by the invention has the advantages that the control part controls the transferring system, the sampling system, the incubating system, the cleaning system and the optical detection system to work automatically, so that automation in the whole process of analysis operation is achieved, the uncertain problems such as individual difference, artificial errors, irregular operation and the like in manual operation are avoided, and the accuracy of chemiluminescence immunity analysis is improved.

Owner:深圳雷杜生命科学股份有限公司

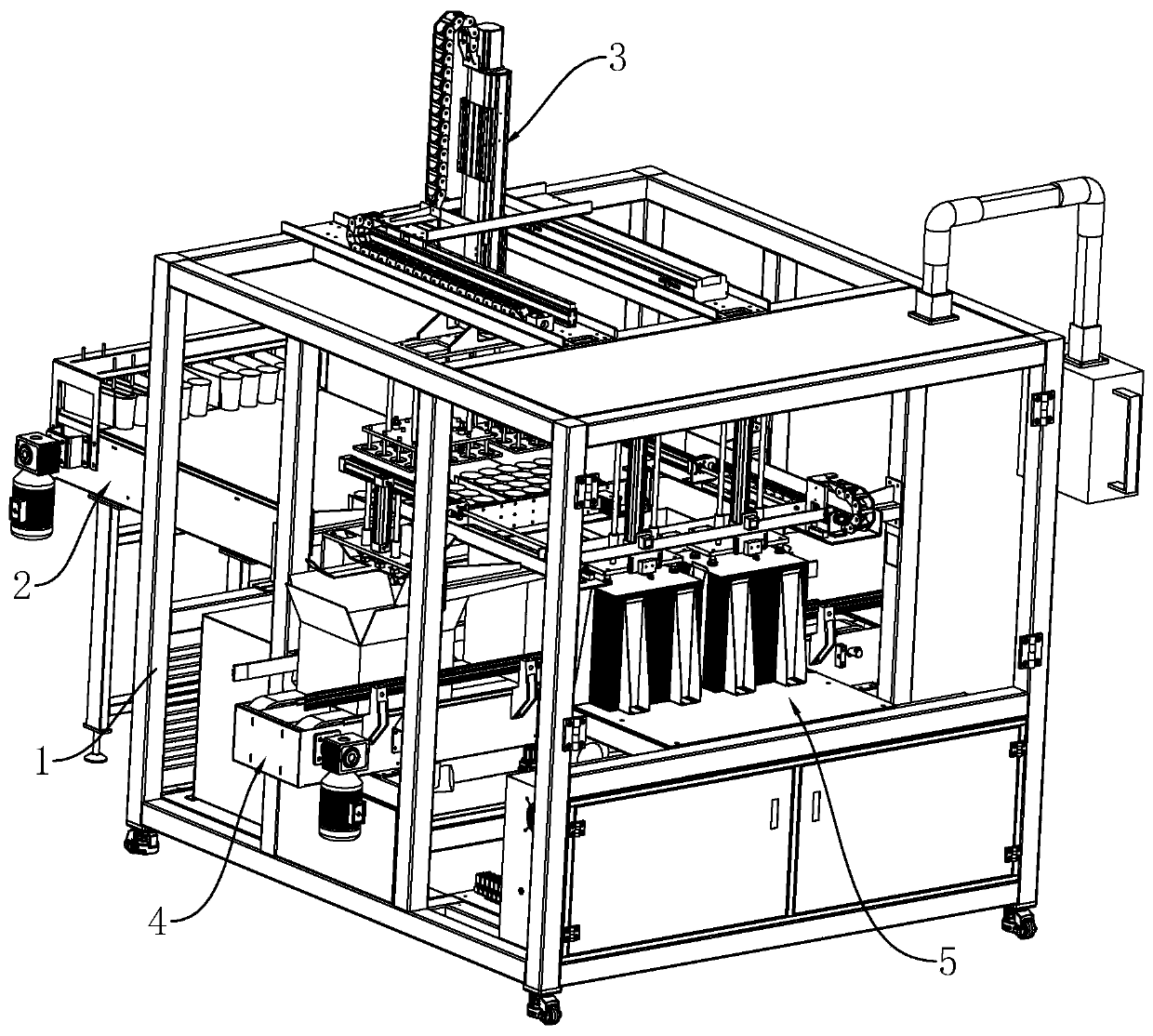

Full-automatic coffee capsule packing machine

The invention relates to a full--automatic coffee capsule packing machine which comprises a cup dropping system, a material feeding system, a sealing membrane heat sealing mechanism, a sealing membrane punching mechanism, a mechanical arm automatic conveying and fetching system and an automatic packing mechanism. Due to the fact that the automatic cup dropping system is used for dropping material cups to a cup feeding plate according to timing sequence, working efficiency is greatly improved, besides, the phenomenon of the material cups stacking or lacking is not generated; due to the fact that the material cups filled with coffee are conveyed to the automatic packing mechanism by adopting the mechanical arm automatic conveying and fetching system, and the conveying and fetching system conveys the material cups by adopting a roundtrip chain and a cup pushing cylinder according to timing sequence, working efficiency is high, and the phenomenon of the material cups stacking is not generated.

Owner:江苏神翌机械有限公司

Full-automatic chemiluminescence immunity analyzer

ActiveCN106199025AAvoid individual differencesAvoid manual errorMaterial analysisControl systemTransfer system

A full-automatic chemiluminescence immunity analyzer comprises a frame, a transferring system, a sampling system, an incubation system, a cleaning system, an optical detection system and a control system. The transferring system comprises a cup feeding mechanism, a cup inlet and a grasping mechanism; the sampling system comprises a sample tray, a reagent tray, a sample adding mechanism and two first driving sources; the incubation system comprises an incubation tray, a second driving source and a mixing mechanism; the cleaning system comprises a cleaning plate and a third driving source; the optical detection system comprises photometric plate and an optical collection mechanism. When sample analysis is required, the full-automatic chemiluminescence immunity analyzer is started and controlled to operate by the control system, and then the transferring system, the sampling system, the incubation system, the cleaning system and the optical detection system operate correspondingly, so that all operations are automatic operations. The full-automatic chemiluminescence immunity analyzer has advantages that probabilistic problems including individual differences, manual errors, operational nonuniformity and the like of manual operations are avoided effectively, and accuracy in chemiluminescence immunity analysis is improved.

Owner:深圳雷杜生命科学股份有限公司

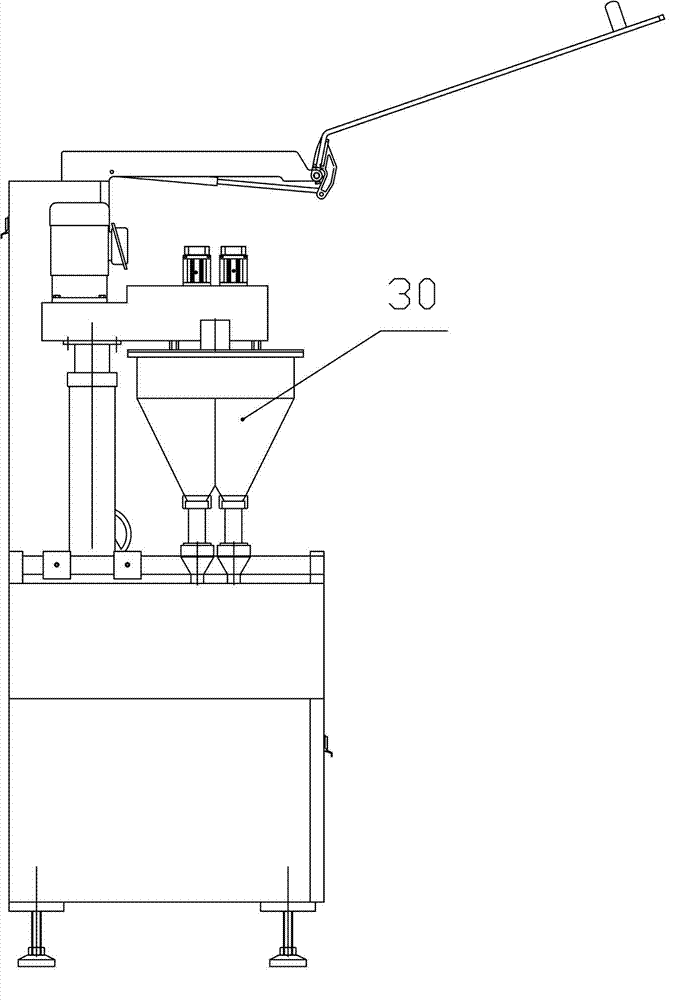

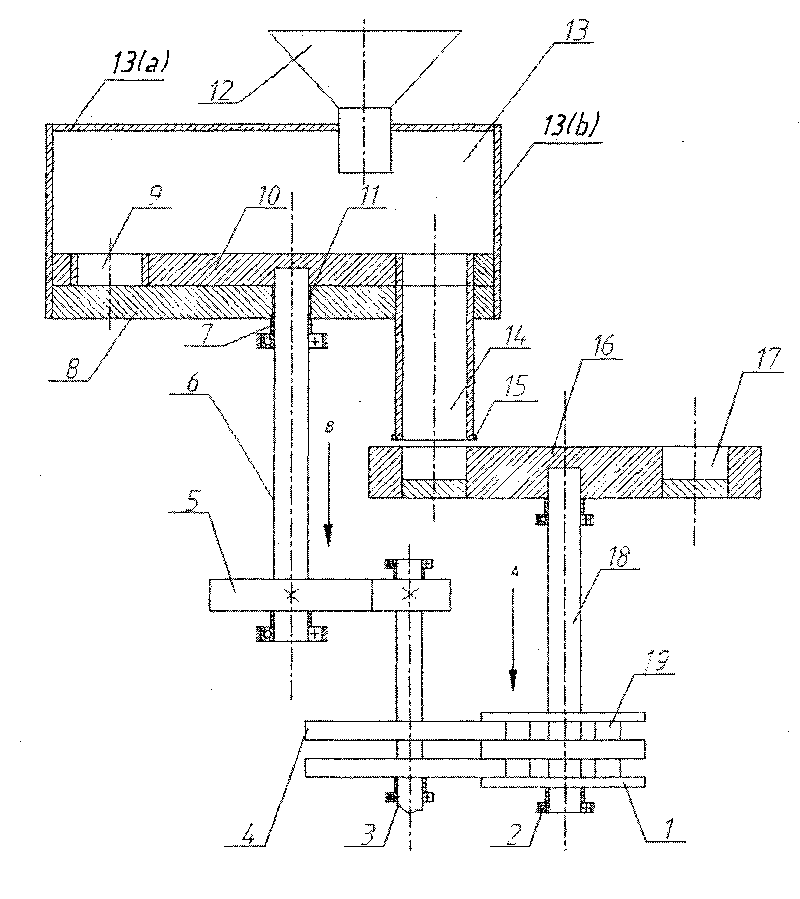

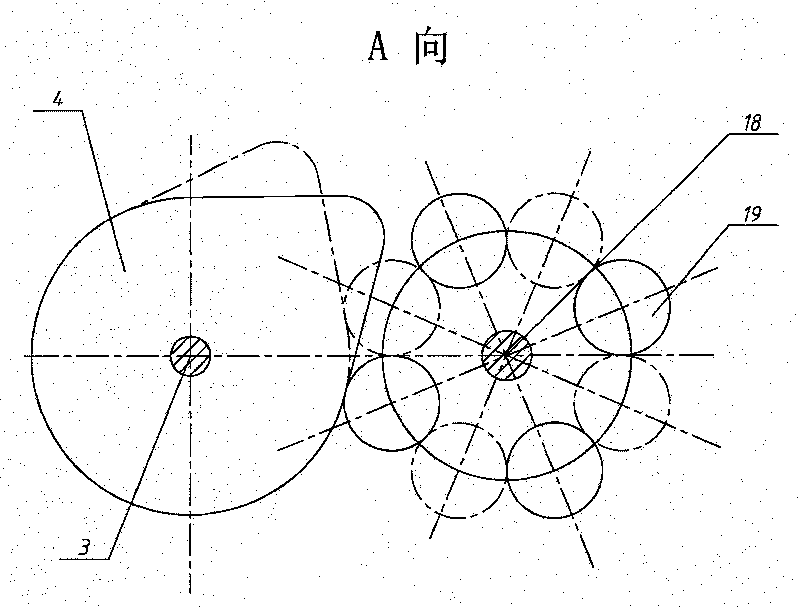

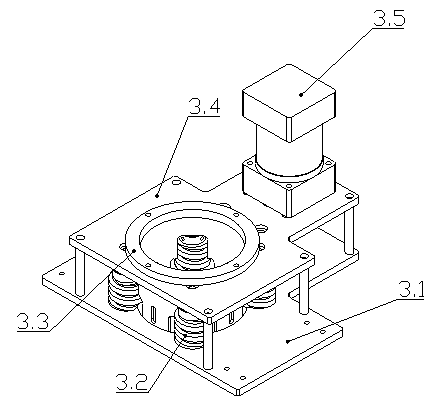

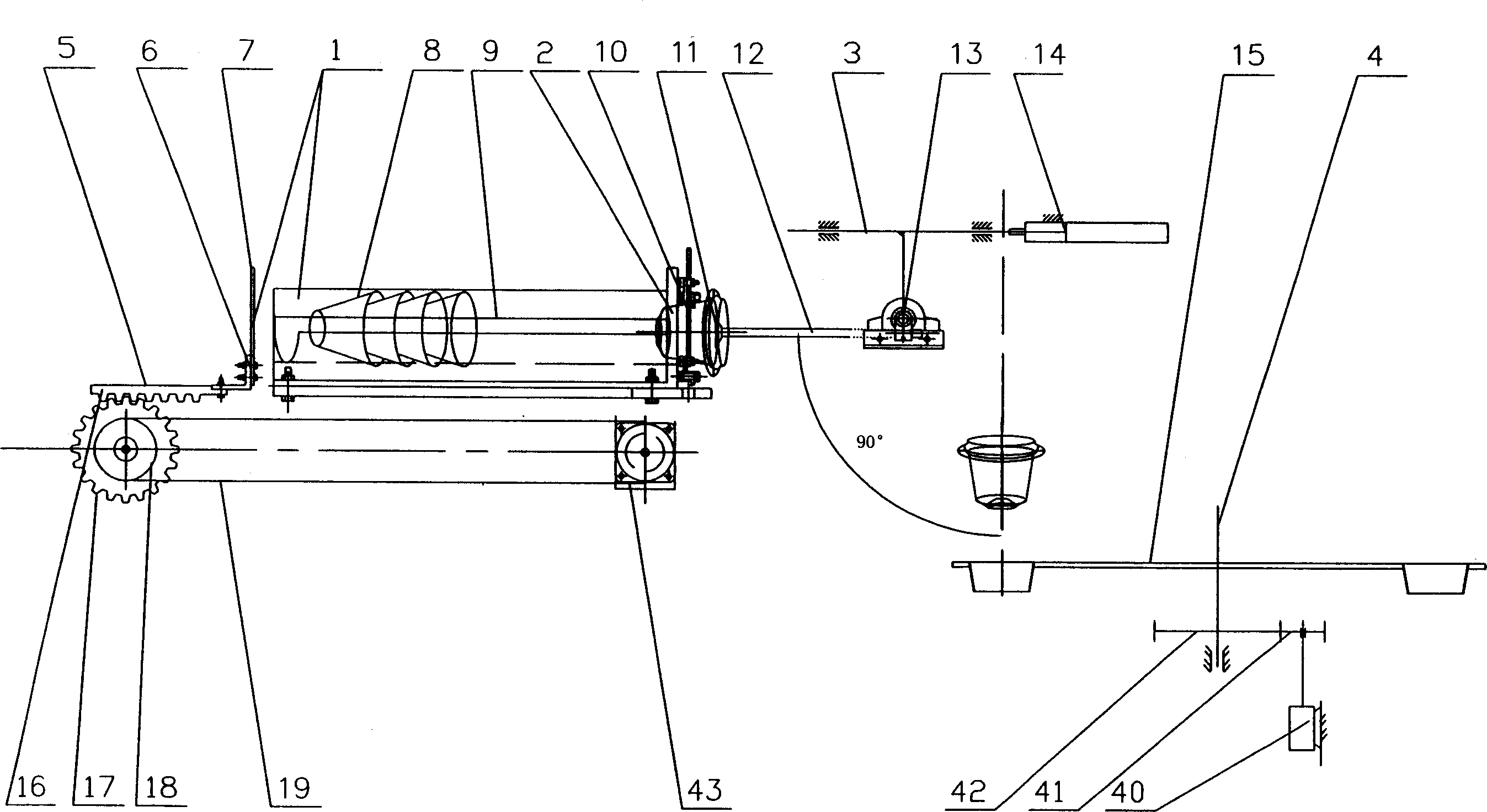

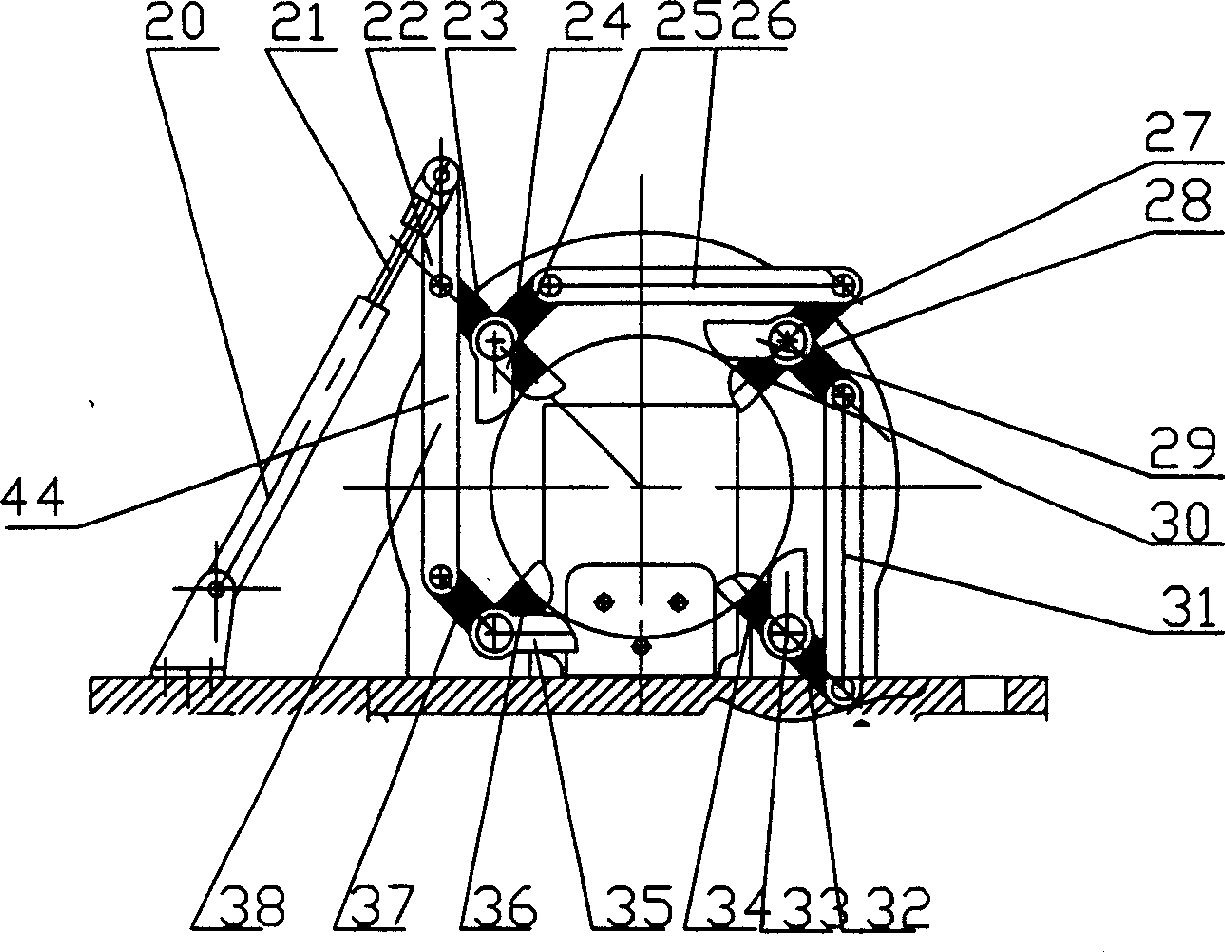

Intermittent particulate material feeding device

InactiveCN101691073AGuarantee product qualityVolume accuracy guaranteePressesParticulatesDrive wheel

The invention relates to an intermittent particulate material feeding device, which comprises a turntable containing cup feeding mechanism, an incomplete gear, a parallel indexing cam, a rotary working platform, a connecting shaft and the like. The intermittent particulate material feeding device is characterized in that the incomplete gear is fixedly connected with a driving wheel of the parallel indexing cam by the same shaft (a driving shaft), a driven wheel of the incomplete gear is fixedly connected with an upper turntable of the turntable containing cup feeding mechanism by the same shaft, and a driven wheel of the parallel indexing cam is fixedly connected with the rotary working platform by the same shaft so that a machine can make the turntable containing cup feeding mechanism and the rotary working platform achieve synchronous intermittent rotation in the running process. When the intermittent particulate material feeding device works, materials fall into a material containing chamber from a hopper; the upper turntable dials the materials into a containing cup by a scratch board and scratches overflow parts in the rotating process; and when the containing cup filled with the materials rotates to a discharging station along with the upper turntable, the particulate materials fall down along a sliding cylinder to finish the feeding process. The intermittent particulate material feeding device has a simple structure, a low price and high production efficiency, can ensure the volume of the used particulate materials, and can automatically feed a rotary intermittent four-station powder pressure forming machine.

