Patents

Literature

37results about How to "Continuous and smooth operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

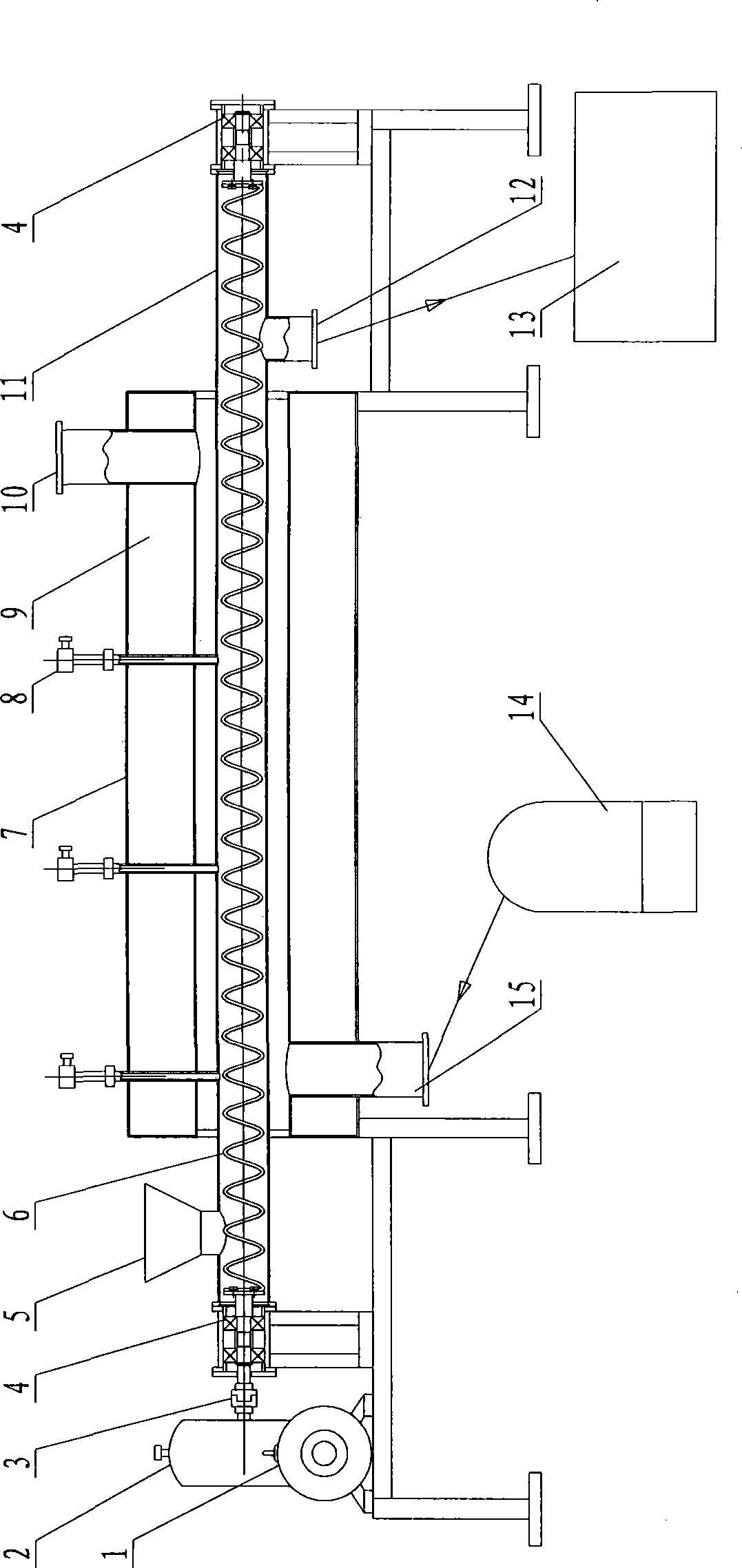

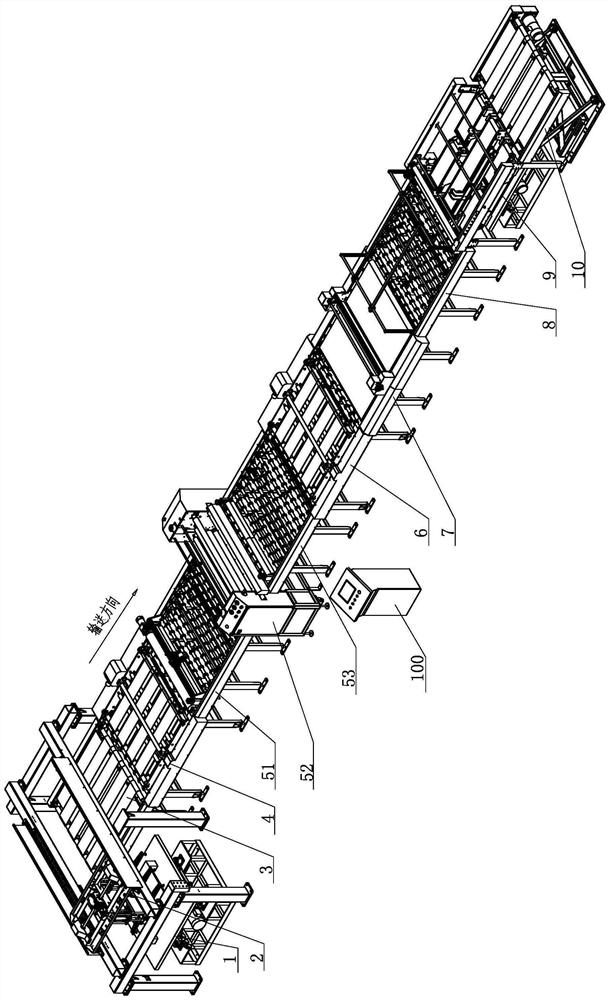

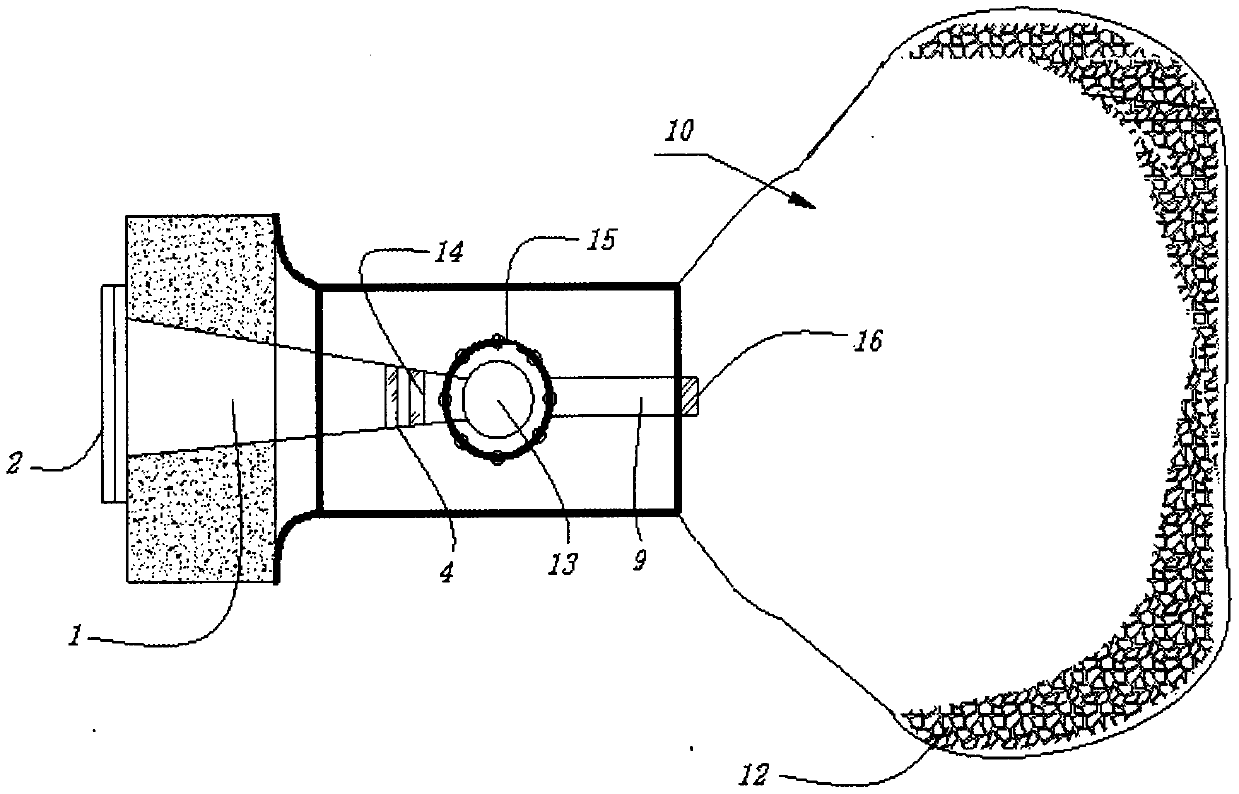

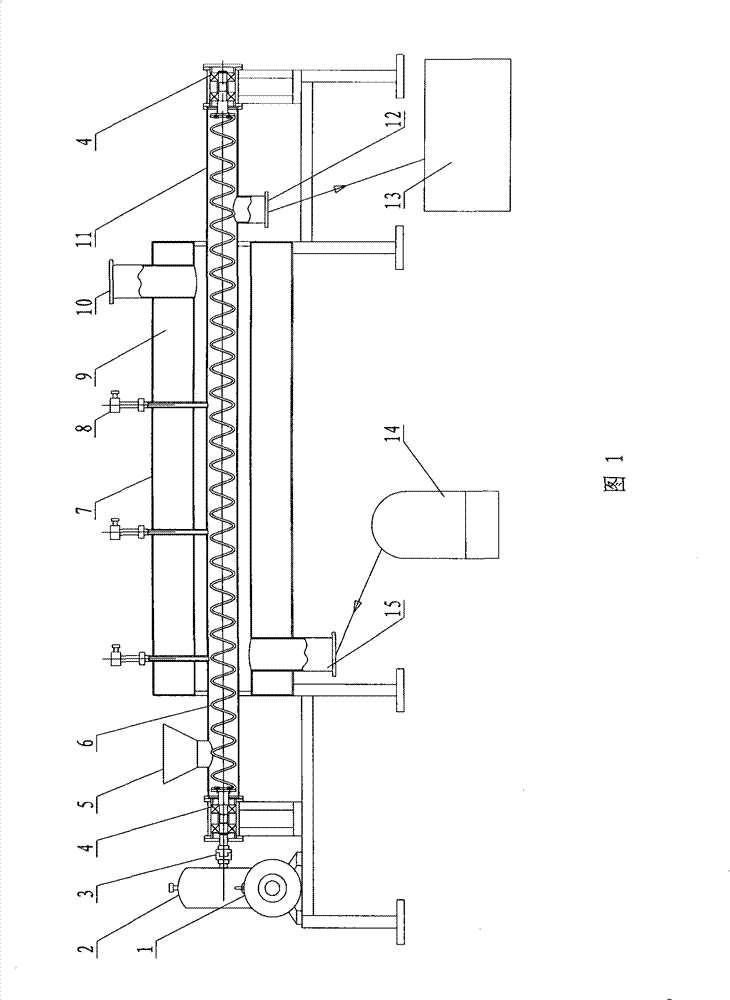

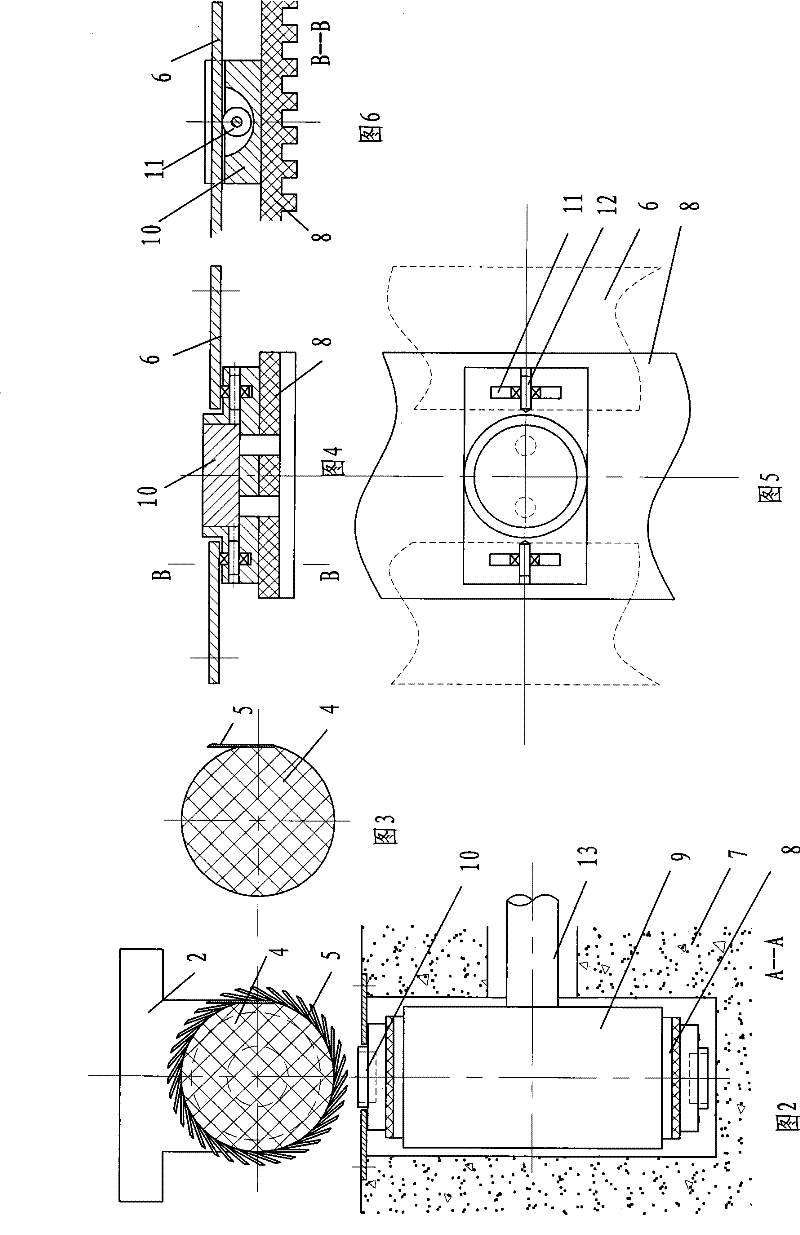

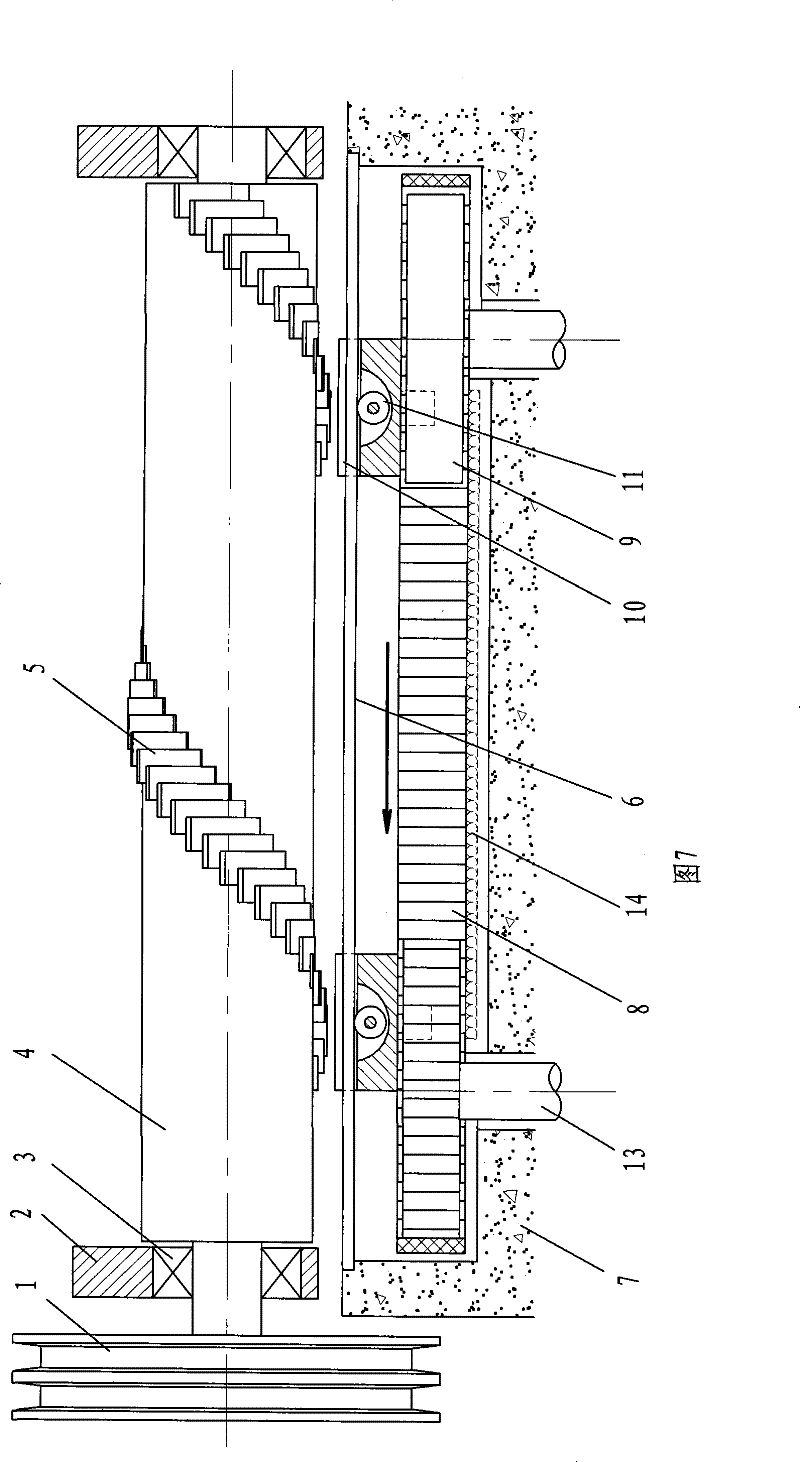

Biomass continuous pyrolysis charing apparatus with flexible spiral conveying apparatus

The invention discloses a biomass continuous pyrogenation carbonizing apparatus provided with a flexible screw conveying appliance, which comprises a motor (1), a coupling (3), bearings (4), a flexible screw spring (6), a pyrolysis tube (11), a feed inlet (5), a carbon discharging outlet (12) and a heating device; one end of the pyrolysis tube (11) is provided with the feed inlet (5) communicatedwith the inner cavity of the pyrolysis tube (11), and the other end is provided with the carbon discharging outlet (12) communicated with the inner cavity thereof; the inner cavity of the pyrolysis tube (11) is inserted with the flexible screw spring (6) along the axial direction; one end of the flexible screw spring (6) is connected with the output shaft of the motor (1) through the first bearing (4) and the coupling (3), and the other end is supported on the second bearing (4); and the outer side of the pyrolysis tube (11) is provided with the heating device for heating the pyrolysis tube (11). The biomass continuous pyrogenation carbonizing apparatus is easily suitable for long-distance convey and has simple structure.

Owner:SOUTH CHINA AGRI UNIV

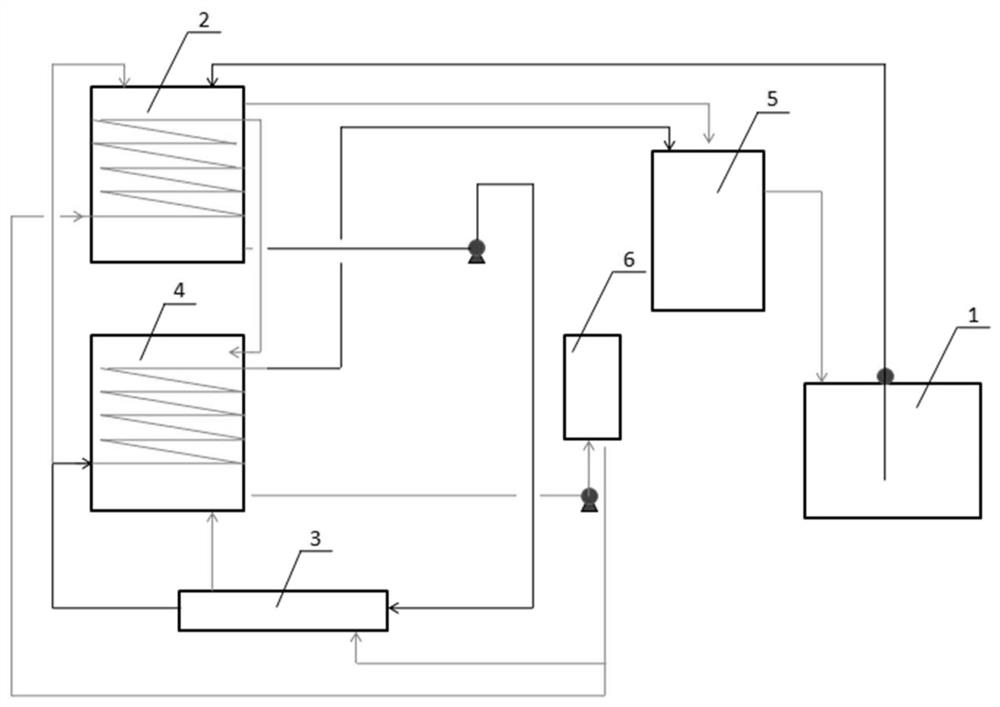

Low-pressure saturated steam recycling equipment

The invention discloses low-pressure saturated steam recycling equipment, which includes a heat accumulator, a steam drum and a steam turbine, wherein the heat accumulator is communicated with a high-pressure section of the steam turbine, so as to provide first low-pressure saturated steam for the high-pressure section of the steam turbine; the steam drum is communicated with a low-pressure section of the steam turbine, so as to provide second low-pressure saturated steam for the low-pressure section of the steam turbine; and the pressure and temperature of the first low-pressure saturated steam are both higher than those of the second low-pressure saturated steam. According to the low-pressure saturated steam recycling equipment disclosed by the invention, the first low-pressure saturated steam is conveyed to the high-pressure section of the steam turbine by the heat accumulator, the second low-pressure saturated steam is conveyed to the low-pressure section of the steam turbine by the steam drum, the first low-pressure saturated steam is mixed with the second low-pressure saturated steam after acting in the steam turbine for a period, and the first low-pressure saturated steam and the second low-pressure saturated steam continues acting after mixing, so that the continuous and stable running of the steam turbine is facilitated, and meanwhile the low-pressure saturated steam at different pressure and temperature levels are fully utilized.

Owner:思安新能源股份有限公司

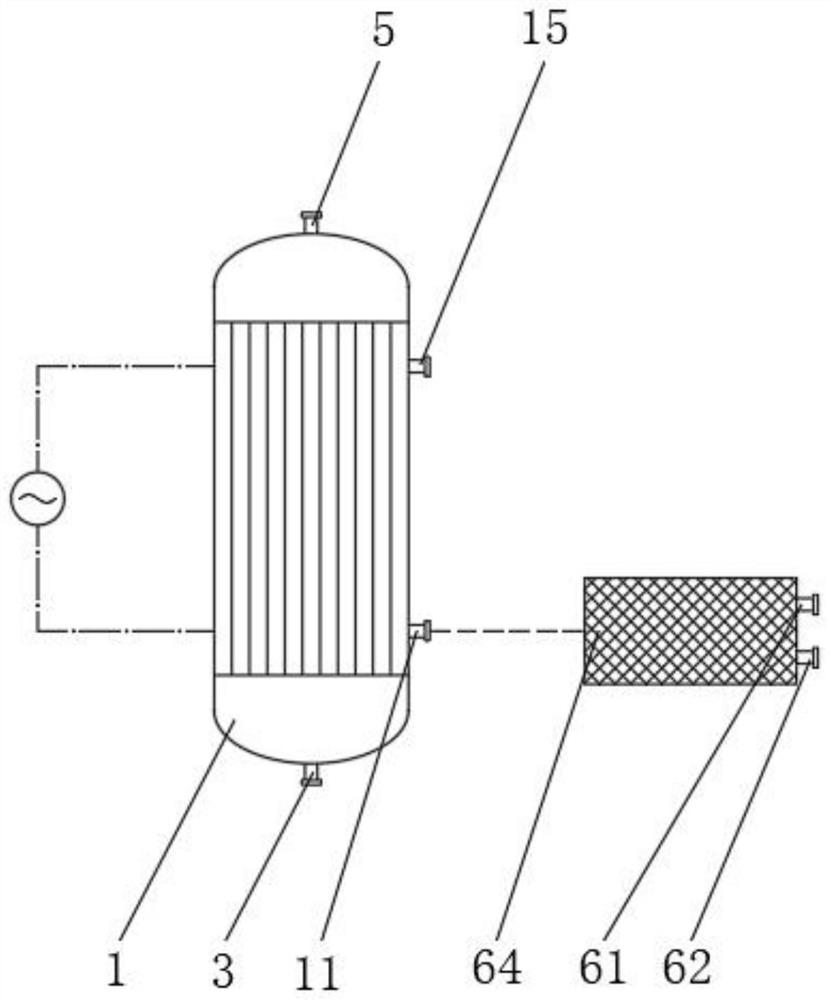

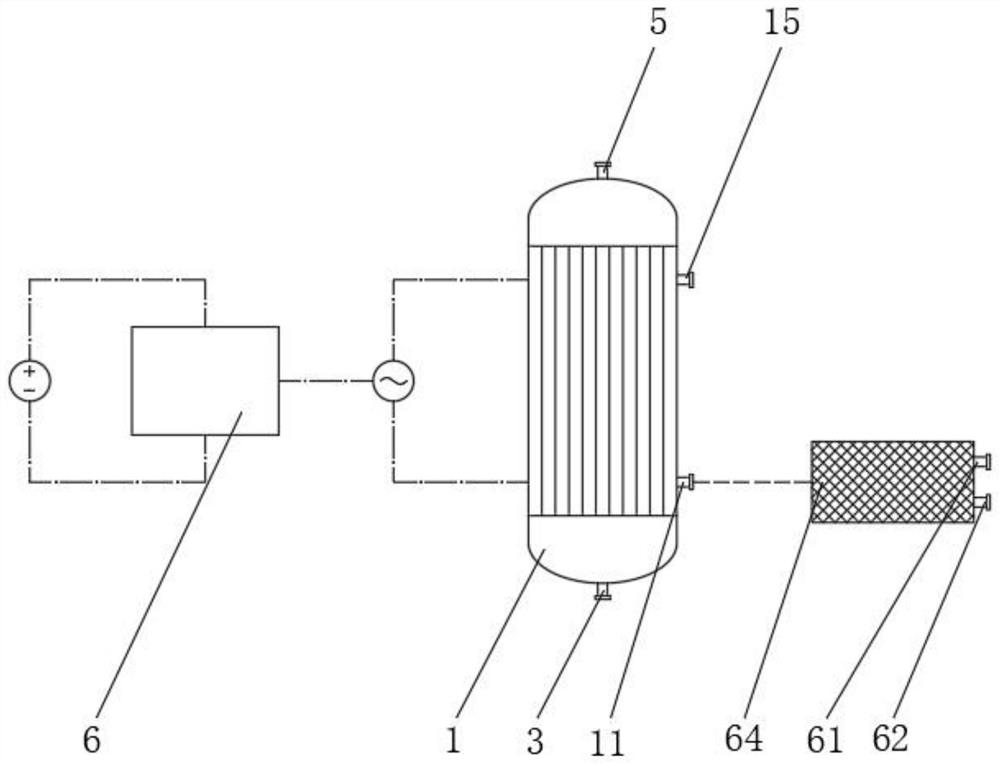

Electrical synergistic heat supply reforming reaction system

ActiveCN112265962AContinuous and smooth operationFast startupHydrogenHydrogen/synthetic gas productionThermodynamicsFlue gas

The invention discloses an electric synergistic heat supply reforming reaction system which comprises a reforming reactor and an electric synergistic heat supply device, a flue gas convection area anda reforming reaction area are formed in the reforming reactor, and the flue gas convection area comprises a flue gas distribution device and a flue gas flow guide device. According to the electric synergistic heat supply reforming reaction system, by switching the heat contribution ratio of electric heating to flue gas heating, the reactor continuously and stably operates when either electric power or fuel gas is insufficient in supply; electric synergistic heat supply is adopted, the reforming reactor is high in starting speed, and the reactor can enter a stable production state within a fewminutes; convection smoke is generated in a non-open-fire catalytic combustion mode, the combustion temperature of catalytic combustion is low, and generation of NOx gas is remarkably reduced; meanwhile, an ultra-high-temperature area in the reactor is avoided, the requirement for reactor material selection is lowered, the service life of equipment is prolonged, and wide application prospects areachieved.

