Full-automatic aluminum substrate film laminating and leveling production line

A technology for aluminum substrates and production lines, which is applied in the field of fully automatic aluminum substrate coating and leveling production lines, can solve the problems of single leveling function, high labor cost, and poor automaticity of coating, and achieve continuous and stable operation, reduce labor input, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

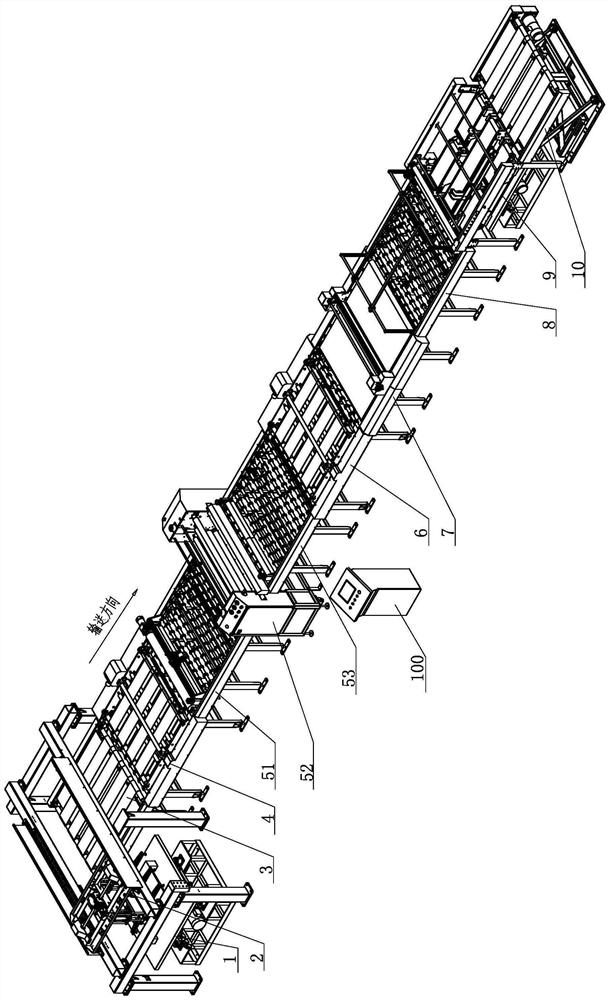

[0046] The invention relates to a fully automatic aluminum substrate coating and leveling production line, such as figure 1 As shown, it includes loading and unloading platform 1, suction cup loading platform 2, feeding and conveying platform 3, 1# turning platform 4, film covering mechanism 5 (including film feeding platform 51. Laminating host 52, lamination discharge platform 53), 2# overturning platform 6, leveling machine 7, inspection platform 8, board receiving and weighing platform 9, lifting and conveying platform 10 and the total operation console 100.

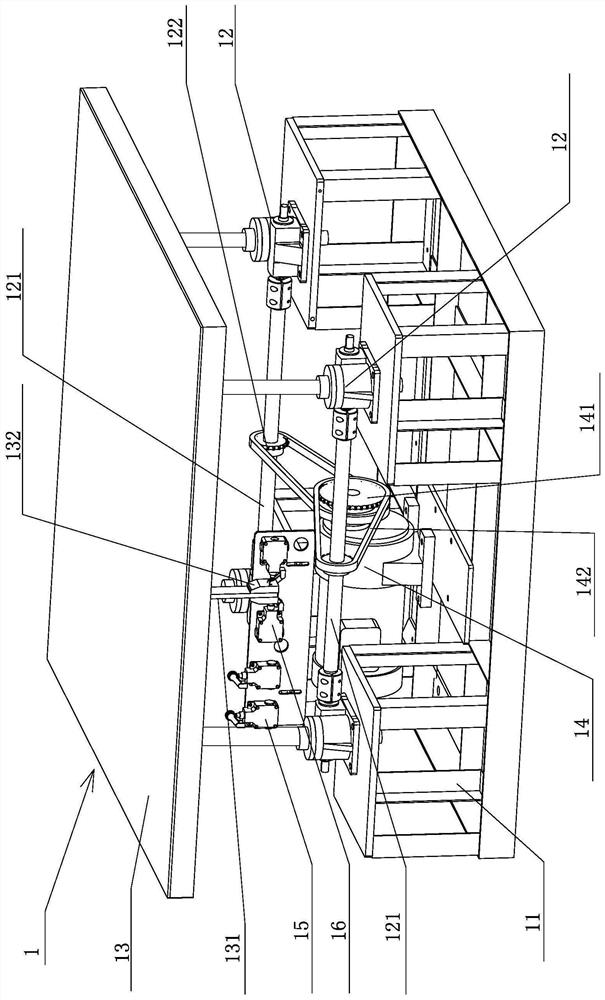

[0047] like figure 2 As shown, the function of the feeding lifting platform 1 is to lift and put the aluminum substrates to be coated here into piles, so as to prepare for the sucker feeding in the next process. placed in the form below. Feeding lifting platform 1 comprises load...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com