Owner:王萍

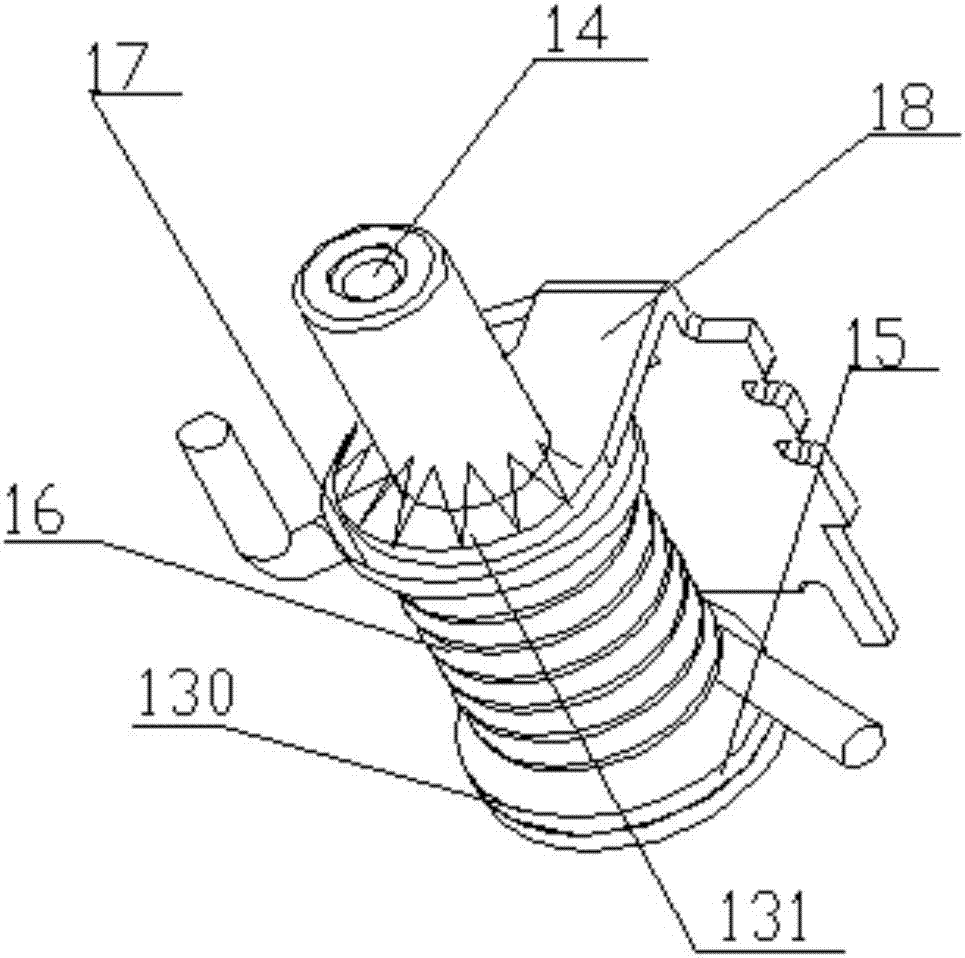

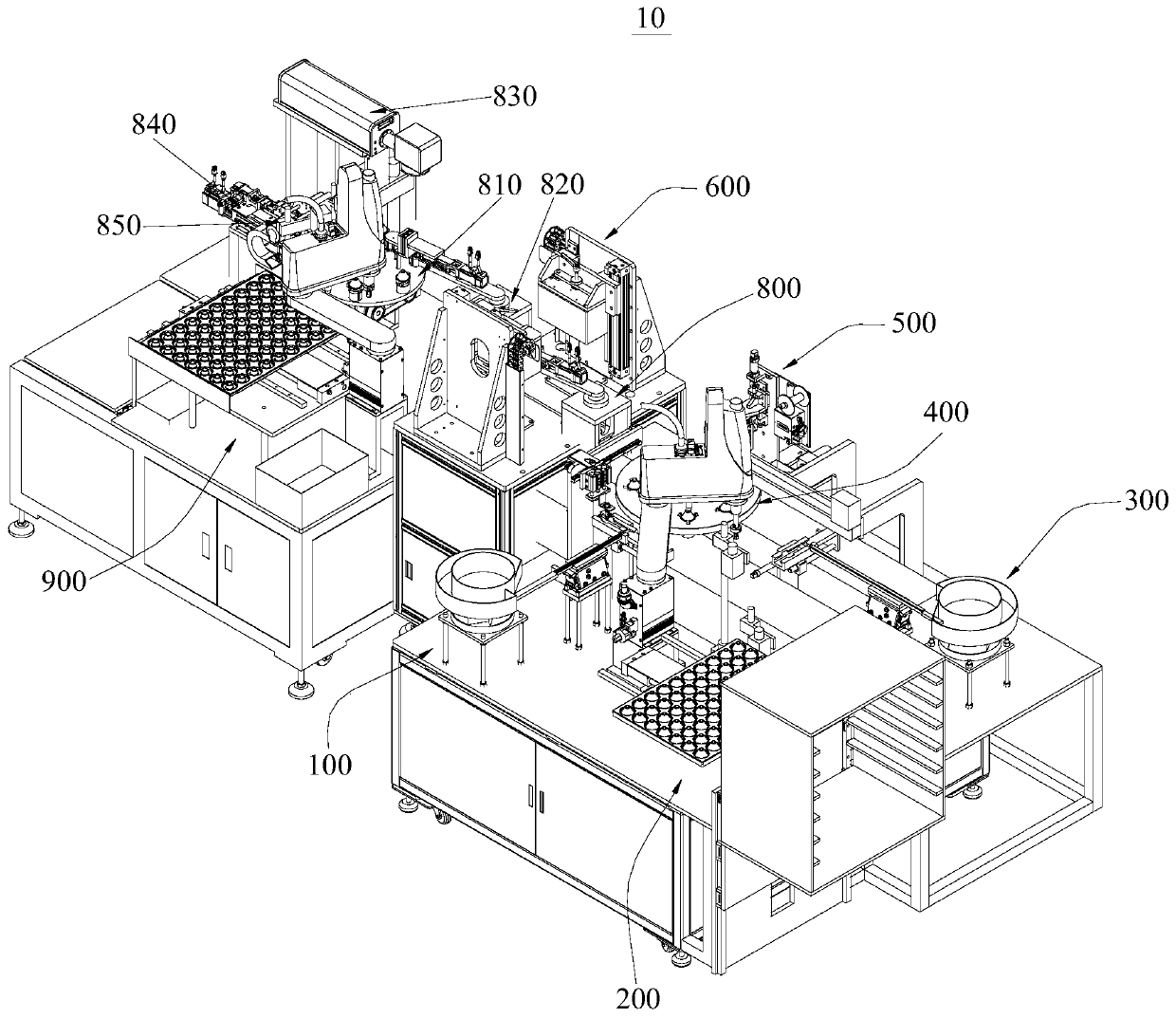

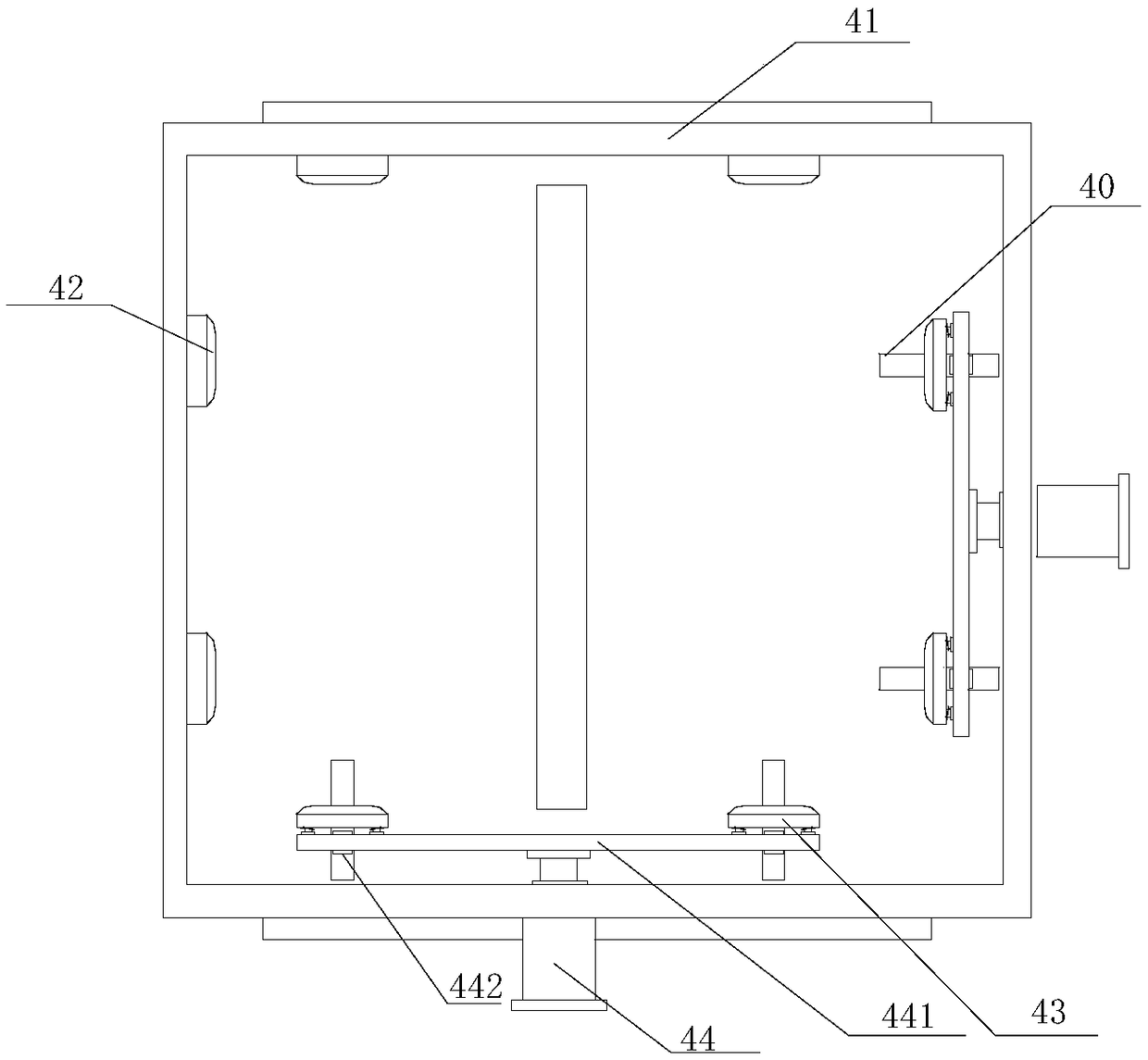

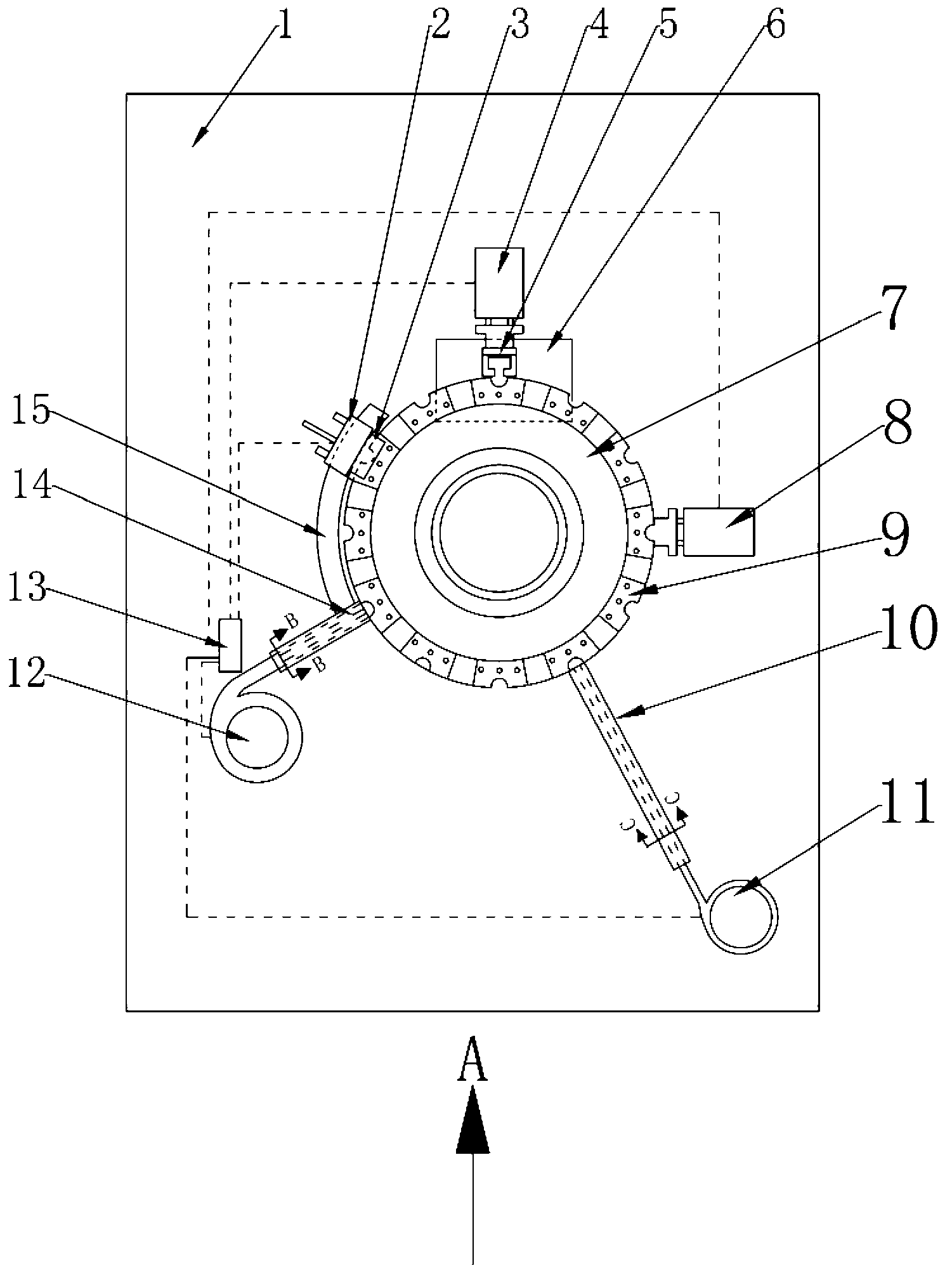

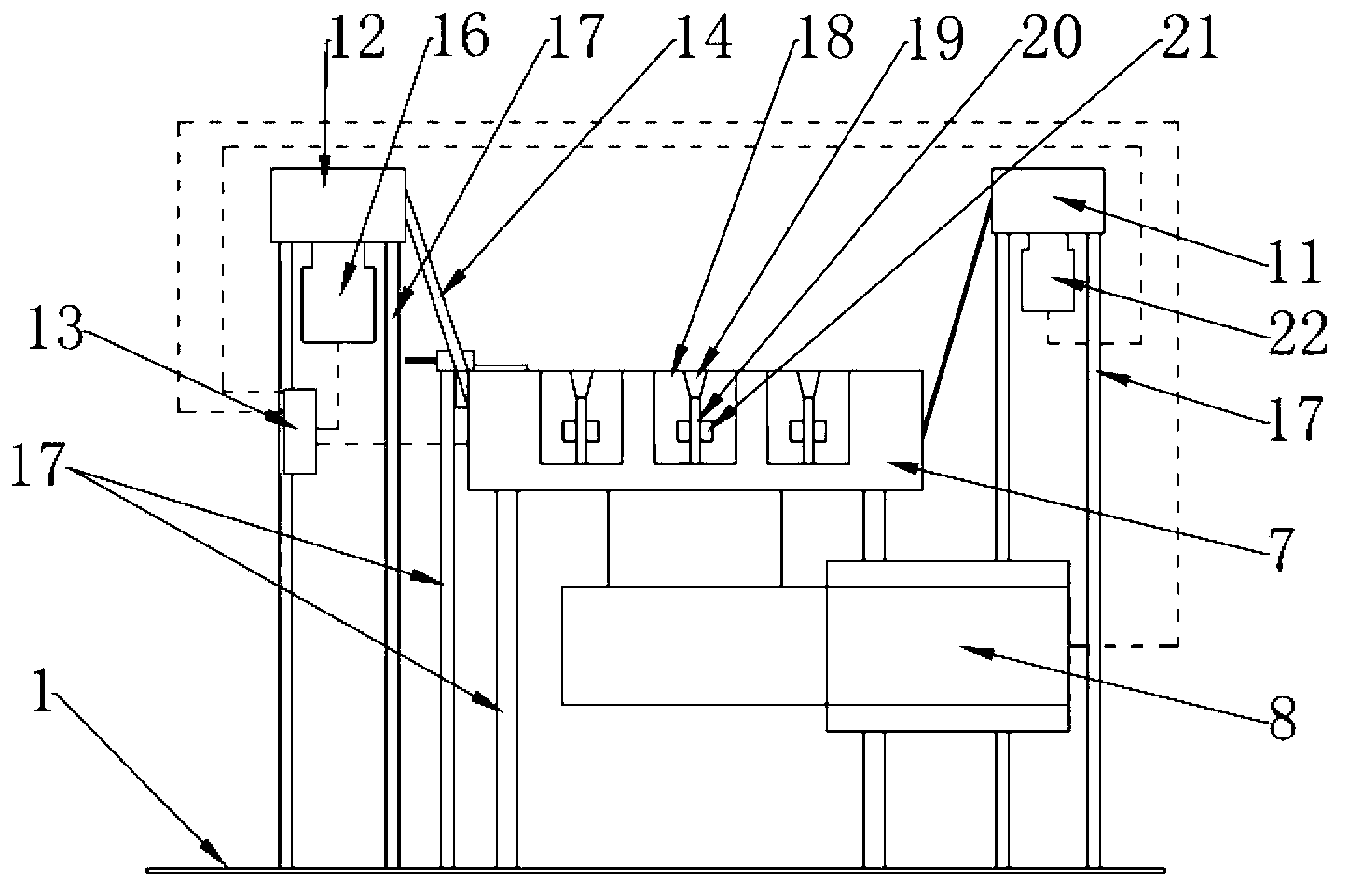

Automatic welding system for coil conductive assembly of circuit breaker

ActiveCN107234313AEliminate positioningEliminate misalignmentMetal working apparatusSoldering auxillary devicesEngineeringManipulator

Owner:YUEQING YEDAO ELECTROMECHANICAL CO LTD

Full-automatic chemiluminescence immunity analyzer

ActiveCN102183639BCompact and reasonable structureHigh degree of automationMaterial analysisTransfer systemControl system

The invention relates to a full-automatic chemiluminescence immunity analyzer, which consists of a reaction cup feeding system, a three-dimensional mobile sample adding module, a sample area, a reagent area, a pump set and a control system. The reaction cup feeding system comprises a stacking module, a transfer module, an incubation module, a washing module and a measuring chamber, wherein the stacking module is positioned at the leftmost end; reaction cup transfer passages of the modules are positioned on the same height; the reaction cup location exit of the incubation module can be alignedwith the transfer groove outlet of the transfer module and the transfer groove inlet of the washing module; the transfer passage exits of the rest modules are aligned; and the three-dimensional mobile sample adding module is positioned above the rest modules. When the system works, a three-dimensional mobile arm automatically distributes sample solution and reagent solution to a reaction cup, thereaction cup sequentially passes through the modules of the transfer system, and operations of incubation, washing, detection and the like are completed. The analyzer has compact and reasonable structure, high automation degree and quick and accurate detection, and is suitable to be used in various hospitals.

Owner:HARBIN INST OF TECH AT WEIHAI

Automatic sample analyzer

ActiveCN105785056AImplement emergency queue jumpingMeeting emergency needsMaterial analysisEmergency treatmentPhysics

The invention discloses an automatic sample analyzer. The automatic sample analyzer comprise a sample injection module for delivering a sample tube, a cup feeding module for delivering a reaction cup, a sample feeding module, which takes a sample from the sample tube and adding the sample into the reaction cup, and an emergency treatment module, which delivers a sample that needs an emergency treatment to a position that is under the sample adding needle of a sample adding module; wherein the emergency treatment module comprises a base, a rotary arm, which is rotatably arranged on the base, and a driving part, which drives the rotary arm to rotate; and the rotary arm is provided with an accommodation groove for accommodating a tube containing a sample which needs an emergency treatment. The provided automatic sample analyzer comprises an emergency treatment module, which can deliver a tube containing a sample that needs an emergency treatment to a position that is under the sample adding needle of a sample adding module, the sample can be sampled and examined, the diagnosis can be carried out, and the needs of emergency treatment are satisfied.