Owner:庄焱法

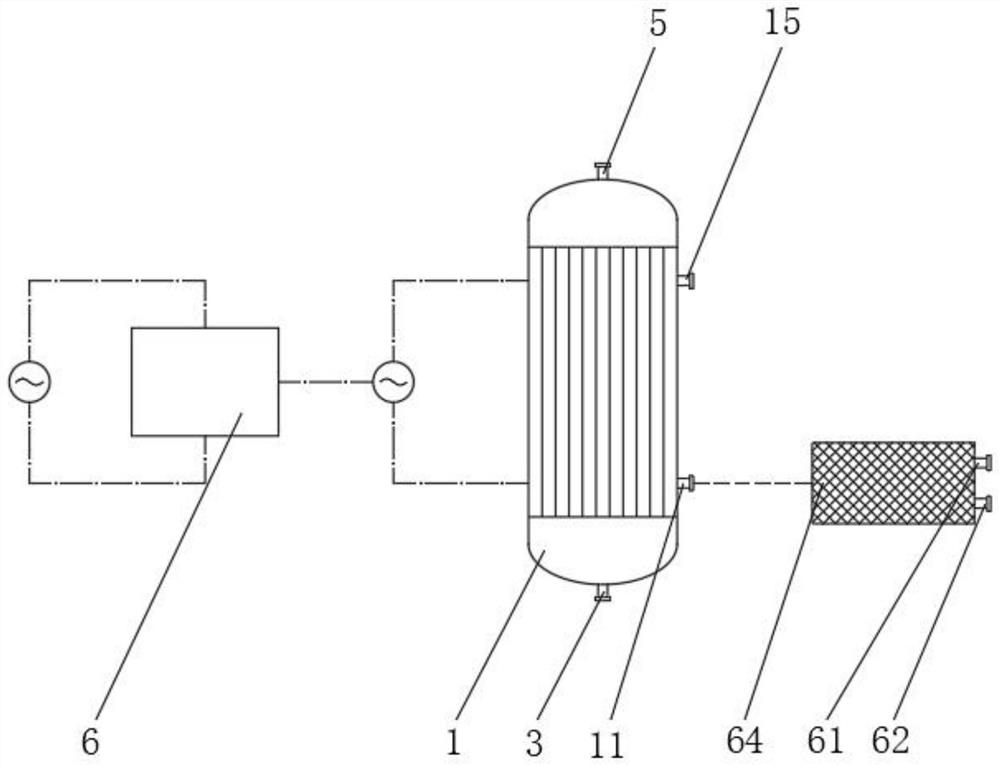

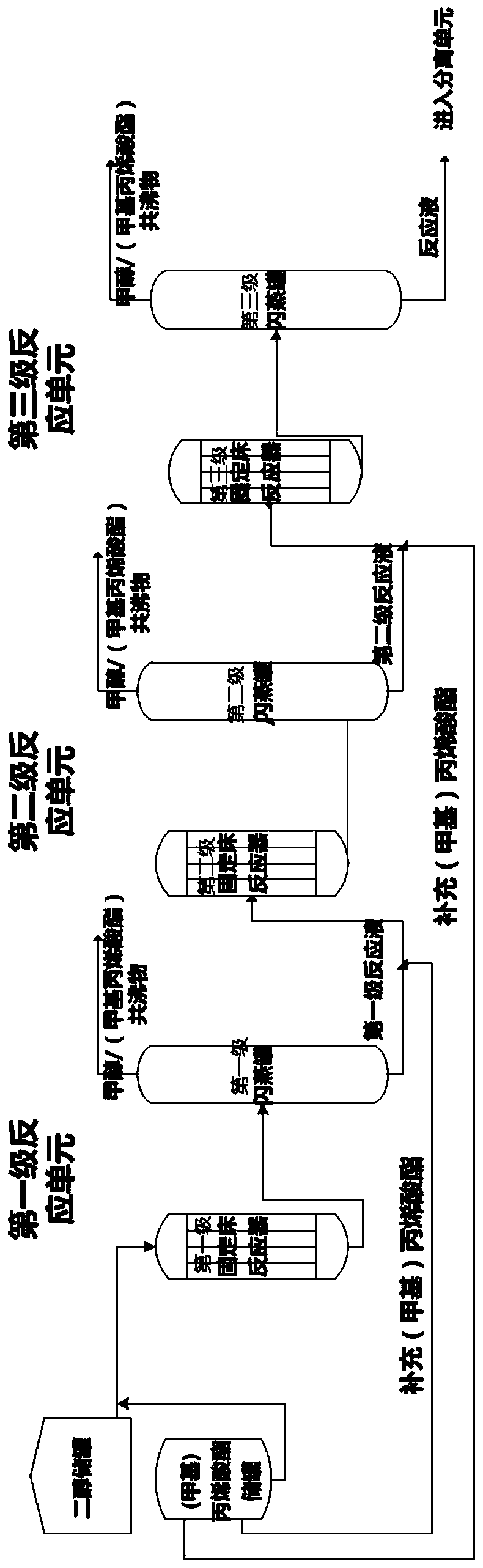

Method for continuously producing (methyl) hydroxyethyl acrylate and (methyl) diester acrylate and sulfoacid resin catalyst

ActiveCN107597187AEfficient productionIncrease productivityPreparation by ester-hydroxy reactionOrganic compound preparationContinuous productionAcrylate

The invention belongs to the technical field of a synthesis compound, and provides a sulfoacid resin catalyst and a method for continuously producing (methyl) hydroxyethyl acrylate and (methyl) diester acrylate. The continuous production method comprises the following steps of (1) contacting dihydric alcohol, (methyl) methyl acrylate and polymerization inhibitors to form reaction liquid; continuously injecting the materials into a reaction device containing the sulfoacid resin catalyst for reaction so as to obtain coarse reaction liquid; (2) injecting the coarse reaction liquid obtained in thestep (1) into a phase splitting tank; performing double-solvent extraction; respectively obtaining a water phase containing (methyl) hydroxyethyl acrylate and an oil phase containing (methyl) diesteracrylate; (3) respectively performing rectification on the water phase and the oil phase in the step (2) to obtain (methyl) hydroxyethyl acrylate and (methyl) diester acrylate products. The method has the advantages that the product separation step is simplified; the separation temperature is low and the product purity is high.

Owner:WANHUA CHEM GRP CO LTD

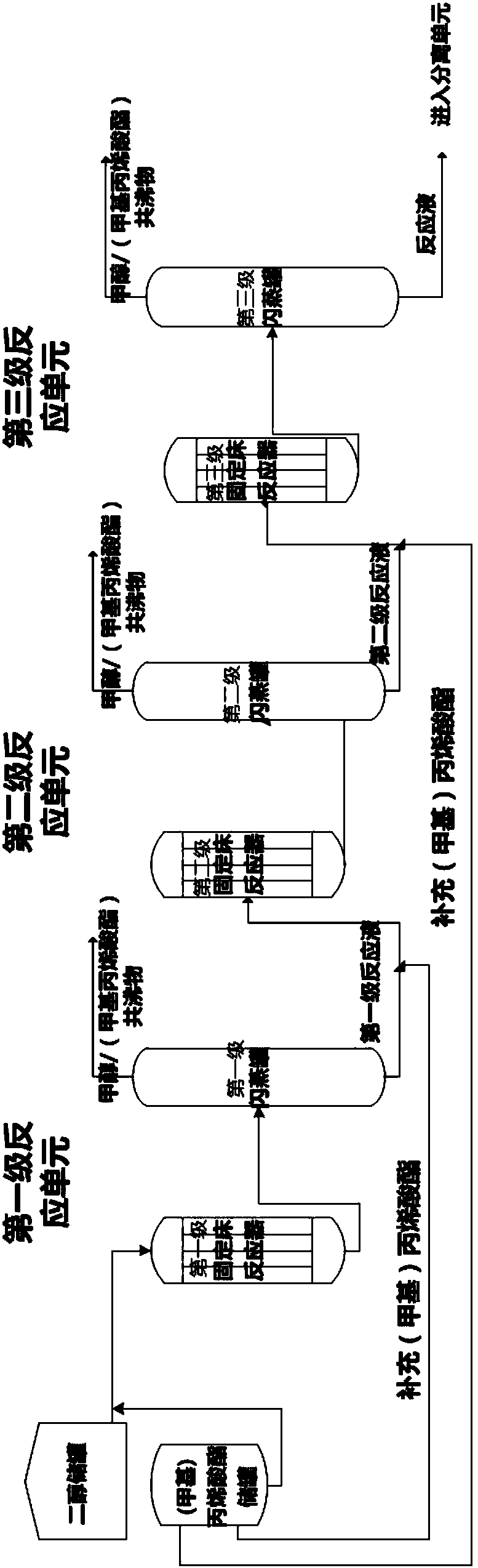

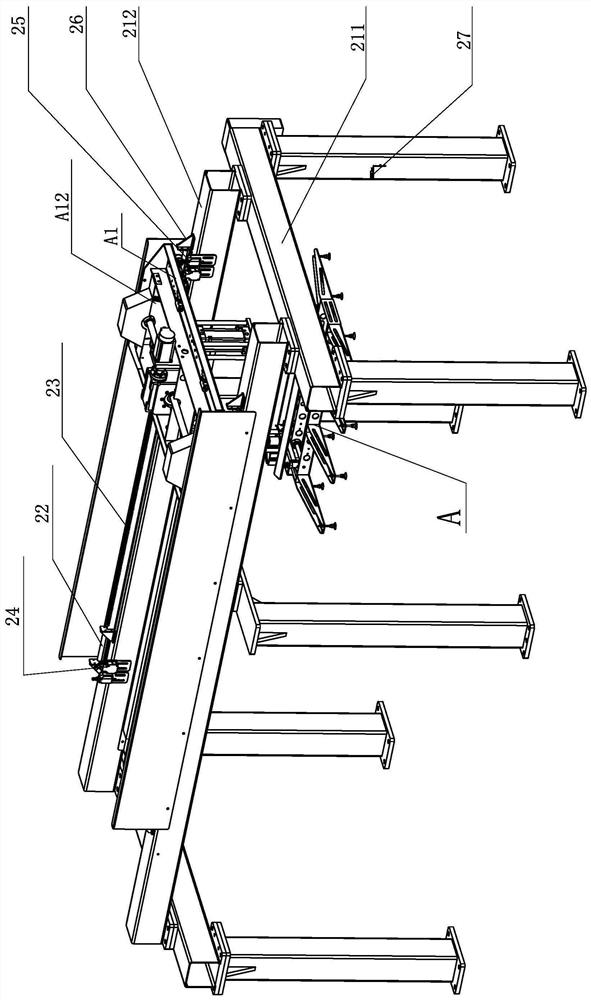

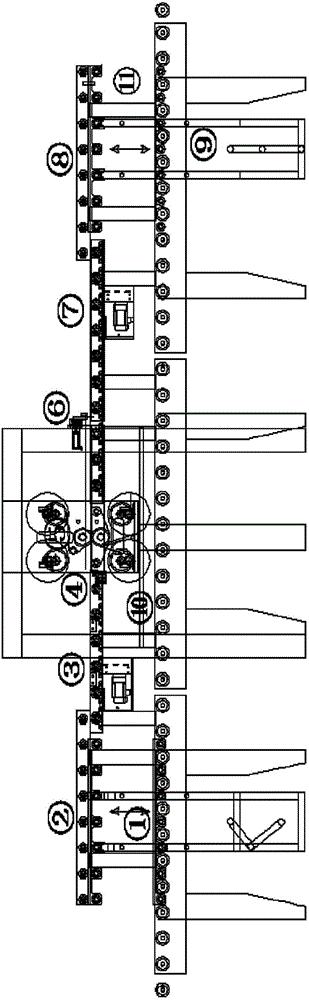

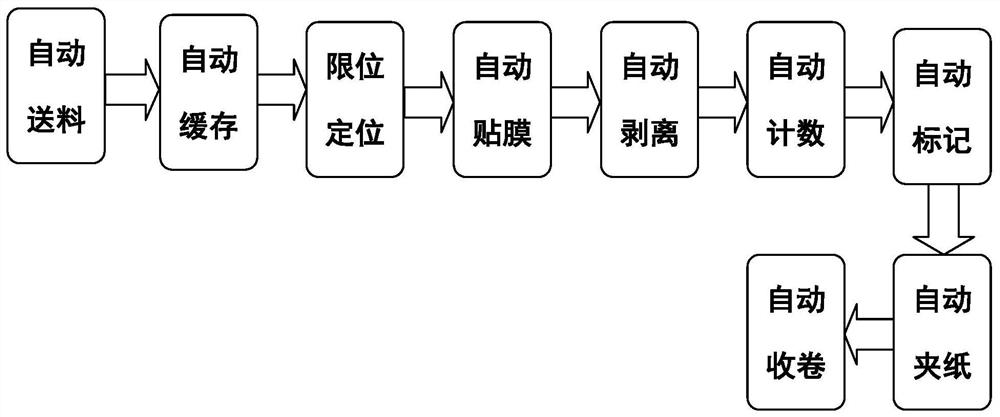

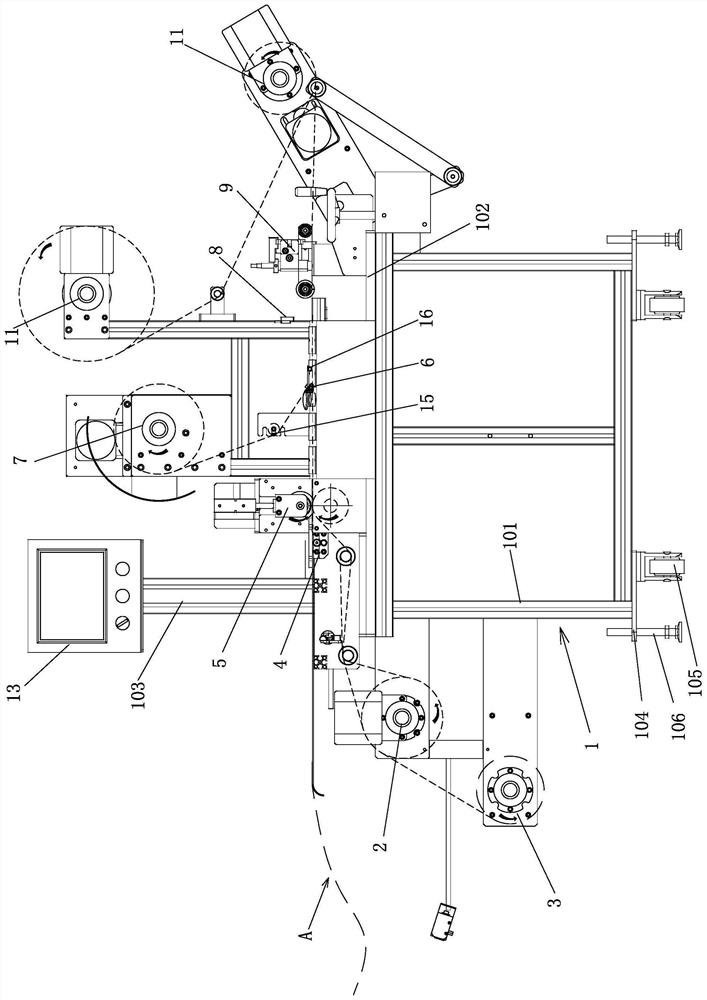

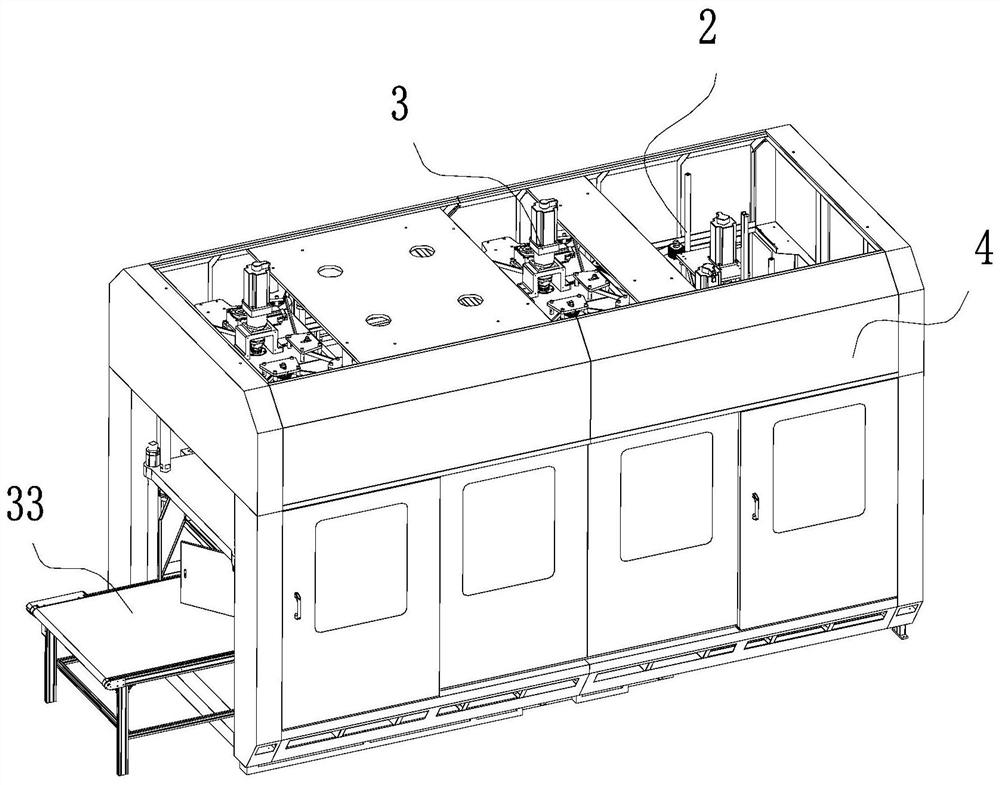

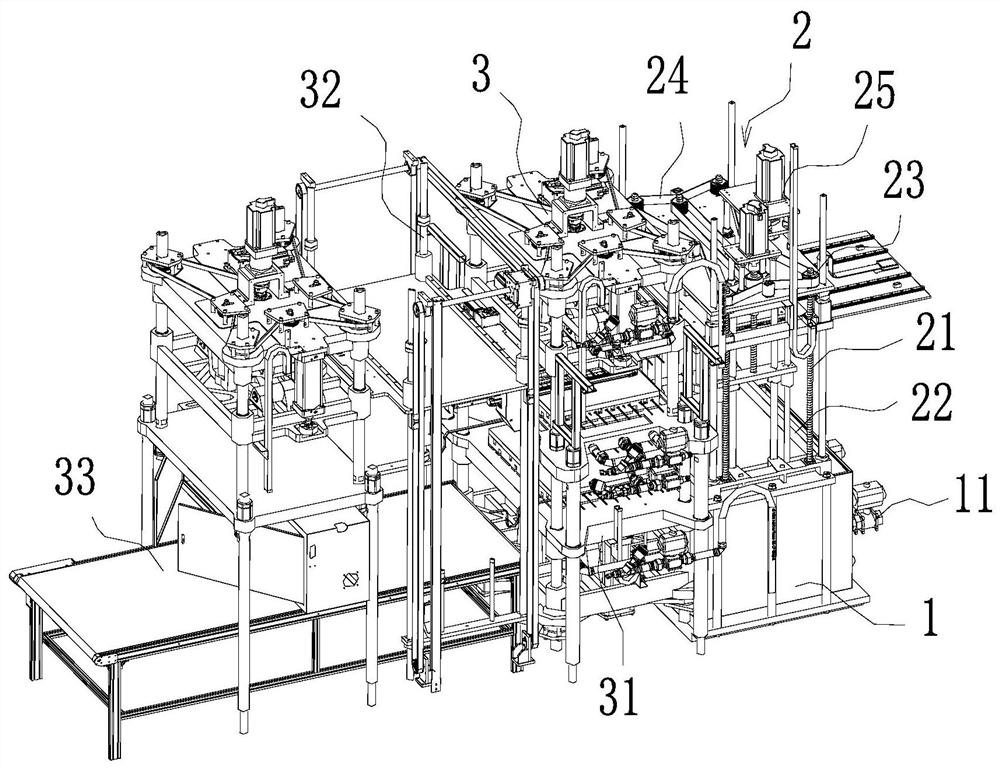

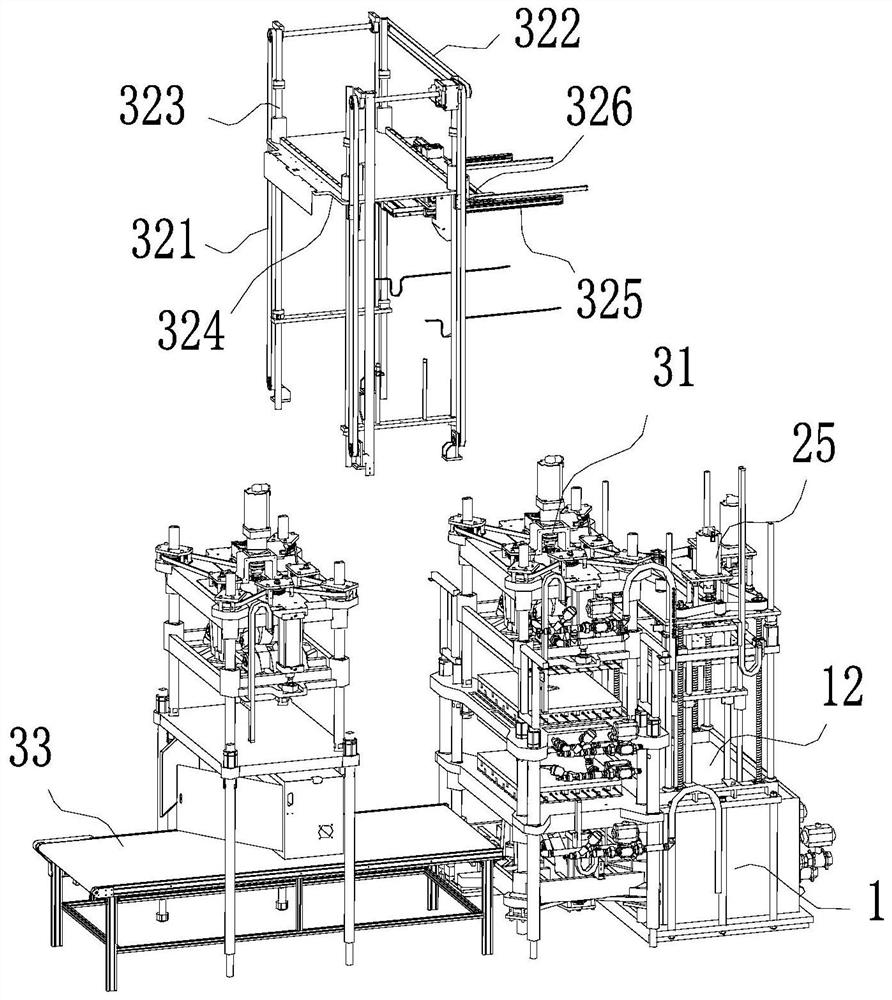

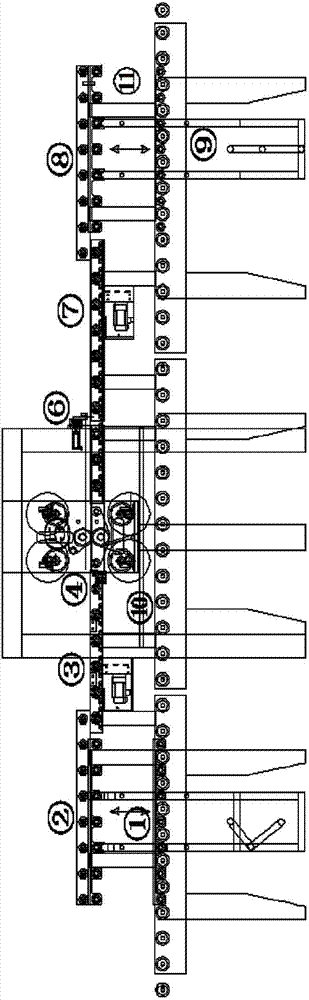

Full-automatic aluminum substrate film laminating and leveling production line

PendingCN112109967AContinuous and smooth operationReduce labor inputPackagingProduction lineMetallurgy

The invention provides a full-automatic aluminum substrate film laminating and leveling production line. The full-automatic aluminum substrate film laminating and leveling production line comprises afeeding lifting table, a suction cup feeding table, a feeding conveying table, a overturning platform 1#, a film laminating mechanism, a overturning platform 2#, a leveling machine, an inspection platform, a plate collecting and weighing platform and a main operation table, wherein the feeding lifting table, the suction cup feeding table, the feeding conveying table, the overturning platform 1#, the film laminating mechanism, the overturning platform 2#, the leveling machine, the inspection platform, the plate collecting and weighing platform and the main operation table are sequentially arranged from the feeding end to the discharging end; the feeding lifting table is used for stacking aluminum substrates; the suction cup feeding table is used for sucking and feeding the single aluminum substrate; the feeding conveying table is used for conveying the aluminum substrates; the overturning platform 1# is used for overturning the conveyed aluminum substrates and enabling the aluminum faces of the aluminum substrates to face upwards and the copper faces of the aluminum substrates to face downwards; the film laminating mechanism is used for laminating films on the overturned aluminum substrates; the overturning platform 2# is used for overturning the laminated aluminum substrates again and enabling the aluminum faces of the aluminum substrates to face downwards and the copper facesof the aluminum substrates to face upwards; the leveling machine is used for leveling the laminated aluminum substrates; the inspection platform is used for inspecting the quality of the aluminum substrates; and the plate collecting and weighing platform is used for weighing, collecting, stacking and conveying the aluminum substrates. According to the full-automatic aluminum substrate film laminating and leveling production line, a series of work such as film laminating, film cutting, thickness measuring, leveling, plate collecting, counting, weighing and packaging can be achieved in a full-automatic and continuous mode, the labor input is reduced, scratches can be effectively prevented, and the film laminating effect is good.

