Automatic glass online lamination method

A fully automatic, glass production line technology, applied in the direction of chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., can solve the problems of easy breakage of thin glass handling, high labor cost investment, poor lamination automaticity, etc., to achieve long-term The effect of time continuous stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with embodiment the present invention is further described.

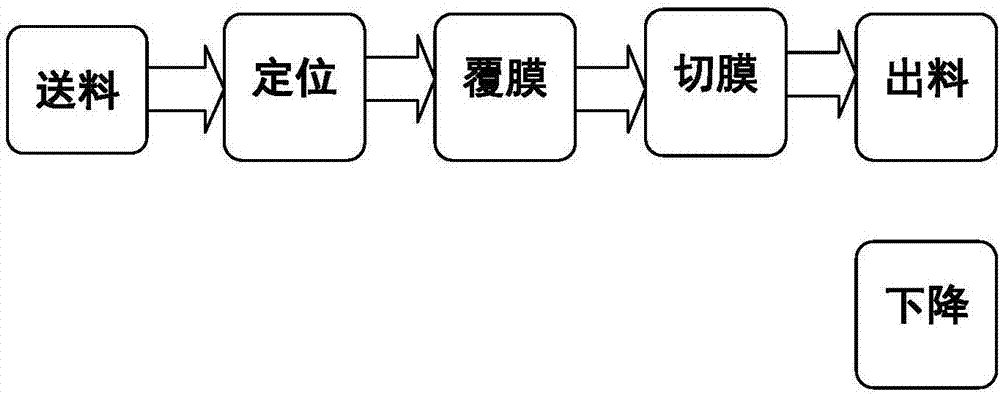

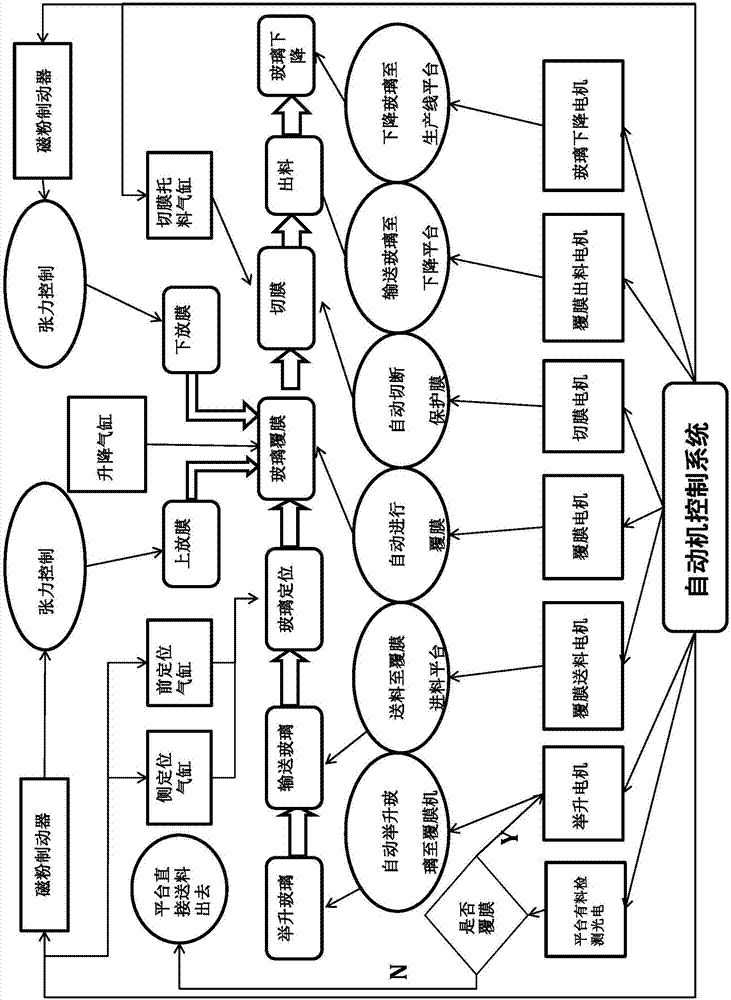

[0042] Such as figure 1 , Figure 4 Shown, a kind of automatic glass online coating method comprises the following steps:

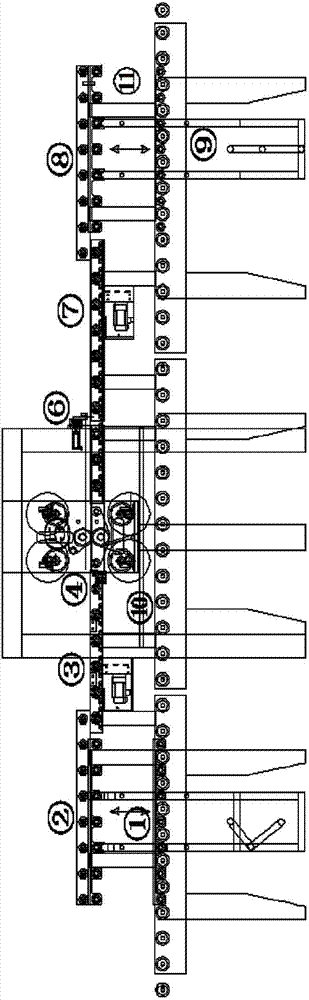

[0043] A. Set the feeding lifting platform 1, feeding platform 2, coating device 3, film cutting mechanism 4, discharging platform 5, discharging lifting platform 6, feeding platform 2, coating device 3, cutting device on the glass production line Membrane mechanism 4 and discharge platform 5 are set above the glass production line. Feeding lifting platform 1 and discharging lifting platform 6 are respectively installed in the glass production line. Loading lifting platform 1 can be lifted to feeding platform 2, and discharging lifting platform 6 It can be raised to the discharge platform 5;

[0044]B. Detect whether there is glass on the feeding platform 7 of the glass production line at the position of the feeding lifting platform 1. If there is, wait for the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com