Owner:MACCURA MEDICAL INSTR CO LTD

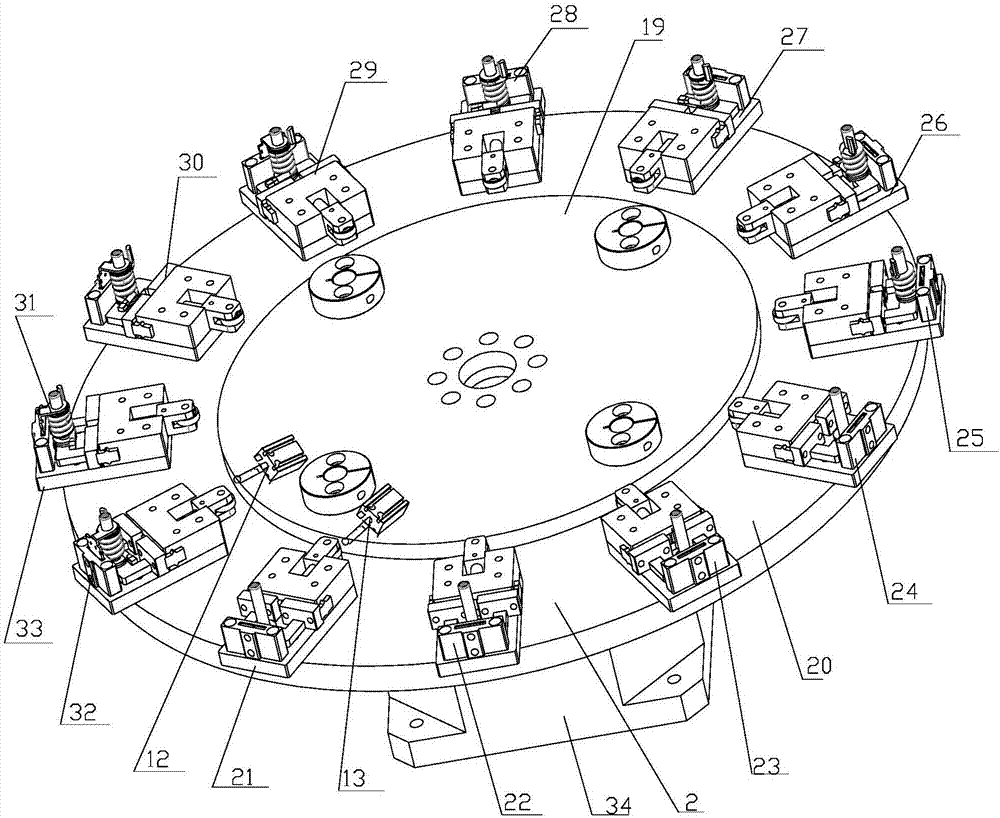

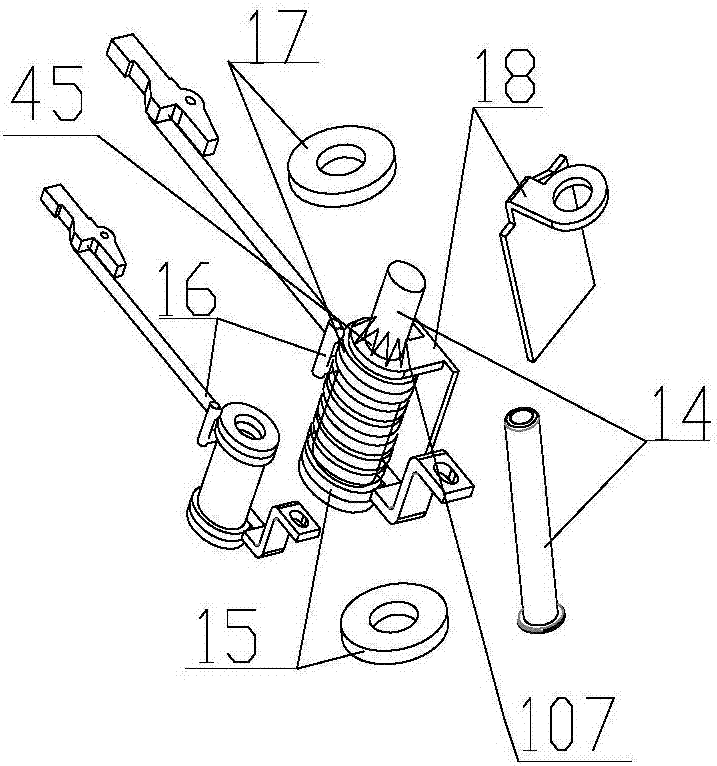

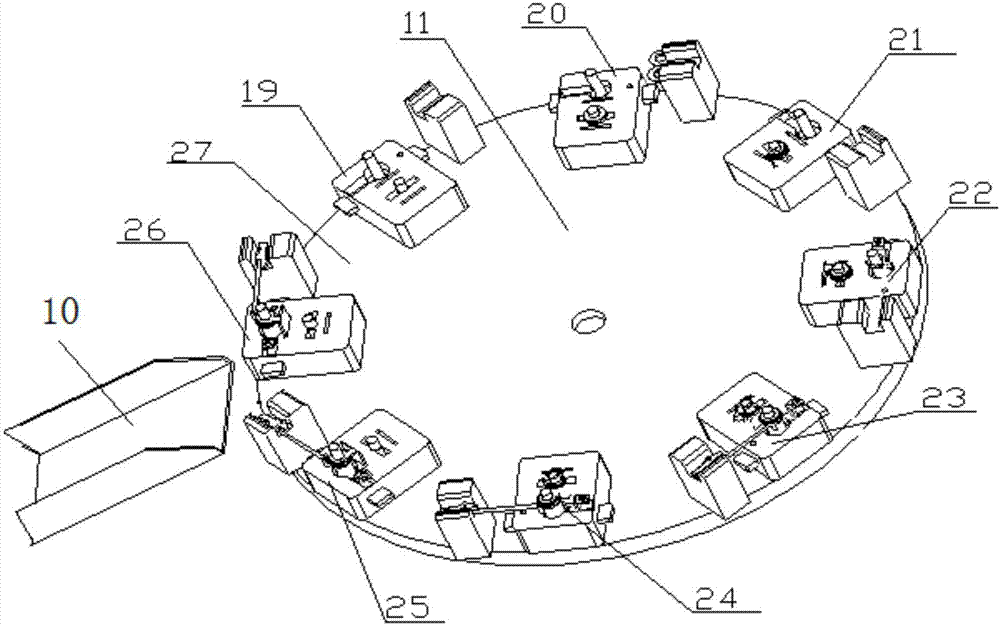

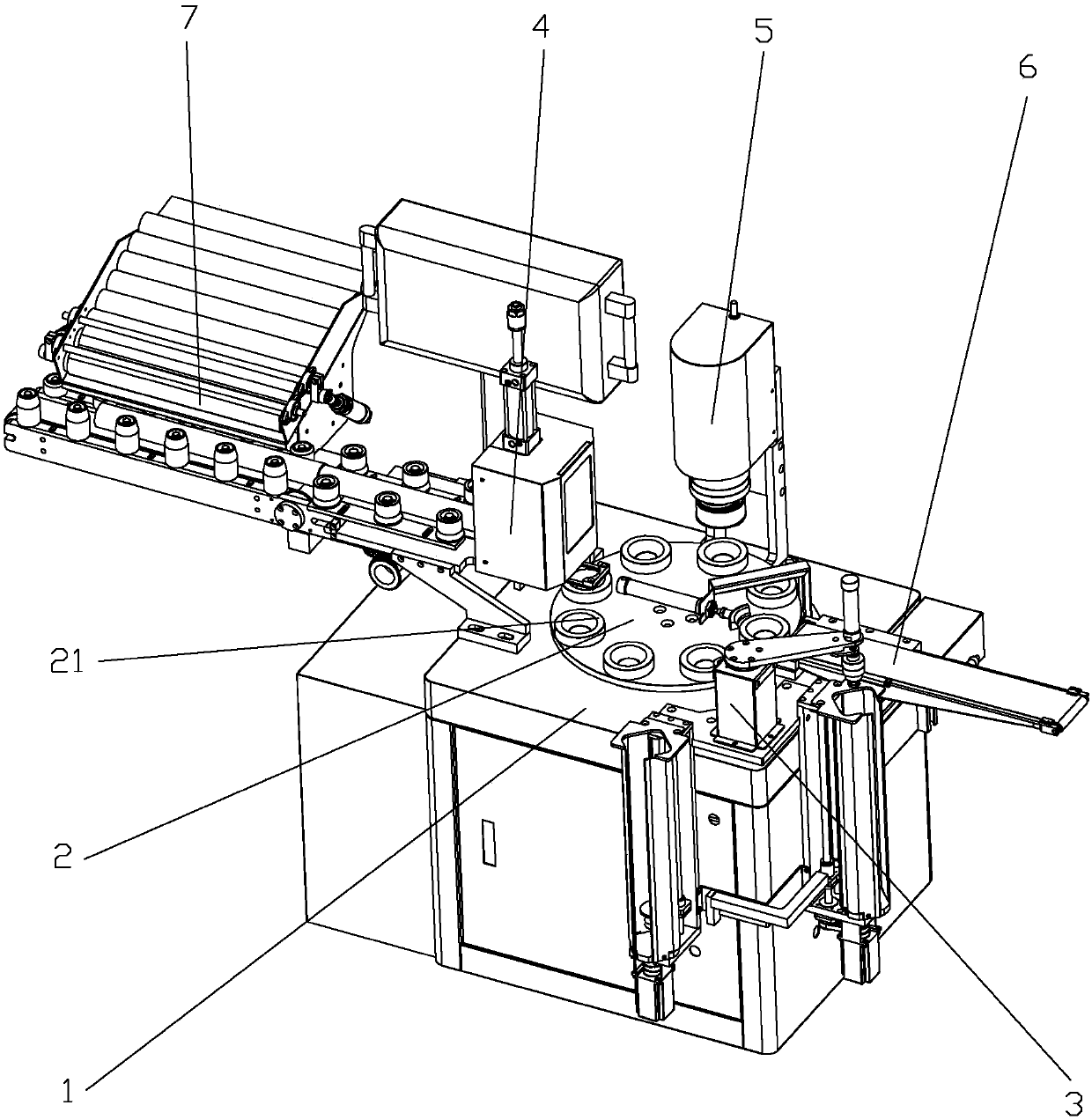

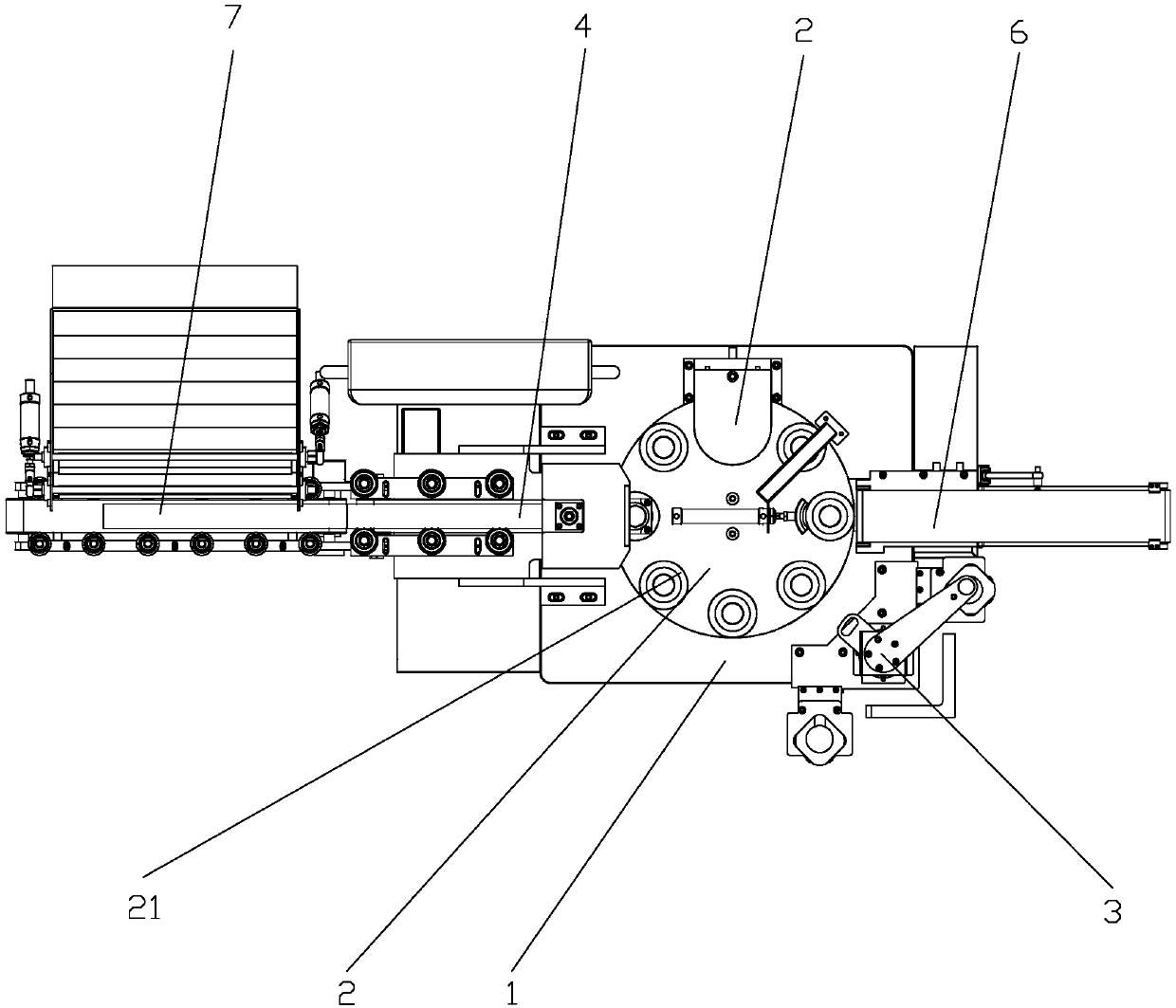

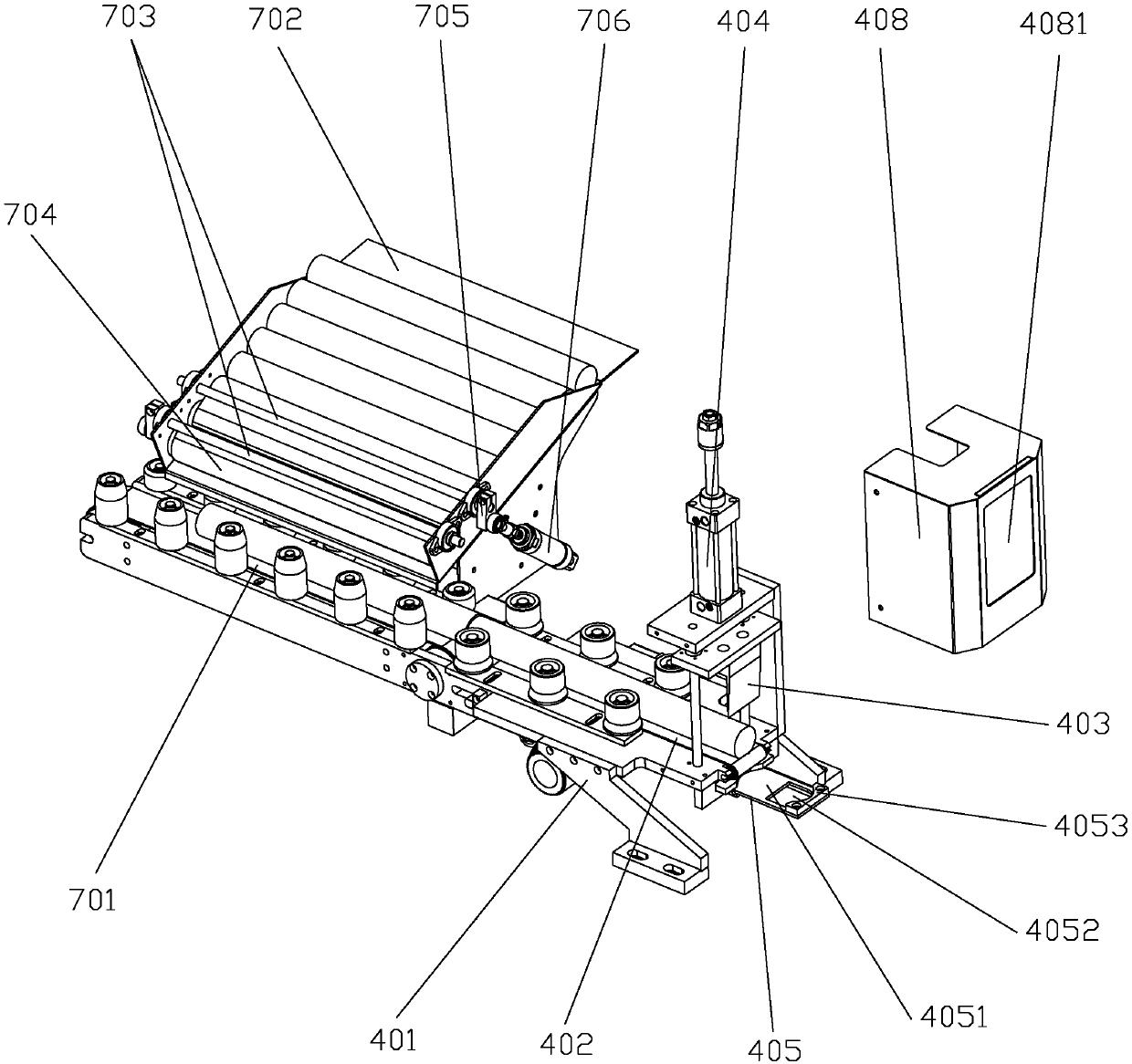

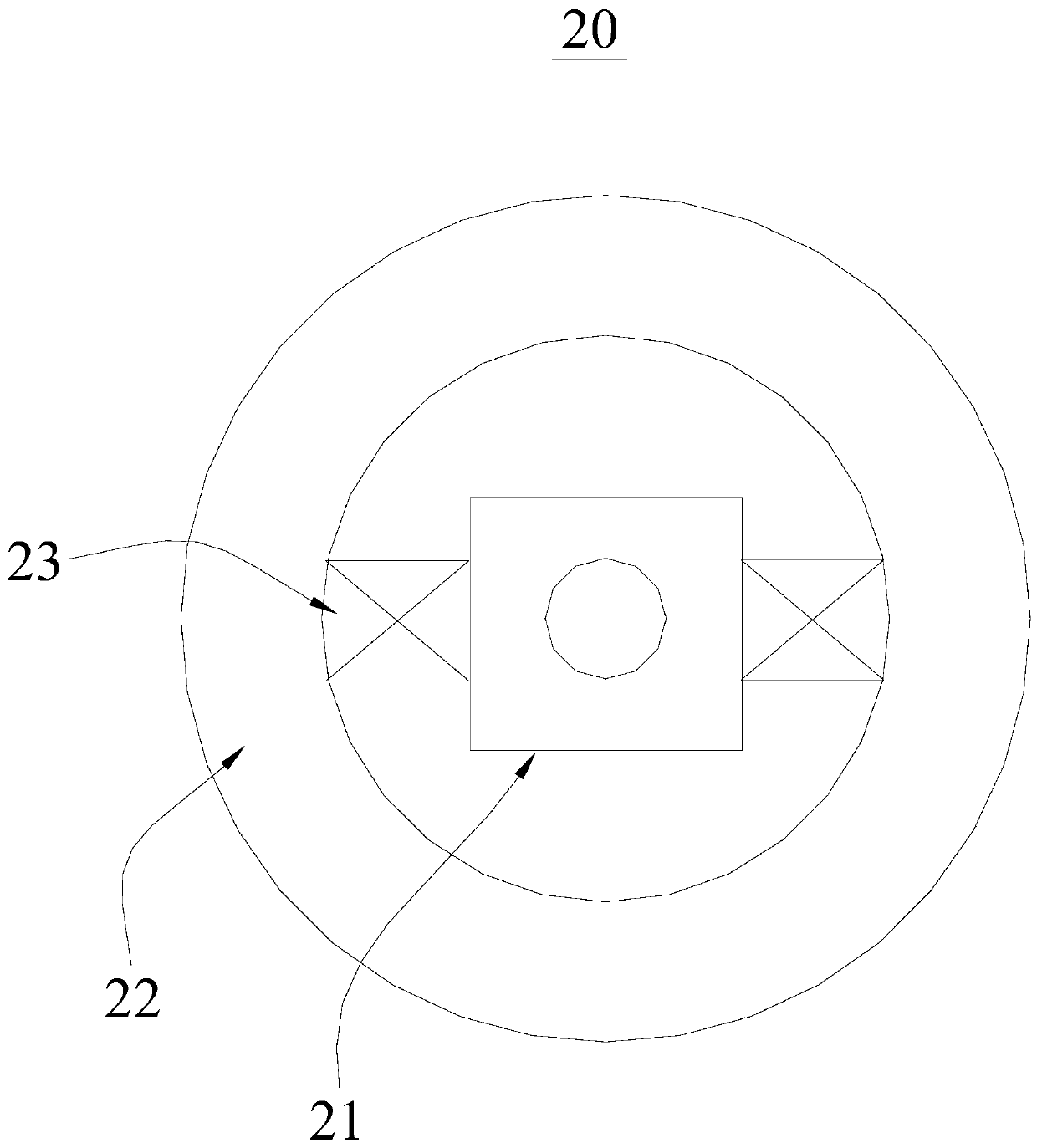

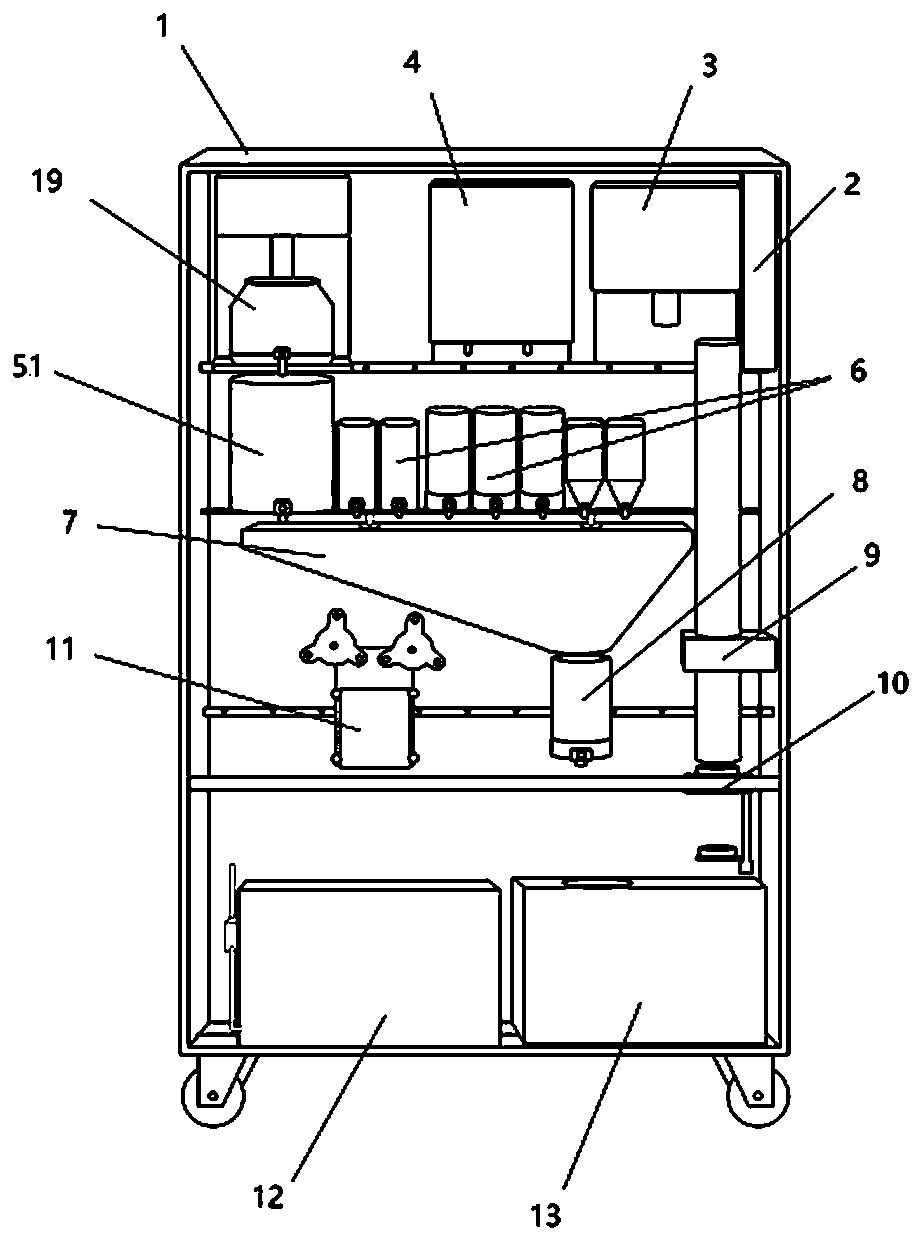

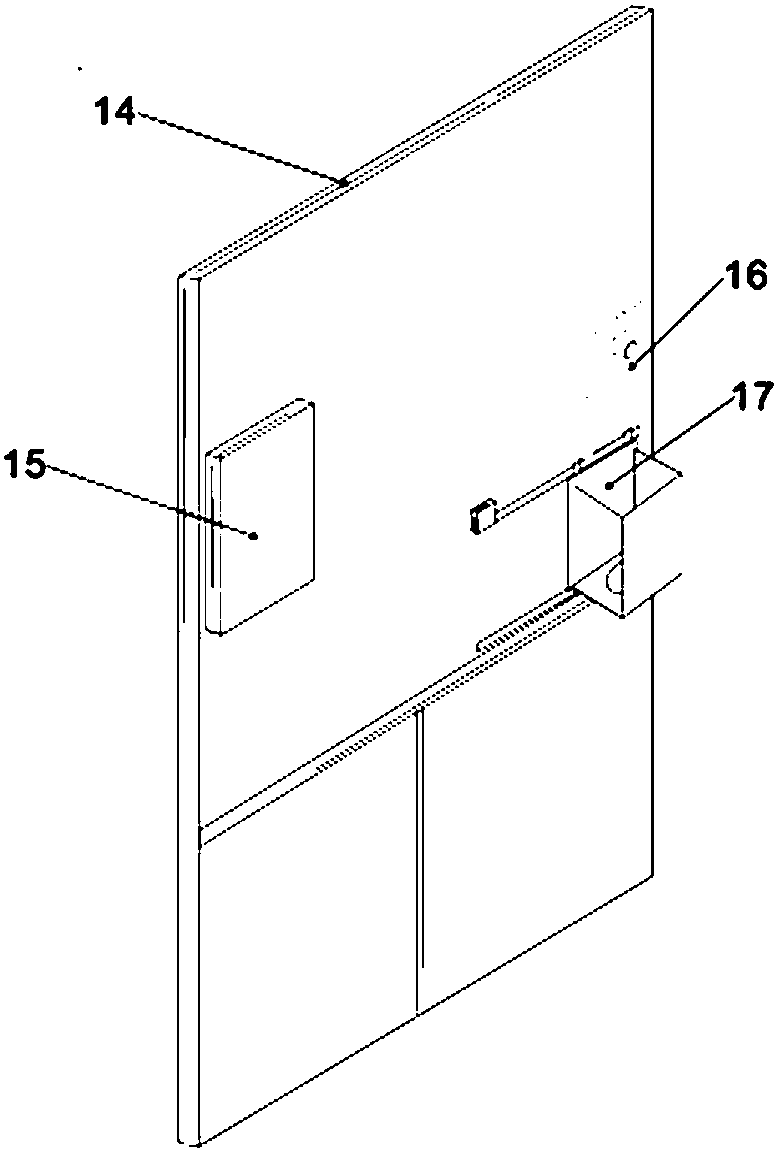

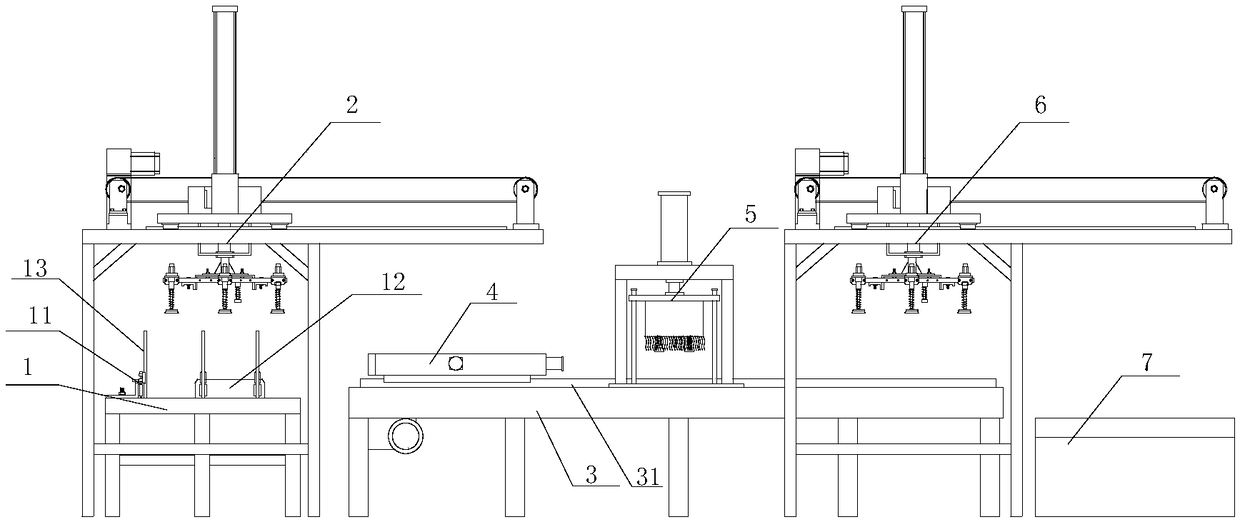

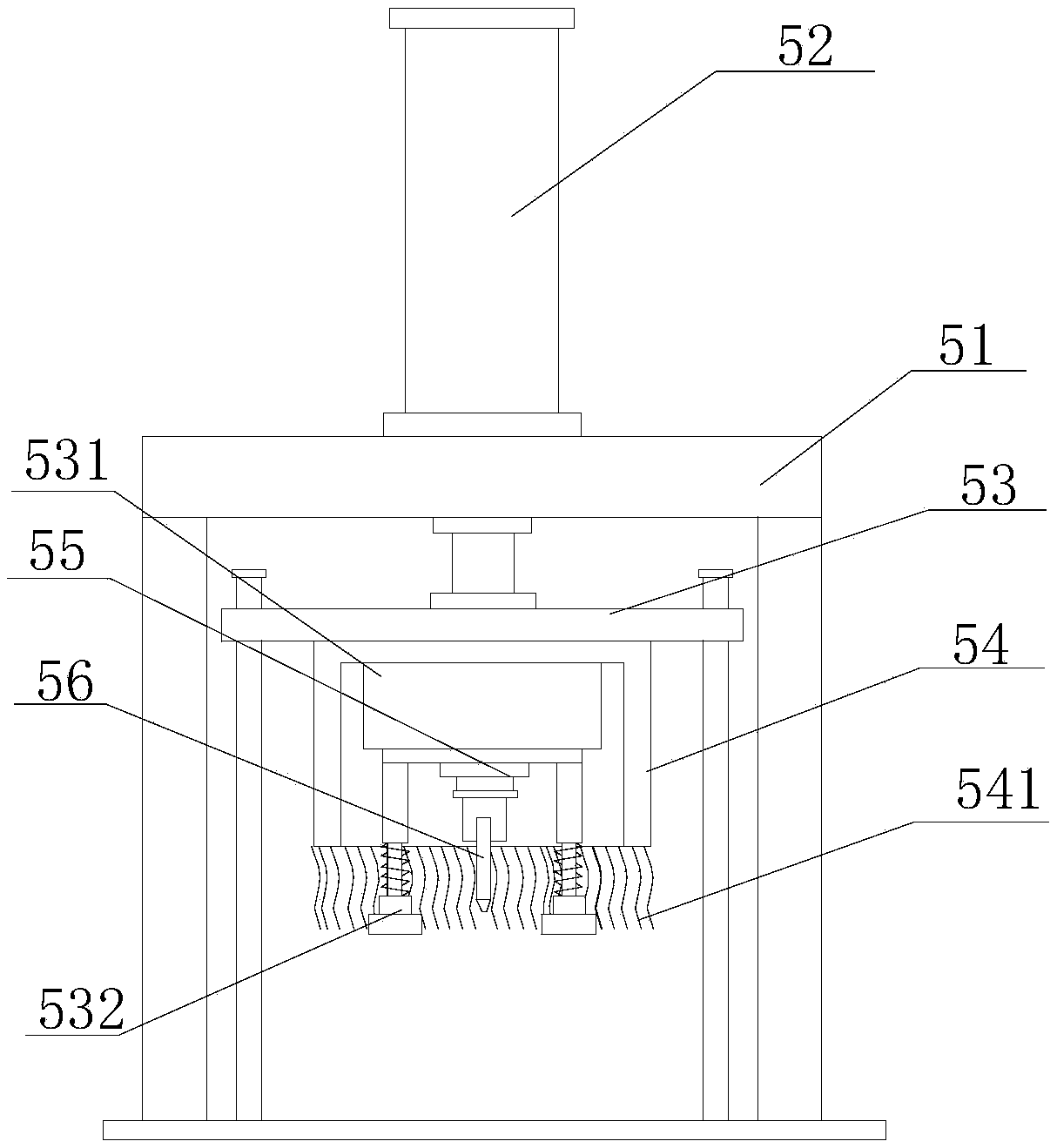

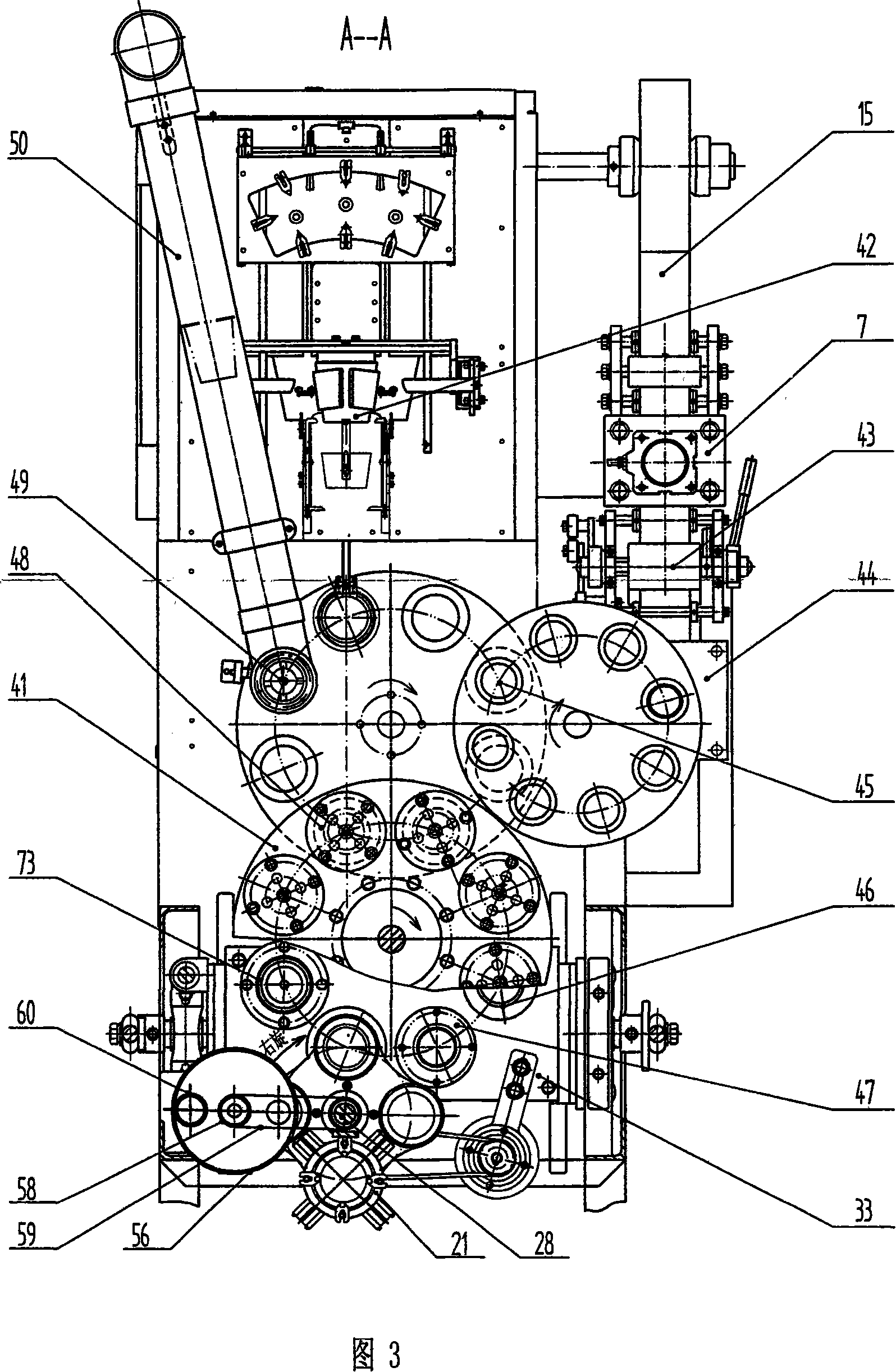

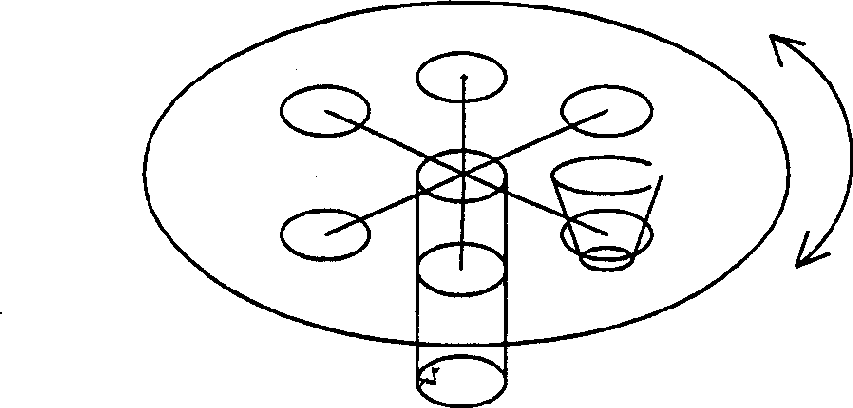

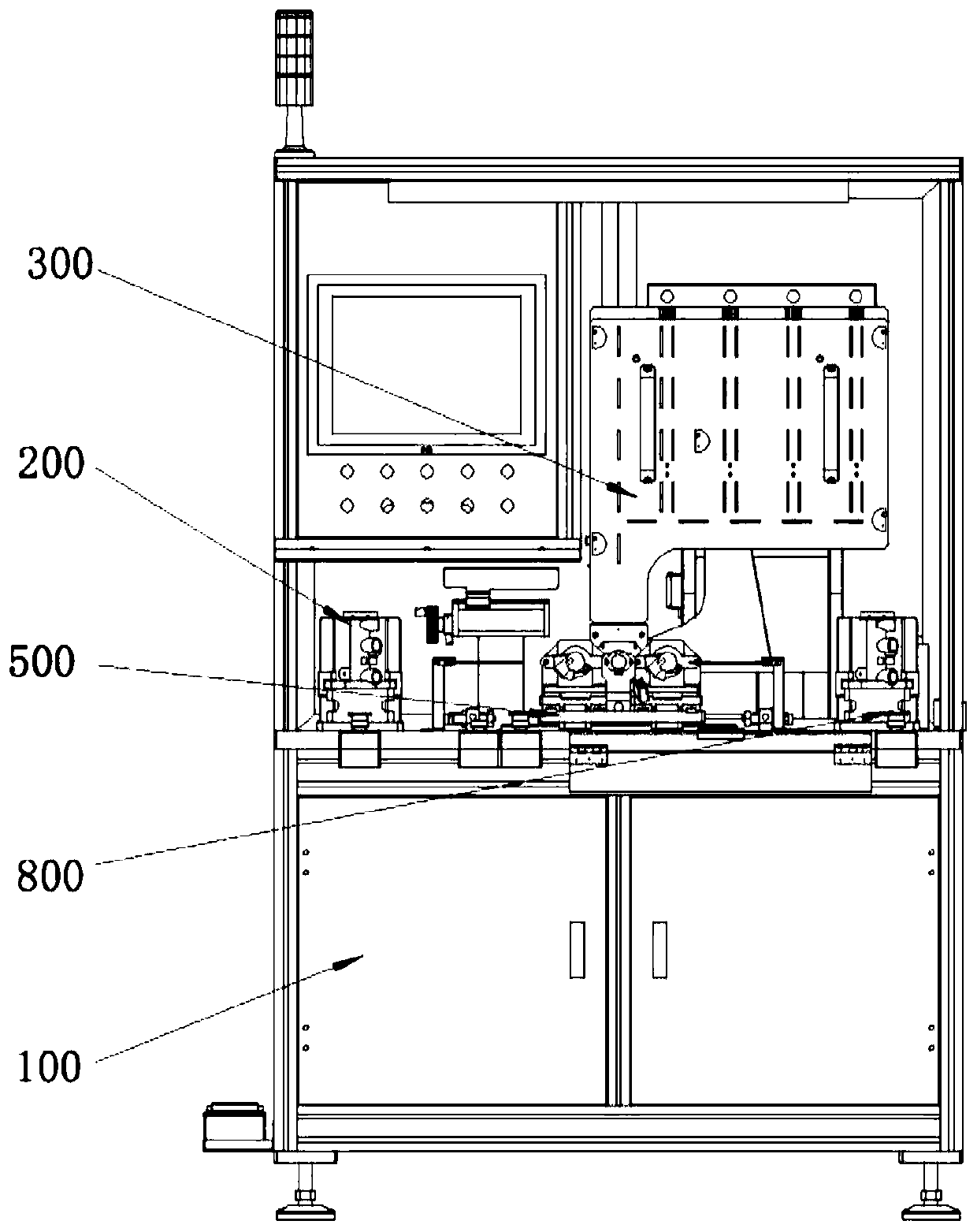

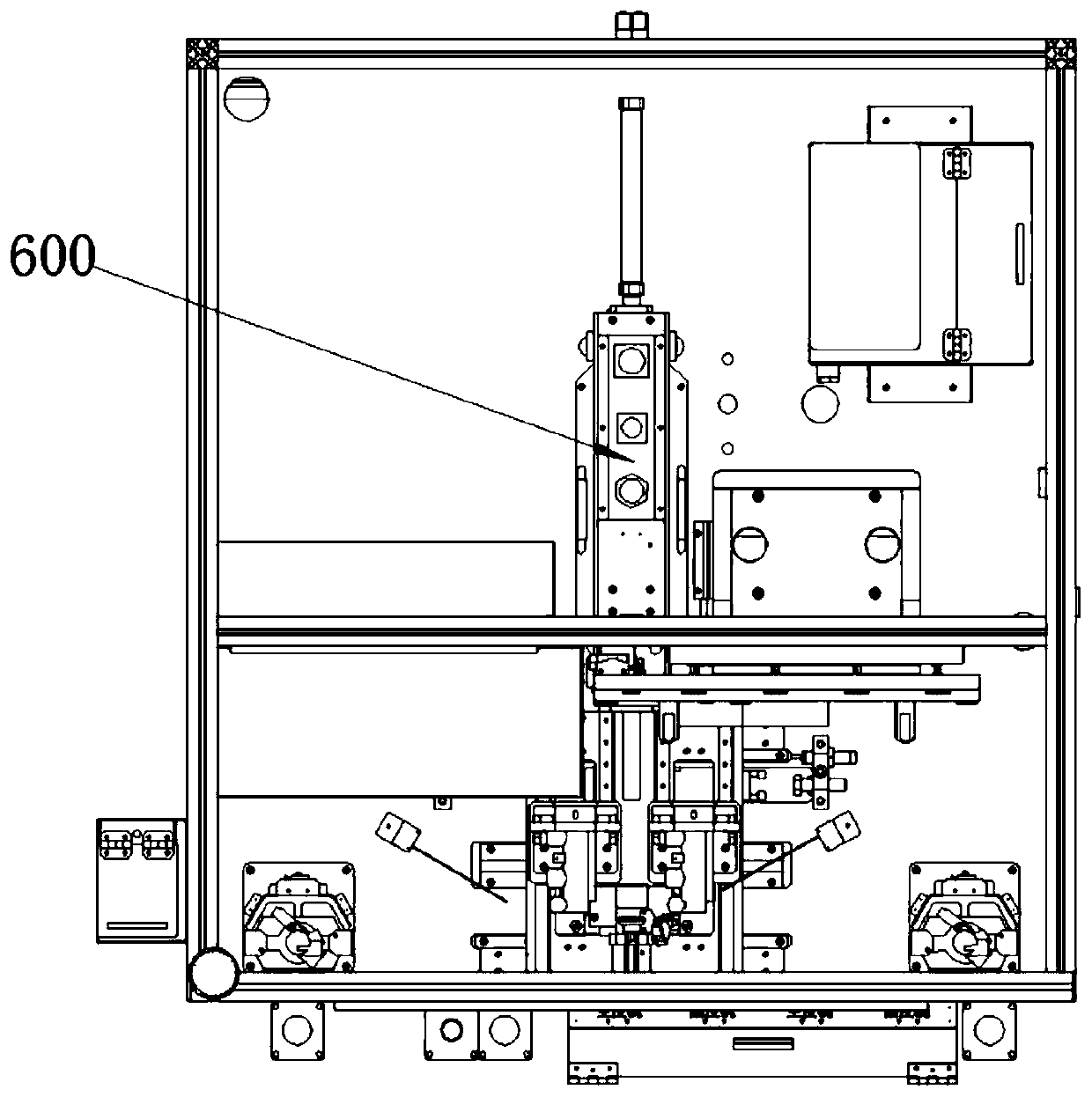

Low-voltage circuit breaker electromagnetic assembly welding system and method

ActiveCN107243682AEliminate weldsIncrease productivitySoldering ironWelding/soldering/cutting articlesLow voltage circuitsSoldering

The invention discloses a low-voltage circuit breaker electromagnetic assembly welding system. The system comprises a rotary disc assembly arranged on a machine frame; the rotary disc assembly comprises a rotary disc and eight fixture assemblies; the rotary disc is arranged on a horizontal table, the lower surface of the rotary disc is provided with a multi-station indexing mechanism, and rotary disc is provided with a transmission mechanism of its own; eight feeding and discharging mechanisms are sequentially arranged in the positions, surrounding the periphery of the rotary disc, of the horizontal table and the machine frame, specifically, the eight feeding and discharging mechanisms comprise the oil cup feeding mechanism, the lower gasket feeding mechanism, the upper gasket feeding mechanism, the magnet yoke feeding mechanism, the coil feeding mechanism, the upper gasket taking mechanism, the magnet yoke taking mechanism and the soldering mechanism, and the outer side of the soldering mechanism is provided with a finished product discharging outlet. All the mechanisms are connected with a central controller. The invention further discloses a full-automatic circuit breaker electromagnetic assembly welding method. According to the system and the method, the structure is compact, the full-automatic degree is high, and the finished product quality is good.