Owner:深圳市龙锋泰自动化有限公司

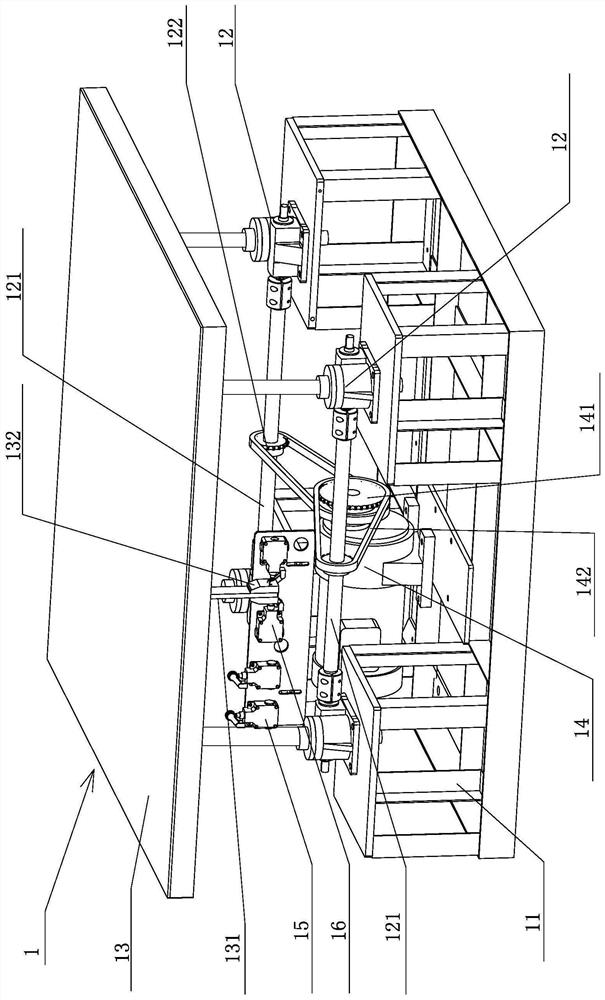

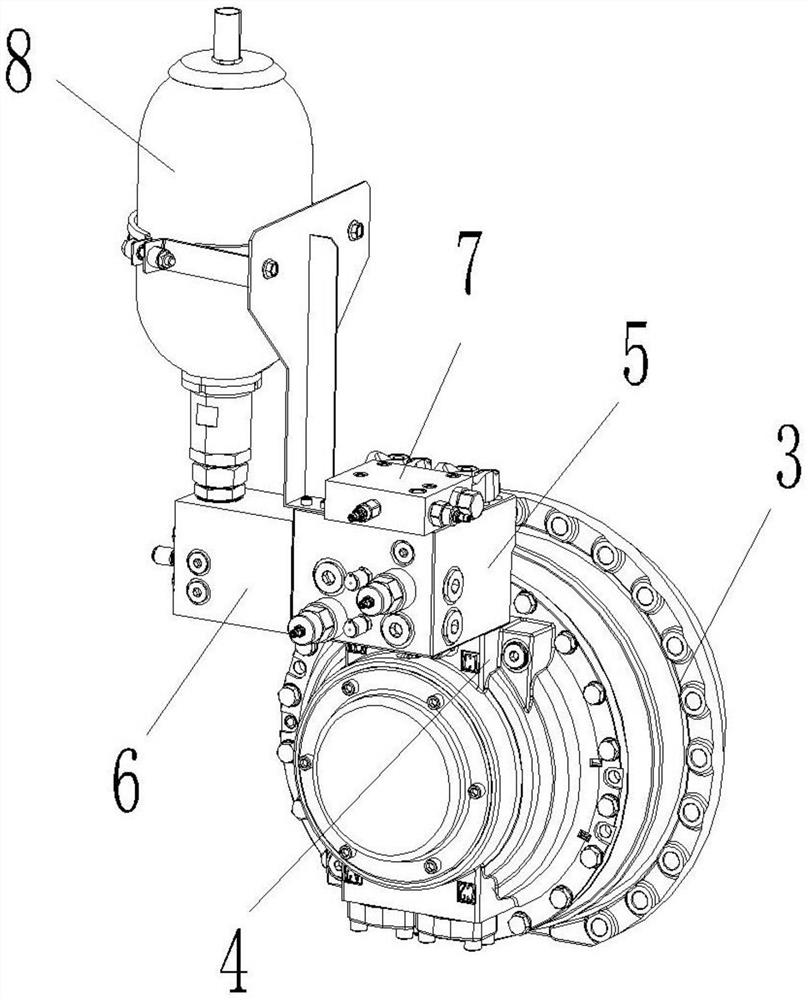

Hydraulic track rock loader

ActiveCN103216230AUnrestricted loading areaShorten the timeSlitting machinesHydraulic motorHydraulic pump

The invention belongs to the field of mine loading machines, and particularly relates to a hydraulic track rock loader. The hydraulic track rock loader is characterized by comprising a bucket part, a bucket hoisting part, a traveling part, a hydraulic system and an electric control system, wherein a bucket hoisting hydraulic motor can drive the bucket part to move; a track driving hydraulic motor can drive the traveling part to move; the hydraulic system is connected with the electric control system and controls the bucket hoisting hydraulic motor and the track driving hydraulic motor. The hydraulic track rock loader disclosed by the invention travels by utilizing a track without the need of paving a guide rail, thus saving the time and the manpower and material resources; the motor is used to drive the hydraulic system of a hydraulic pump to serve as power, and only one motor is used on the integral machine, thereby greatly saving space and cost; the motor can operate continuously and stably, thus greatly prolonging the service life of the motor and the machine.

Owner:ZIBO DALI MINING MASCH CO LTD

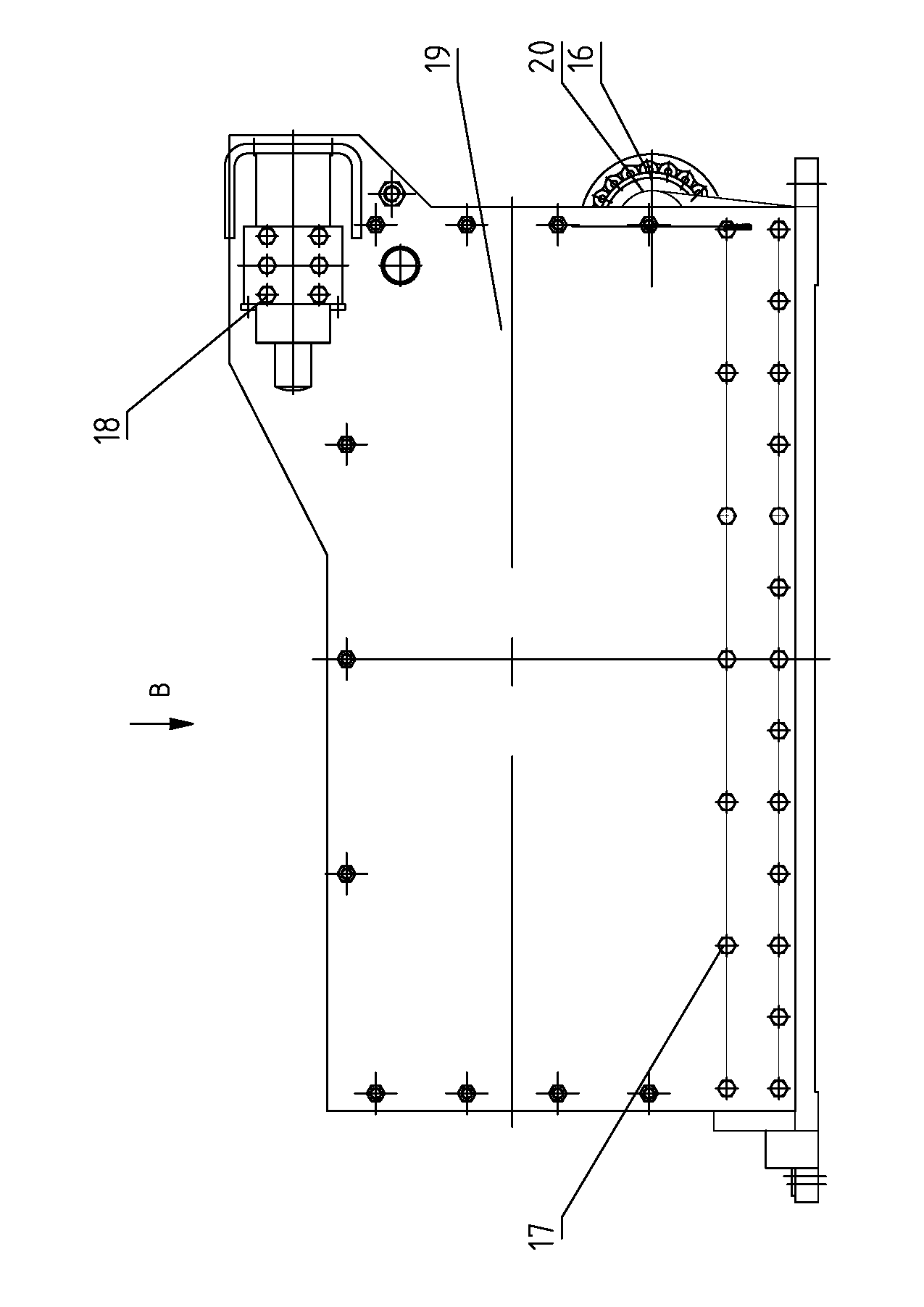

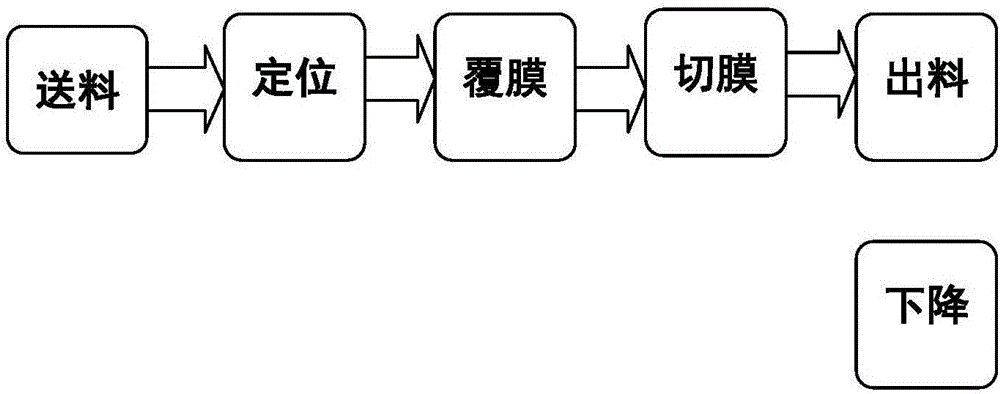

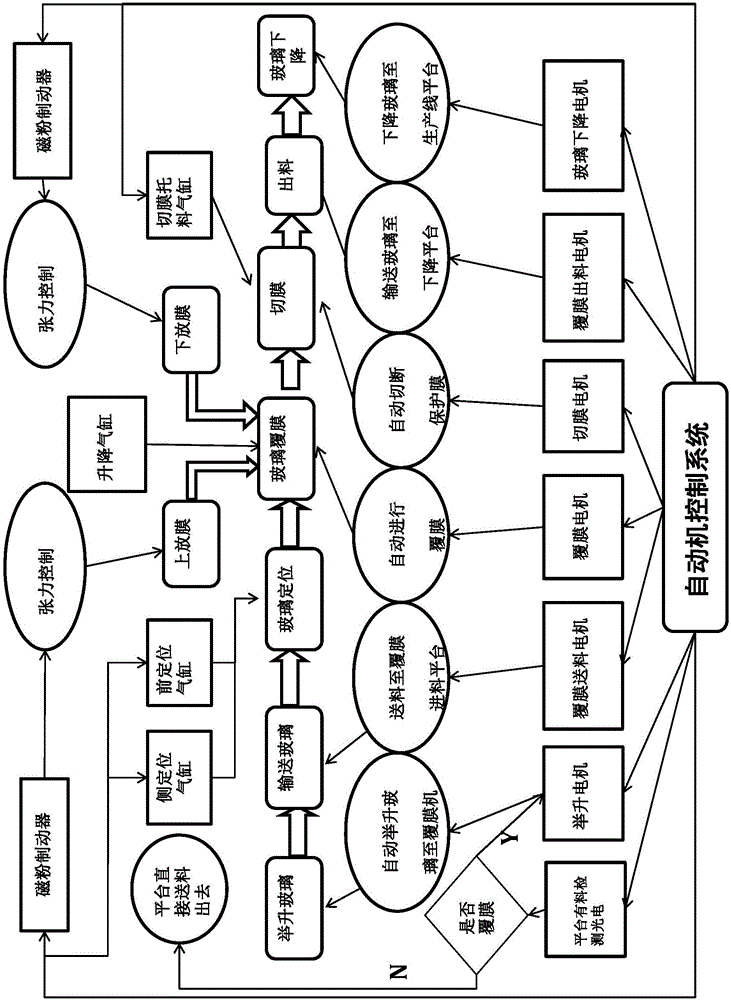

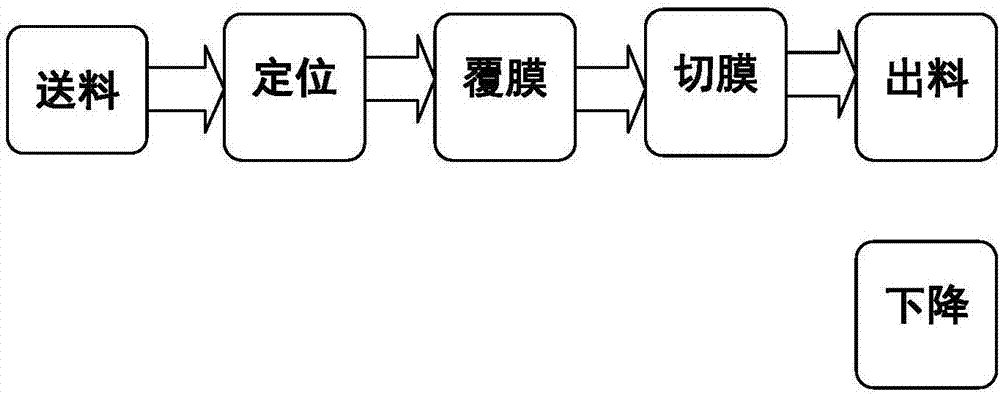

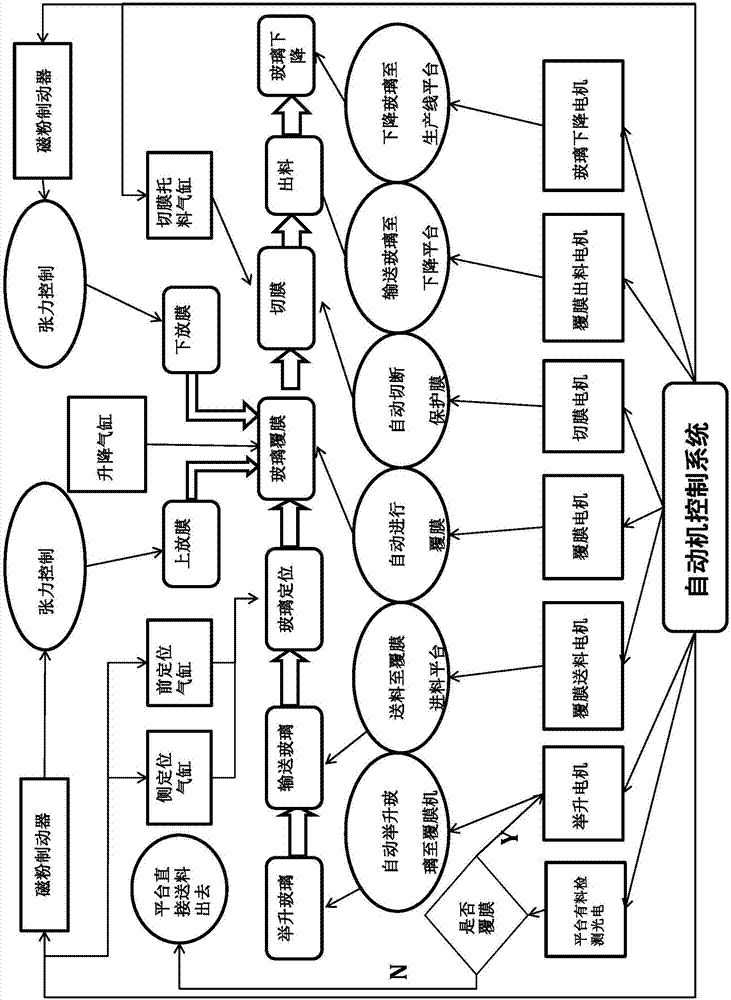

Full-automatic on-line coating method of glass

ActiveCN106541674ADoes not affect normal productionContinuous and smooth operationLamination ancillary operationsLaminationProduction lineBiochemical engineering

The invention discloses a full-automatic on-line coating method of glass, relating to an on-line coating method of the glass. The method comprises the following steps: arranging a feeding lifting platform, a feeding platform, a film coating device, a film cutting mechanism, a discharging platform and a discharging lifting platform on a glass production line, wherein the feeding platform, the film coating device, the film cutting mechanism and the discharging platform are arranged above the glass production line; lifting the glass from the glass production line to the feeding platform through the feeding lifting platform; and after coating films, returning the film-coated glass to the glass production line by the discharging lifting platform. According to the full-automatic on-line coating method of the glass disclosed by the invention, the glass can be selectively received to implement film coating without affecting the production of the glass on the glass production line.

Owner:深圳市龙锋泰自动化有限公司

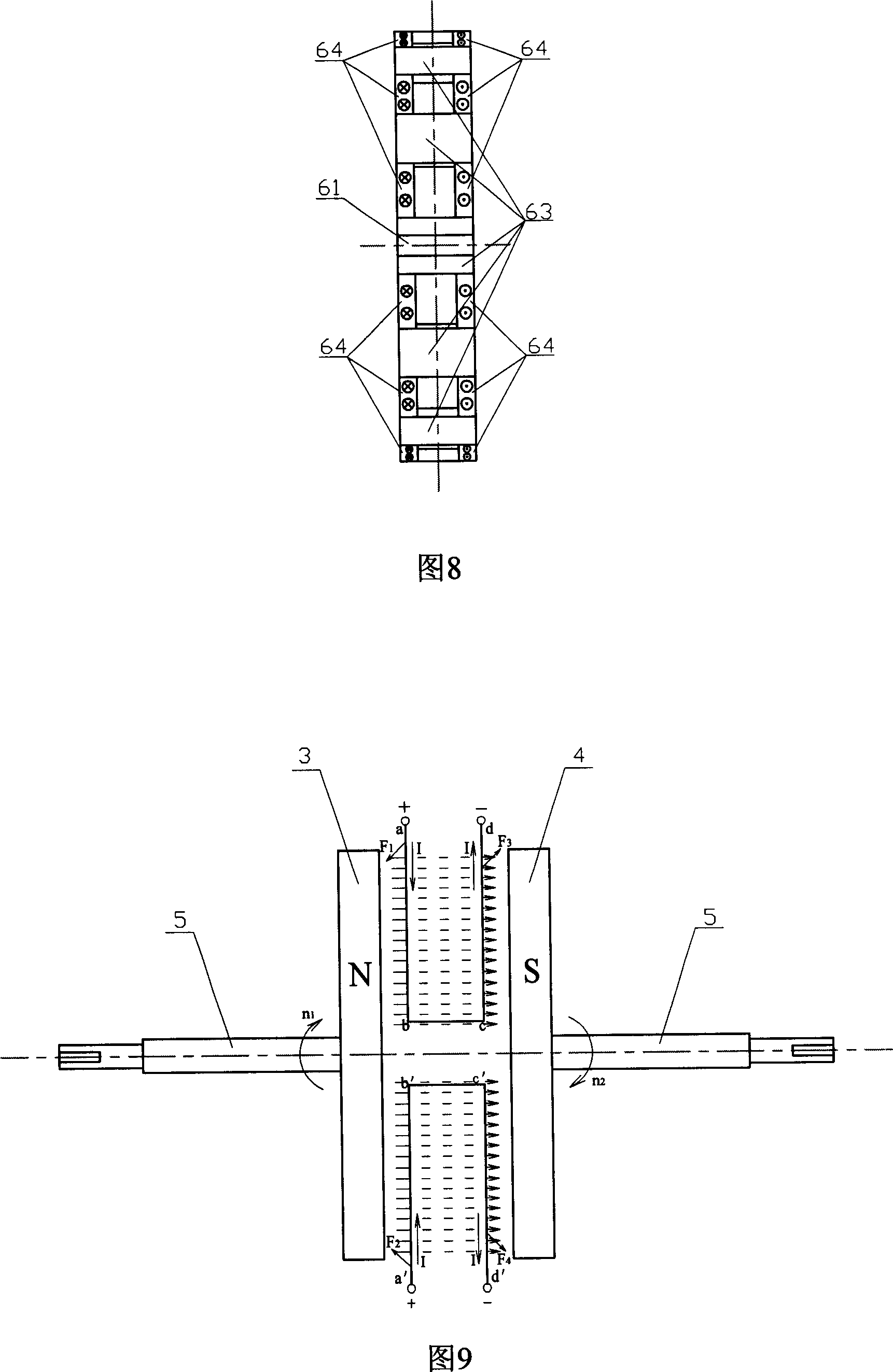

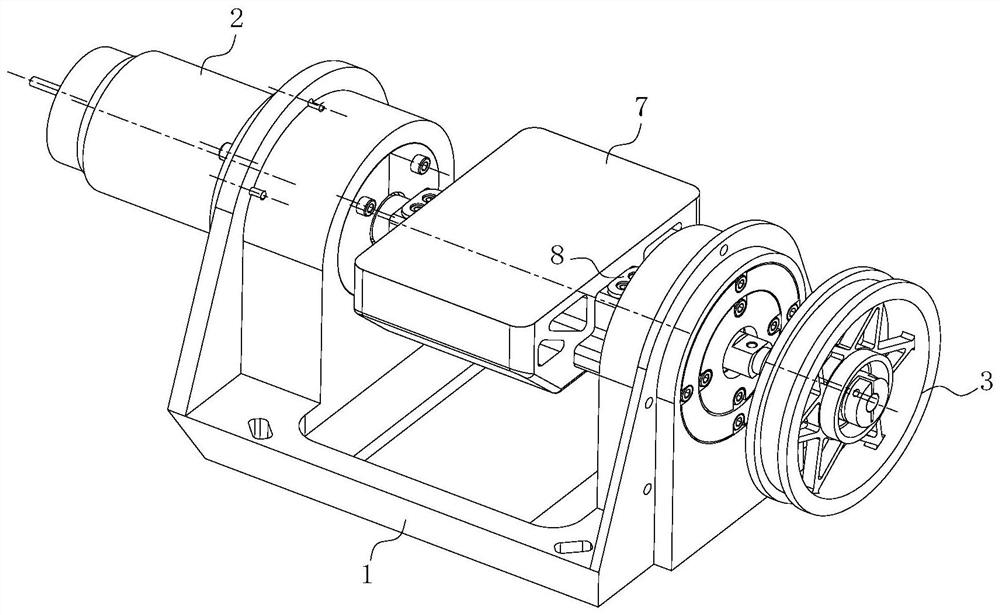

Transmission mechanism utilizing permanent magnet

InactiveCN101320935AAvoid damageSimple structureDynamo-electric brakes/clutchesGearingMagnetic tension forceTransmission belt

A transmission device using a permanent magnet, belongs to the technical field of the mechanical transmission, particularly to a mechanical apparatus for converting the mechanical straight line motion into the transmission by the magnetic force of the permanent magnet, including a power output part and a power driving part, wherein the power output part has a non-magnetic principal axis supported on the bearing, the surface of the principal axis is fixed with a plurality of adsorbed sheets in the helical form axially; the driving part is provided with a guide wheel and a transmission belt towed by the outside force; a plurality of permanent magnets are fixed on the outer surface of the transmission belt; the transmission belt in the working area is parallel with the axial of the principal axis; a gap is arranged between the permanent magnet and the adsorbed sheets; the distance between the neighbor permanent magnet is equal to the helical pitch of the adsorbed sheets on the principal axis. In use, the straight line motion of the permanent magnet is converted to the rotation of the principal axis. The device is used in the mechanical technical field for changing the mechanical motion state.

