Paper cup detector

A technology for inspection machines and paper cups, which is applied in the direction of optical testing for flaws/defects, and can solve problems such as uncompact structure, large floor space, and water leakage from paper cups and bowls.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

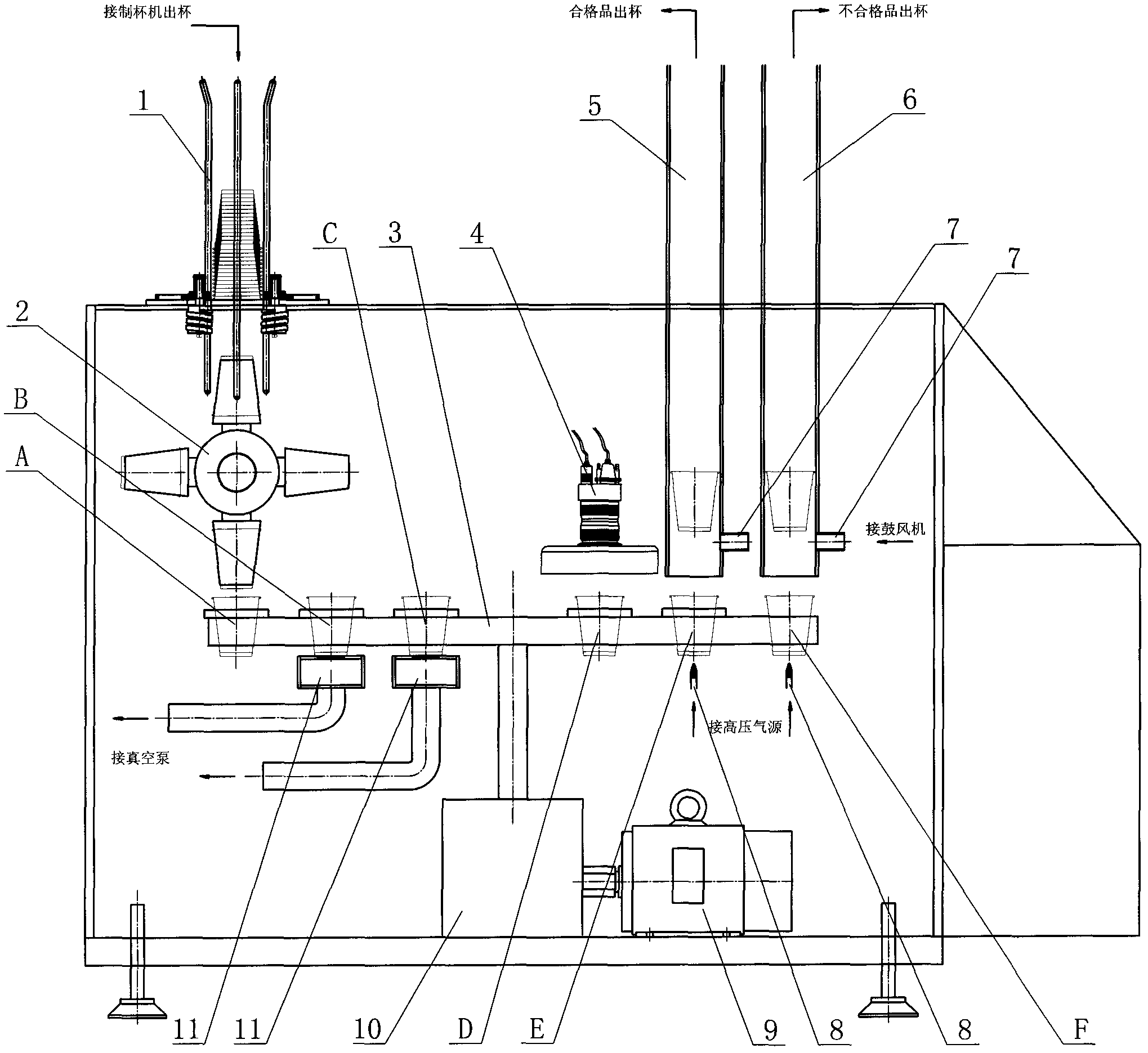

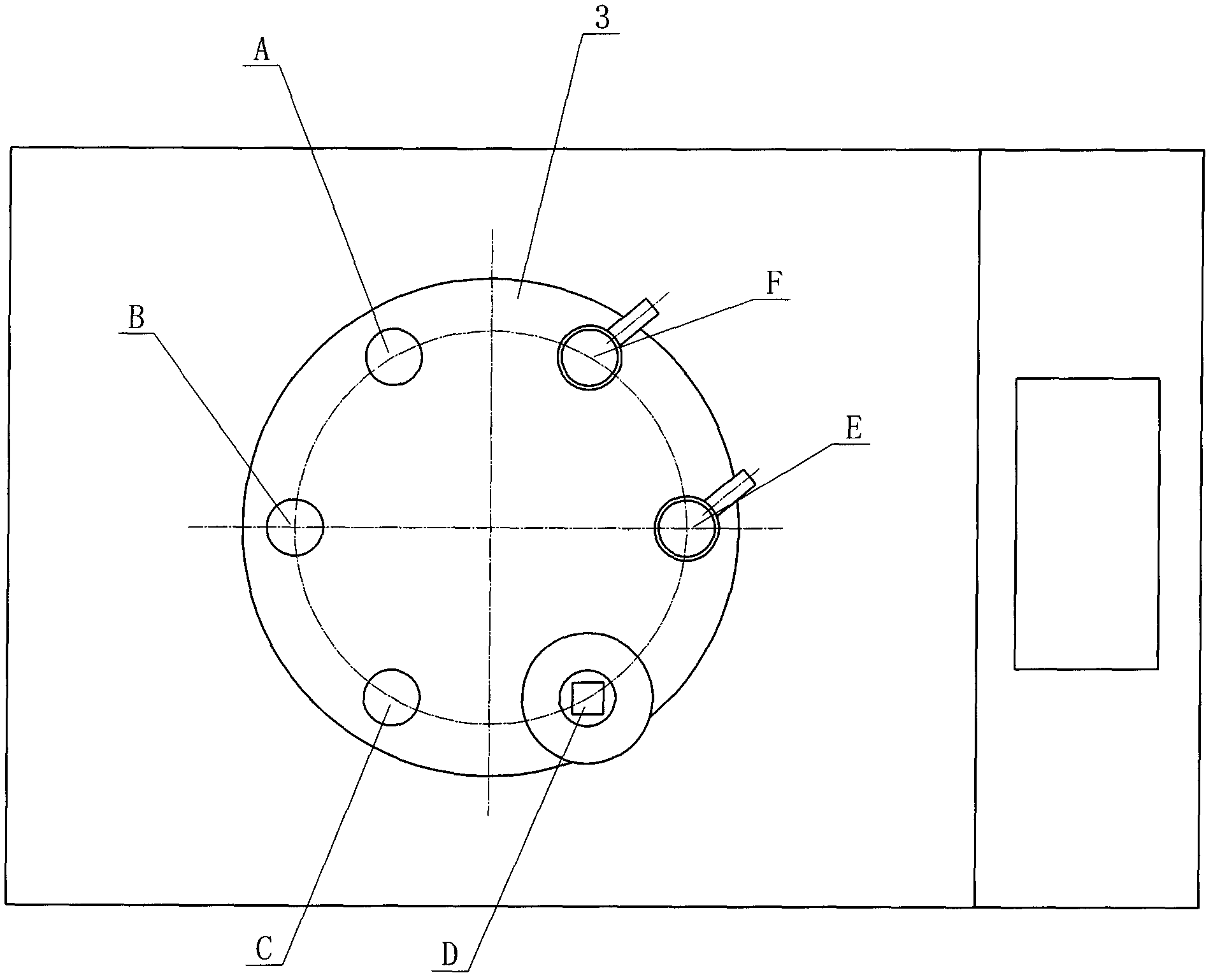

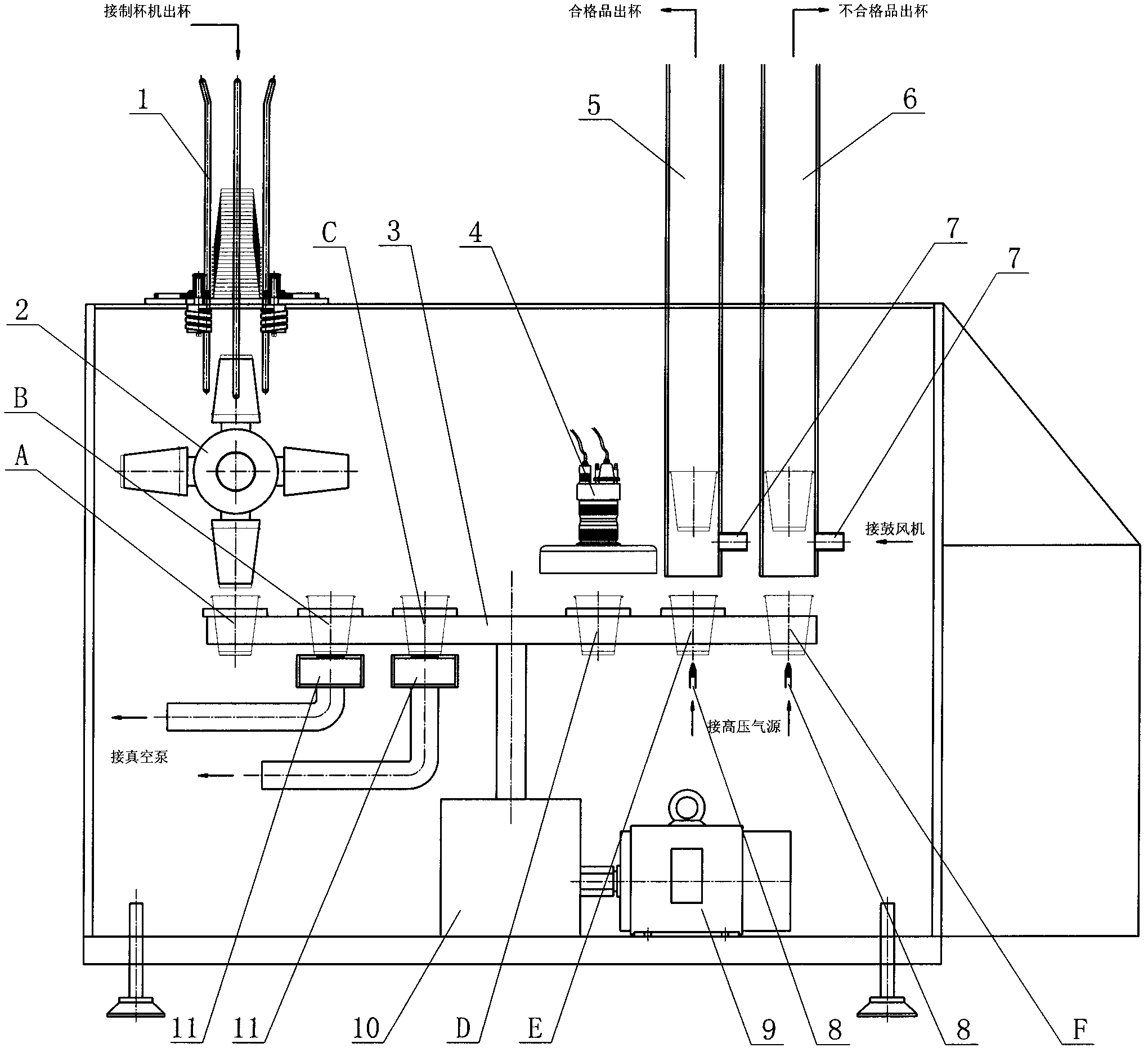

[0012] Reference figure 1 , 2 , The paper cup and bowl inspection machine of the present invention includes a cup feeding device, a cup feeding device, an image detection device 4 and a cup output device. The cup feeding device includes a rotating cup receiving table 2, which is removed from the cup storage barrel 1. The paper cup is received inside. The cup feeding device has an indexing plate 3 that rotates. The indexing plate 3 is connected to the indexing box 10 and is driven by a motor 9. The indexing plate can also be directly driven by a servo motor. 3 There are a total of six stations, including a cup-in station A, two cup-bottom force stations B and C, an image detection station D, and two cup-out stations ( A qualified product cup-out station E, and a non-conforming product cup-out station F); the cup-in station A receives the paper cups sent by the rotating cup receiving table 2, and sets the force at the bottom of the cup at stations B and C There is a force applyin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com