Owner:YUEQING YEDAO ELECTROMECHANICAL CO LTD

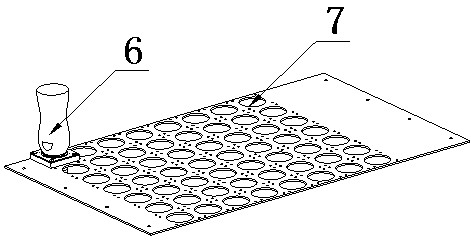

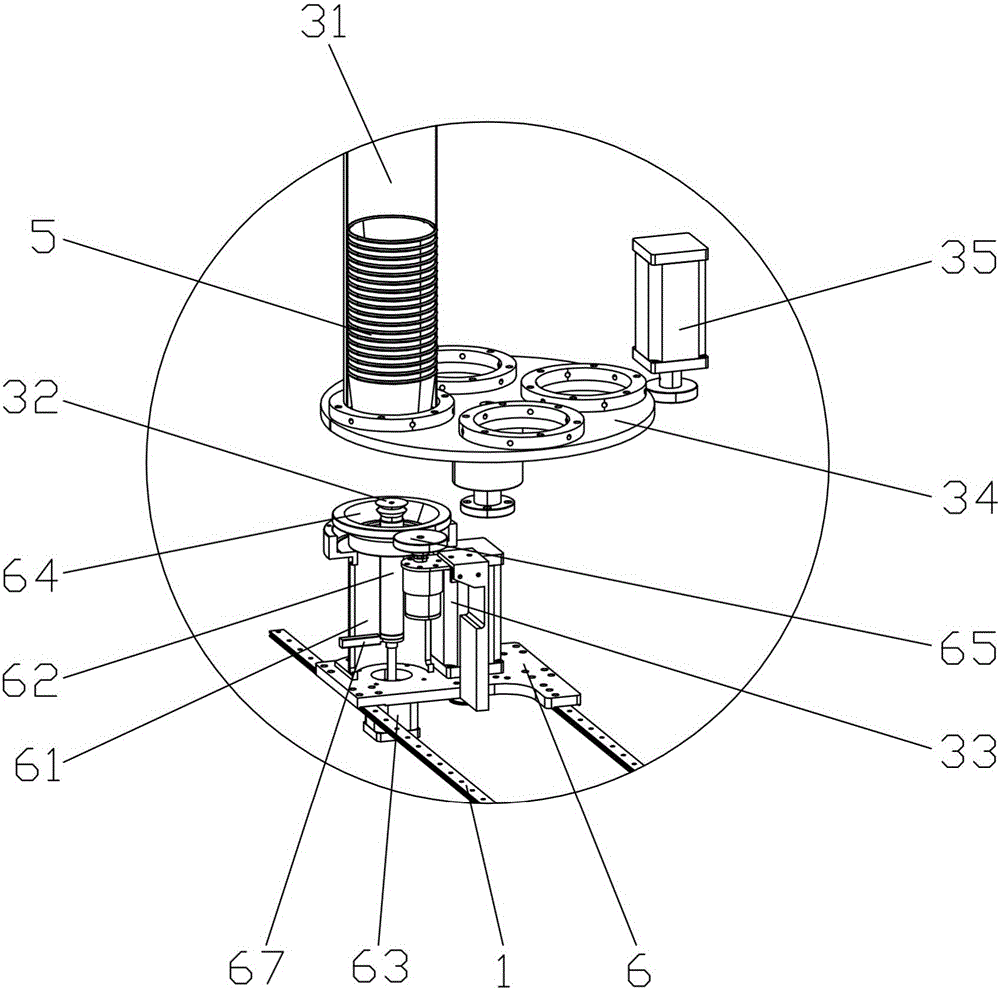

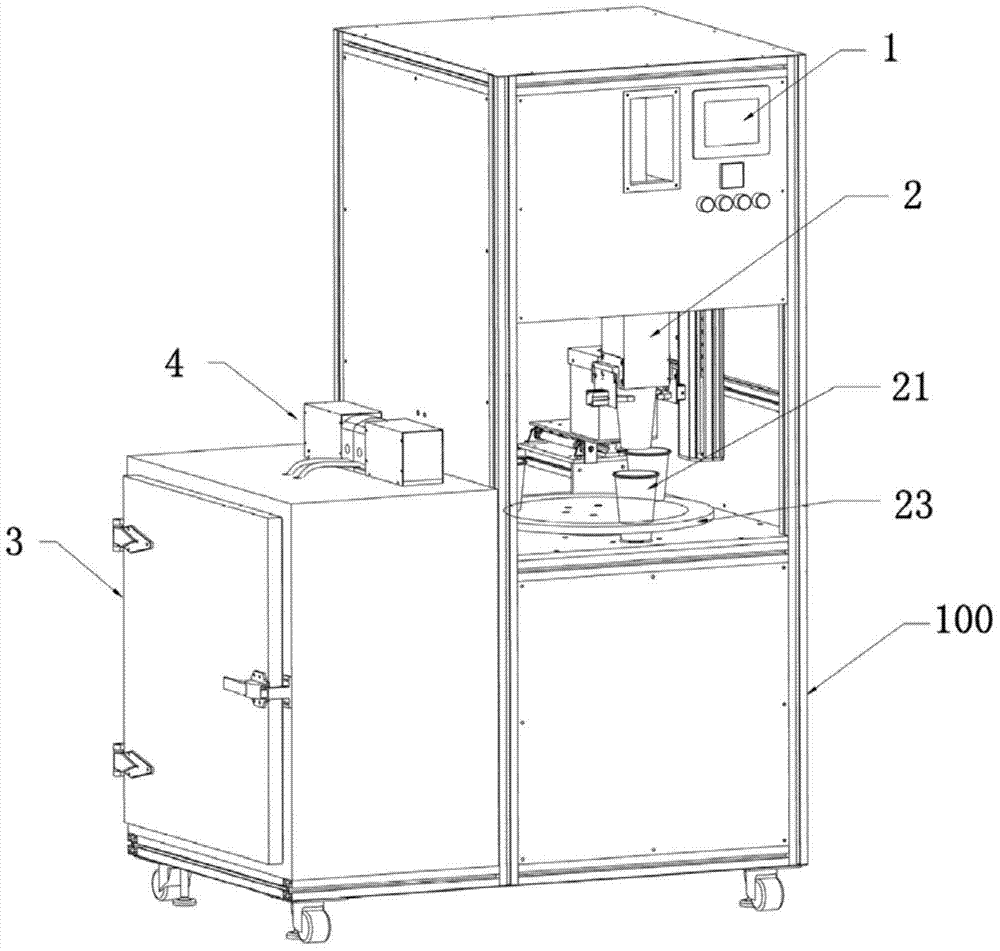

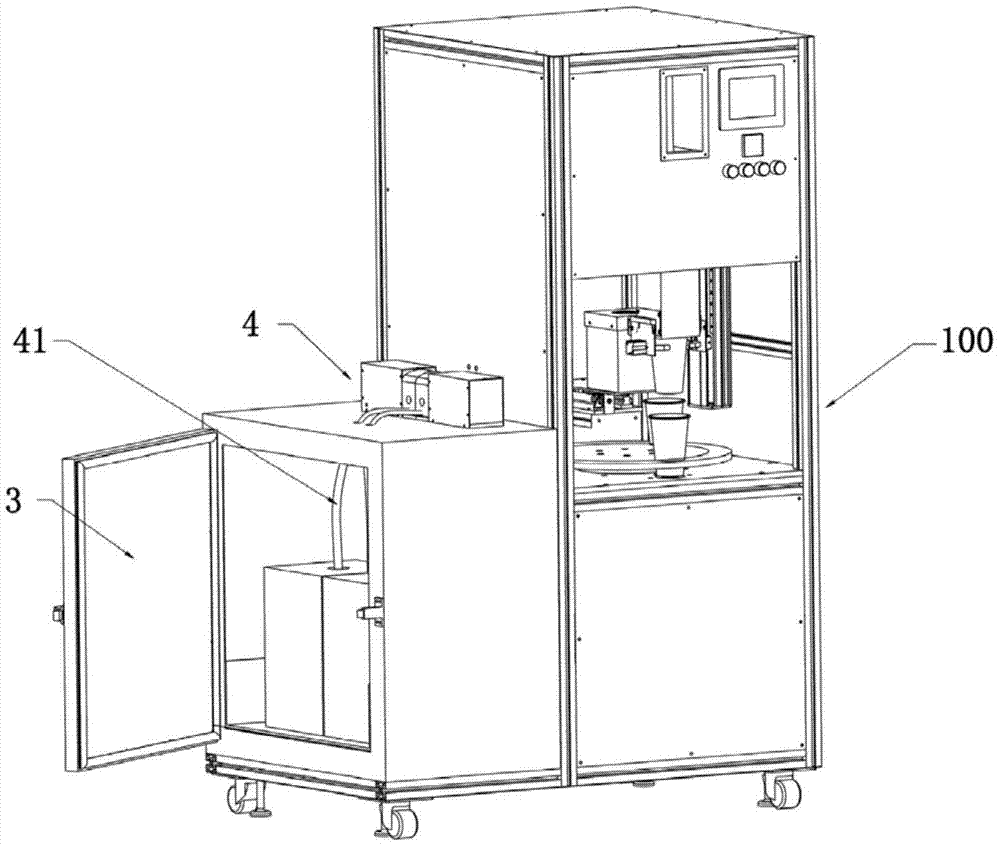

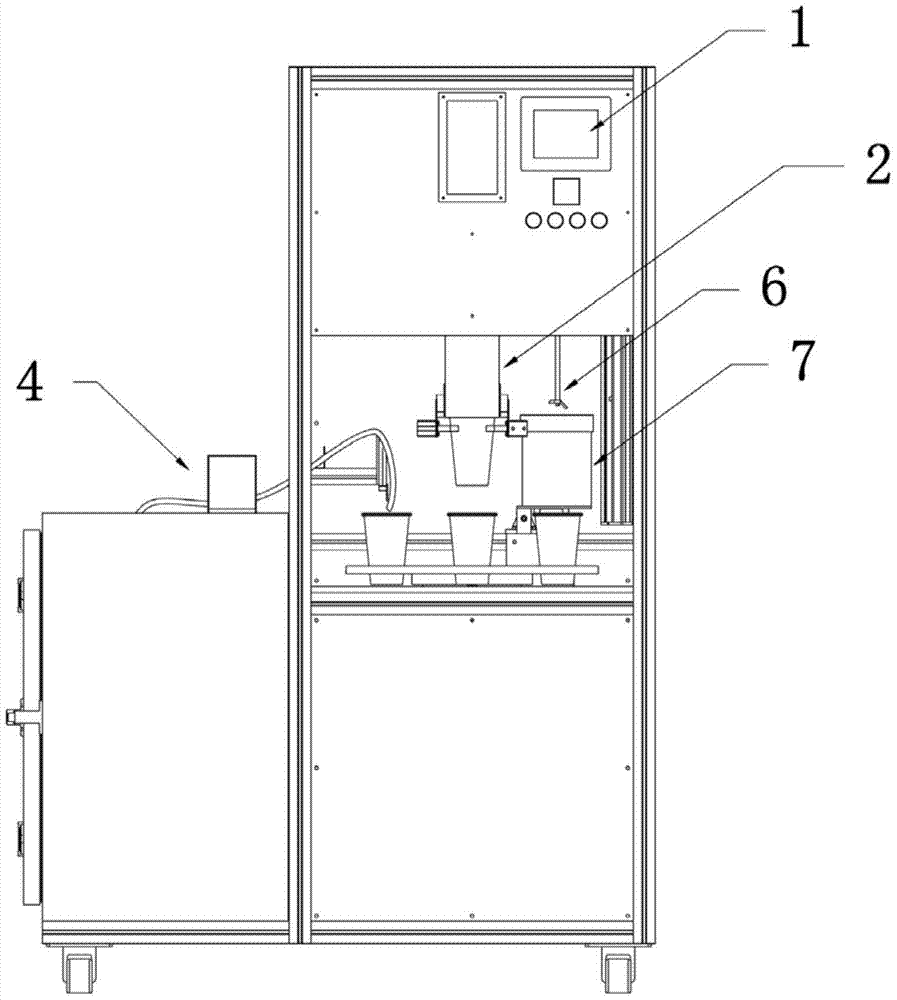

Automatic shaping machine of egg tart shell

InactiveCN107711955AEnsure consistencyFully automated production processDough shapingDough dividingEngineeringConveyor belt

The invention discloses an automatic shaping machine of an egg tart shell. The automatic shaping machine comprises a main machine frame, wherein a rotating plate is arranged on the main machine frame;a plurality of cup holders are uniformly distributed on the rotating plate in the circumferential direction; a cavity allowing a tin foil cup to be placed is formed in the corresponding cup holder; apower device for driving the rotating plate to rotate is connected to the main machine frame; a tin foil cup feeding device, a dough cutting device, a shaping device and a finished product outputtingdevice which are sequentially arranged around the rotating plate are connected to the main machine frame; the dough cutting device comprises a mounting frame fixedly connected to the main machine frame; a horizontal dough conveyor belt is arranged on the mounting frame; a cutter is arranged above the end part of the dough conveyor belt; a cutter cylinder is connected to the cutter to push the cutter to move up and down; a heating component is arranged in the cutter; and a dough pushing mechanism is arranged below the end part of the dough conveyor belt.

Owner:江门市神川自动化设备有限公司

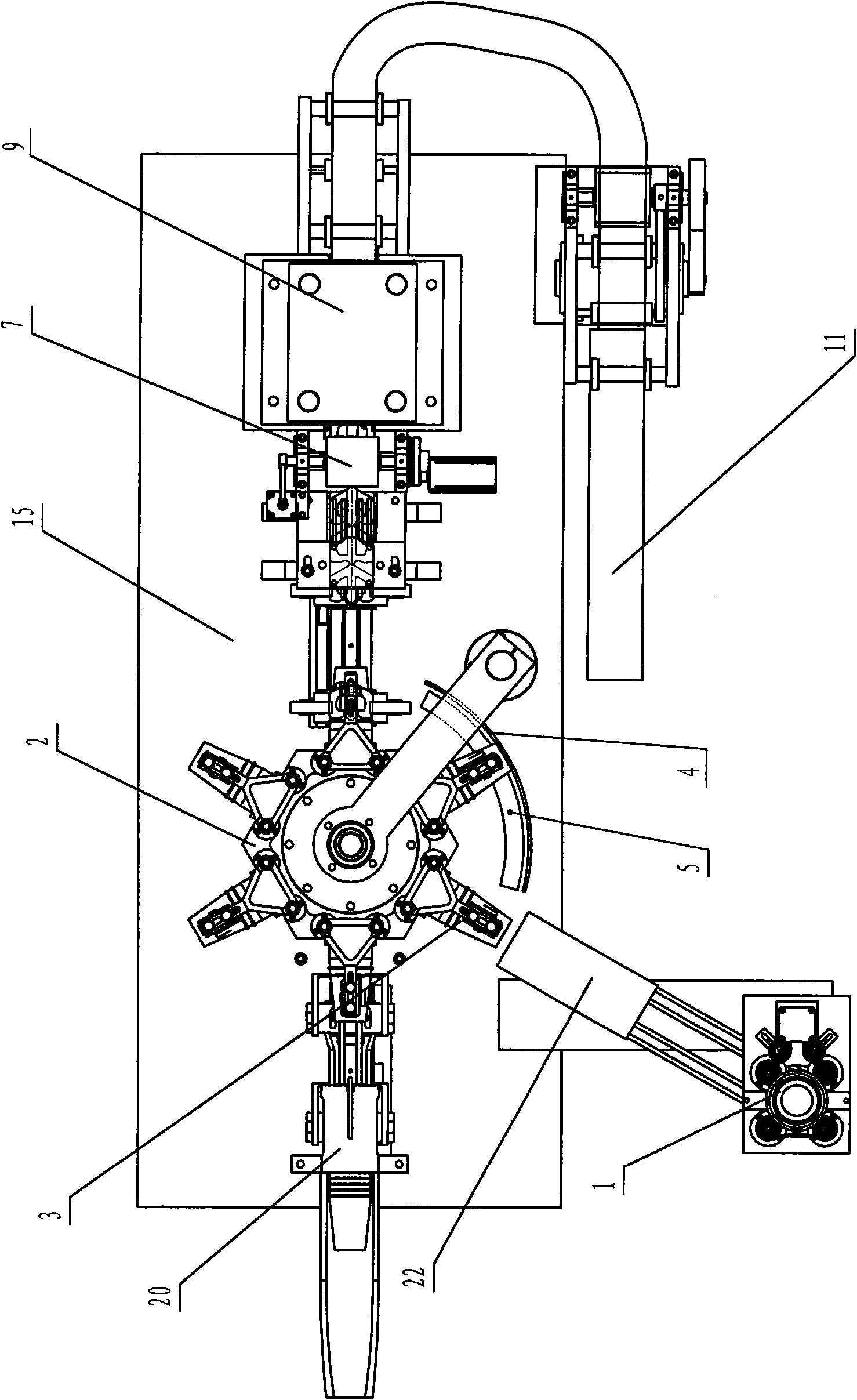

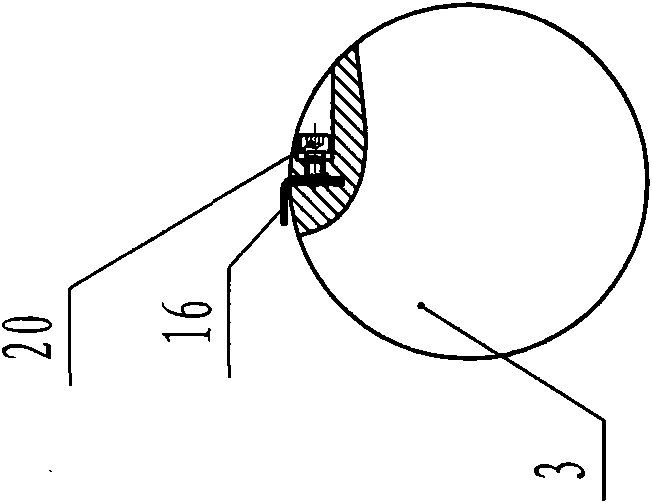

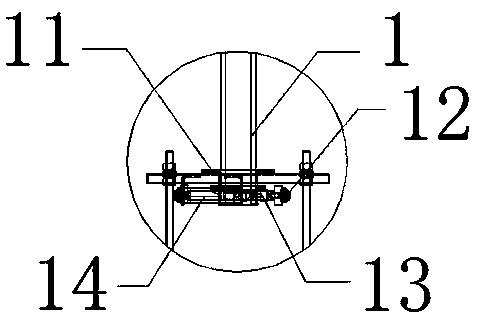

Paper glass handle-sticking machine

ActiveCN101596796APrecise positioningIncrease production capacityPaper/cardboard wound articlesBox making operationsPaper tapePulp and paper industry

The invention discloses a paper glass handle-sticking machine, which comprises a machine frame (15), a cup feeding mechanism, a rotating table (2), wherein the periphery of the rotating table (2) is provided with a cup mould (3) which is provided with a cup supplying working position, a locating working position and a pressing working position when rotating along the rotating table (2); the paper glass handle-sticking machine is characterized in that the machine frame (15) is provided with a paper tape feeding mechanism, a cup handle die cutting mechanism (9), and a cup handle cutting-off mechanism (7); one side of the rotating table (2) is provided with a manipulator (6); and a pressing device which sticks the cup handle to the surface of the paper glass is arranged above the cup mould (3). The paper glass handle-sticking machine with the structure can precisely locate and stick the cup handle on the wall of the paper glass, has high automation degree and simple structure, and greatly increases production efficiency.

Owner:ZHEJIANG RUIDA MACHINERY

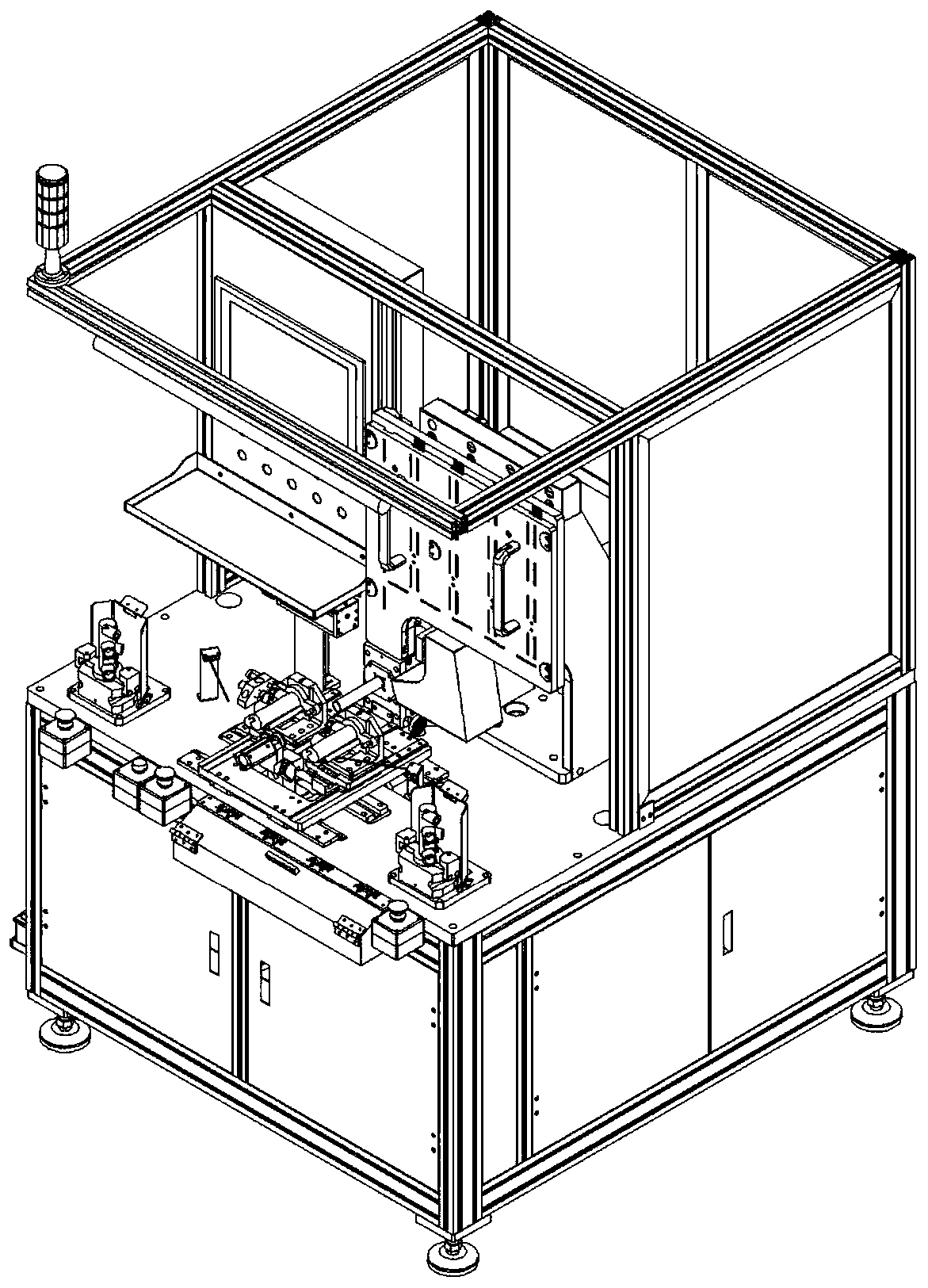

Automatic assembling equipment for LED lamp

PendingCN110449782AIncrease productivityImprove installation accuracyWelding/cutting auxillary devicesAssembly machinesEngineeringLED lamp

The invention relates to automatic assembling equipment for an LED lamp. The automatic assembling equipment for LED lamp comprises an LED lamp source assembly feeding device, a lamp cup feeding device, a PCB board feeding device, an assembly positioning transmission device, a welding fixing device and an LED lamp source position correcting device, wherein the LED lamp source assembly feeding device is used for feeding the LED lamp source assembly, the lamp cup feeding device is used for feeding the lamp cup, and the PCB board feeding device is used for feeding the PCB board, the assembly positioning transmission device is used for assembling and positioning the LED lamp, the welding fixing device is used for welding and fixing the PCB board, and the LED lamp source position correcting device is used for correcting the position of the LED lamp. According to the automatic assembling equipment for LED lamp, the LED lamp source assembly feeding device, the lamp cup feeding device, the PCBboard feeding device, the assembly positioning transmission device, the welding fixing device and the LED lamp source position correcting device are arranged, so that the LED lamp can be assembled andinstalled instead of manual work, and the overall production efficiency and installation precision are effectively improved.