Owner:龚达明

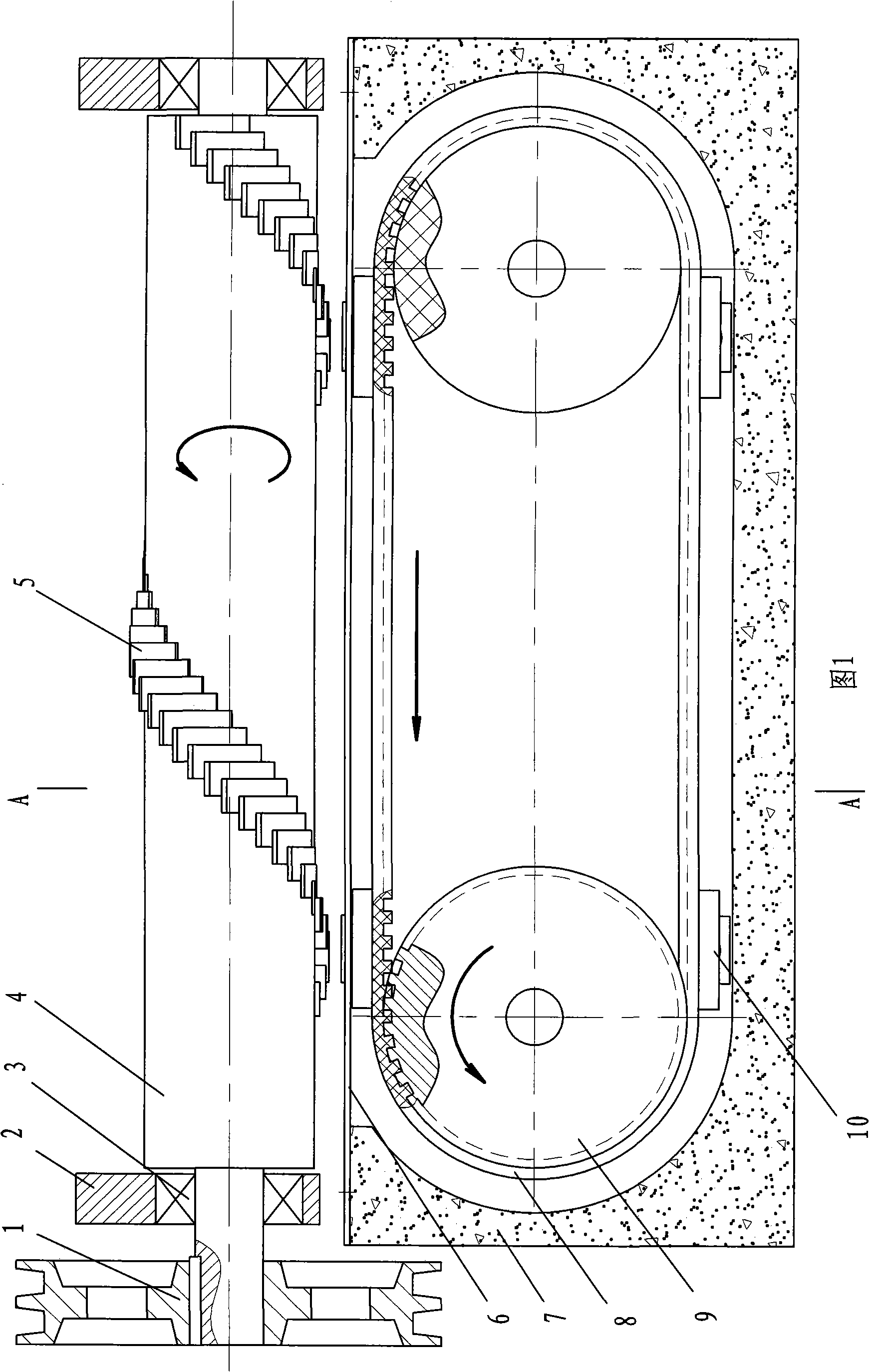

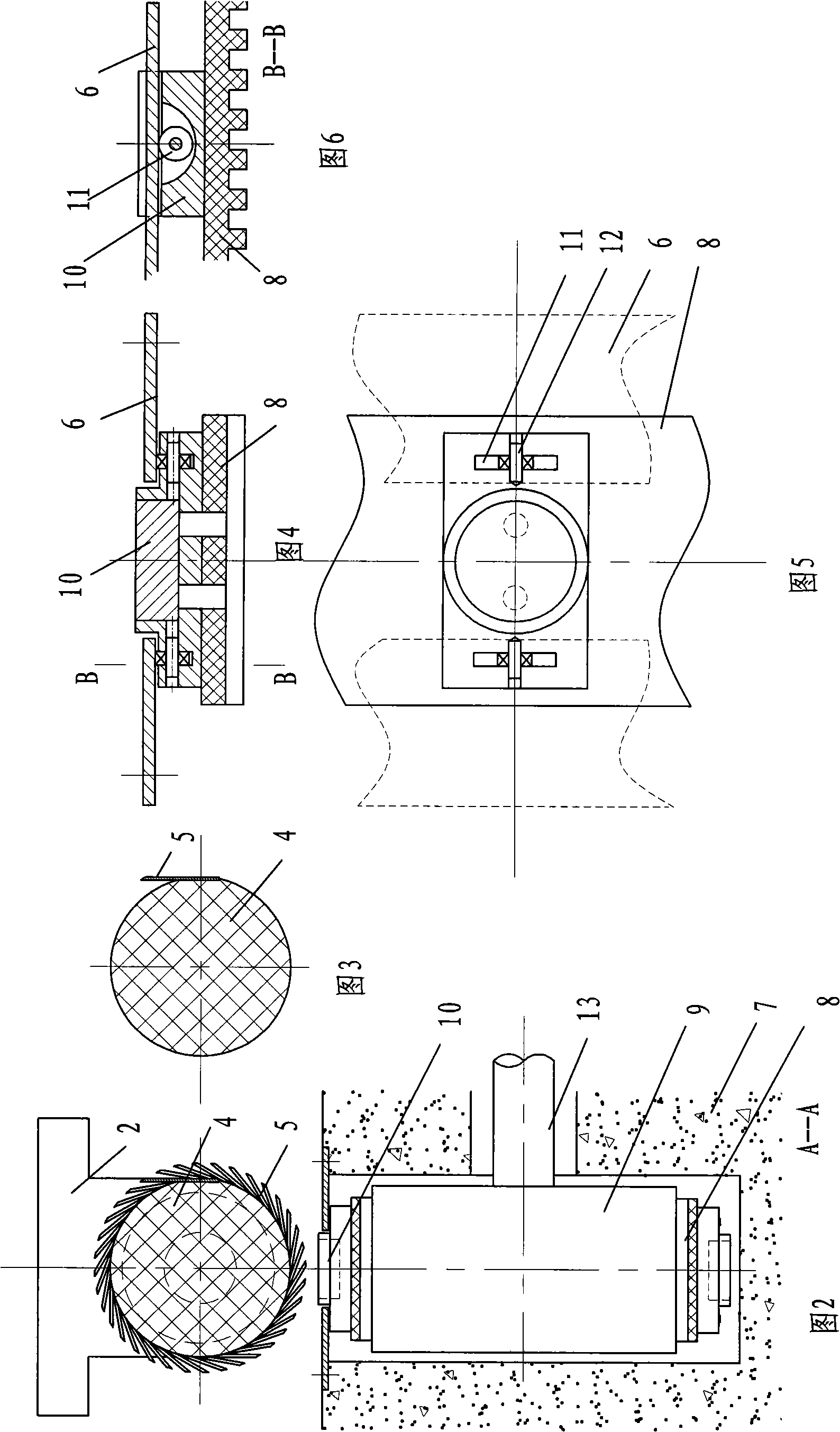

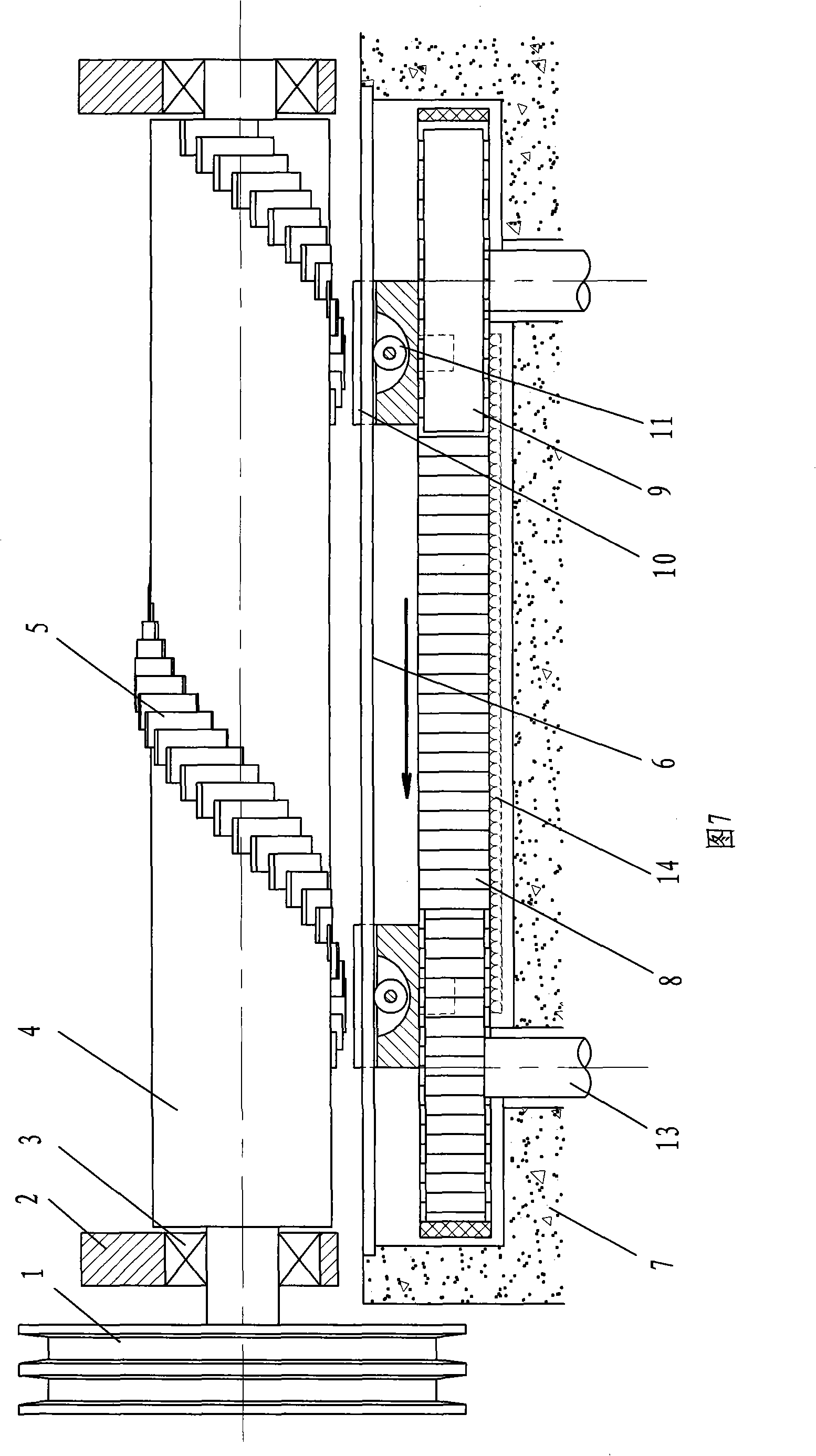

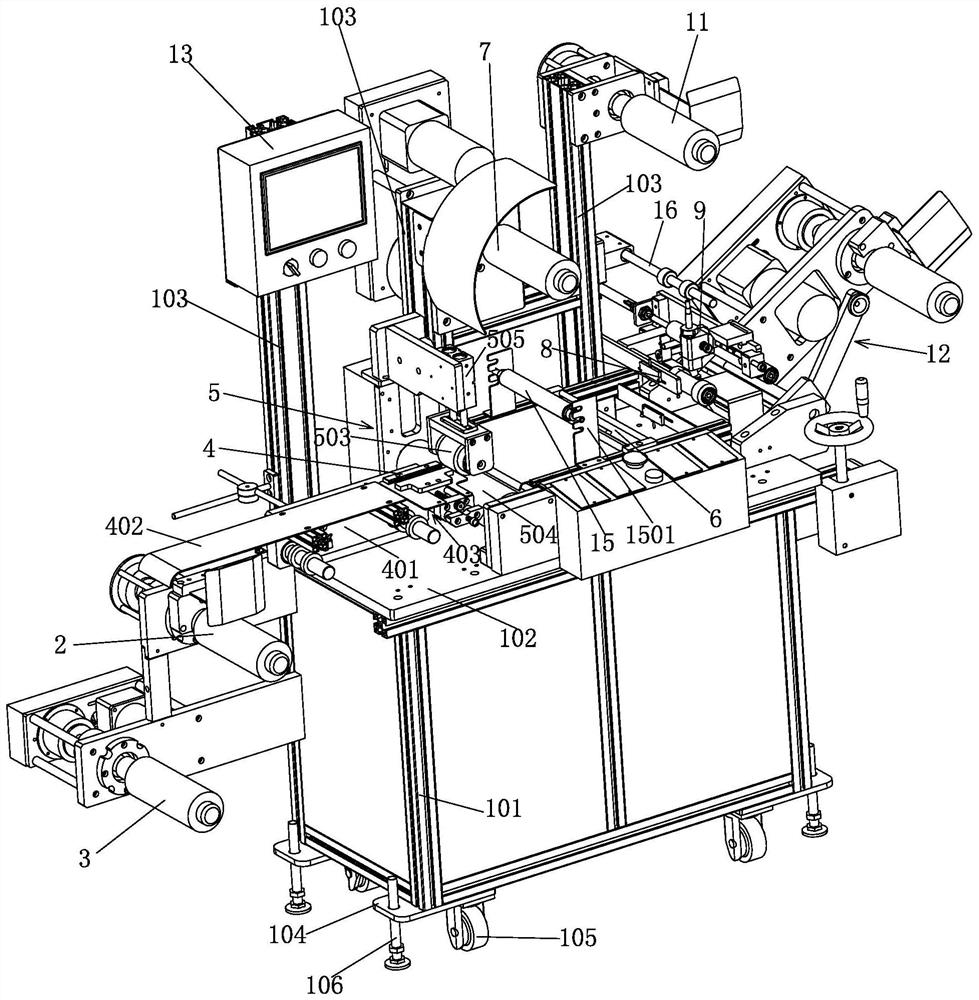

Automatic stainless steel sheet rolling and packing machine

PendingCN112141389AContinuous and smooth operationAvoid scratchesWrappingStructural engineeringWaste material

The invention provides an automatic stainless steel sheet rolling and packing machine. The automatic stainless steel sheet rolling and packing machine comprises a rack, and a film releasing mechanism,a waste film collecting mechanism, a positioning and adjusting mechanism, a film laminating mechanism, a stripping assembly, a waste material collecting mechanism, a counting photoelectric mechanism,an automatic marking mechanism, a paper releasing mechanism, a material collecting mechanism and a control box which are disposed on the rack. The automatic stainless steel sheet rolling and packingmachine has the advantages of improving the collection efficiency, being simple and practical to operate and complete in function, reducing the cost and improving the productivity.

