Automatic assembling system of plunger main cylinder sealing leather cup

A technology of sealing leather cups and automatic assembly, which is applied in injection devices, metal processing, metal processing equipment, etc., can solve the problems of affecting the sealing performance of the master cylinder, warping edges, and low efficiency of manual assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

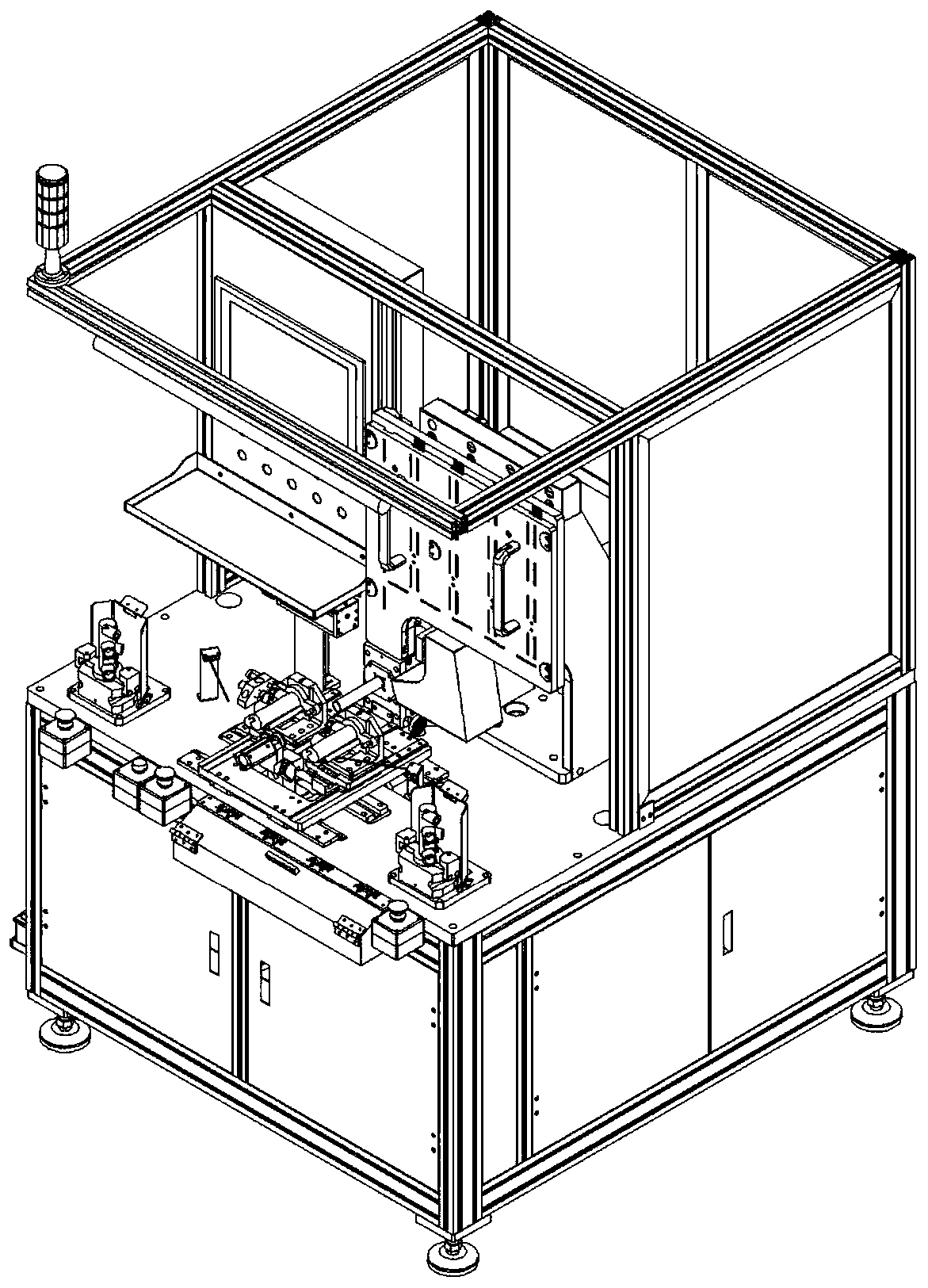

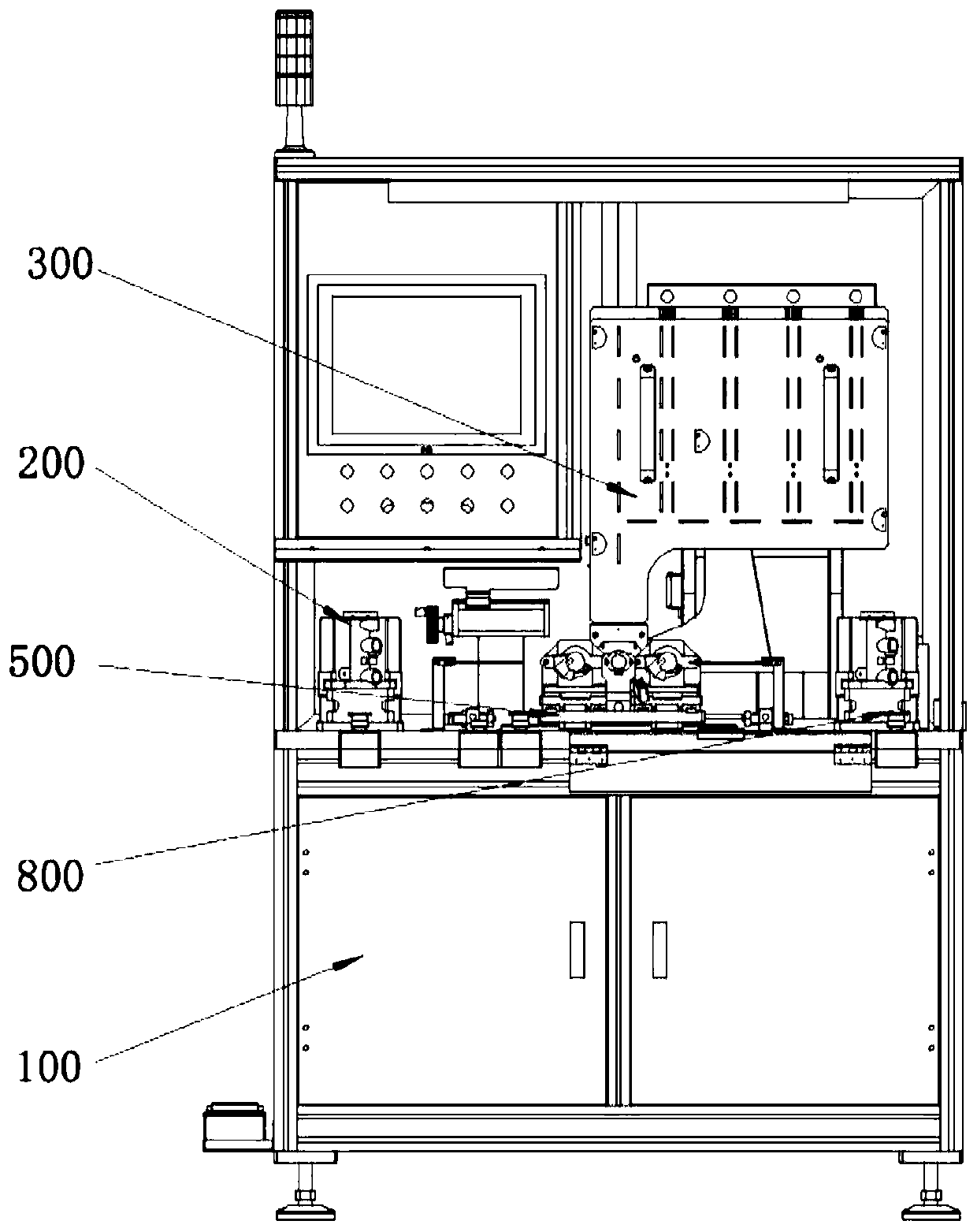

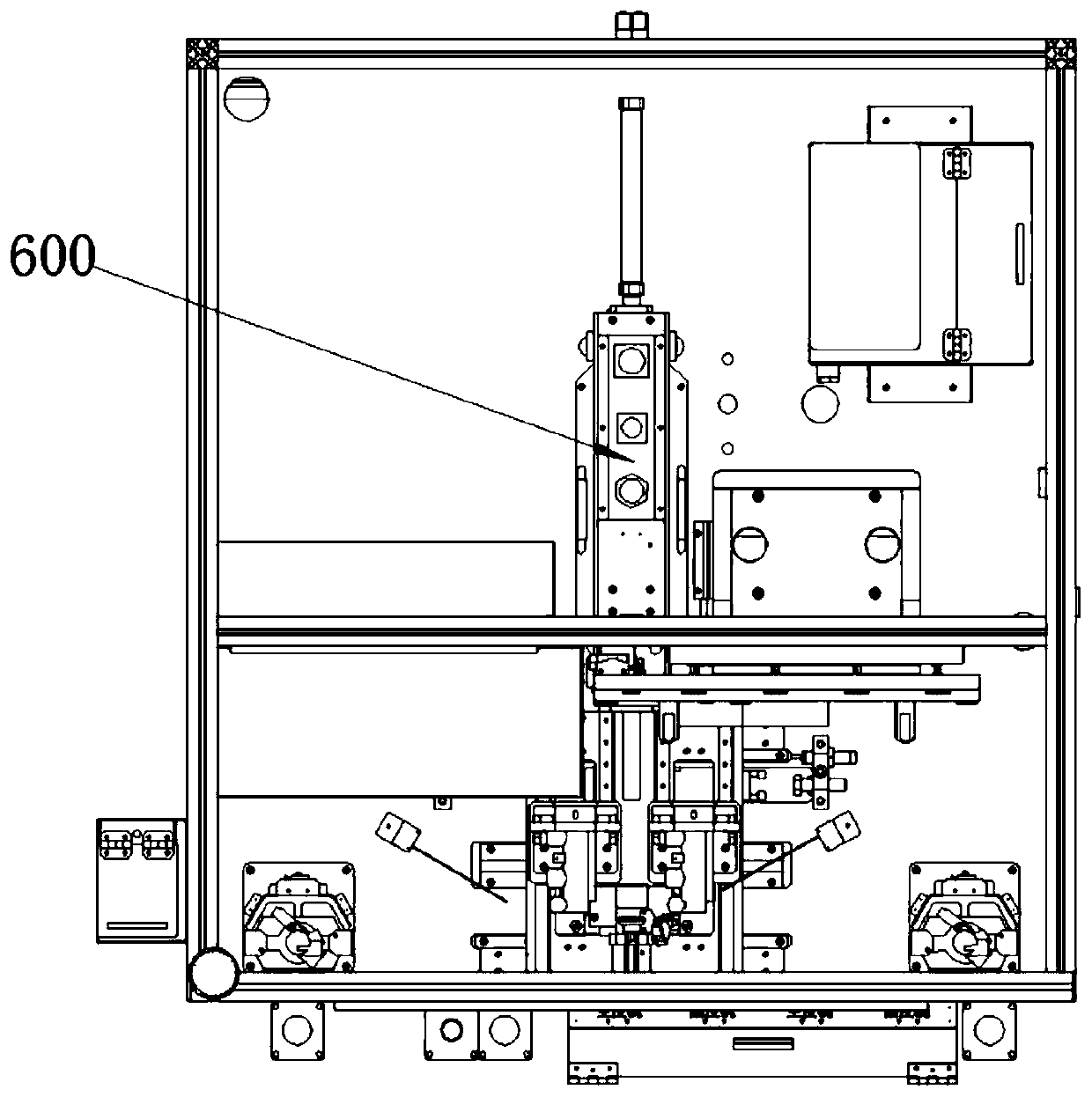

[0029] An automatic assembly mechanism for a plunger master cylinder seal cup, including a stand 100 for placing various mechanisms, a plunger pump oiling mechanism 200 placed on the left side of the stand 100 for cylinder oiling, and a cylinder at the bottom For flushing oil and controlling the amount of oil, the cup feeding mechanism 300 is placed in the middle of the stand 100, the cylinder servo feed mechanism servo module installation assembly 400 includes a servo motor mechanism and the cylinder servo feed mechanism 500 cooperates to complete the cylinder displacement feed. Vision system 700 carries out visual inspection after leather cup is delivered to detection position by leather cup feeding mechanism 300, and qualified leather cup will fall on the leather cup loading mechanism 600 by cylinder control, and unqualified leather cup is blown into waste box by cylinder blowing. The leather bowl mechanism 800 is installed on the right side of the stand 100, and the straig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com