Owner:HUIZHOU SAINTS LIGHTING CO LTD

Multifunctional coffee dual-line filling machine

InactiveCN106347767AWrapper twisting/gatheringPackaging under vacuum/special atmosphereNitrogenEngineering

The invention discloses a multifunctional coffee dual-line filling machine. The filling machine comprises a rack, an upper rack door frame, a door, a cup feeding device, a touch screen, a cup retaining device arranged on the rack behind the cup feeding device and a template guide rail, wherein a longitudinal air cylinder and a transverse air cylinder are arranged at two ends of the template guide rail; a plurality of templates are arranged on the template guide rail in a sliding manner; a cup grasping device, an inner cup pressing device, an inner cup detection device, a discharging device, a powder suction device, a film suction device, a film detection device, a hot-seal nitrogen inflating device, a capsule cup hot-seal device and a cup drafting device are sequentially in pair on corresponding positions of the templates according to a cup filling process; a vacuum charging device is arranged above the discharging device, and a powder shaking air cylinder is arranged under the discharging device; and a waste rejection device is arranged behind the cup drafting device. The multifunctional coffee dual-line filling machine has high automatic degree, can be used for completely replacing manual filling and conveniently quickly filling and switching different types of cups, and has the advantages of high filling efficiency and high finished product yield.

Owner:温州市途麦机械有限公司

Intelligent soft drink making and selling machine

ActiveCN108022370AWith automatic cleaning functionControl the amount of ice cubesBeverage vesselsApparatus for dispensing fluids/granular materialsElectricityWater storage

The invention discloses an intelligent soft drinking making and selling machine. The intelligent soft drinking making and selling machine comprises an equipment cavity, a cold and hot water mechanism,a raw material adding mechanism, a tea cooking mechanism, an ice making mechanism, a stirring mechanism, an automatic cleaning mechanism, a water storage mechanism, a cup feeding mechanism, a sealingmechanism, a cup loading mechanism, a door opening mechanism and a straw mechanism, and the cold and hot water mechanism, the raw material adding mechanism, the tea cooking mechanism, the ice makingmechanism, the stirring mechanism, the automatic cleaning mechanism, the water storage mechanism, the cup feeding mechanism, the sealing mechanism, the cup loading mechanism, the door opening mechanism and the straw mechanism are located inside the equipment cavity; the intelligent soft drinking making and selling machine further comprises an operating screen and a controller, and the operating screen is electrically connected with the controller and is used for inputting a user operating instruction; the tea cooking mechanism is used for providing tea water for the raw material adding mechanism. The intelligent soft drinking making and selling machine has the advantages that diversified soft drinking making can be conducted, the soft drinking making process of the intelligent soft drinking making and selling machine is coincident with the whole process of artificial drink making, and manual operation is not needed in the making process; the quantity of added materials and the making time can be controlled, and thus the mouthfeel and the quality are superior; the intelligent soft drinking making and selling machine has the functions of automatically cooking tea and automatically making ice, and thus the machine is more automated; the machine has a unique cup feeding function, and thus precise cup feeding of various cup bodies can be adapted to; the machine has the function of being automatically cleaned, and thus the quality and the hygiene of drinks are better guaranteed.

Owner:黄学松

Wallboard cutting device

PendingCN108839277APrecise cuttingReduce labor intensityWorking accessoriesStone-like material working toolsEngineeringUltimate tensile strength

The invention provides a wallboard cutting device, comprising a feeding platform, a vacuum cup feeding device, a frame, a feeding sliding seat, a cutting device, a vacuum cup blanking device and a blanking platform; the frame is provided with a feeding guide rail; the feeding sliding seat is movably installed on the feeding guide rail; fixed limiting stoppers and movable limiting stoppers are arranged in the feeding sliding seat; the movable limiting stoppers are installed on a drive plate through first elastic supports; the drive plate is connected with a telescopic link of a limiting air cylinder; a protective cover is arranged below the cutting device; a cutting knife component in arranged in the protective cover; two ends of the frame are respectively provided with the feeding platformand the blanking platform; the feeding platform is provided with the vacuum cup feeding device; and the vacuum cup blanking device is arranged above the blanking platform. Automatic feeding is performed by employing a vacuum cup, and positioning feeding is performed by the feeding sliding seat, thereby guaranteeing accurate cutting; automatic stacking and blanking can be performed after cutting is ended, so that labor strength can be reduced, and the production efficiency is increased.

Owner:浙江欧舍家居新材股份有限公司

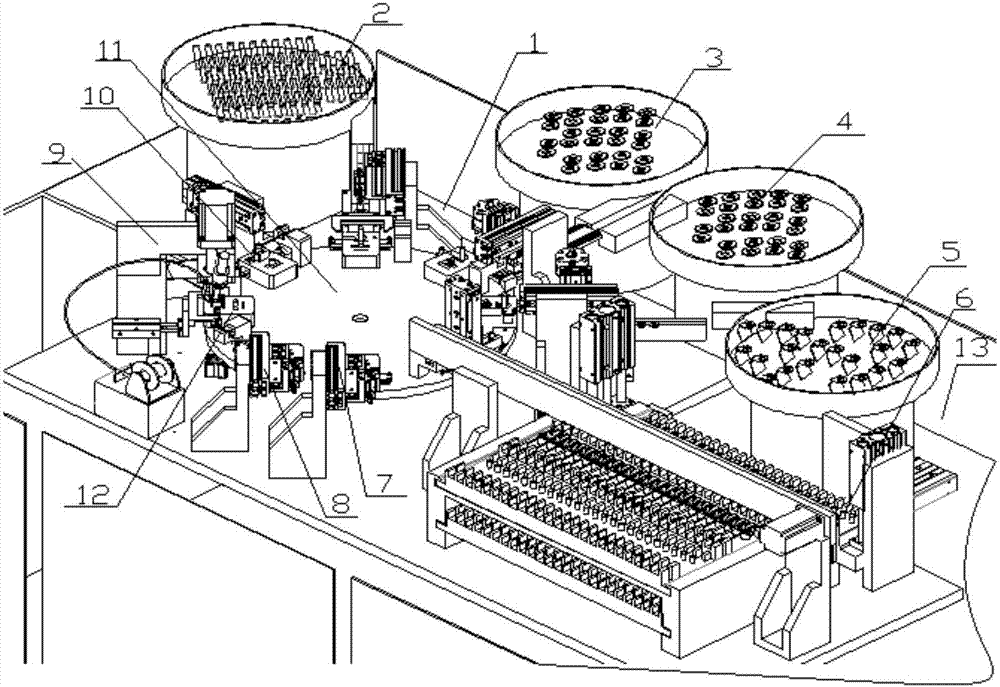

Ear stud full-automatic processing manufacturing system

InactiveCN103284420ARealize large-scale productionIncrease productivityJewelleryEngineeringManipulator

The invention relates to an ear stud full-automatic processing manufacturing system. The ear stud full-automatic processing manufacturing system comprises a bottom plate, a rotating control disc, a mechanical arm with a welding and carrying function, a controller and a finished product box, wherein a plurality of material discs are uniformly arranged on the periphery of the rotating control disc; one side of the rotating control disc is provided with an ear stud combination device for enabling a needle to insert into an ear cup hole, and an annular plate is arranged between the combination device and an ear cup feeding device and can prevent an ear cup from dropping from the ear cup hole; the mechanical arm is arranged behind the ear stud combination device, and the finished product box is arranged below the mechanical arm; the mechanical arm is connected with a mechanical arm servo motor, and the rotating control disc is connected with a control disc servo motor. The ear stud full-automatic processing manufacturing system provided by the invention adopts mechanization to replace manual operation, the manufacturing efficiency and product quality are improved, and the ear stud can realize large-scale manufacture.

Owner:李仰华

Three-layer drug delivery machine and drug delivery method thereof

ActiveCN102602552AAvoid cross contaminationClean thoroughlyWrapper twisting/gatheringSolid materialMotor driveEngineering

The invention discloses a three-layer drug delivery machine. The three-layer drug delivery machine comprises a machine frame, a drug receiving device, a mounting plate, a cup feeding mechanism, a sealing mechanism and a dispensing metering device, wherein the machine frame is divided into three layers, and each layer is provided with two parallel slide rails and a motor screw rod; the slide rails are connected with the drug receiving device in a sliding way and driven by a motor driving rod; the mounting plate is arranged above the drug receiving device; the sealing mechanism and the cup feeding mechanism are arranged on the side surface of the machine frame; 60 to 200 mounting holes for mounting the dispensing metering device are arranged on the mounting plate. The invention also discloses a drug delivery method for the three-layer drug delivery machine. The drug delivery method comprises the steps of filling drug cups, feeding the drugs into the cups, repeatedly implementing the operations in another layer, sealing, and picking the cups. The three-layer drug delivery machine disclosed by the invention is controlled by a mechanical automatic program, has fast speed on drug feeding, saves time and force, avoids cross contamination of the drugs, and keeps the drugs clean; moreover, the three-layer drug delivery machine is easy to dismount, and convenient to maintain.

Owner:SICHUAN NEO GREEN PHARMA TECH DEV

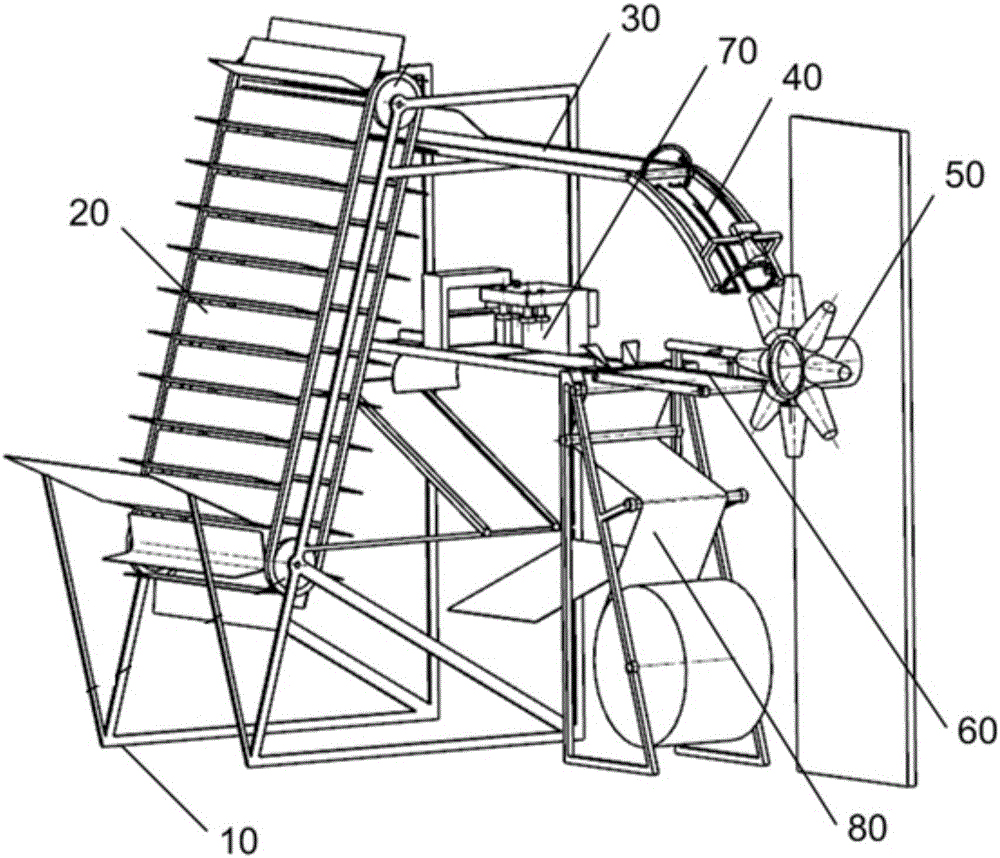

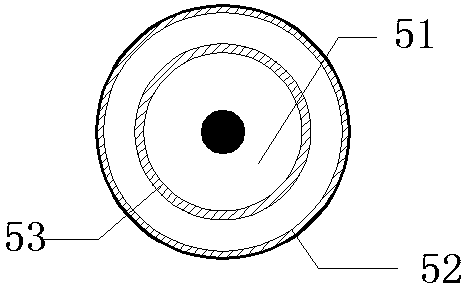

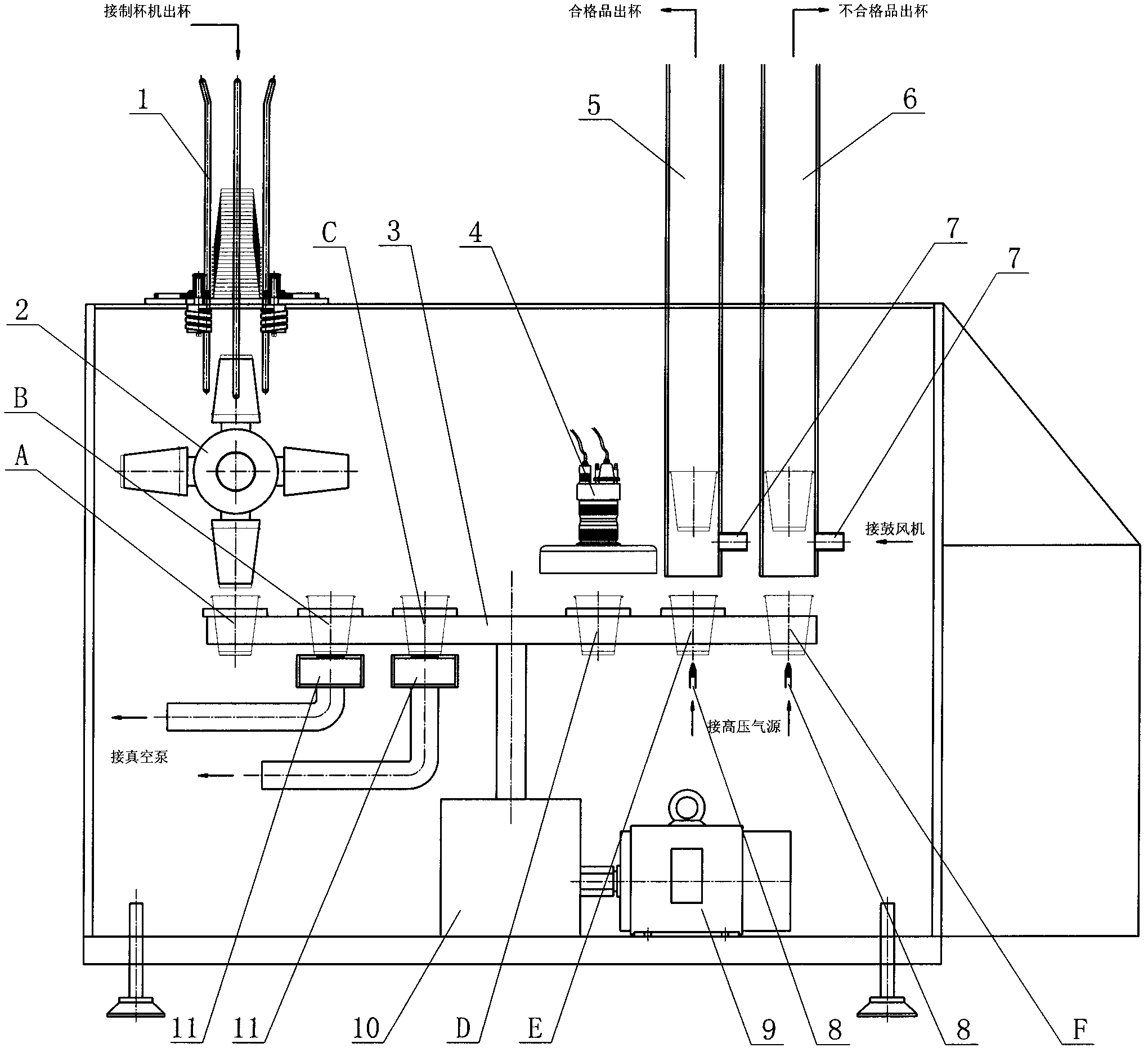

Paper container product detection machine and detection method thereof

ActiveCN103454284ARealize detectionImplement automatic detectionOptically investigating flaws/contaminationPulp and paper industryLeak detection

The invention discloses a paper container product detection machine and a detection method thereof. The paper container product detection machine comprises a frame, a spiral cup-feeding device, a drum type sucking disc cup-overturning device, a camera detection device, a vacuum conveying device and a cup delivery device, wherein the vacuum conveying device is arranged on the right part of a worktable, the drum type sucking disc cup-overturning device is arranged above the left end of the vacuum conveying device, and the spiral cup-feeding device is arranged above the drum type sucking disc cup-overturning device. The camera detection device comprises a first camera detection unit and a second camera detection device, wherein the first camera detection device is arranged on the left side of the drum type sucking disc cup-overturning device, the second camera detection device is arranged above the middle part of the vacuum conveying device, and the cup delivery device is arranged above the right end of the vacuum conveying device. The paper container product detection machine provided by the invention can detect paper containers such as paper cups and paper bowls and automatically detects by multiple detection steps, so that the probability of leak detection and wrong detection is reduced, so that the detection efficiency and the detection quality are improved simultaneously when the manual cost is lowered.

Owner:ZHEJAING DISCOVER MACHINERY MFG CO LTD

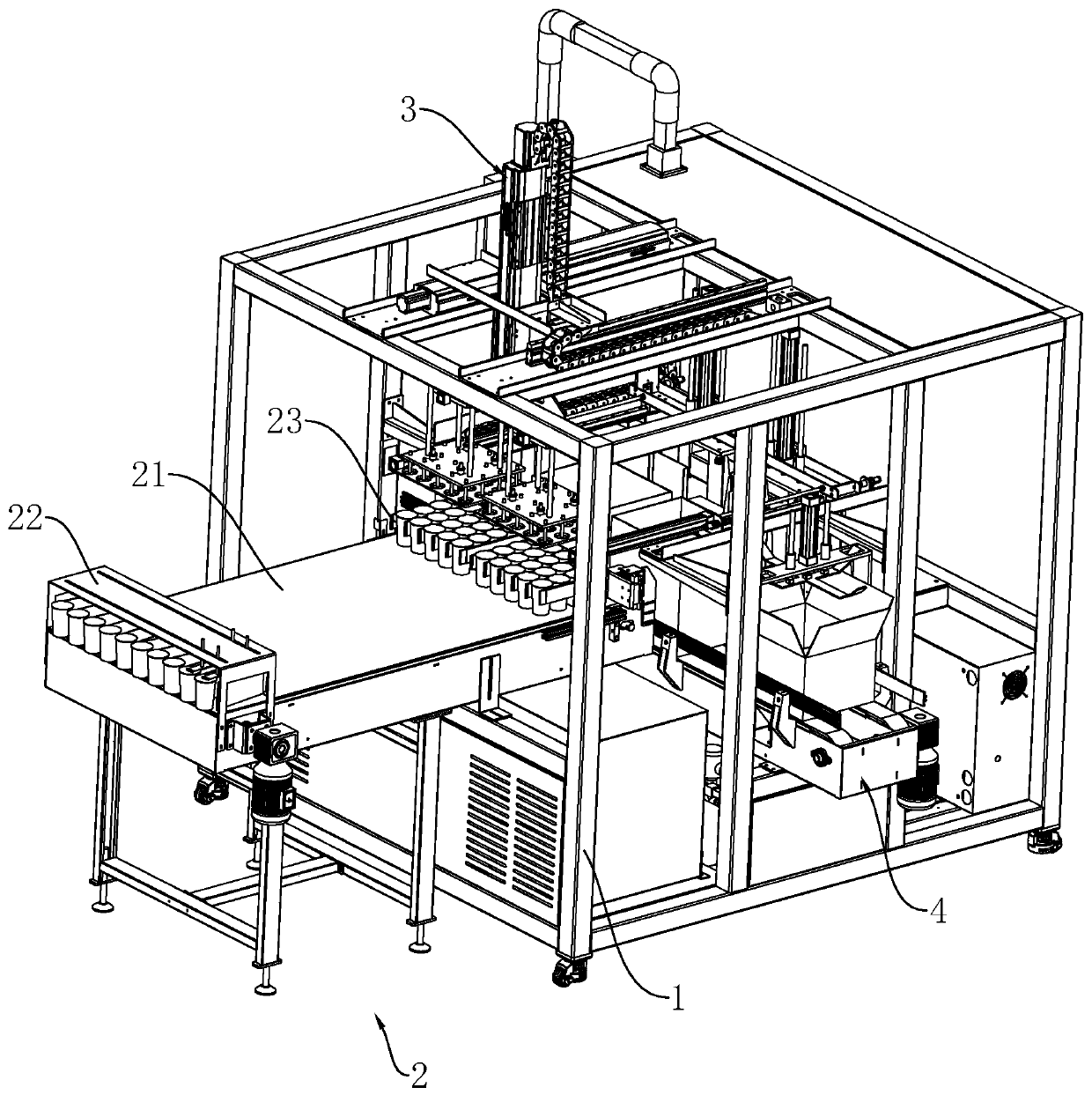

Automatic case packer

ActiveCN111216957AImprove packaging efficiencyReduce labor costsIndividual articlesStructural engineeringIndustrial engineering

The invention discloses an automatic case packer. According to the technical scheme, the automatic case packer is characterized by comprising a rack; a cup feeding device, a cup moving device and a case feeding device are arranged on the rack; the cup feeding device comprises a product conveying belt, a partition piece arranged at the feeding end of the product conveying belt and a cup holding mechanism arranged at the discharging end of the product conveying belt; the cup holding mechanism comprises a baffle plate positioned on the upper side of the product conveying belt and a plurality of holding plates which are connected to the side, facing the partition piece, of the baffle plate at intervals; a waiting area for cup-packed beverages to be clamped in and to be moved into a packaging case is arranged between every two adjacent holding plates; the waiting areas are right opposite to corresponding partition areas; the upper sides of the holding plates are attached to the lower sidesof the convex edges of the cup-packed beverages so as to hold the cup-packed beverages; and the cup holding mechanism can hold the cup-packed beverages up, so that the cup-packed beverages are not poured due to the driving of the product conveying belt. The automatic case packer is suitable for automatic encasement of the cup-packed beverages, and labor cost is saved.