Owner:深圳市龙锋泰自动化有限公司

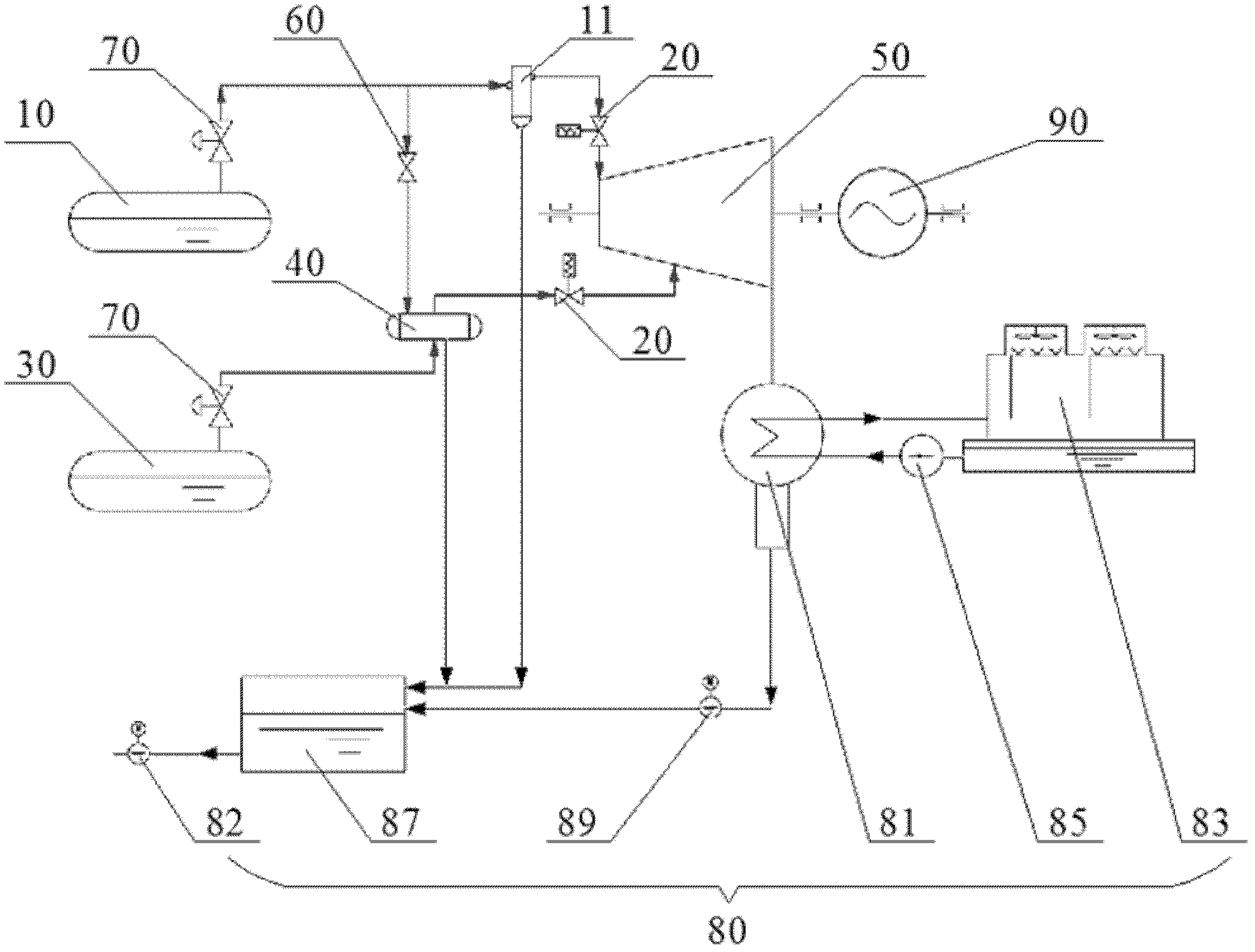

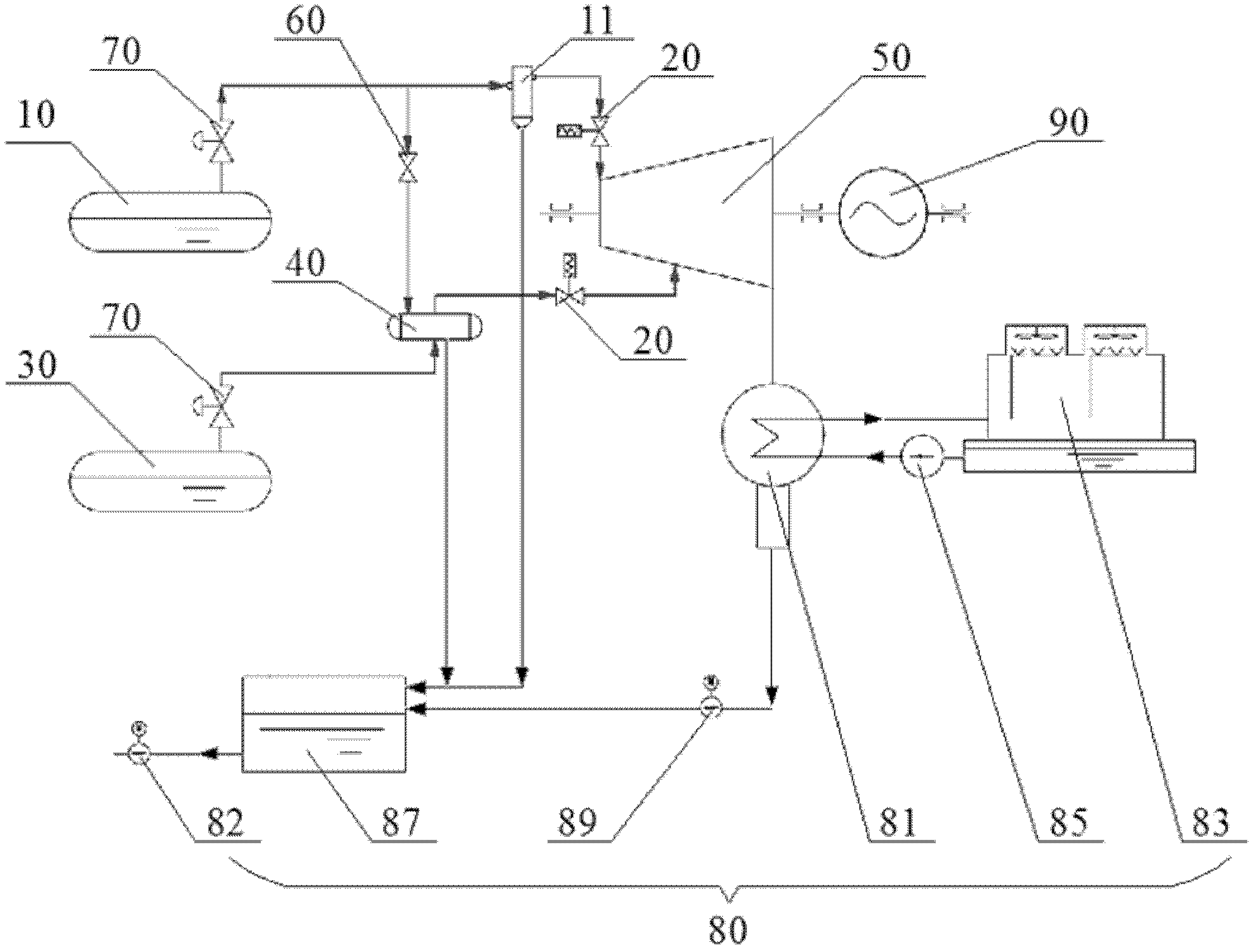

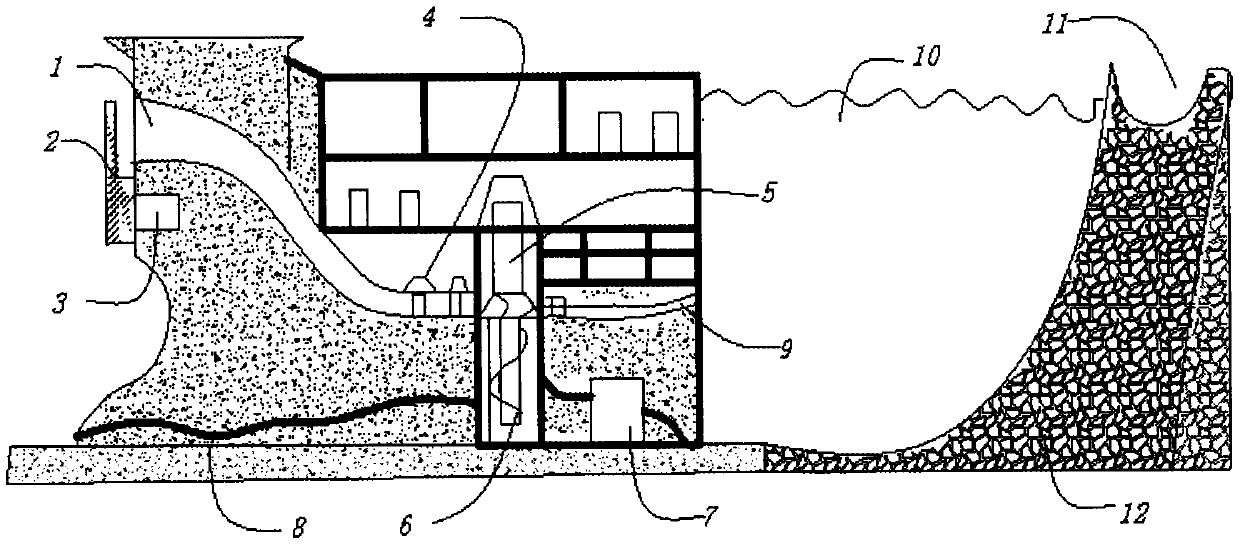

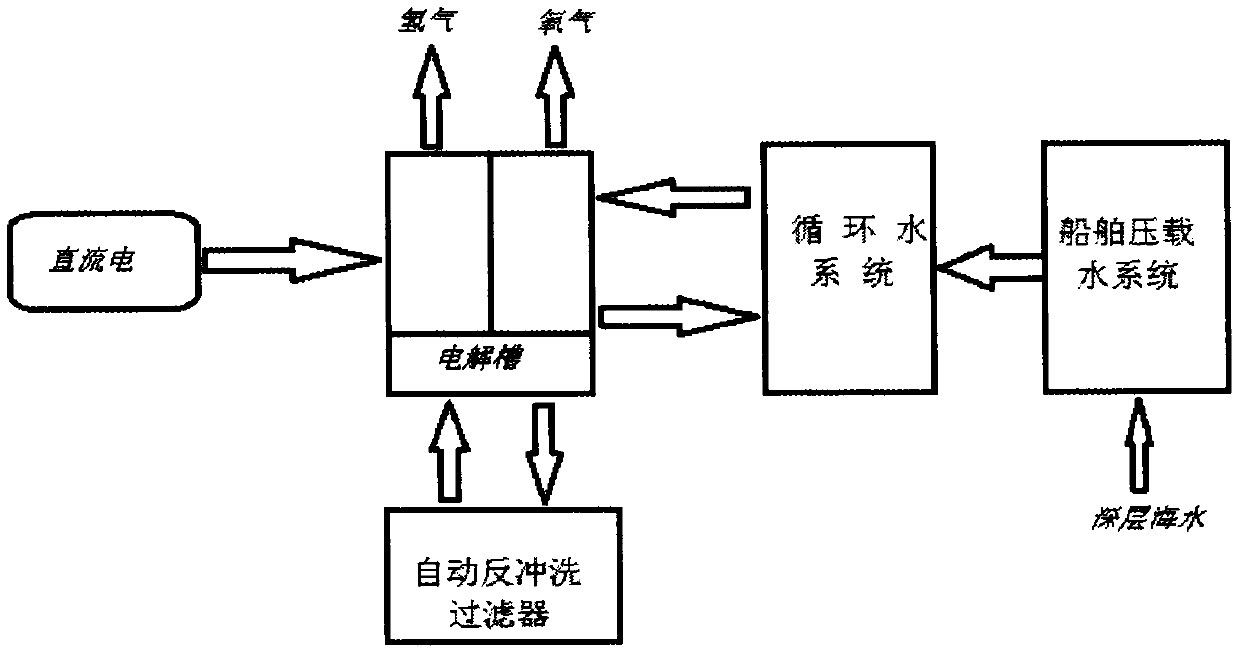

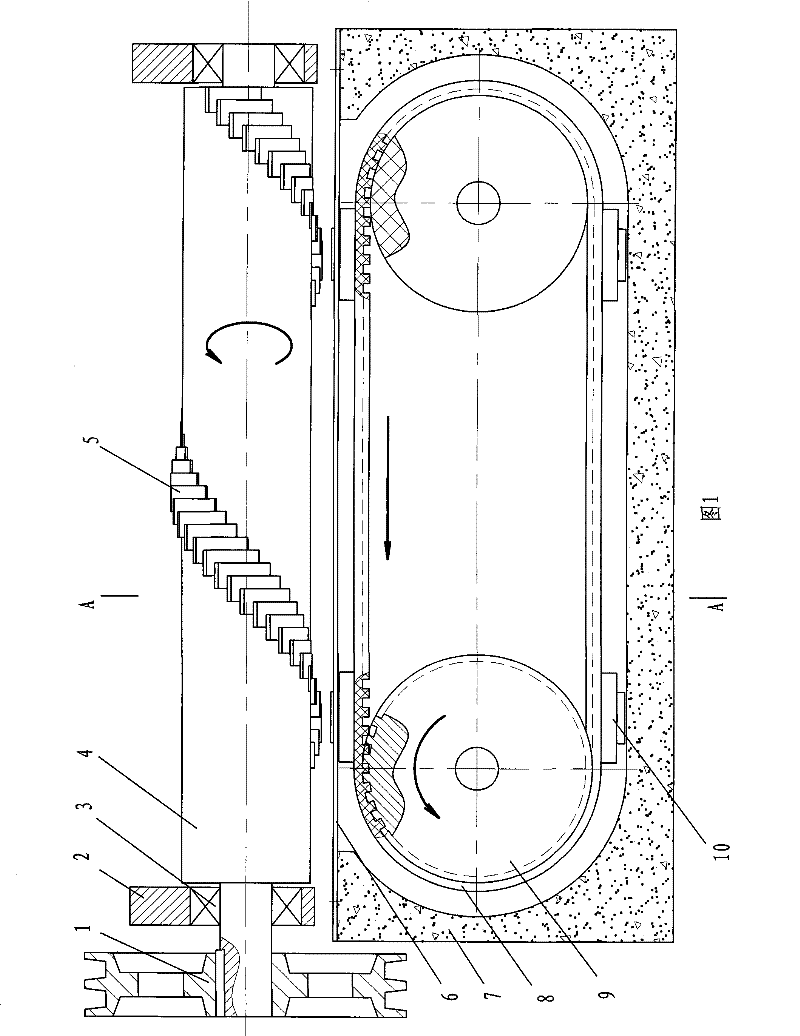

Seawater power generation hydrogen production power station built on offshore island reef

InactiveCN111219284AContinuous and smooth operationElectrolysis componentsHydro energy generationWater storageElectrolysis

The invention relates to a seawater power generation and hydrogen production power station built on an offshore island reef, and provides a technical scheme of the seawater power generation and hydrogen production power station built on the offshore island reef in order to solve the technical problems that offshore power generation is difficult to transport remotely and hydrogen energy manufacturing needs a large amount of electric energy. The system comprises a power station for pushing a hydro-generator to generate power by utilizing seawater waves to surge into a water diversion channel (1), an electric water cable floating ball system positioned in front of the power station to expel aquatic organisms, and a water storage reservoir (10) positioned behind the power station to supplementwater and generate power, and the generated electric energy electrolyzes seawater in situ to produce hydrogen energy to be used by passing ships. The system has the advantages of being low in power station construction and power generation cost, more environment-friendly and energy-saving than land hydrogen production, and capable of achieving unattended full-automatic operation through remote centralized control.

Owner:李德宏

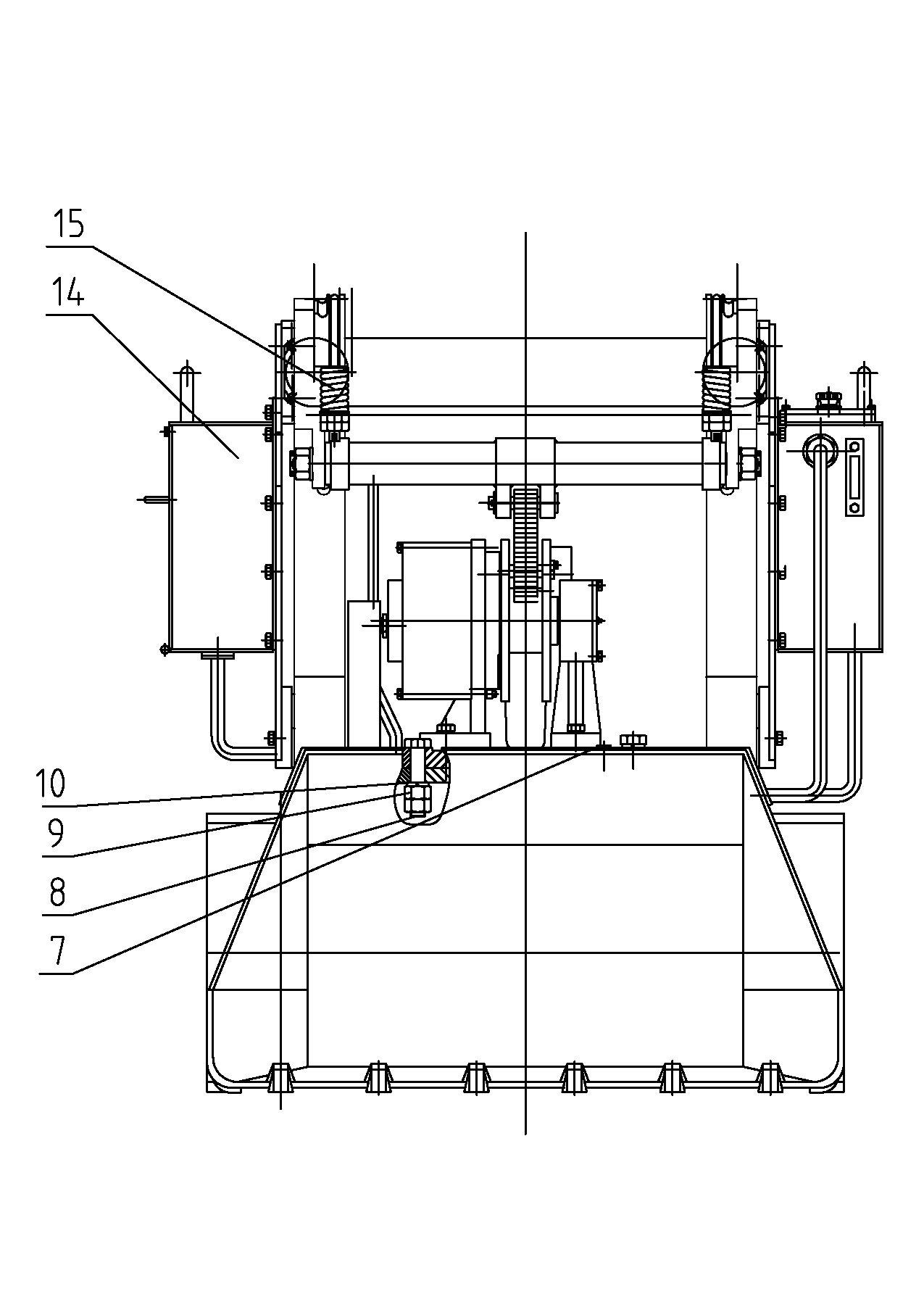

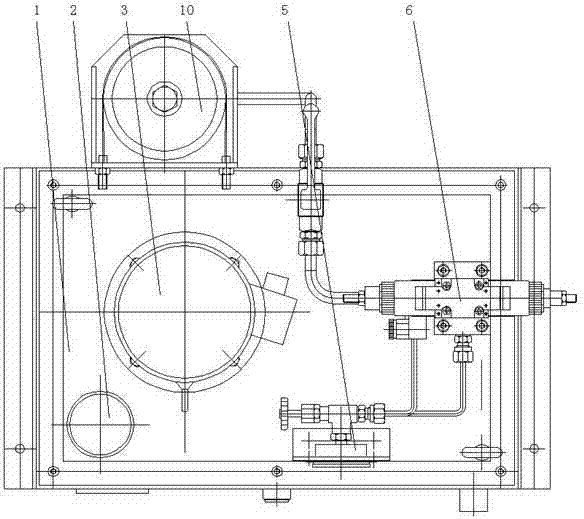

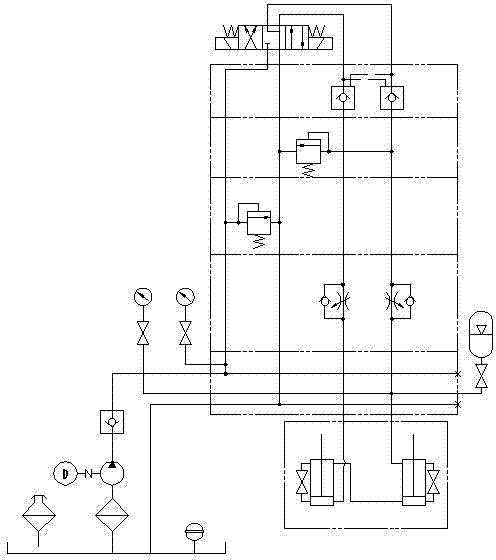

Hydraulic station of plate freezer

The invention discloses a hydraulic station of a plate freezer. The hydraulic station comprises an oil tank, a motor pump group, a control valve group, and an oil cylinder. The motor pump group and the control valve group are mounted on the oil tank, the motor pump group is connected with the oil cylinder via the control valve group and controls the oil cylinder to lift, the control valve group is composed of a solenoid operated directional valve, a modular pilot operated check valve, a stacked unidirectional throttle valve, an overflow valve, a modular relief valve and a check valve, the modular pilot operated check valve and the stacked unidirectional throttle valve are connected between the solenoid operated directional valve and the oil cylinder, and the modular relief valve and the check valve are connected between the solenoid operated directional valve and the motor pump group. The invention has compact structure, reasonable layout, and convenient use, and adopts simple and practical synchronization loop and pressure holding loop to ensure continuous smooth operation of the machine.

Owner:大连维乐液压制造有限公司

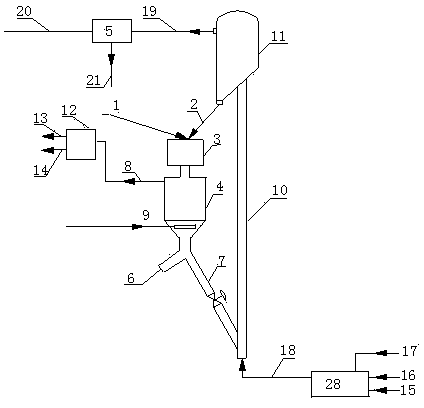

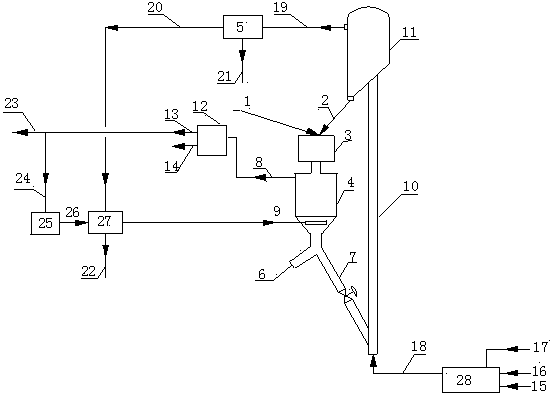

Coal solid heat carrier pyrolysis method and system for guide type stripping reinforced oil gas accelerated introduction

InactiveCN102786966BReduced responseEvenly mixedDirect heating destructive distillationEnergy inputHeat carrierProcess engineering

The invention discloses a coal solid heat carrier pyrolysis method and a system for guide type stripping reinforced oil gas accelerated introduction. In the process that powder particles flow in a mix apparatus, the segmentation, diversion and remixing effects of a mixed element can be used for reaching the purpose of uniform mixing of the solid materials. A pyrolysis reaction is generated in a moving-bed reactor, stripping gas is introduced into a distributor and is combined with a pyrolysis gas gas collection device by intersecting to realize partial lowering and accelerated introduction of oil gas, oil gas polymerization and secondary cracking reaction can be minimized, and the coal pyrolysis tar yield can be enhanced.

