Hydraulic station of plate freezer

A freezer and hydraulic station technology, which is applied to mechanical equipment, fluid pressure actuators, servo motors, etc., can solve the problems of reduced reliability of the unit and complex structure of the hydraulic station, and achieve a compact structure, reasonable layout, and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

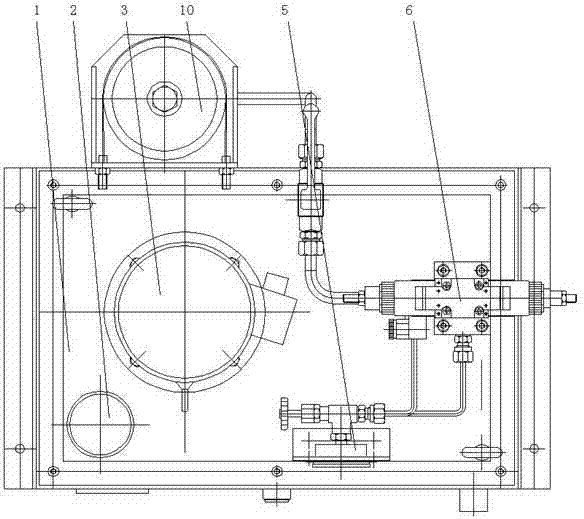

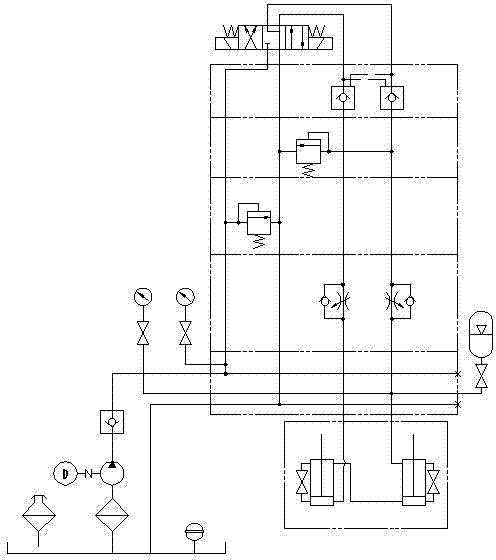

[0017] Such as Figure 1-3 As shown, the present invention is mainly made up of fuel tank 1, motor pump group 3, control valve group 6, oil cylinder 8, described control valve group 6 is connected with pressure indicator 5, described motor pump group 3, control valve group 6, The pressure indicators are all mounted on the fuel tank 1, the fuel tank 1 is also equipped with an air filter 2, a liquid level gauge 7, and an oil drain plug 4 is installed on the bottom side, and the motor pump unit 3 passes through The control valve group 6 is connected with the oil cylinder 8 and controls the lifting of the oil cylinder 8. The control valve group 6 is mainly composed of an electromagnetic reversing valve, a superimposed hydraulic control check valve, a superimposed one-way throttle valve, an overflow valve, Composed of a superimposed overflow valve and a one-way valve, the superimposed hydraulic control check valve and superimposed one-way throttle valve are connected between the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com