Owner:温州兄弟机械有限公司

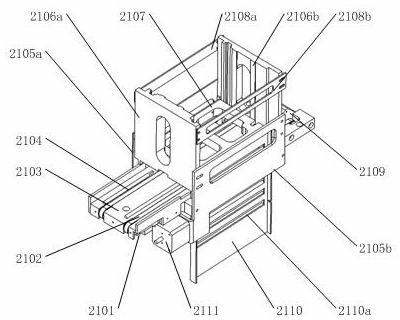

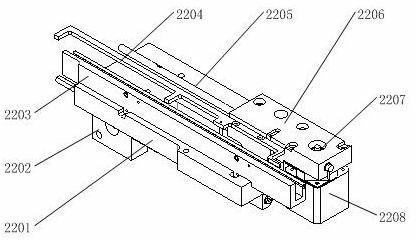

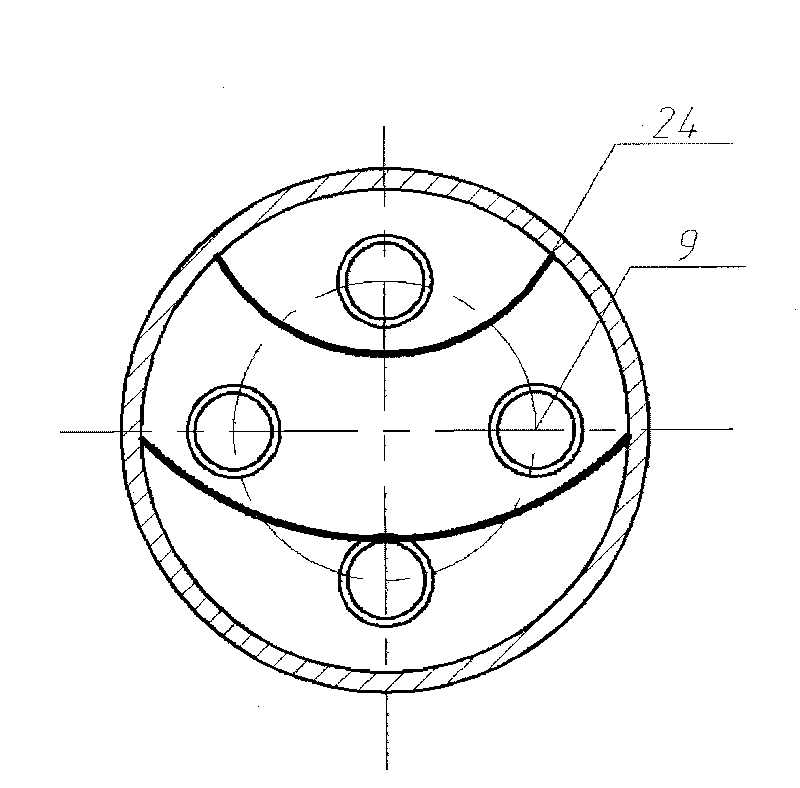

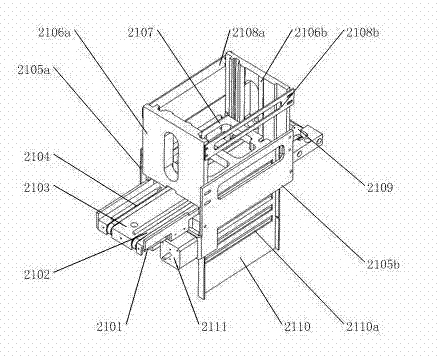

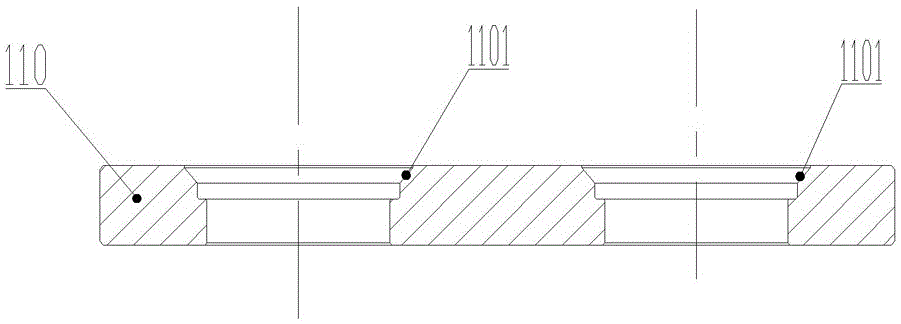

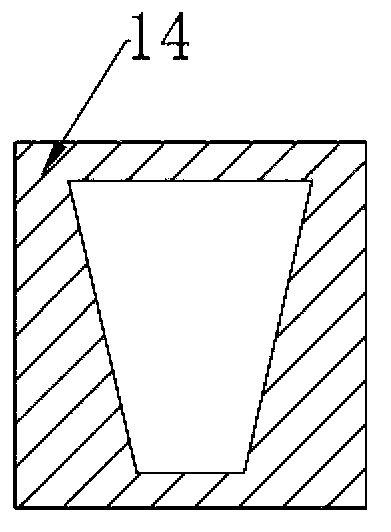

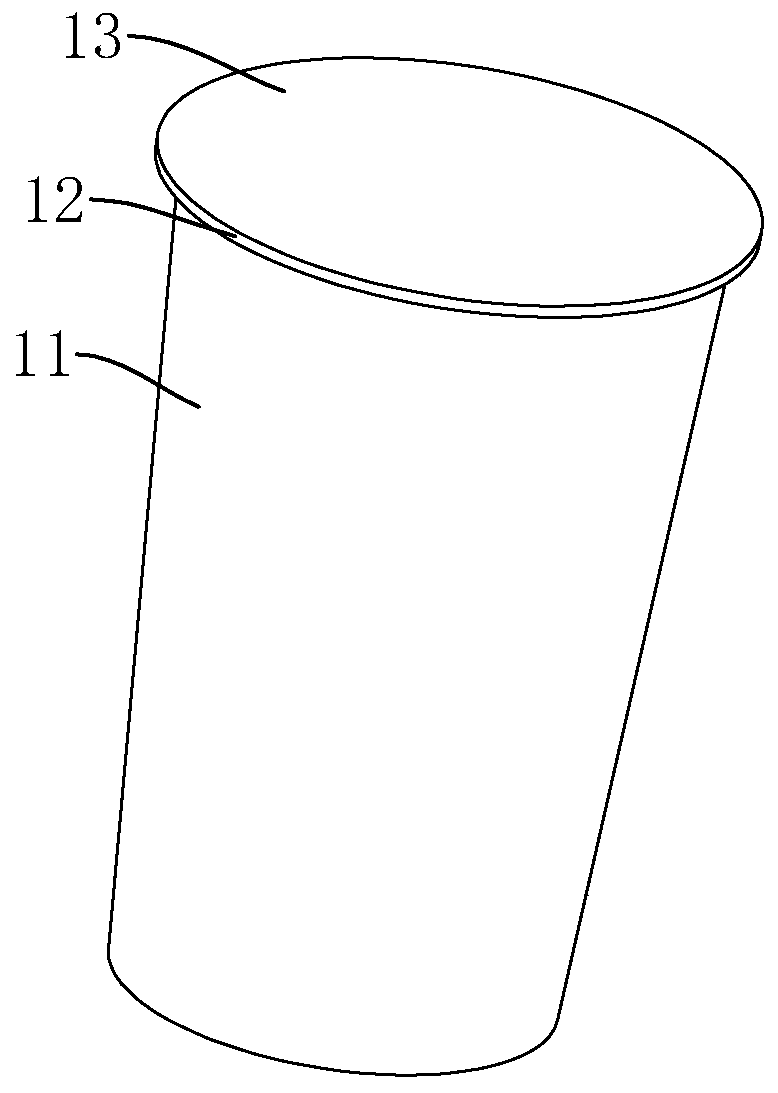

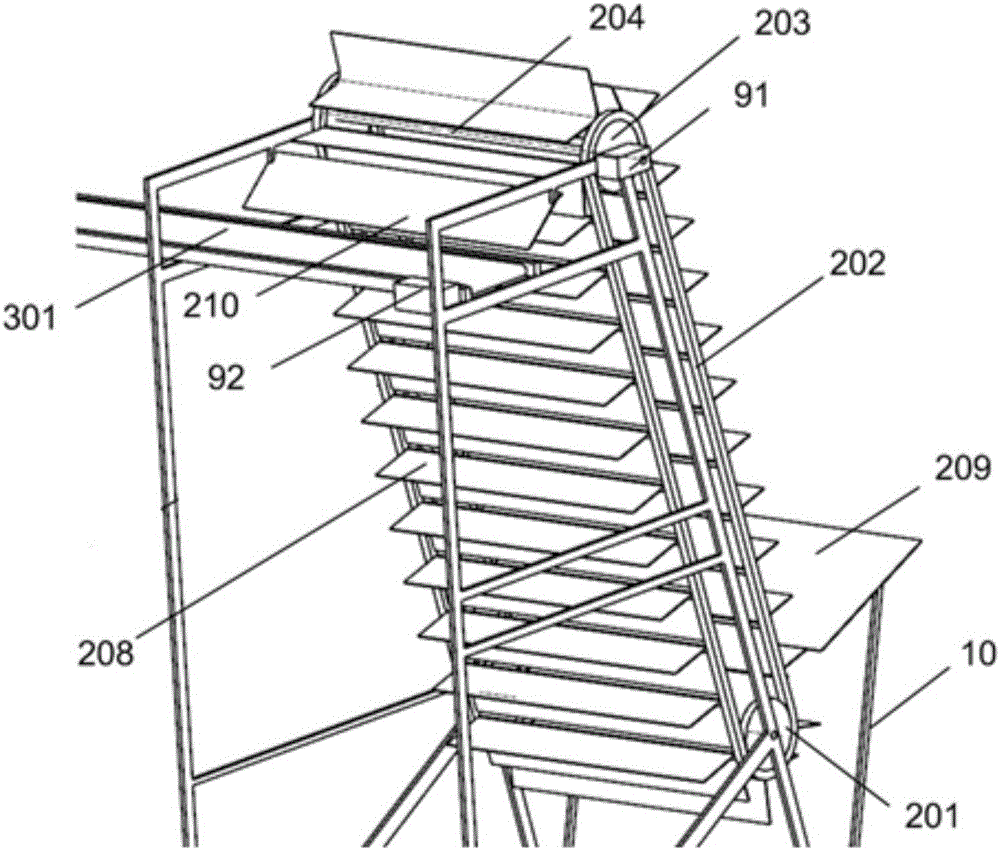

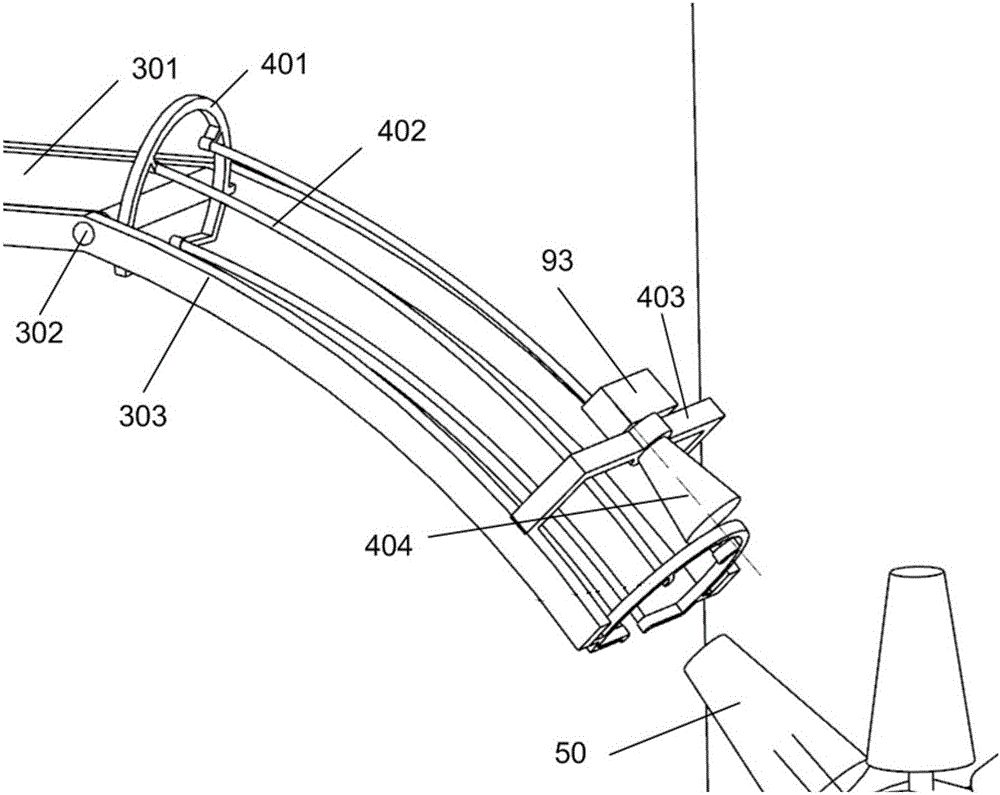

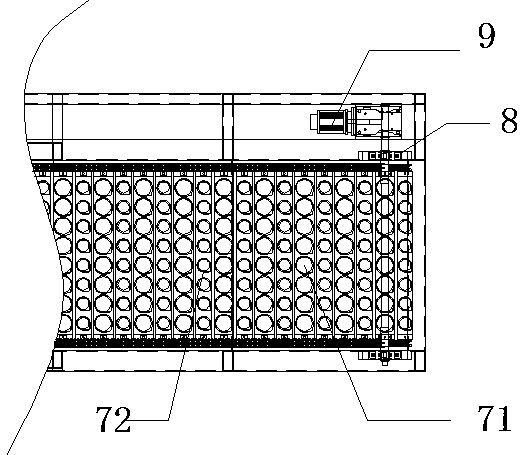

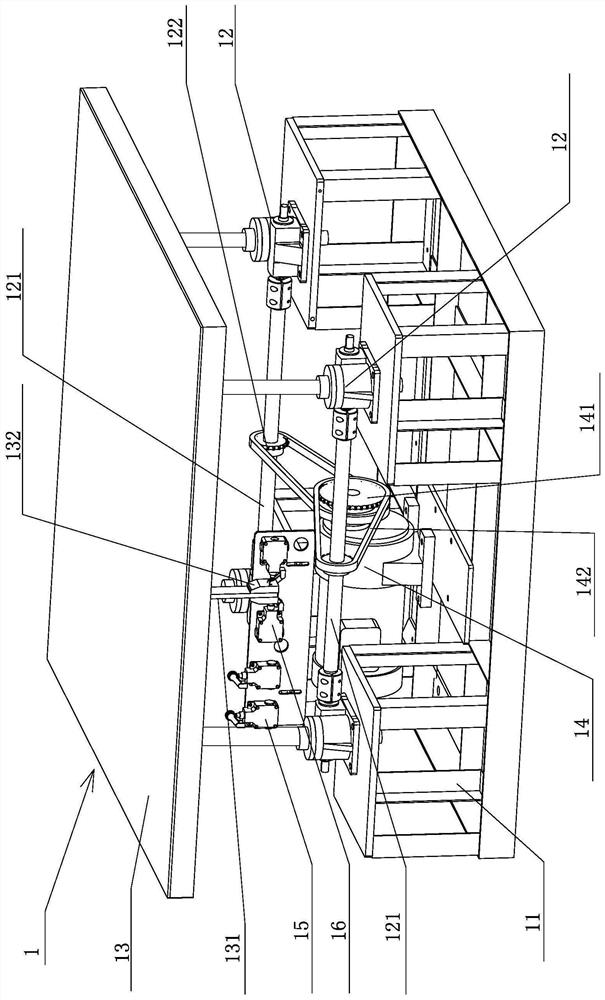

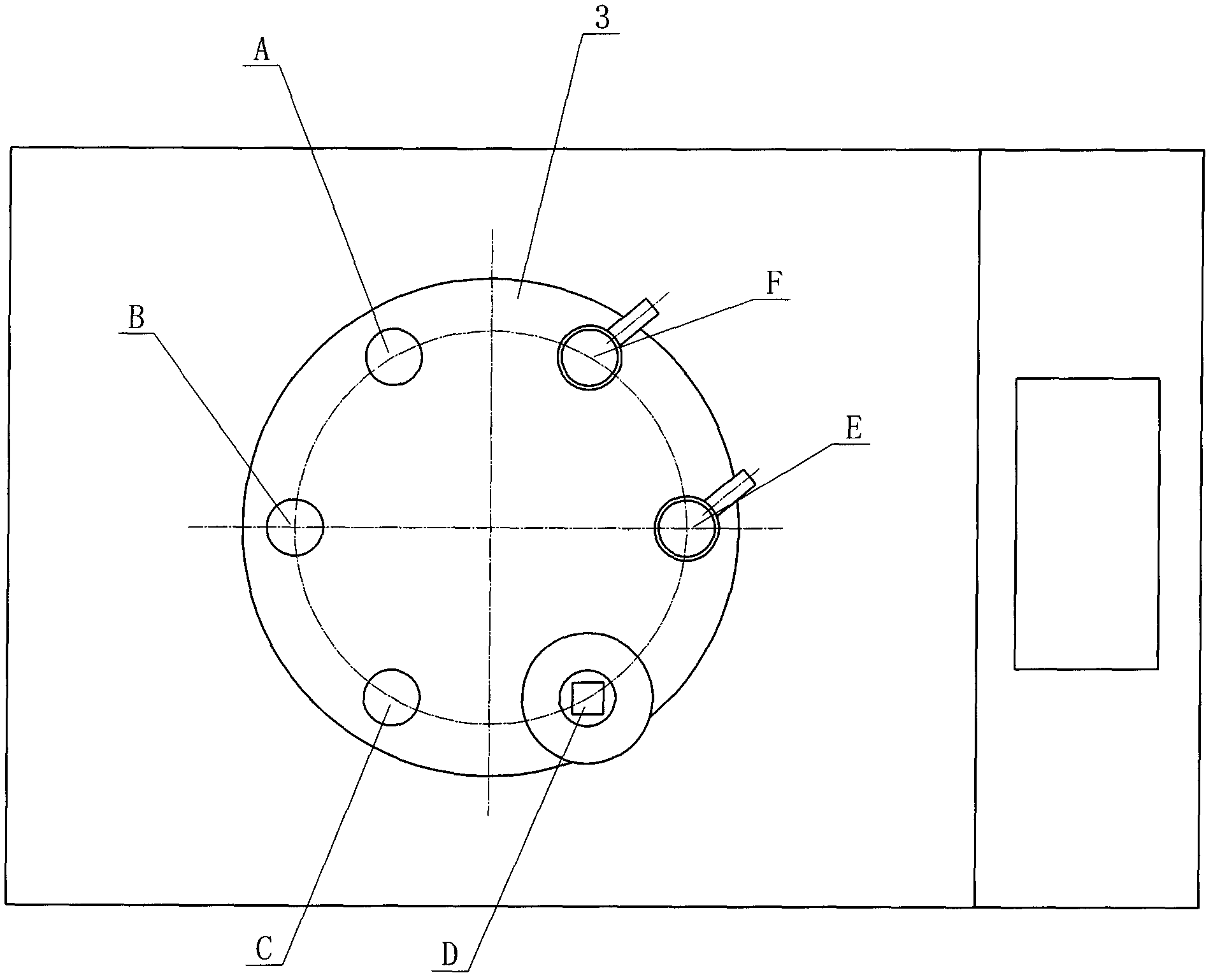

Integral cup feeding and collecting device of curved surface offset printing press

InactiveCN105936176ASolve uncoordinated, labor-inefficient technical problemsRealize into the cupConveyorsWrapping material feeding apparatusEngineeringTower

The invention relates to an integral cup feeding and collecting device of a curved surface offset printing press. The device comprises a main frame, a cup feeding module, a cup mold module, a cup collecting module, a packing module and a control unit; the cup feeding module includes a lifting tower type cup frame module, a fed cup conveying module and a cup separation module; the lifting tower type cup frame module lifts multiple stacked cup bodies to be printed; the cup separation module separates the multiple cup bodies; multiple mold heads of the cup mold module eject up the separated cup bodies; the cup collecting module stacks the printed cup bodies with a set number as a cup set; a packing film conveying module of the packing module feeds a packing film to a second conveying belt of the packing module; a packing component of the packing module wraps the packing film on the cup set for sealing; and the control unit controls the cup feeding module, the cup mold module, the cup collecting module and the packing module to cooperatively act. The integral cup feeding and collecting device can guarantee a cup feeding station and a cup collecting station in one area, and realizes automatic operation coordinated with the printing speed through control of a servo motor.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

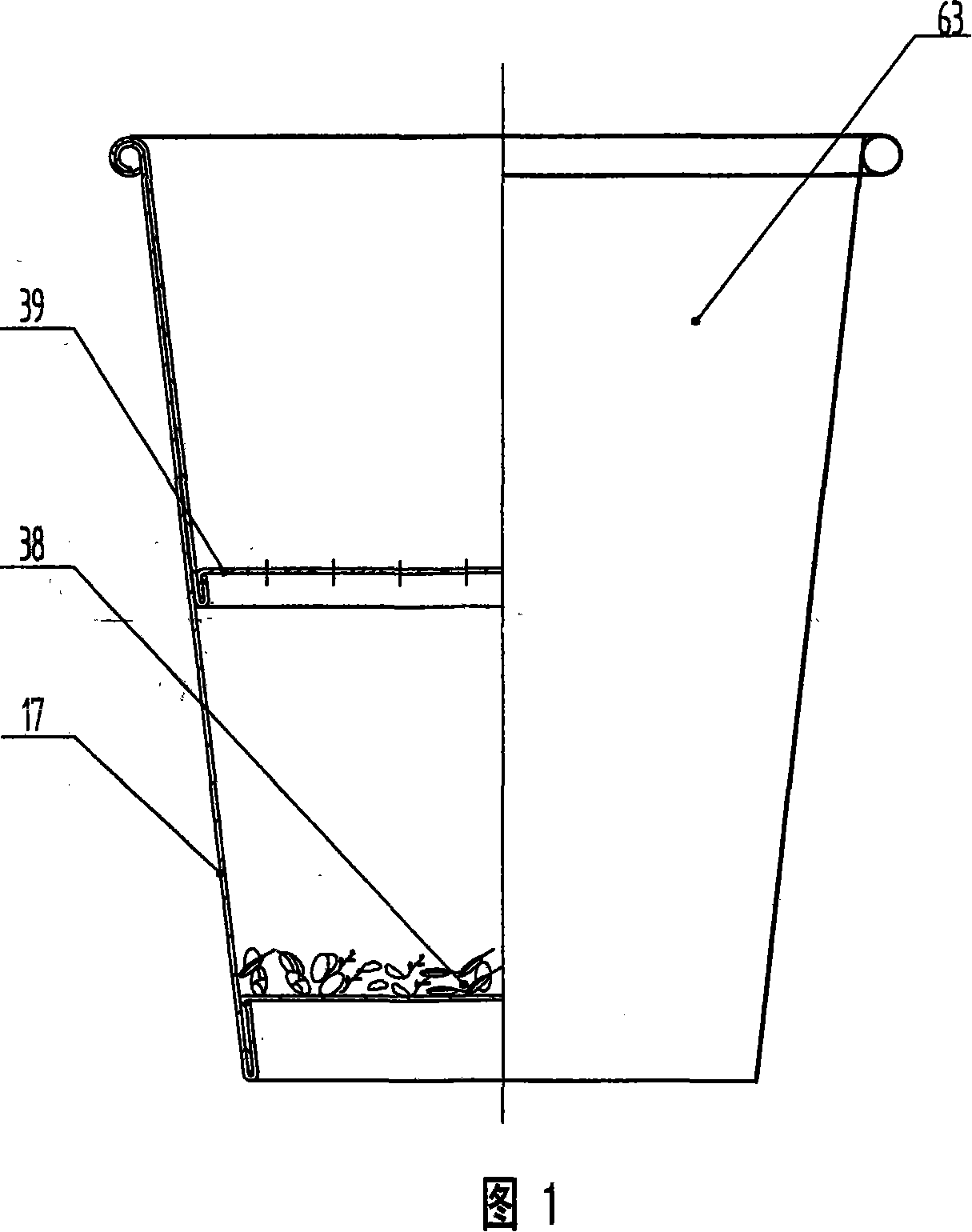

Tea-water separating type paper teacup forming combined machine

InactiveCN101121445AHard wallSimple structurePaper/cardboard wound articlesSolid materialEngineeringTea leaf

The present invention discloses a forming machine set of a paper teacup of separated tea and water, including a forming machine of a monolayer lining cup and a forming machine of a monolayer external cup with a pipeline mechanism arranged between the two forming machines to feed the external cup. A sieve pore mechanism of the cup bottom, an external cup sucking and putting mechanism, a cup feeding mechanism of a turnplate and a tea adding mechanism are arranged on the forming machine of the lining cup. A platform of a lower model is provided with a cup ringing mechanism of a slide bar and an edge curling mechanism of double layer. The teacup produced by the present invention has two layers, the cup bottom of the lining cup provided with the sieve pores and the external cup used to contain the tea. The two layers are rolled together and connected at the cup mouth. The present invention has the advantages of separated tea and water, a solid cup wall, heat insulation, convenience and practicality.