Owner:DALIAN UNIV OF TECH +2

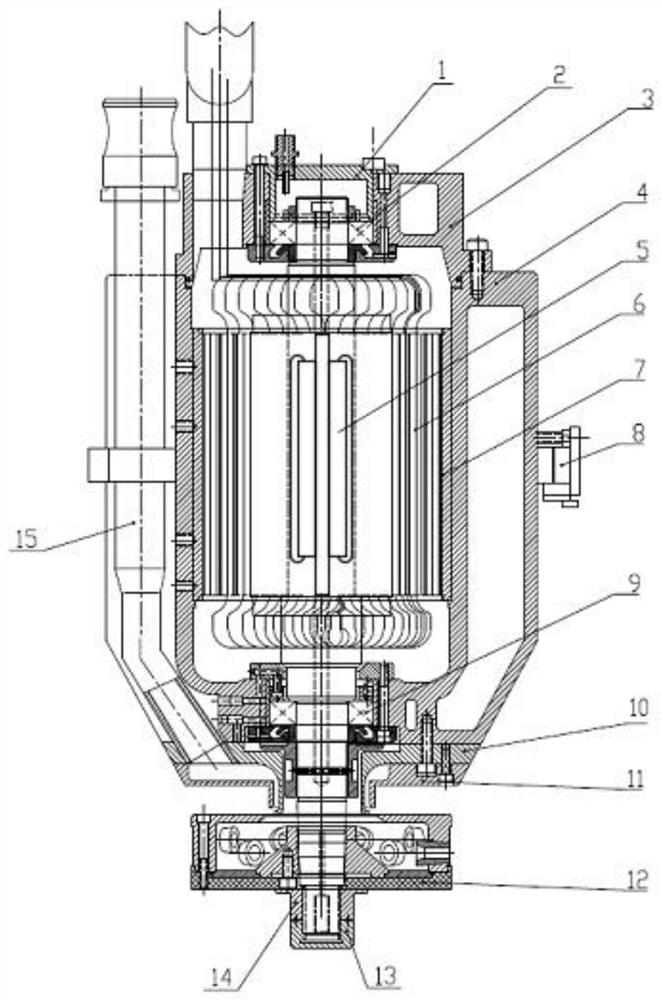

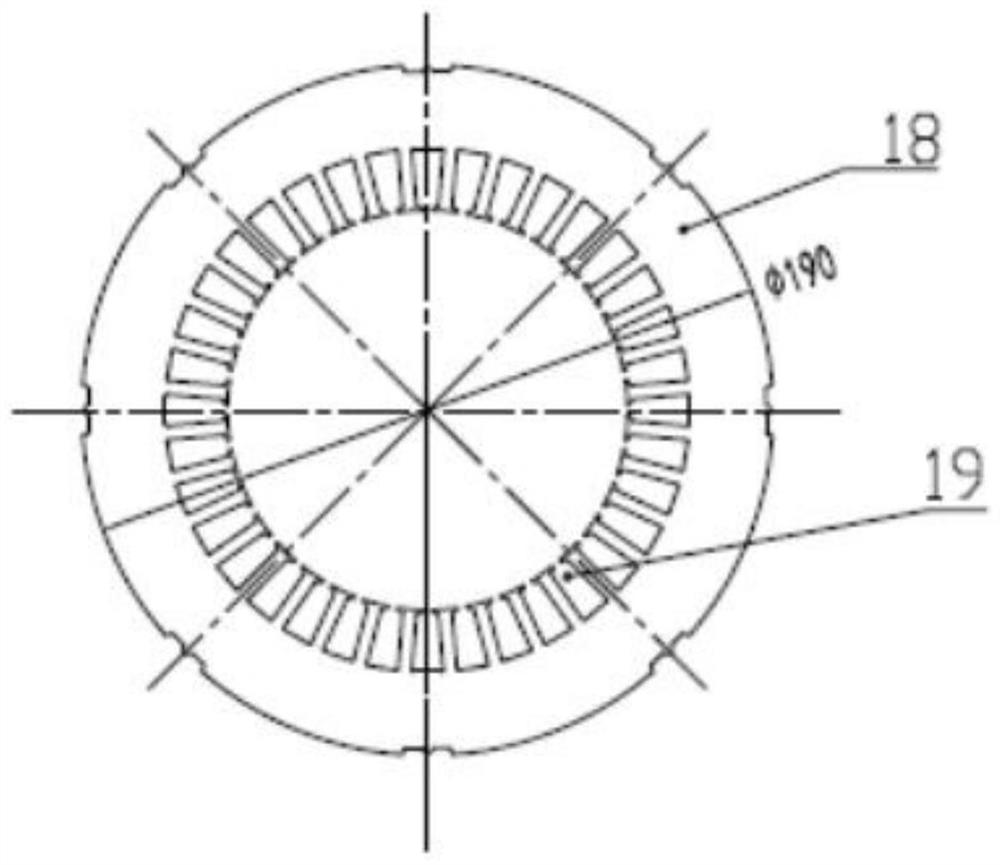

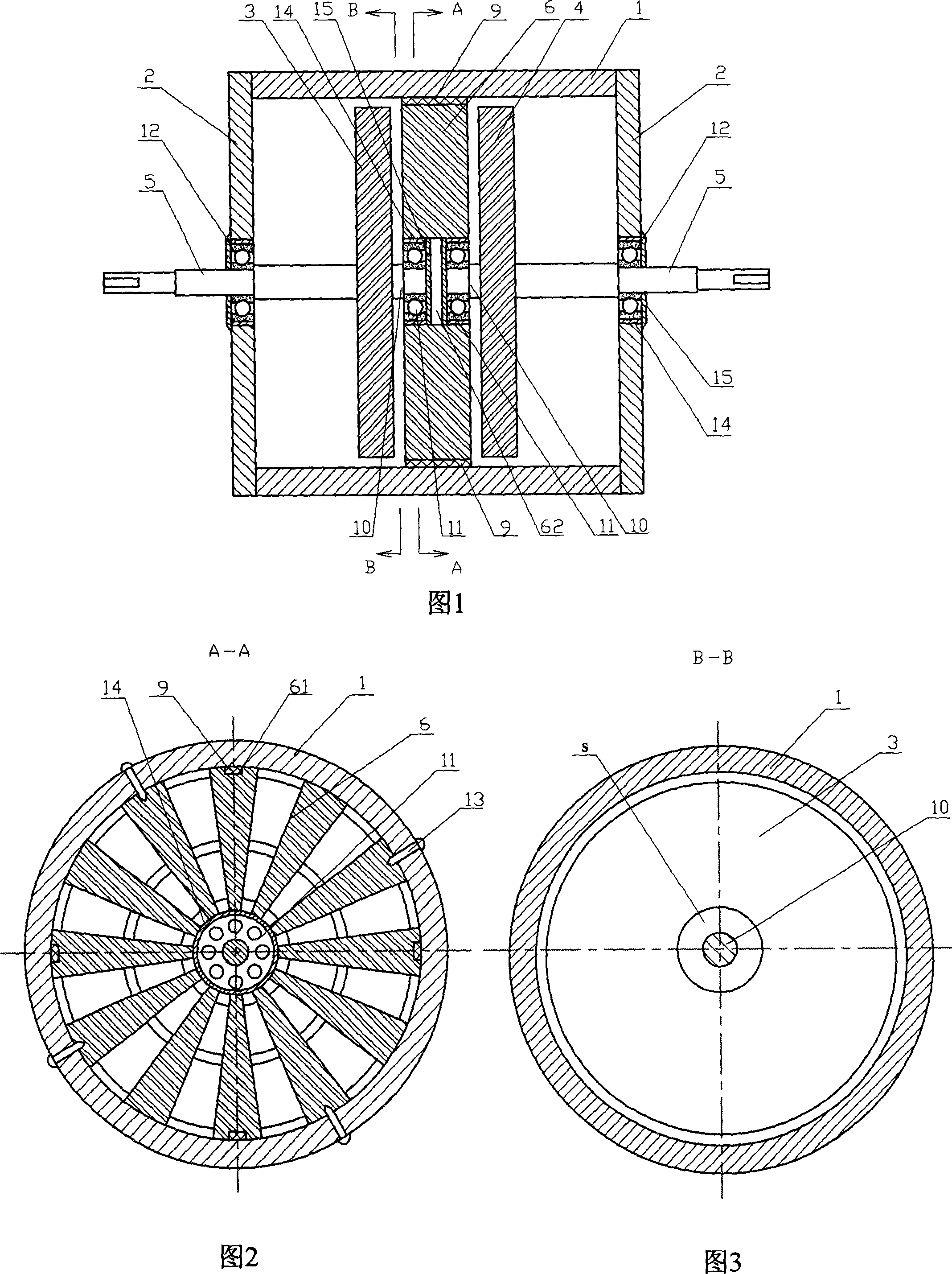

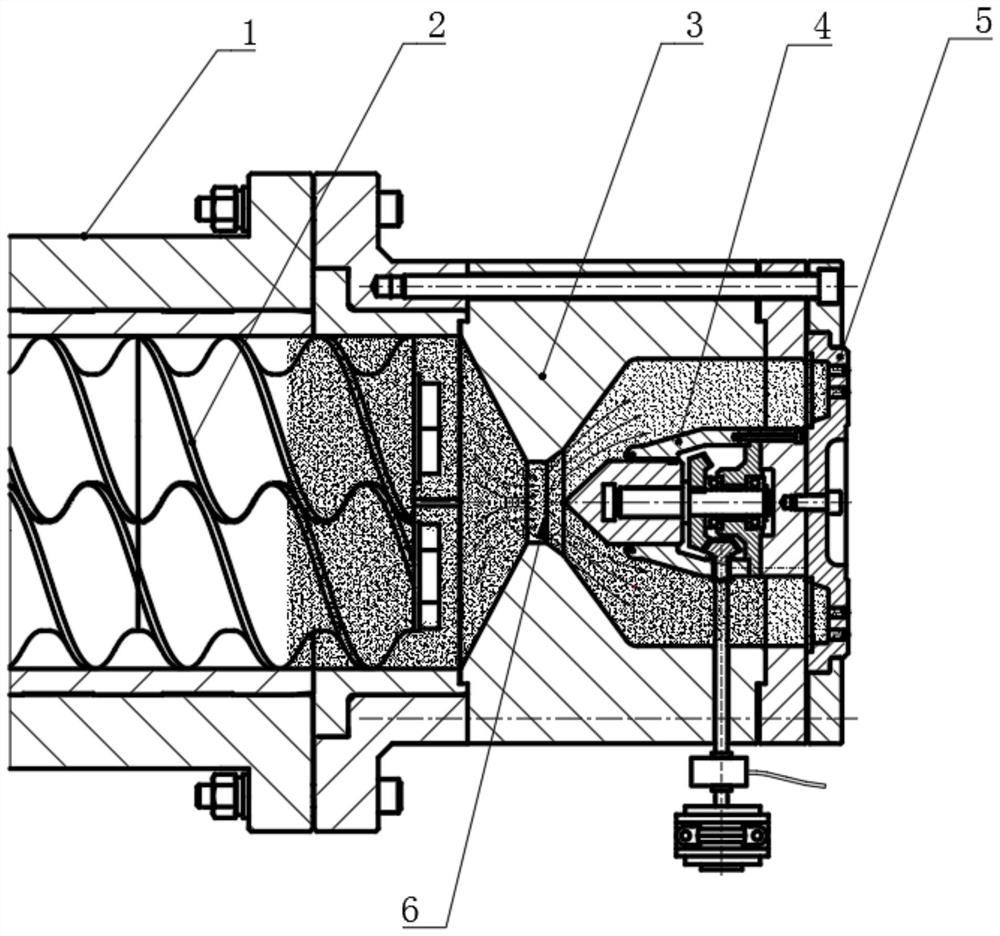

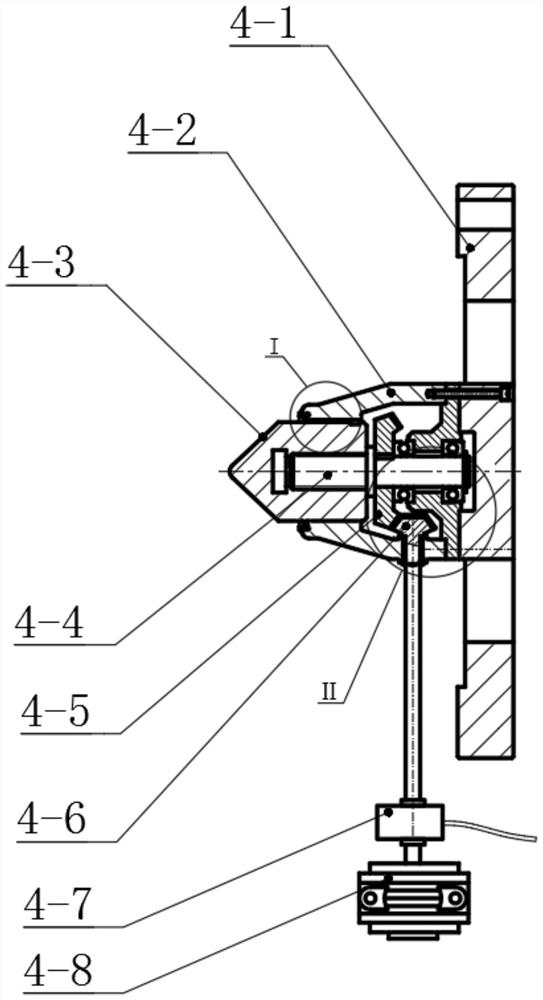

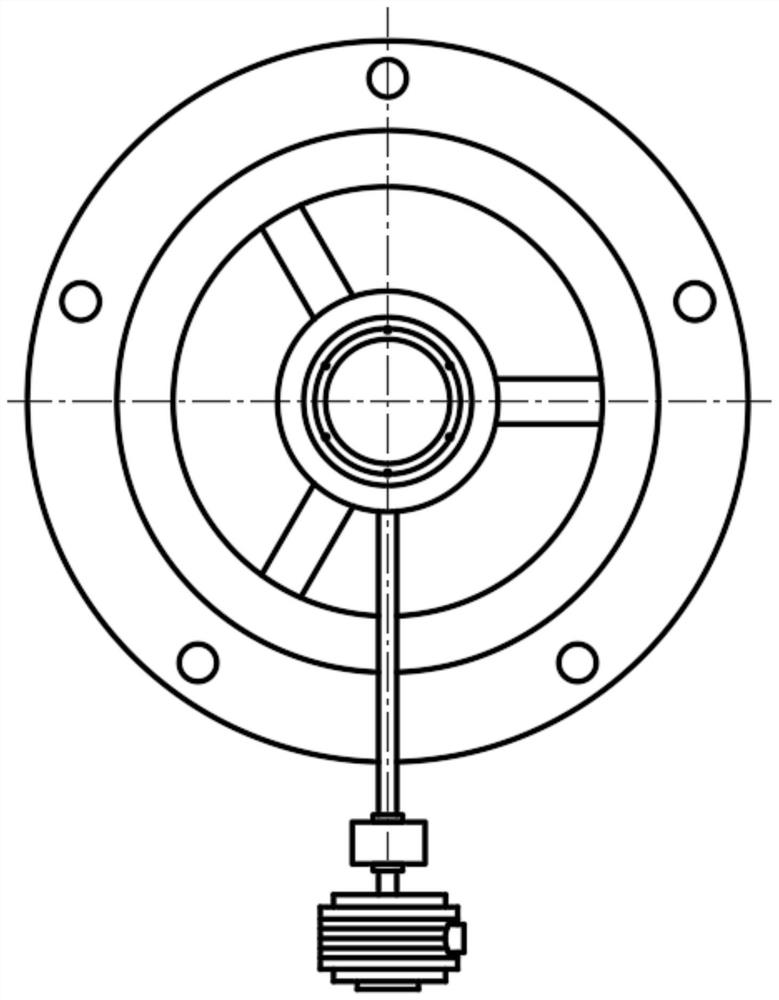

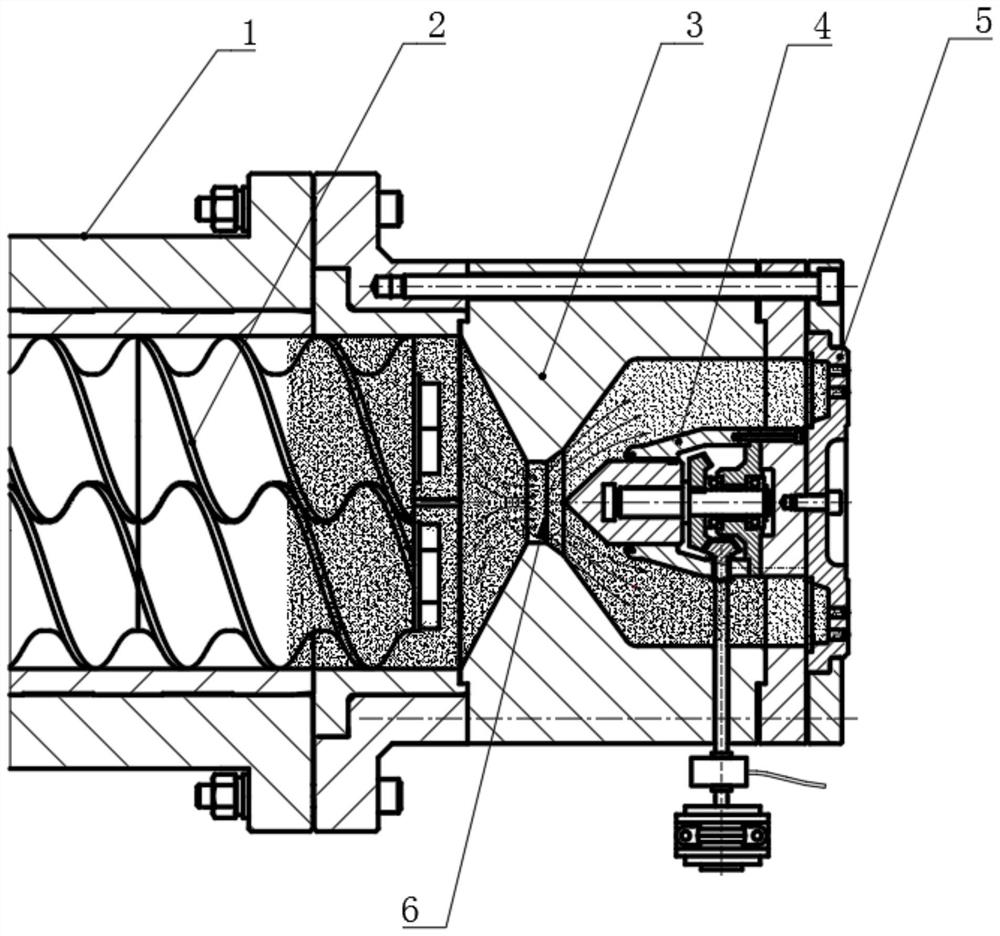

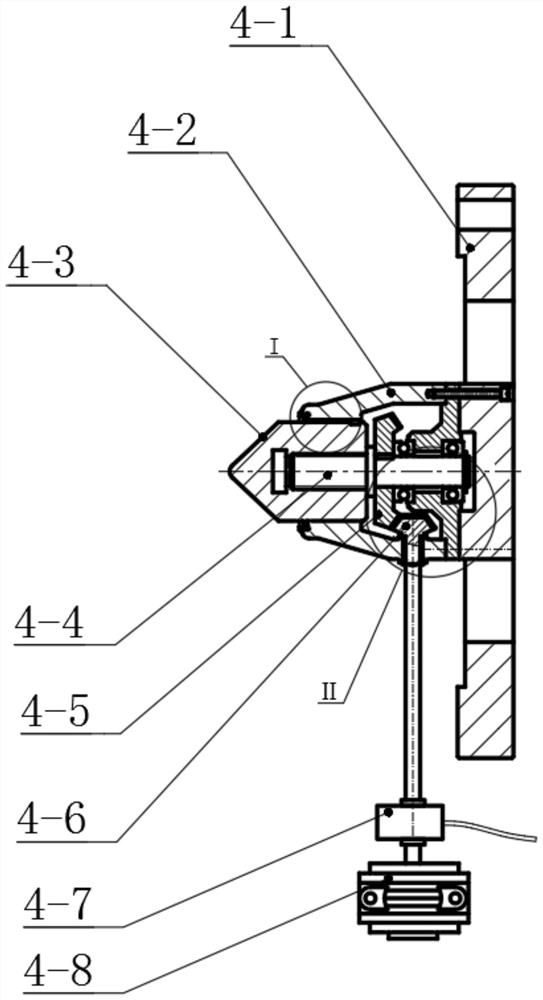

Novel high-speed rotary atomizer and manufacturing method thereof

PendingCN112495609AGuaranteed high speed operationContinuous and smooth operationMovable spraying apparatusPower stationElectric machine

The invention relates to the technical field of flue gas deacidification in the waste incineration industry, in particular to a novel high-speed rotary atomizer and a manufacturing method thereof. Thenovel high-speed rotary atomizer comprises an atomizer body, an atomizing disc, a variable-frequency driving system, a lubricating system, a cooling system, a feeding system and a cleaning system. High-power, high-speed, continuous and stable operation is achieved through an arranged high-speed motor. The atomizing disc of the equipment adopts a double-row nozzle form, the high-speed motor adoptsa novel groove type, the total power is 55 KW, the rotating speed can reach 15000 rpm or above, the dynamic balance meets G0.4, test equipments can be provided for researching the atomizing effect oflime slurry, the lime slurry flow, the slurry concentration and the relation between the rotating speed of the atomizing disc and the slurry atomizing effect are conveniently researched, the high-speed rotary atomizer can be directly used in a waste incineration power plant to completely or partially replace imported equipment, direct economic and social benefits are brought to the environmentalprotection cause of China, equipment investment and operation and maintenance cost can be saved for the waste incineration power plant, the cost of a set of imported high-speed rotary atomizer at present is RMB 1.5-2.0 million, however, the equipment procurement cost can be reduced by 30-45% by adopting domestic equipment.

Owner:上海喆林环保科技有限公司 +1

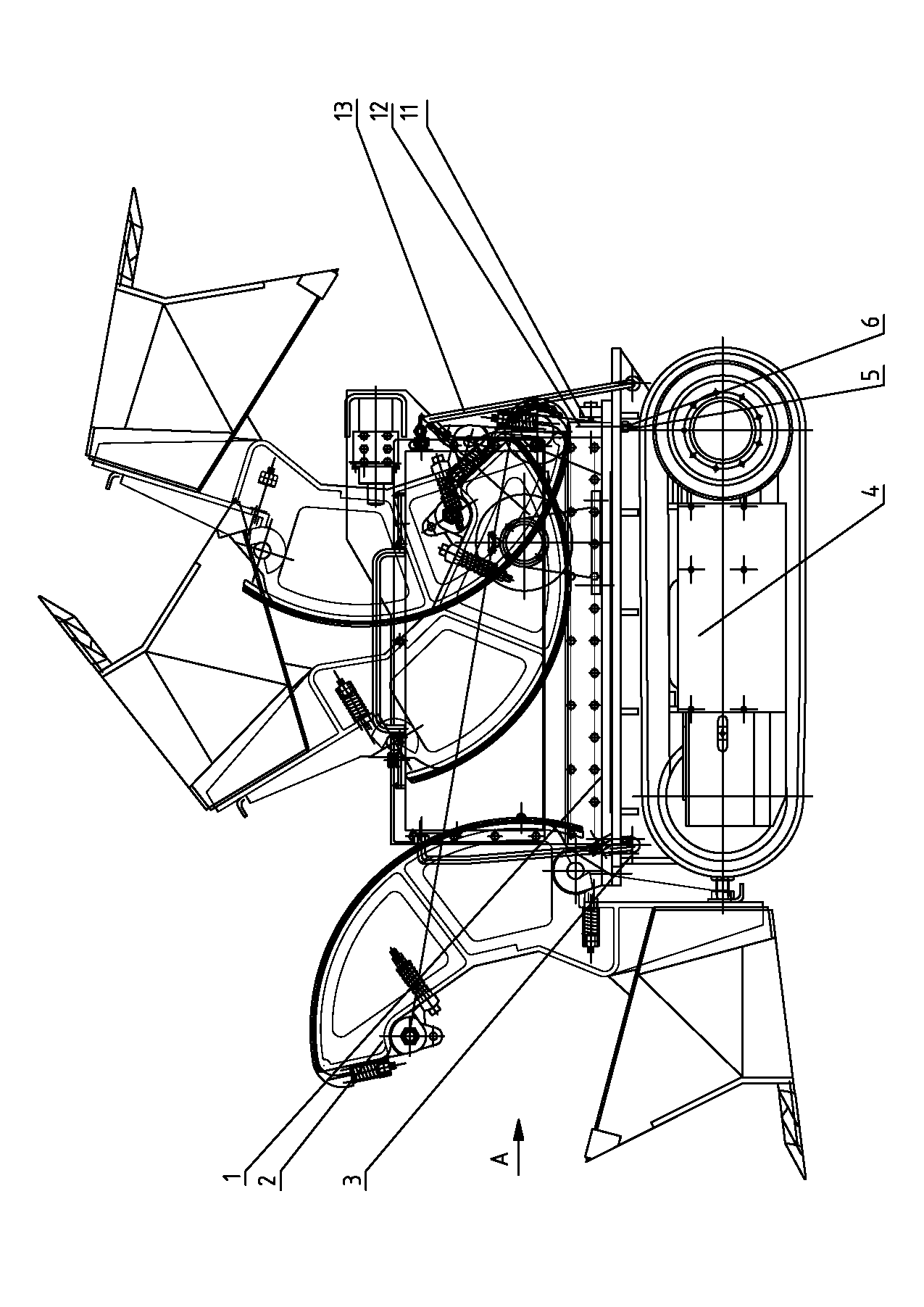

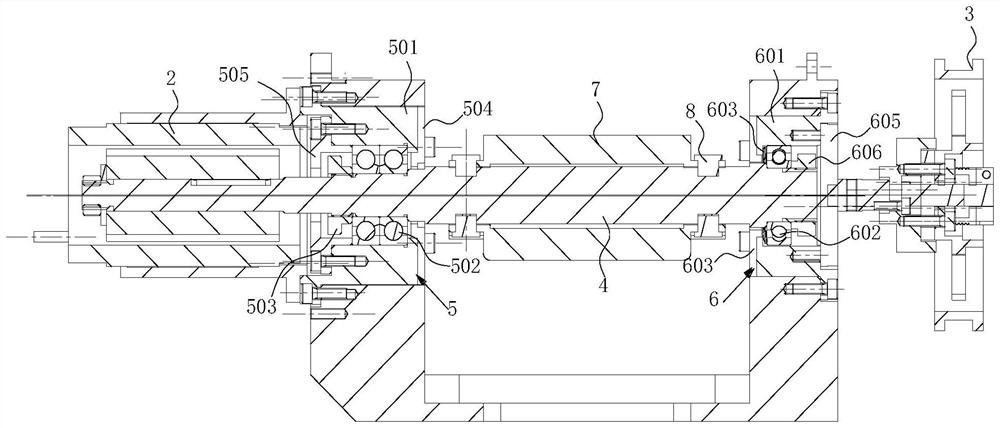

Biomass continuous pyrolysis charing apparatus with flexible spiral conveying apparatus

The invention discloses a biomass continuous pyrogenation carbonizing apparatus provided with a flexible screw conveying appliance, which comprises a motor (1), a coupling (3), bearings (4), a flexible screw spring (6), a pyrolysis tube (11), a feed inlet (5), a carbon discharging outlet (12) and a heating device; one end of the pyrolysis tube (11) is provided with the feed inlet (5) communicated with the inner cavity of the pyrolysis tube (11), and the other end is provided with the carbon discharging outlet (12) communicated with the inner cavity thereof; the inner cavity of the pyrolysis tube (11) is inserted with the flexible screw spring (6) along the axial direction; one end of the flexible screw spring (6) is connected with the output shaft of the motor (1) through the first bearing (4) and the coupling (3), and the other end is supported on the second bearing (4); and the outer side of the pyrolysis tube (11) is provided with the heating device for heating the pyrolysis tube (11). The biomass continuous pyrogenation carbonizing apparatus is easily suitable for long-distance convey and has simple structure.

Owner:SOUTH CHINA AGRI UNIV

Continuous production method of hydroxy (meth)acrylate and diester of (meth)acrylate and sulfonic acid resin catalyst

ActiveCN107597187BEfficient productionIncrease productivityOrganic compound preparationPreparation by ester-hydroxy reactionPolymer scienceMeth-

The invention belongs to the technical field of a synthesis compound, and provides a sulfoacid resin catalyst and a method for continuously producing (methyl) hydroxyethyl acrylate and (methyl) diester acrylate. The continuous production method comprises the following steps of (1) contacting dihydric alcohol, (methyl) methyl acrylate and polymerization inhibitors to form reaction liquid; continuously injecting the materials into a reaction device containing the sulfoacid resin catalyst for reaction so as to obtain coarse reaction liquid; (2) injecting the coarse reaction liquid obtained in thestep (1) into a phase splitting tank; performing double-solvent extraction; respectively obtaining a water phase containing (methyl) hydroxyethyl acrylate and an oil phase containing (methyl) diesteracrylate; (3) respectively performing rectification on the water phase and the oil phase in the step (2) to obtain (methyl) hydroxyethyl acrylate and (methyl) diester acrylate products. The method has the advantages that the product separation step is simplified; the separation temperature is low and the product purity is high.

Owner:WANHUA CHEM GRP CO LTD

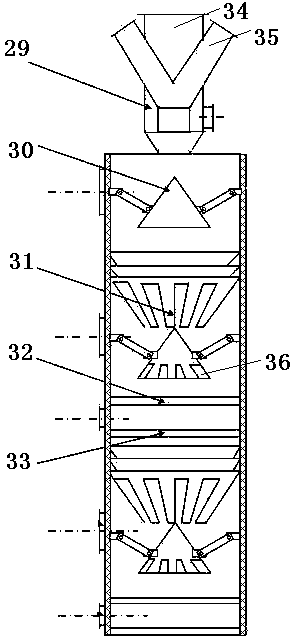

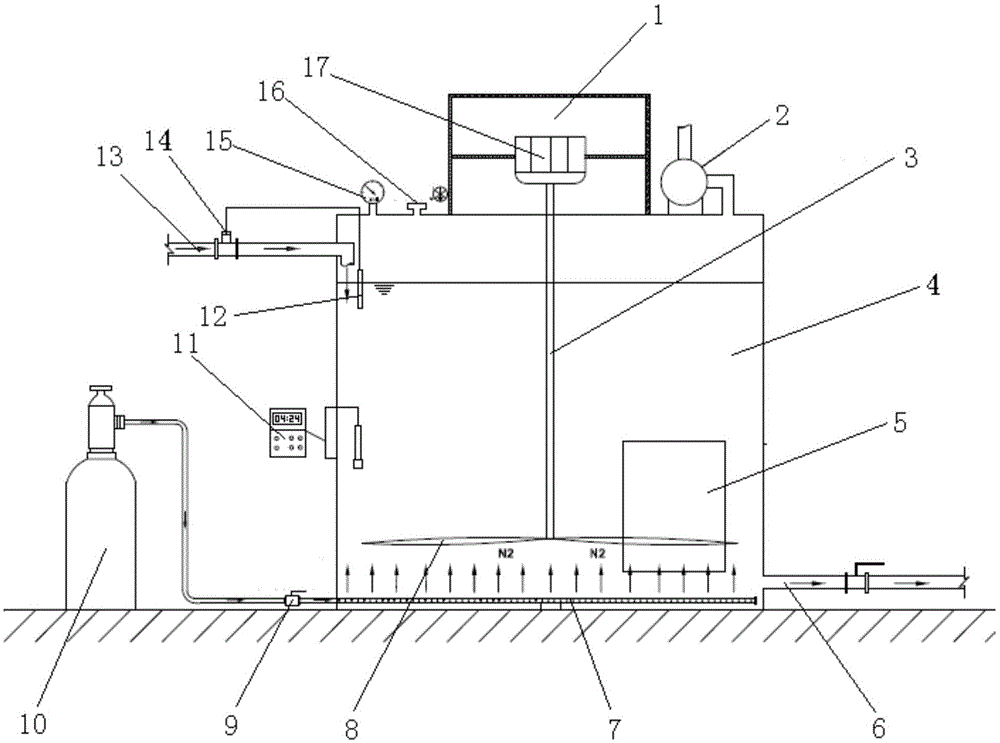

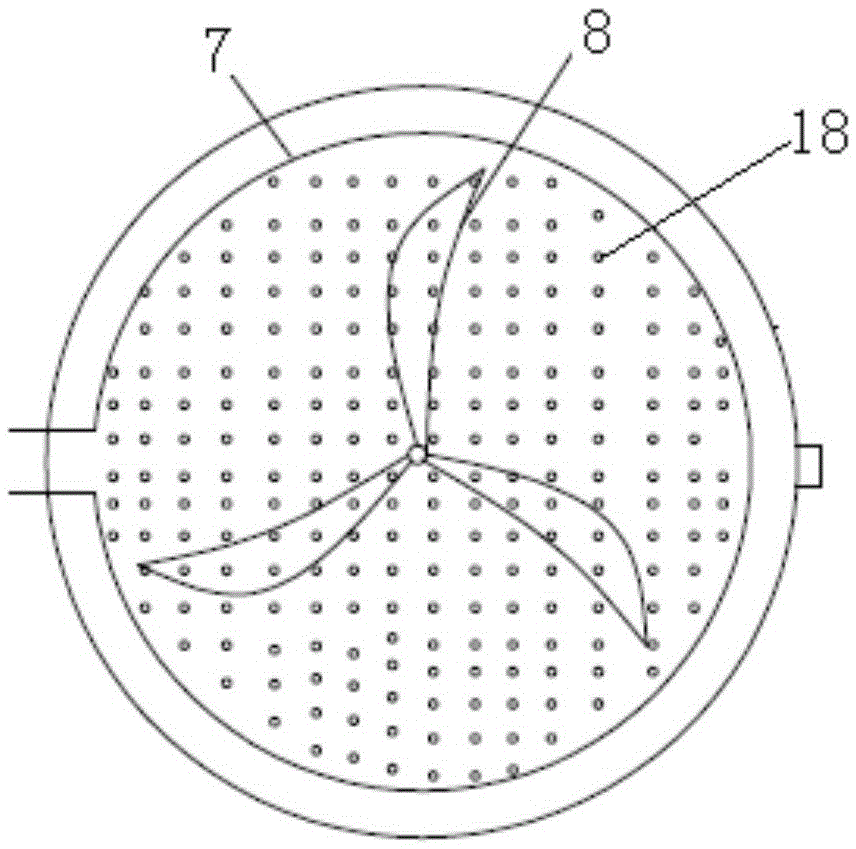

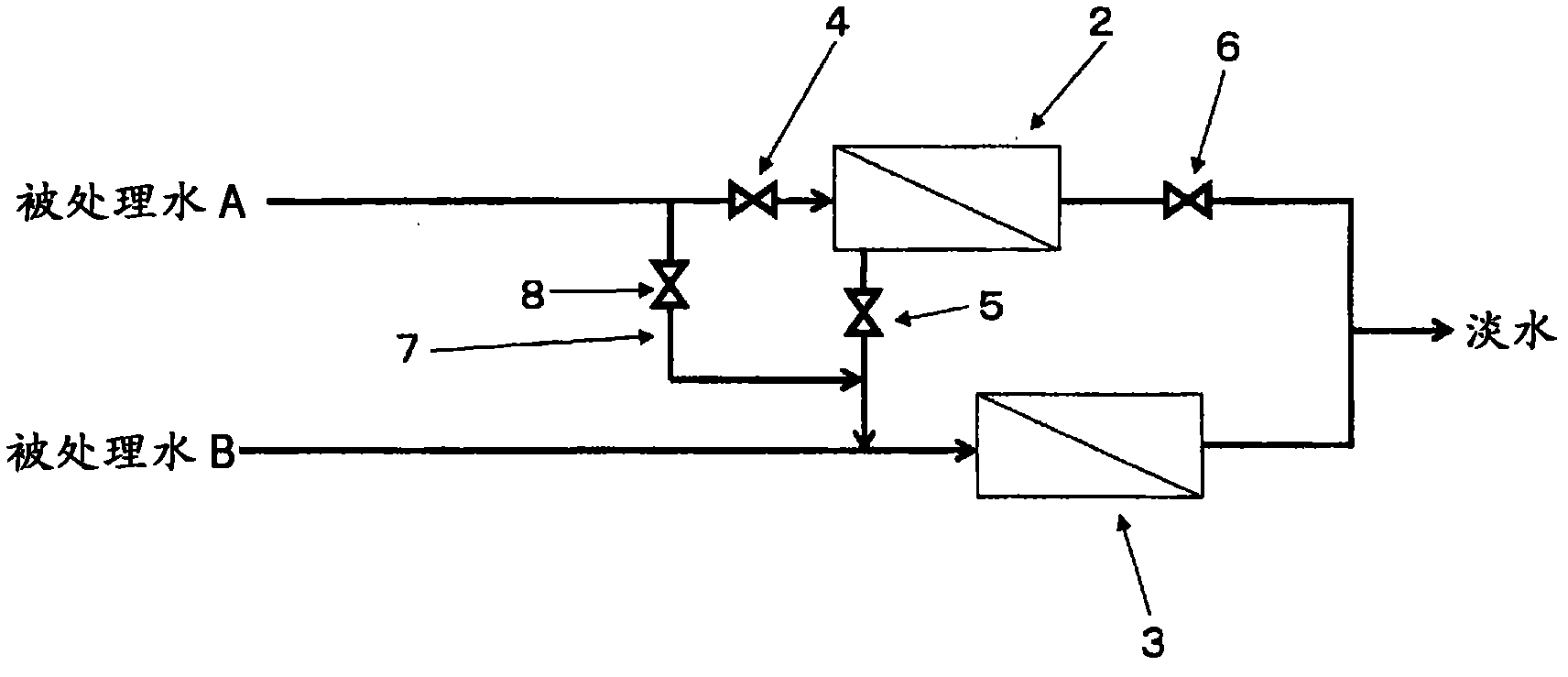

An integrated reducing agent mixing and proportioning equipment for soil pollution remediation

ActiveCN104587873BQuick clearLoss of chemical activityRotary stirring mixersTransportation and packagingNitrogenEngineering

The invention relates to the technical field of soil and groundwater pollution remediation, in particular to an integrated reducing agent mixing and proportioning equipment for soil pollution remediation. An integrated reducing agent mixing and proportioning equipment for soil pollution remediation, including a mixer, a mixing tank, a nitrogen bottle, a gas diffusion plate metering dosing pump and supporting metering and monitoring equipment, characterized in that: the lower part of the mixer is connected with Mixing bucket; the upper part of the mixer is connected to the motor, and the lower end of the motor is connected to the agitator blade with a connecting rod, and the agitator blade extends into the lower part of the mixing bucket; one side of the upper part of the mixing bucket is connected to the water inlet pipe, and the lower part of the mixing bucket is The side is connected to the nitrogen cylinder with pipelines, the top side of the mixing barrel is connected to the metering dosing pump, and the other side of the lower part of the mixing barrel is the chemical outlet pipeline. Compared with the existing technology, the integrated equipment is easy to move, relatively low in cost, easy to equip and overhaul, easy to operate and maintain, capable of continuous and stable operation, and precise proportioning of medicaments.

Owner:TIANYU ECO ENVIRONMENT CO LTD

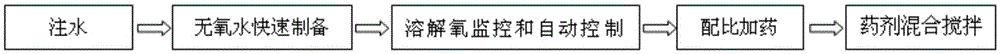

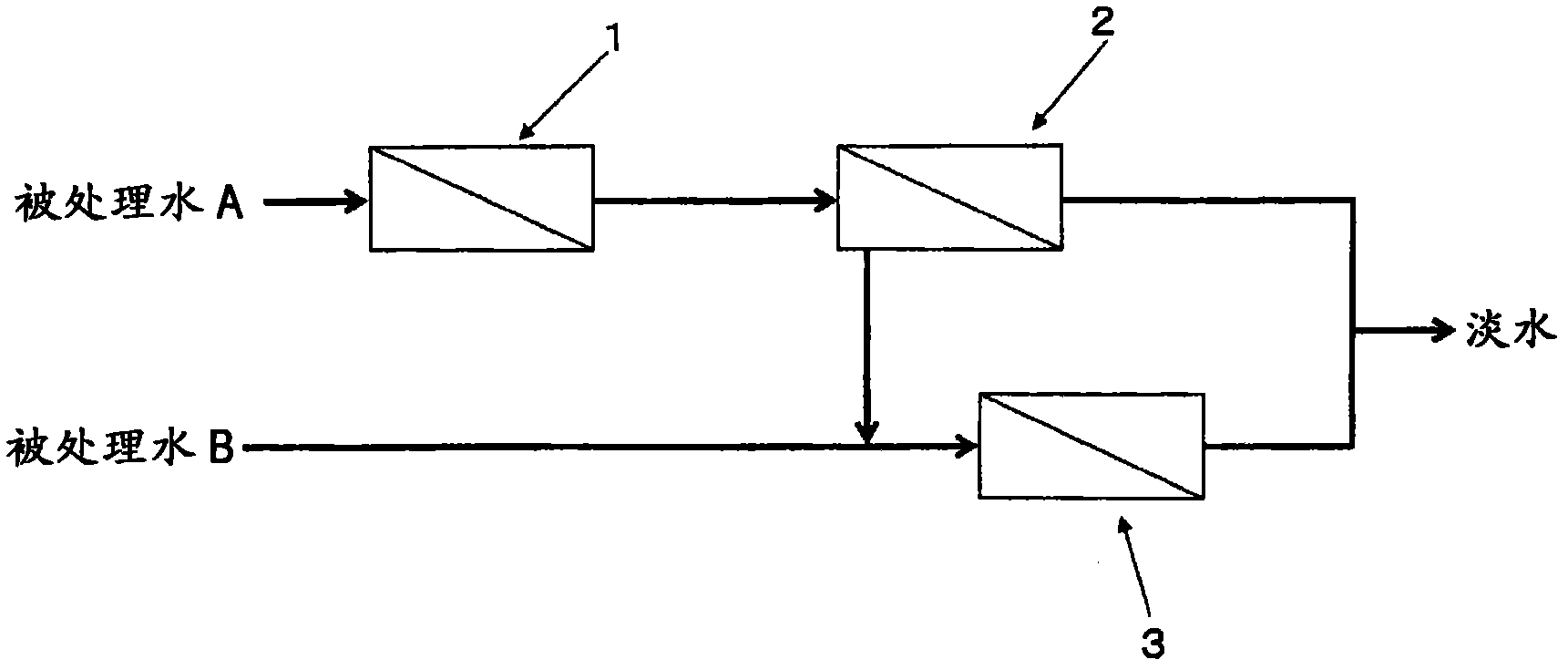

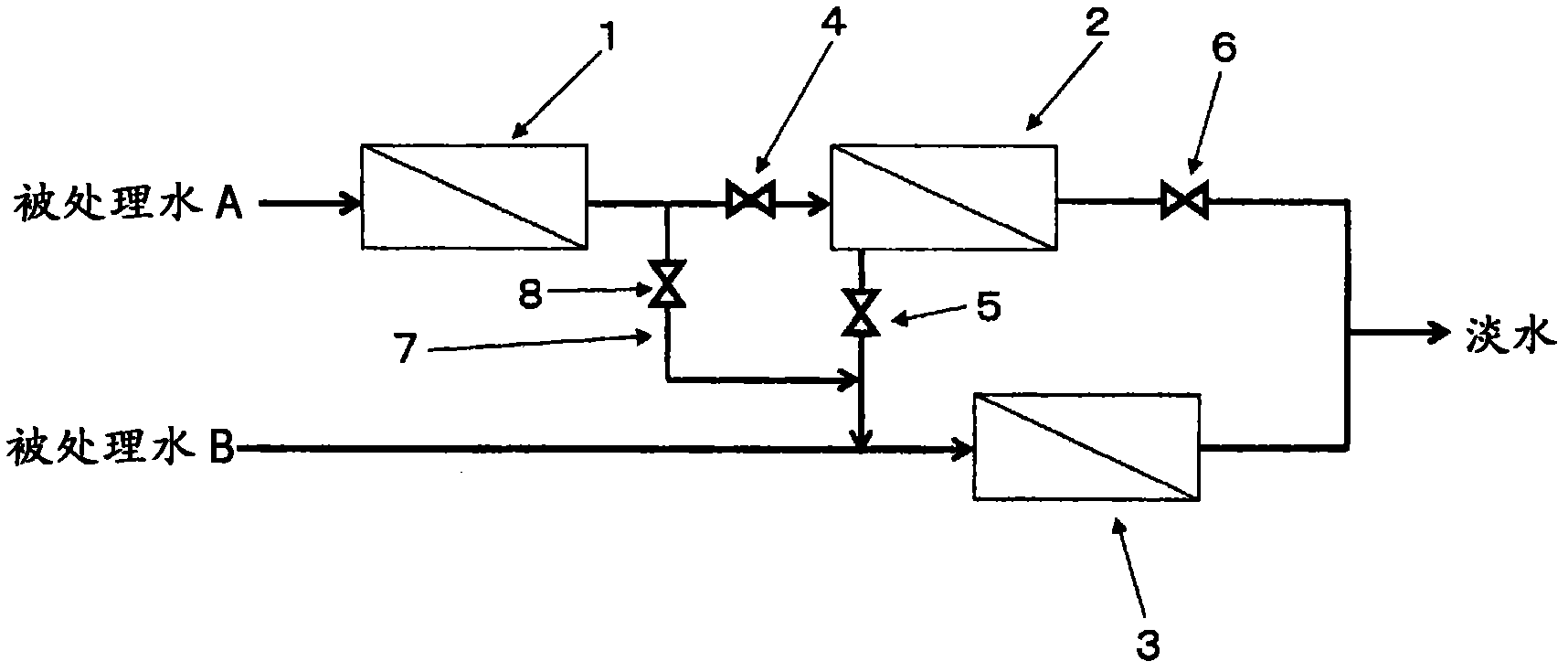

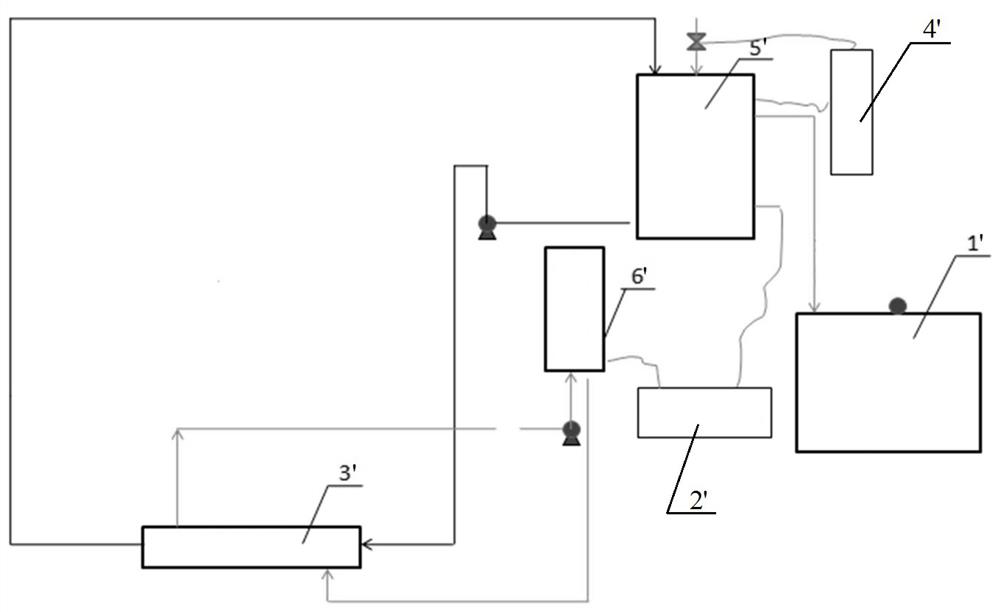

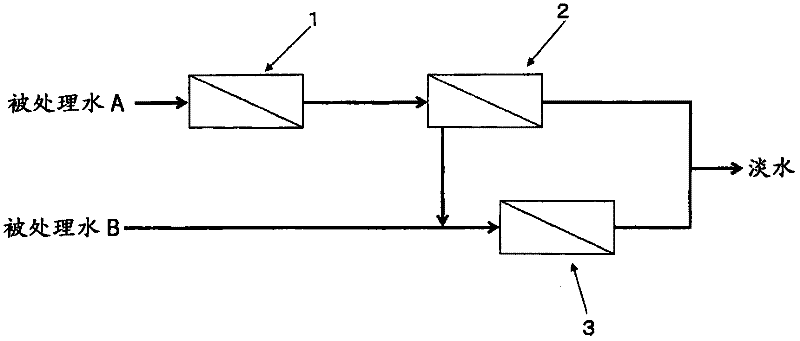

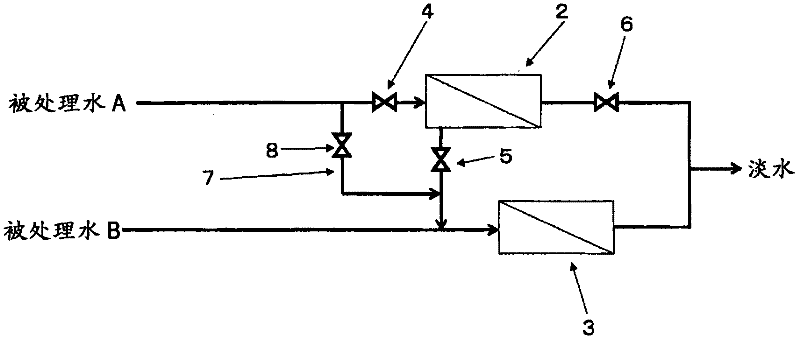

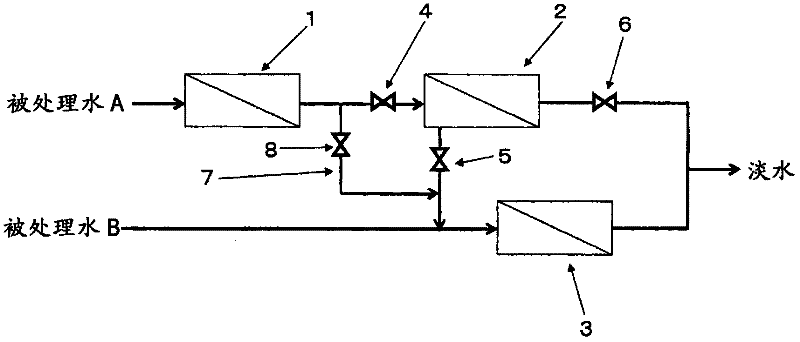

Water producing system

ActiveCN102471100BContinuous and smooth operationSemi-permeable membranesMembranesTreatment targetsSemipermeable membrane

To provide a water producing system that produces fresh water by treating treatment target water A at a first semipermeable membrane treatment plant 2, that mixes concentrate resulted by the treatment carried out at the first semipermeable membrane treatment plant 2 with treatment target water B, and that treats the mixed water at a second semipermeable membrane treatment plant 3 to produce fresh water, characterized in provision of a bypass line that allows the treatment target water A to be mixed with the treatment target water B or the concentrate while bypassing the first semipermeable membrane treatment plant 2, so that the second semipermeable membrane treatment plant 3 can operate even when any trouble occurs at the first semipermeable membrane treatment plant 2 and treatment cannot be carried out thereby.

Owner:TORAY IND INC

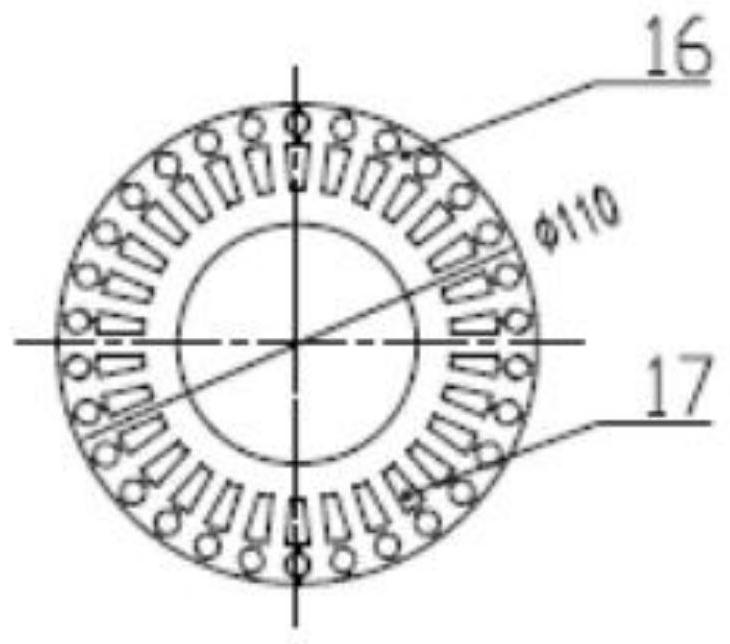

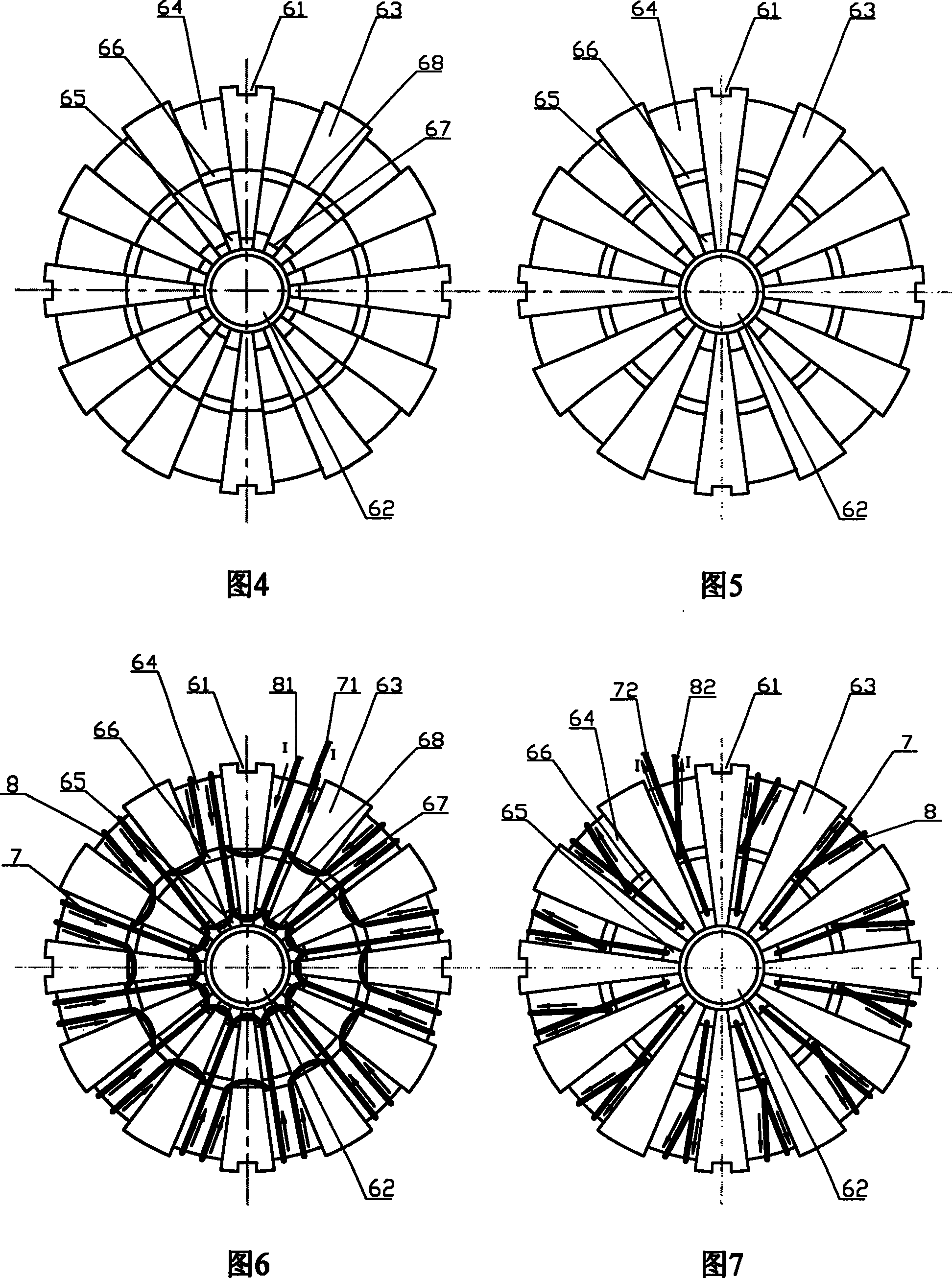

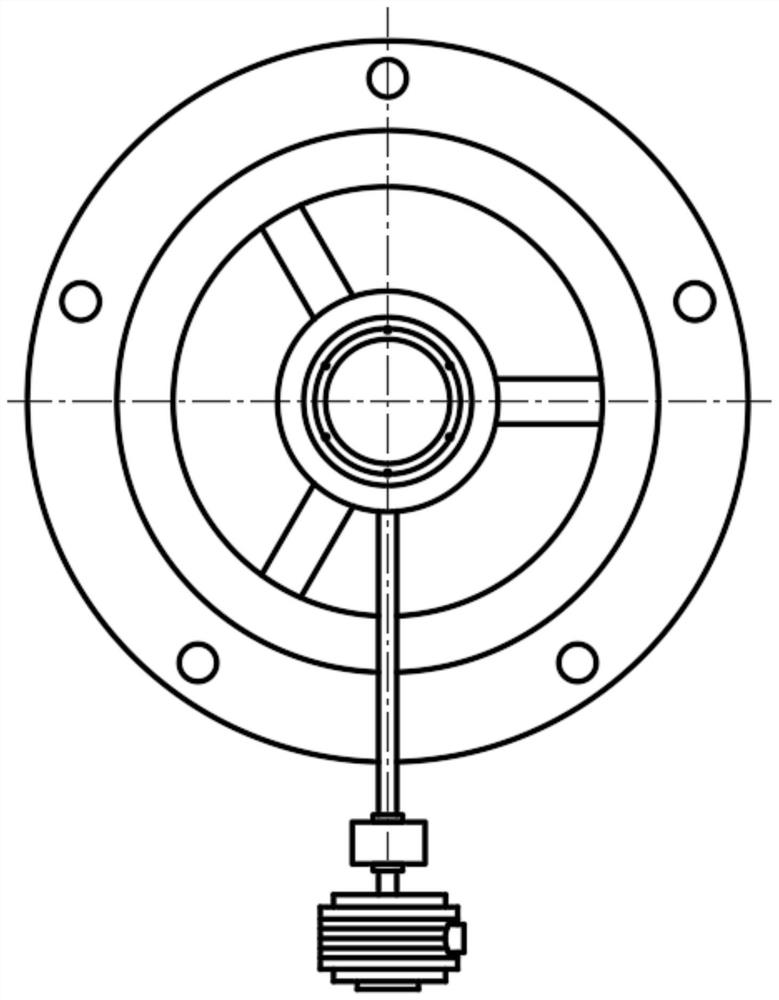

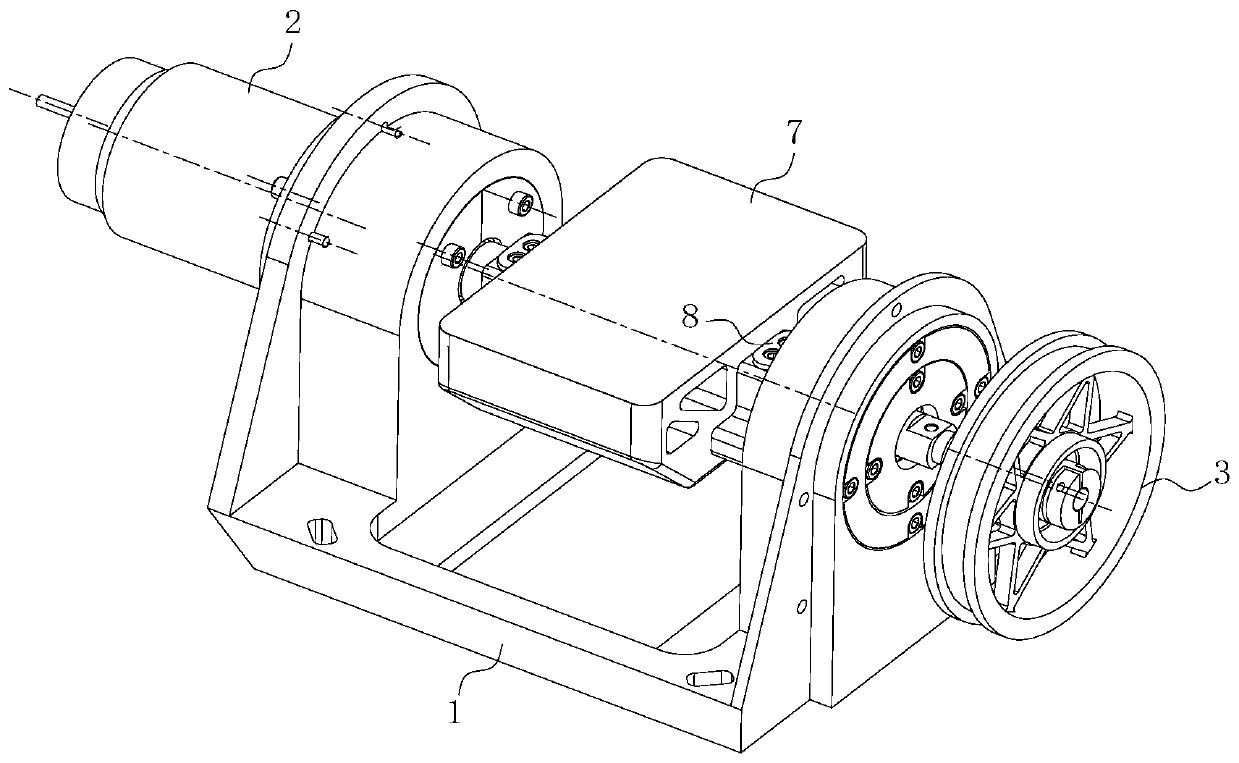

Disk birotor dual veer DC brushless motor

InactiveCN1801587BContinuous and smooth operationReduce manufacturing costMagnetic circuit rotating partsBrushless motorsManufacturing cost reduction

The invention discloses a disc dual-rotor dual-rotation direction dc brushless motor, which comprises: a base, an end cap on two ends of base, a stator with a disc stator core fixed between rotors and a disc stator winding sector-shaped coiled on core, two rotors with inner surface as N and S-pole permanent magnets and arranged vertically in base, and output shaft with one end fixed on outer surface of rotor ad another end extended out the cap. Wherein, the two side surfaces of stator core are opposite to the inner surfaces of rotor; the stator core has same current direction as winding coil on same side while the current direction of two windings opposite. This invention has simple structure, runs reliably, and can reduce cost and energy consumption.