Owner:黄友总

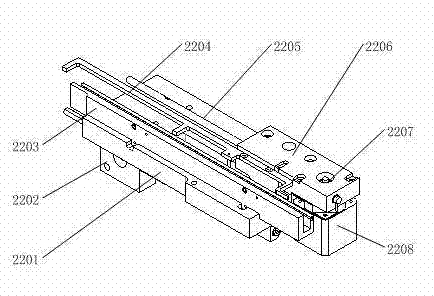

Automatic speed servo adjusting filling and sealing packaging machine

ActiveCN104150032AIncrease productivityReduce production manpowerWrapper twisting/gatheringProduction lineElectric machine

The invention relates to the technical field of packing and sealing machine, in particular to an automatic speed servo adjusting filling and sealing packaging machine comprising a cup placing mechanism, a fruit grain filling device, a filling machine, a film uncoiling mechanism, a sealing machine, a covering device and a speed servo adjusting cup feeding device. The speed servo adjusting cup feeding device comprises a cup conveying chain connected to a speed adjusting servo motor through a servo gear, the cup conveying chain is provided with cup dies with large diameters and cup dies with small diameters at intervals in an adjacent manner, the speed adjusting servo motor controls the operating speed of the cup conveying chain through a PLC, large and small cup mouth sealing switch is implemented, and a large pressing head and a small pressing head are arranged at the sealing pressing port of the bottom of the sealing machine. The machine has the advantages that sealing manners can be adjusted rapidly according to the production requirements, producing efficiency is improved, the design of a production line is integrated, production labor can be saved, purpose of reducing the production cost is achieved, energy consumption is reduced, and the requirements of energy saving and environment protecting are met.

Owner:汕头市中冠机械有限公司

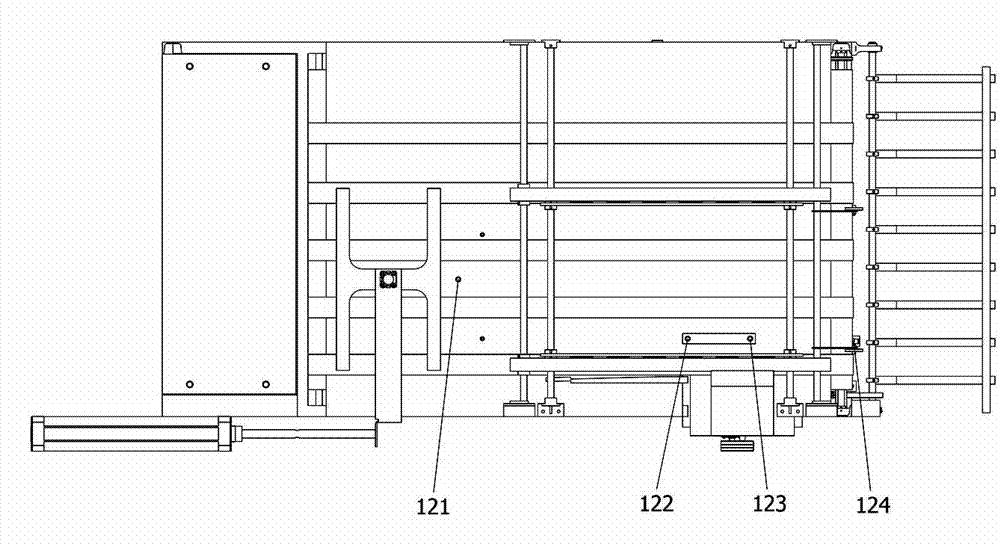

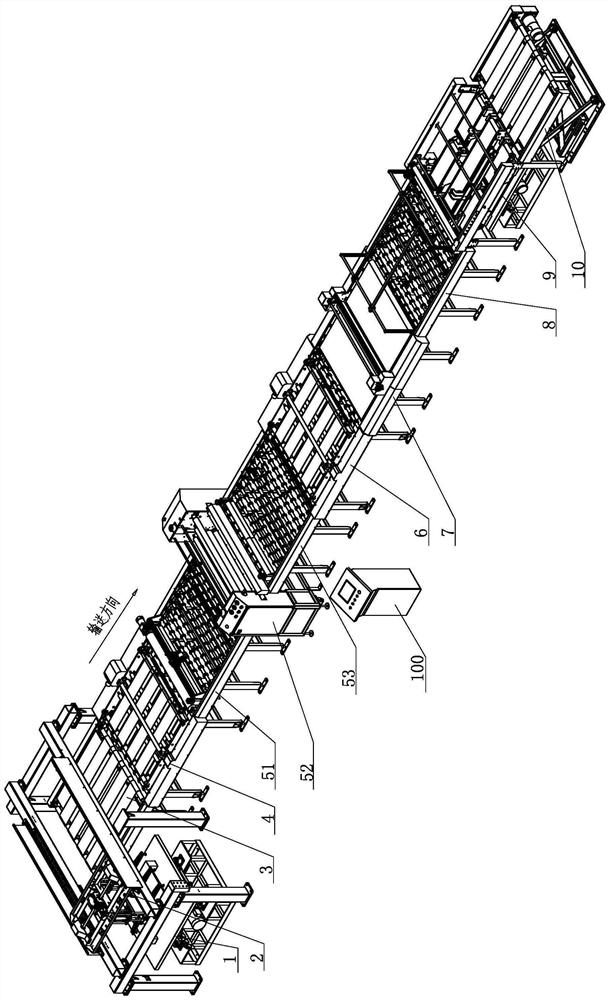

Full-automatic aluminum substrate film laminating and leveling production line

PendingCN112109967AContinuous and smooth operationReduce labor inputPackagingProduction lineMetallurgy

The invention provides a full-automatic aluminum substrate film laminating and leveling production line. The full-automatic aluminum substrate film laminating and leveling production line comprises afeeding lifting table, a suction cup feeding table, a feeding conveying table, a overturning platform 1#, a film laminating mechanism, a overturning platform 2#, a leveling machine, an inspection platform, a plate collecting and weighing platform and a main operation table, wherein the feeding lifting table, the suction cup feeding table, the feeding conveying table, the overturning platform 1#, the film laminating mechanism, the overturning platform 2#, the leveling machine, the inspection platform, the plate collecting and weighing platform and the main operation table are sequentially arranged from the feeding end to the discharging end; the feeding lifting table is used for stacking aluminum substrates; the suction cup feeding table is used for sucking and feeding the single aluminum substrate; the feeding conveying table is used for conveying the aluminum substrates; the overturning platform 1# is used for overturning the conveyed aluminum substrates and enabling the aluminum faces of the aluminum substrates to face upwards and the copper faces of the aluminum substrates to face downwards; the film laminating mechanism is used for laminating films on the overturned aluminum substrates; the overturning platform 2# is used for overturning the laminated aluminum substrates again and enabling the aluminum faces of the aluminum substrates to face downwards and the copper facesof the aluminum substrates to face upwards; the leveling machine is used for leveling the laminated aluminum substrates; the inspection platform is used for inspecting the quality of the aluminum substrates; and the plate collecting and weighing platform is used for weighing, collecting, stacking and conveying the aluminum substrates. According to the full-automatic aluminum substrate film laminating and leveling production line, a series of work such as film laminating, film cutting, thickness measuring, leveling, plate collecting, counting, weighing and packaging can be achieved in a full-automatic and continuous mode, the labor input is reduced, scratches can be effectively prevented, and the film laminating effect is good.

Owner:深圳市龙锋泰自动化有限公司

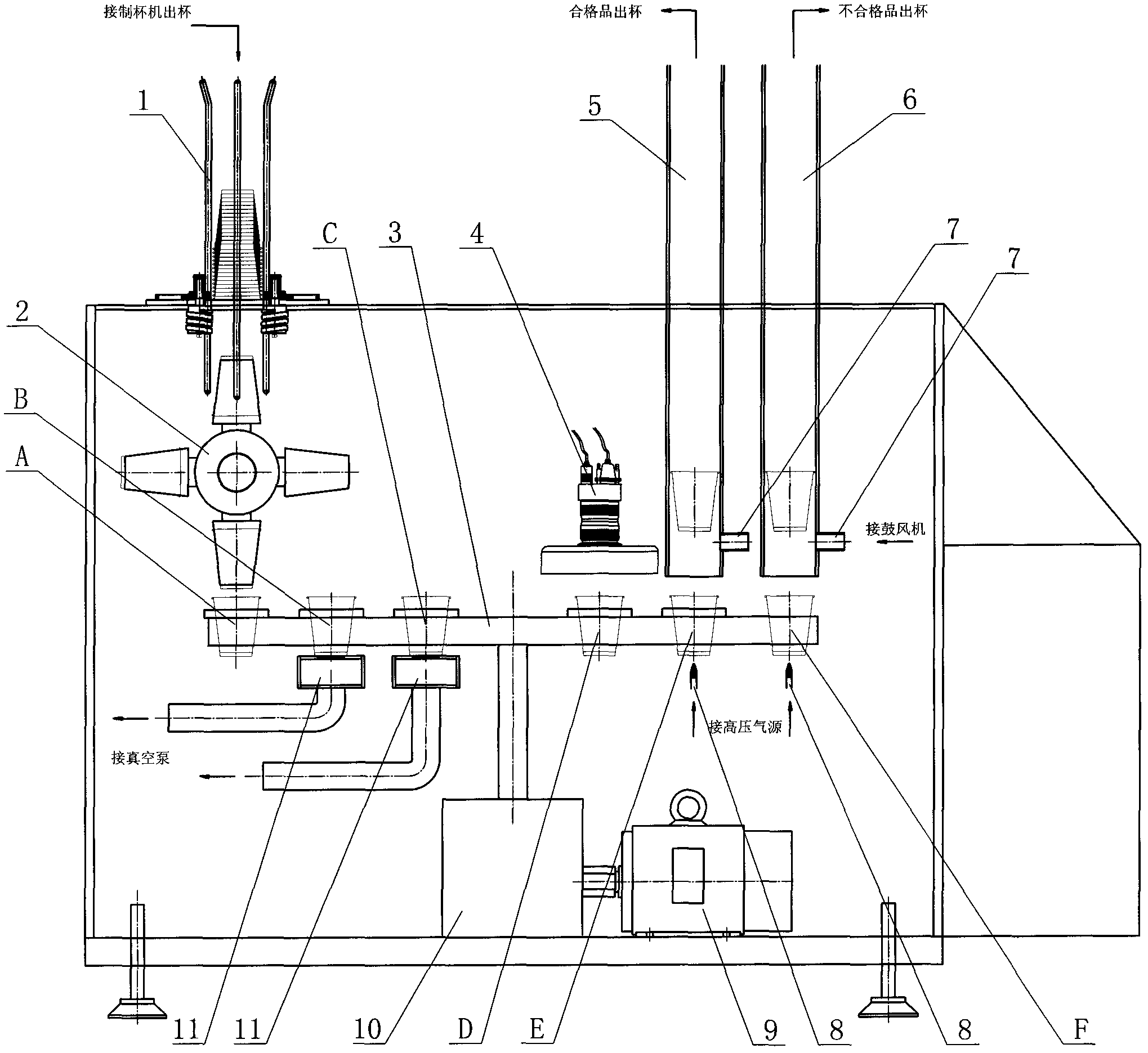

Paper cup detector

InactiveCN102539445ACompact structureComprehensive detection functionOptically investigating flaws/contaminationImage detectionEngineering

The invention discloses a paper cup detector, which comprises a cup feeding device, a cup conveying device, an image detection device and a cup discharging device, and is characterized in that: the cup conveying device is provided with a cup feeding station, a cup bottom force applying station, an image detection station and a cup discharging station; paper cups fed by using the cup feeding device are received on the cup feeding station; the cup bottom force applying station is provided with a force applying device for applying force to a cup bottom; the image detection device is arranged on the image detection station, and is used for performing image detection on paper cups; the cup discharging device is used for receiving cups discharged from the cup conveying device on the cup discharging station; and the cup conveying device is provided with a graduated plate rotating in a graduated way. According to the paper cup detector, paper cups with the defects of cup bottom poor sticking, miss sticking, infirm cup bottom sticking and the like can be detected, the detection function of equipment is perfected, and the detection accuracy of the equipment is increased; and moreover, the structure of the equipment is simple and compact.

Owner:ZHEJIANG SINI MACHINERY

Full-automatic ice cream machine

PendingCN105707401ARealize automatic productionSelf-serviceFrozen sweetsIce CreamsElectric machinery

The invention discloses a full-automatic ice cream machine.The full-automatic ice cream machine comprises horizontal guide rails and a conveying module located on the horizontal guide rails; a cup feeding module and an ice cream outlet module are arranged above the conveying module; the cup feeding module comprises a cup barrel which is vertically installed; the inner side of the cup barrel is provided with a protruding positioning capable of clamping an ice cream cup; the conveying module comprises a telescopic sucker towards the bottom end of the cup barrel and a mobile motor used for driving the conveying module to horizontally move.By means of reasonable design, especially cooperation of the conveying module, the cup feeding module and the ice cream outlet module, of the ice cream machine, the automatic ice cream making effect is achieved, people can convenient make ice cream on their own, the structure is simple, use is easy, and application and popularization of the technology are facilitated.

Owner:刘波梅

Fluid burdening blender and fluid burdening method

ActiveCN103566790AImprove securityEasy to cleanRotary stirring mixersMixer accessoriesThermostatBiomedical engineering

The invention discloses a fluid burdening blender. The fluid burdening blender comprises a rack, wherein the rack is provided with a touch screen for setting various data, a charging cup feeding device for an automatic feeding charging cup, a thermostat for keeping constant temperature of a fluid, a fluid feeding device for conveying the fluid, a practical receiving volume verifying device for judging whether the practical feeding volume fits an error range, a stirring device for stirring the fluid in the charging cup, and a stirring head cleaning device for cleaning. The fluid burdening blender disclosed by the invention can judge whether the practical feeding volume fits the error range through the practical receiving volume verifying device in operation, the practical feeding volume of each burdening is exactly fed, the accuracy of the burdening is improved, the matching precision is stable, and a self-diagnostic function is realized; the fluid burdening blender does not use a pressure storage tank, thereby being good in safety and convenient to clean. In addition, the invention also provides a fluid burdening method.

Owner:DONGGUAN ZHILI AUTOMATION EQUIP

Chinese traditional medicine granule medicine cup automatic conveyer

The invention is a Chinese medicinal particle medicine cup automatic transporting device, including: machine cup feeding device, cup separating device, cup sending device and turntable mechanism. Its connecting mode: the cup separating device is situated on the right side of the cup feeding device, the cup sending device is situated on the right side of the cup separating device, and the turntable mechanism is situated on the bottom side of the cup sending device. It has very strong practical value, solves the technical problems of feeding, separating and transporting cups, replacing the courses of artificially transporting medicine and packaging with paper bags, completely changes the mode of packaging traditional Chinese medicine, and provides an important technical link for automating Chinese medicine distribution.

Owner:SHANGHAI JIAO TONG UNIV

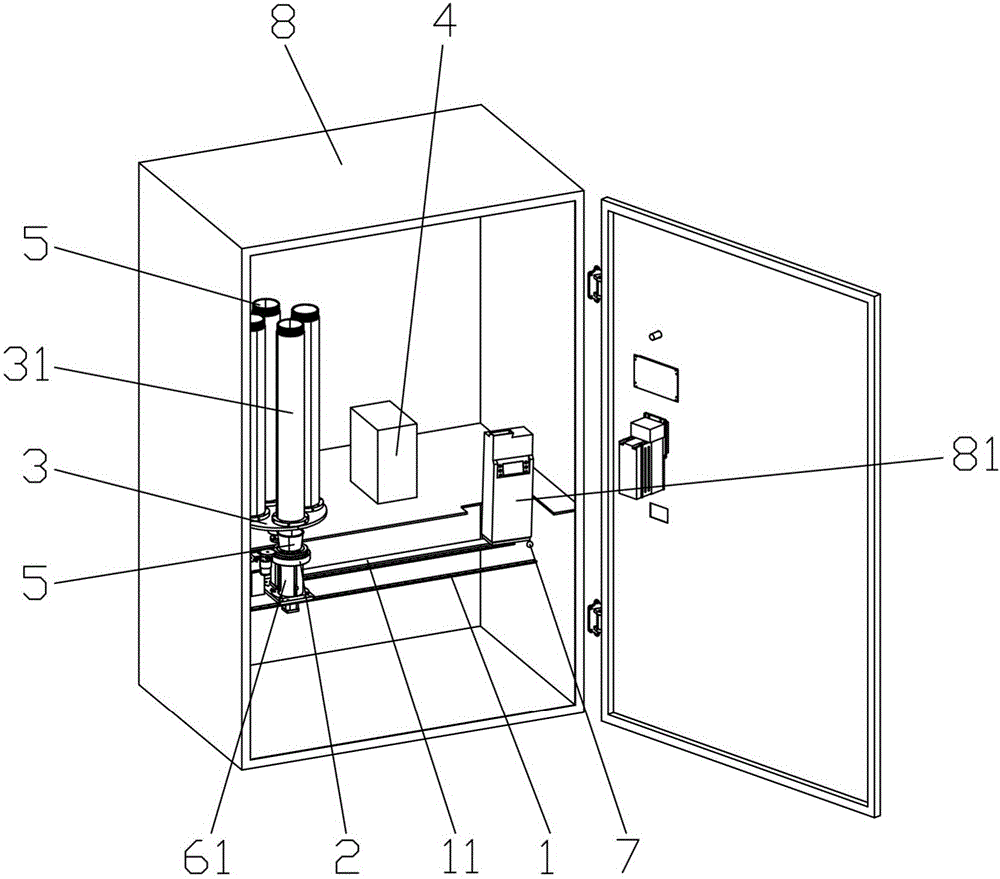

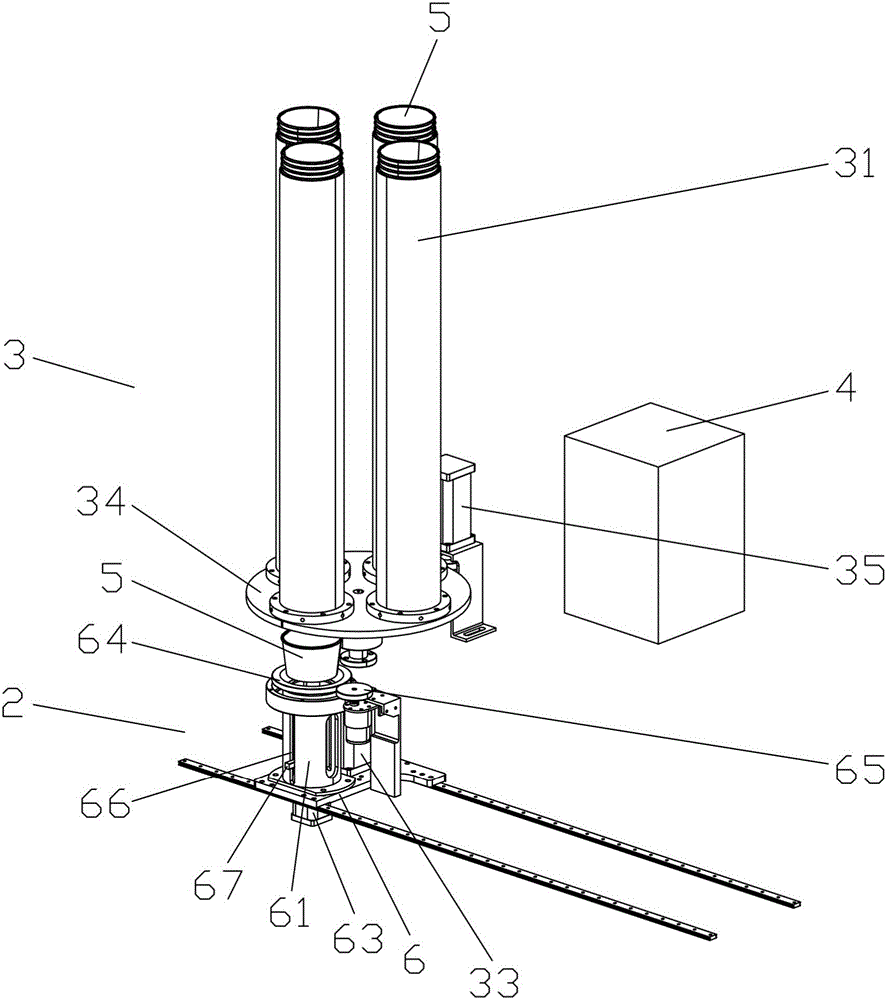

Automatic assembling system of plunger main cylinder sealing leather cup

PendingCN109807603ACompact structureSufficient source of gasSpraying apparatusMetal working apparatusEngineeringPlunger pump

An automatic assembling system of a plunger main cylinder sealing leather cup comprises a rack. A plunger pump oil coating mechanism used for coating a cylinder body with oil, a leather cup arrangingmechanism used for pushing the leather cup into the cylinder body and a leather cup flattening mechanism used for flattening edge warp of the leather cup in the main cylinder. A leather cup feeding mechanism is arranged above the leather cup arranging mechanism. The leather cup feeding mechanism is provided with four feeding openings and contain four kinds of leather cups to be assembled. A visualsystem is further installed on the leather cup feeding mechanism. The visual system conducts visual detection when the leather cup feeding mechanism feeds leather cups to the detection position. Qualified leather cups are controlled through the air cylinder to fall onto the leather cup arranging mechanism, and the air cylinder blows air to enable unqualified leather cups to bound into a waste box. A cylinder body servo feeding mechanism is arranged in front of the leather cup arranging mechanism, and the cylinder body servo feeding mechanism fixes the cylinder body and conveys the cylinder body to the installation position.

Owner:HANGZHOU WOLEI INTELLIGENT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com