Owner:曾琼东

Extrusion equipment

ActiveCN111758986AEfficient removalAvoid enteringFeeding-stuffFood shapingEngineeringMechanical engineering

The invention belongs to the technical field of food, pet and feed machinery, and discloses an extrusion equipment. An extrusion cavity outlet of the extrusion device is sequentially connected with aVenturi effector and a pressure adjusting device, and a middle part of the Venturi effector is of a necking structure; the pressure adjusting device comprises a piston and a piston sleeve which are matched with each other, the piston is coaxially arranged at a feeding end of the piston sleeve, the piston, the piston sleeve, the Venturi effector and the extrusion cavity of the extrusion device arecoaxially arranged, the piston faces the Venturi effector, the piston and a necking structure of the Venturi effector form an extrusion channel, and under action of the piston driving device, the piston moves axially away from or close to the necking structure of the Venturi effector relative to the piston sleeve to change the size of the extrusion channel; and a material cleaning sealing piece isarranged on the piston sleeve and used for cleaning materials on a sliding surface of the piston and preventing materials from entering the piston sleeve. The extrusion equipment solves a technical problem that an extrusion force cannot be continuously adjusted in the prior art.

Owner:FAMSUN CO LTD

Transmission mechanism utilizing permanent magnet

InactiveCN101320935BAvoid damageSimple structureDynamo-electric brakes/clutchesGearingMagnetic tension forceTransmission belt

A transmission device using a permanent magnet, belongs to the technical field of the mechanical transmission, particularly to a mechanical apparatus for converting the mechanical straight line motion into the transmission by the magnetic force of the permanent magnet, including a power output part and a power driving part, wherein the power output part has a non-magnetic principal axis supportedon the bearing, the surface of the principal axis is fixed with a plurality of adsorbed sheets in the helical form axially; the driving part is provided with a guide wheel and a transmission belt towed by the outside force; a plurality of permanent magnets are fixed on the outer surface of the transmission belt; the transmission belt in the working area is parallel with the axial of the principalaxis; a gap is arranged between the permanent magnet and the adsorbed sheets; the distance between the neighbor permanent magnet is equal to the helical pitch of the adsorbed sheets on the principal axis. In use, the straight line motion of the permanent magnet is converted to the rotation of the principal axis. The device is used in the mechanical technical field for changing the mechanical motion state.

Owner:龚达明

an extrusion device

ActiveCN111758986BEfficient removalAvoid enteringFeeding-stuffFood shapingEngineeringMechanical engineering

The invention belongs to the technical field of food, pet and feed machinery. An extrusion device, the outlet of the extrusion chamber of the extrusion device is sequentially connected with a Venturi effector and a pressure adjustment device, the middle part of the Venturi effector is a necking structure; the pressure adjustment device includes a matching piston and a piston sleeve, and the pistons are coaxial Installed on the feed end of the piston sleeve, the piston, the piston sleeve, the Venturi effector, and the extrusion chamber of the extrusion equipment are coaxially arranged, the piston faces the Venturi effector, and the necking structure of the piston and the Venturi effector forms an extrusion channel. Under the action of the piston driving device, the piston moves away from or close to the necking structure of the Venturi effector relative to the piston sleeve to change the size of the extrusion channel; the piston sleeve is provided with a cleaning seal for cleaning the piston. material on the sliding surface and prevent the material from entering the interior of the piston sleeve. The invention solves the technical problem that the extrusion force cannot be continuously adjusted in the prior art.

Owner:FAMSUN CO LTD

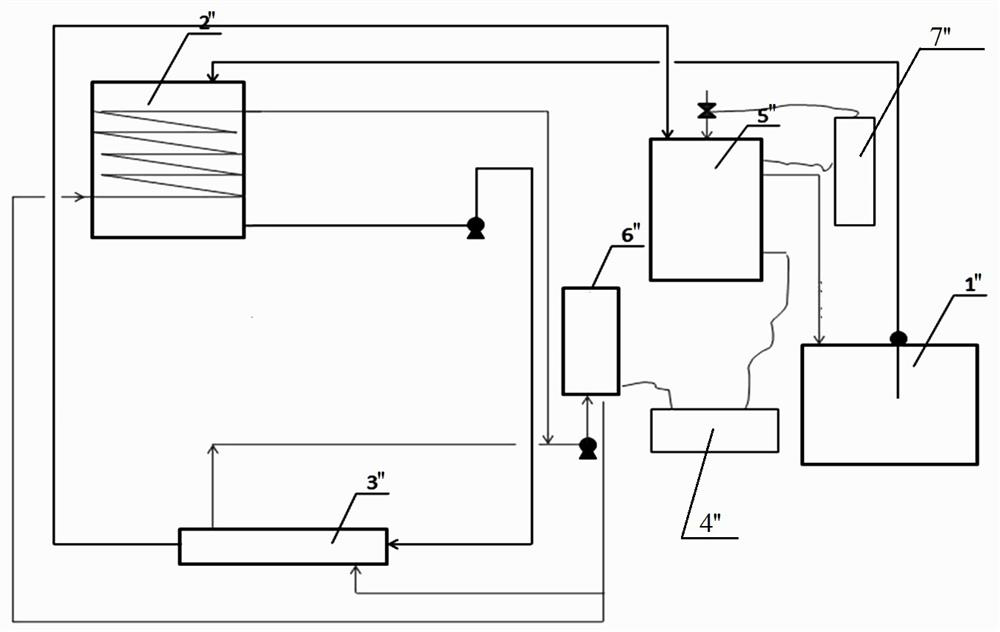

Device and method for recycling phosphorus-containing wastewater in vacuum system of vacuum rectification of yellow phosphorus

ActiveCN110302551BStable suction volumeContinuous normal drivingVacuum distillation separationFractional distillationCooling effectWastewater

The invention discloses a device and method for recycling phosphorus-containing waste water in a yellow phosphorus decompression rectification vacuum system. The device comprises a phosphorus-containing waste water collection tank, a cold water tank one, a heat exchanger, a cold water tank two, a vacuum water tank, and a water chiller; It is characterized in that the phosphorus-containing wastewater collection tank is connected to the first cold water tank; the first cold water tank is connected to the heat exchanger, the heat exchanger is connected to the second cold water tank, the second cold water tank is connected to the vacuum water tank, the vacuum water tank is connected to the phosphorus-containing wastewater collection tank, Form a circulation line. The device is simple in structure and highly efficient in recycling. The invention also discloses a method for recycling phosphorus-containing waste water in a yellow phosphorus decompression rectification vacuum system. After the phosphorus-containing waste water is collected, it undergoes three-stage cooling and recycling. The cooling effect is good, the vacuum pump operates normally, the rectification system is stable, and no clean water is added. and waste water, which solves the problem of unstable vacuum in the rectification system and the generation of phosphorus-containing waste water.

Owner:HUBEI SINOPHORUS ELECTRONIC MATERIALS CO LTD

Method for handling (meth) acrylic ester-containing solution

ActiveCN1697823BContinuous and smooth operationInhibition formationOrganic compound preparationCarboxylic acid esters preparationMeth-Distillation

The present invention provides a method for handling a (meth)acrylic ester-containing solution in which the (meth)acrylic ester-containing solution is treated by at least one process selected from washing, neutralization and extraction, the said method being capable of ensuring a stable continuous operation of the treating system for a long period of time without deteriorating a liquid-liquid separation efficiency and a distillation efficiency in subsequent steps while inhibiting the formation of sludge, when waste water or a waste aqueous solution obtained by recovering effective ingredientsfrom the (meth)acrylic ester-containing solution treated by said at least one process is recycled to the previous process and reused therein. The above waste water or waste aqueous solution is previously cooled to a temperature of 10 to 50 DEG C and then solids are removed therefrom prior to recycling the waste water or waste aqueous solution to the previous process and reusing the same therein.

Owner:MITSUBISHI RAYON CO LTD

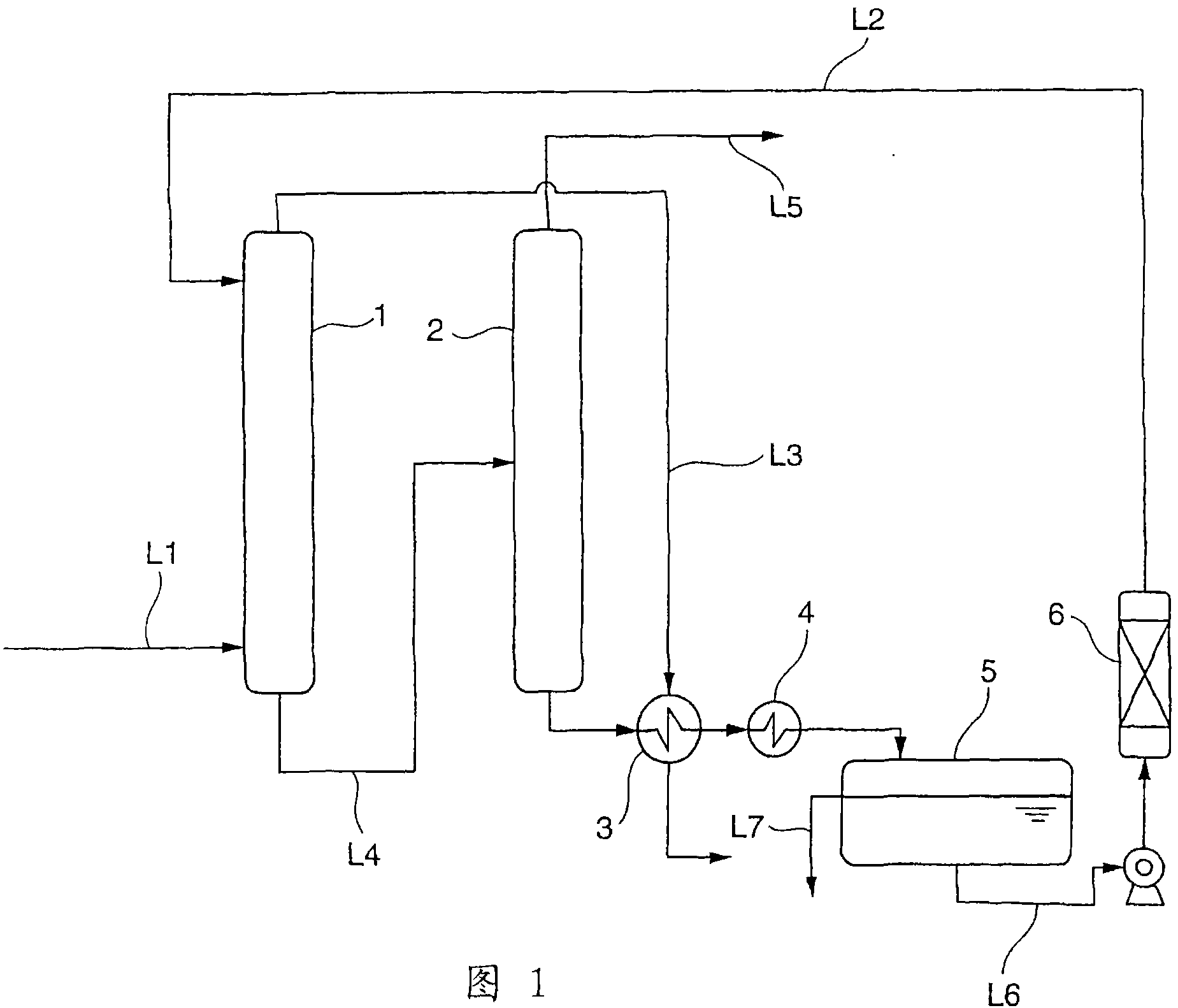

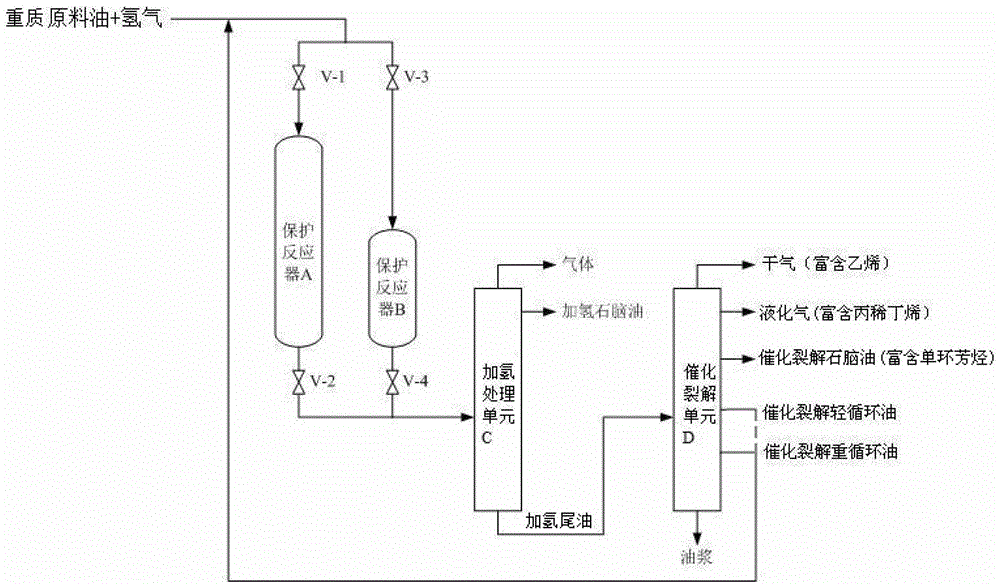

A kind of processing method of heavy crude oil

ActiveCN104119954BLow viscosityColloidal system is stableTreatment with hydrotreatment processesHydrogenAromatic hydrocarbon

The invention provides a heavy raw oil treatment method. The method is carried out in a raw oil treatment apparatus, the apparatus comprises a hydrogenation protection unit, a hydrotreatment unit and a catalytic cracking unit which are sequentially connected in series, the hydrogenation protection unit comprises a main hydrogenation protection reactor and a standby hydrogenation protection reactor which are connected in parallel, and the volume of the main hydrogenation protection reactor is greater than the volume of the standby hydrogenation protection reactor. The method is characterized in that heavy raw oil and hydrogen are introduced to the apparatus, and contact with a plurality of hydrogenation catalyst beds arranged in the apparatus to obtain hydrogenated tail oil; and the main hydrogenation protection reactor and the standby hydrogenation protection reactor are alternately used, and the online time of the main hydrogenation protection reactor is greater than the online time of the standby hydrogenation protection reactor. The method has the advantages of high yield of low carbon olefins and monocyclic aromatic hydrocarbons, and high space utilization rate of the above reactors.

Owner:CHINA PETROLEUM & CHEM CORP +1

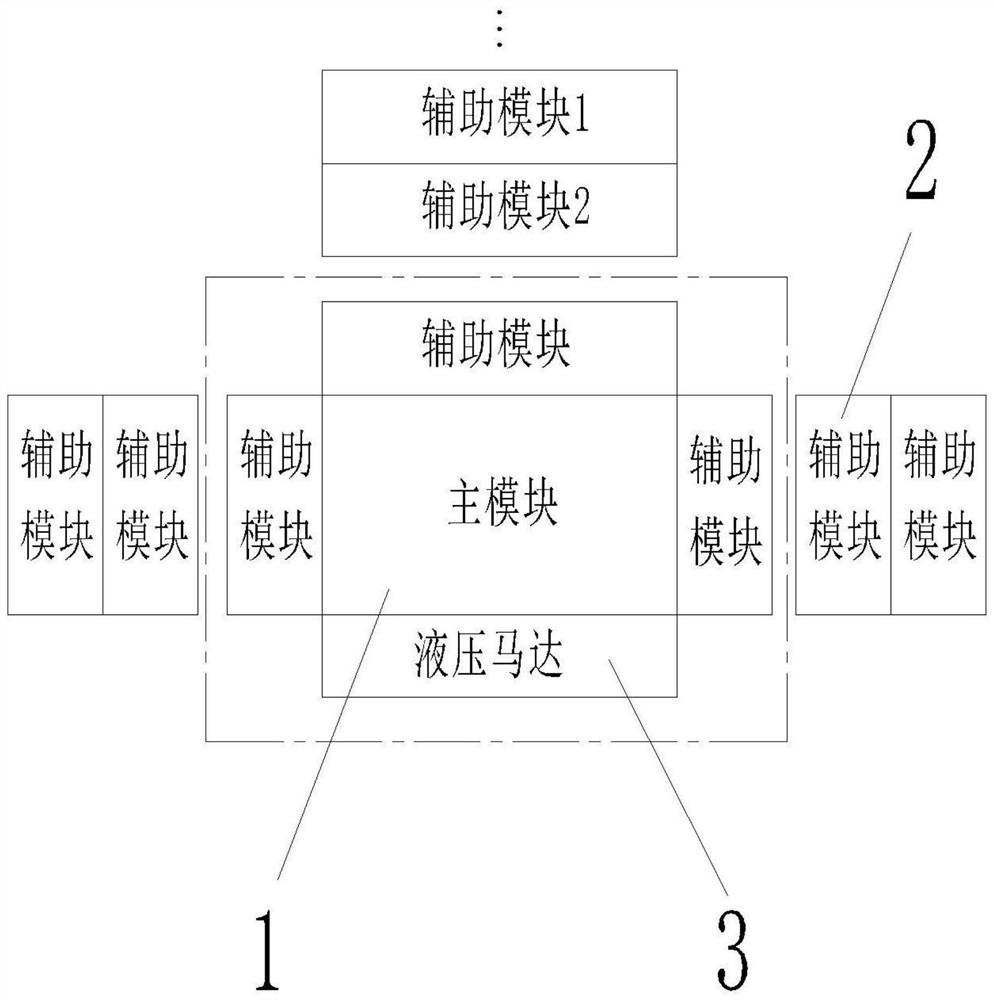

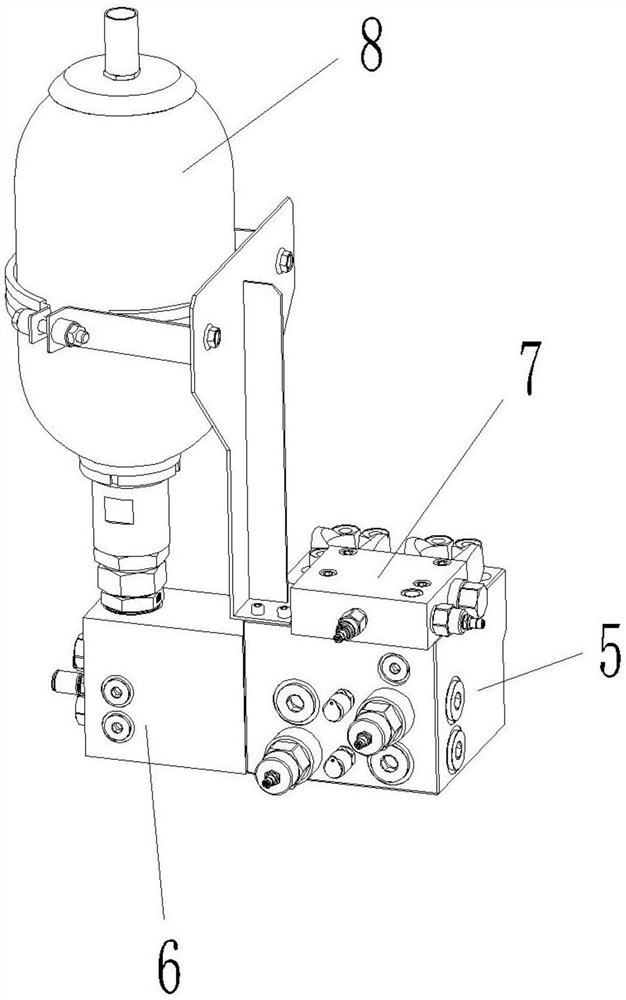

Modular assembly integrated valve block applied to hydraulic motor side

PendingCN114033766AEasy interconnectionMeet diverse needsServomotor componentsServomotorsHydraulic motorControl engineering

The invention discloses a modular assembly integrated valve block applied to a hydraulic motor side, which is characterized in that the modular assembly integrated valve block comprises a main module with fixed functions and a plurality of auxiliary modules with functions capable of being canceled, replaced or combined, the main module and the auxiliary modules are provided with standardized interfaces, each auxiliary module is in oil path communication with the main module through the standardized interface, the main module and the auxiliary modules are detachably mounted together, and the different auxiliary modules are detachably mounted together. The modular assembly integrated valve block applied to the hydraulic motor side adopts standardized and modular design, and is short in design period and low in manufacturing cost.

Owner:NINGBO STF HYDRAULIC TRANSMISSIONS CO LTD

Water producing system

ActiveCN102471100AContinuous and smooth operationWater treatment parameter controlSemi-permeable membranesSemipermeable membraneFresh water

Disclosed is a water producing system which produces fresh water by treating water to be treated (A) in a first semipermeable membrane treatment facility (2) and produces fresh water by mixing concentrated water generated in the treatment in the first semipermeable membrane treatment facility (2) into water to be treated (B) and treats mixed water thereof in a second semipermeable membrane treatment facility (3), the water producing system being characterized in that a bypass line for mixing the water to be treated (A) into the water to be treated (B) or the concentrated water without going through the first semipermeable membrane treatment facility (2) is provided so that the second semipermeable membrane treatment facility (3) can run even when the treatment cannot be performed, for example, due to the occurrence of a problem in the first semipermeable membrane treatment facility (2).

Owner:TORAY IND INC

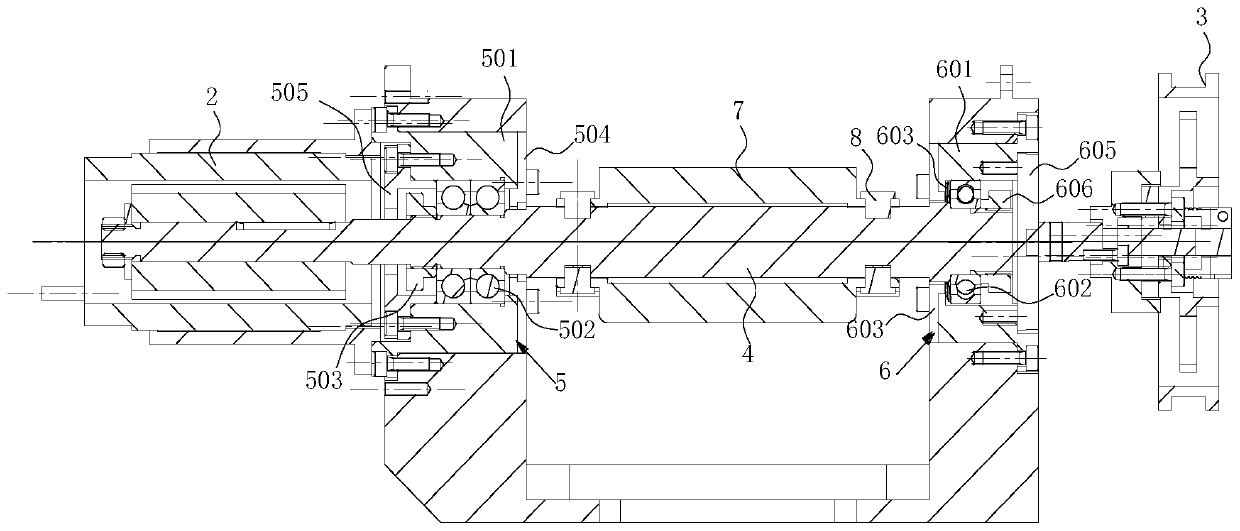

Satellite-borne scanning mechanism

The invention discloses a satellite-borne scanning mechanism, belongs to the technical field of space optical remote sensing, and aims to solve the problems of short service life, complex mechanism and time-consuming and labor-consuming assembly and adjustment in the prior art. A satellite-borne scanning mechanism of the present invention comprises: a support body; a driving motor which is fixed on one side of the supporting body; an encoder which is arranged on the other side of the support body; a central shaft, one end of the central shaft penetrates through one side of the supporting bodyand is coaxially and fixedly connected with the driving motor, and the other end of the central shaft penetrates through the other side of the supporting body and is connected with the encoder; the end, close to the drive motor, of the center shaft is rotationally supported on the supporting body through a rotary supporting structure, and the end, close to the encoder, of the center shaft is movably supported on the supporting body through a movable supporting structure; and a scanning mirror which is fixed on the central shaft through a connecting seat, and the scanning mirror is positionedin the support body.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Double-layer up-and-down die pressing device and paper-plastic forming machine

PendingCN112593459AImprove job productivityImprove fully automated productionTextiles and paperPlastic forming machineMolding machine

The utility model discloses a double-layer up-and-down die pressing device and a paper-plastic forming machine. The double-layer up-and-down die pressing device comprises a servo motor, a multi-wheelsynchronous belt, a first section up-and-down die opening and closing driving rod, a second section up-and-down die opening and closing driving rod, a first layer upper die, a first layer lower die, asecond layer upper die and a second layer lower die, the first section up-and-down die opening and closing driving rod drives the first layer upper die and the first layer lower die to be switched between an opening state and a closing state; the second section up-and-down die opening and closing driving rod drives the second layer upper die and the second layer lower die to be switched between an opening state and a closing state; the multi-wheel synchronous belt comprises an upper multi-wheel synchronous belt body and a lower multi-wheel synchronous belt body which are synchronously driven,and the upper multi-wheel synchronous belt body drives the first section up-and-down die opening and closing driving rod to enable the first layer upper die and the first layer lower die to be closeto each other or far away from each other. Multi-mode operation is synchronously driven, the operation capacity is improved by multiple times, the universality is high, the structure is stable and reliable, and operation is continuous and smooth. Therefore, continuous full-automatic production is effectively improved, and the production efficiency is effectively improved.

Owner:珠海洋洲智能装备技术有限公司

A spaceborne scanning mechanism

ActiveCN110941084BEasy to operateContinuous and smooth operationOptical elementsElectric machineryDrive motor

A space-borne scanning mechanism belongs to the field of space optical remote sensing technology, and aims to solve the problems of short service life, complex mechanism and time-consuming and laborious assembly and adjustment existing in the prior art. A space-borne scanning mechanism of the present invention comprises: a support body; a drive motor fixed on one side of the support body; an encoder arranged on the other side of the support body; a central shaft, one end of which passes through one side of the support body One side is fixedly connected with the drive motor coaxially, and the other end of the central shaft passes through the other side of the support body to connect with the encoder; the end of the central shaft close to the drive motor is connected to the The body is rotatably supported, and one end close to the encoder is supported on the support body through a floating support structure; and a scanning mirror is fixed on the central axis through a connecting seat, and the scanning mirror is located on the support the body.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com