Novel high-speed rotary atomizer and manufacturing method thereof

A technology of high-speed rotation and manufacturing method, applied in the direction of spraying device and spraying device with movable outlet, can solve the problems of inability to install, affect the accuracy and operation of equipment, and achieve the goal of reducing procurement costs, saving equipment investment and operation and maintenance costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

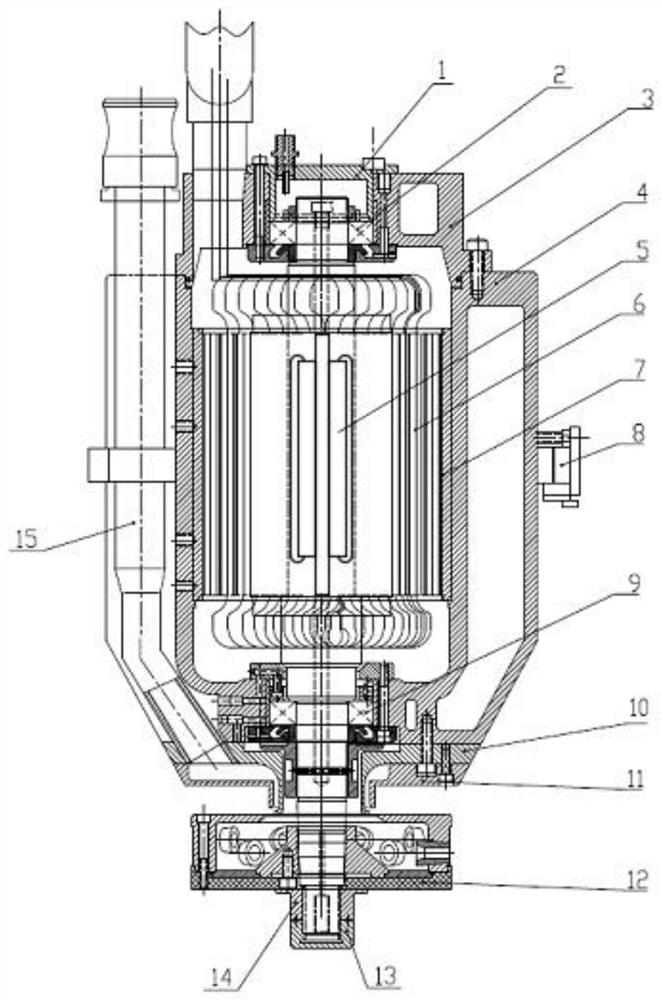

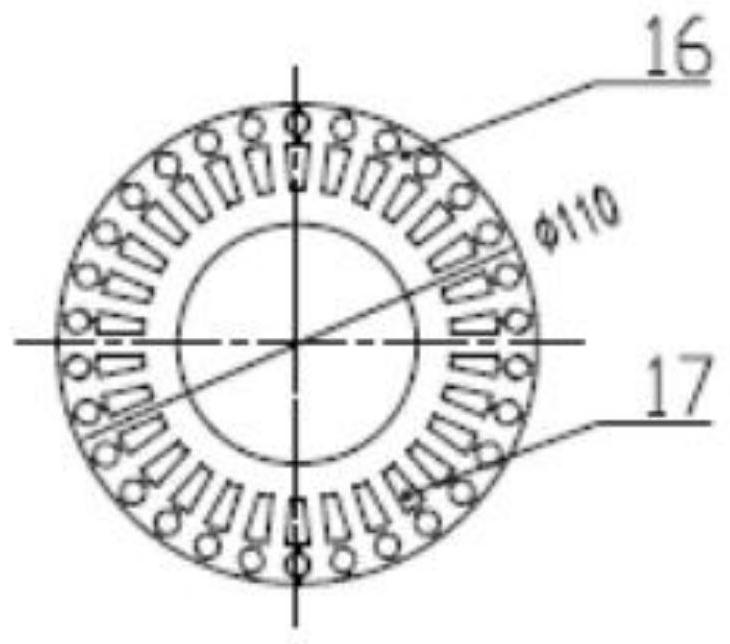

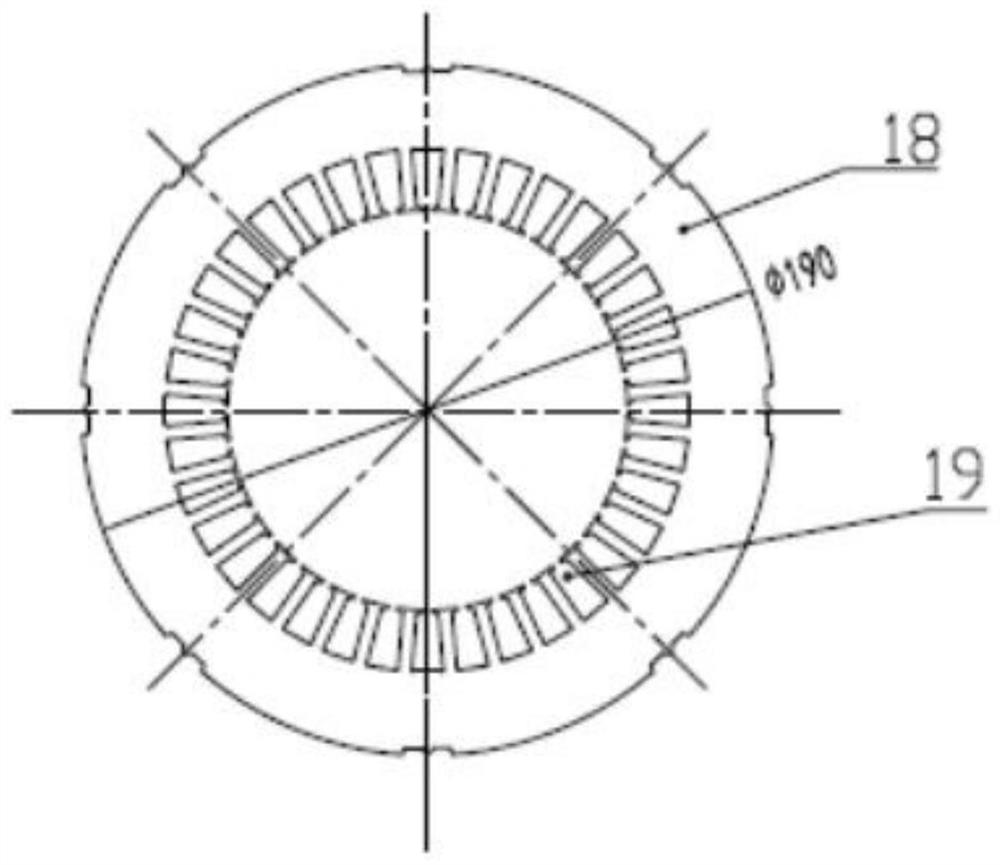

[0024] see Figure 1-3 , the present invention provides a technical solution:

[0025] A new type of high-speed rotary atomizer and its manufacturing method, comprising an atomizer body, an atomization disc 12, a variable frequency drive system, a lubrication system, a cooling system, a feeding system and a cleaning system, the atomizer body includes an end Cover 3, housing 4, feed distributor seat 10 and feed distributor 11, the center of the end cover 3 is provided with a high-precision upper angular contact ceramic ball bearing sleeve 2, the bottom end of the end cover 3 is in contact with the shell The inner side of the upper end of the body 4 is detachably connected by connecting bolts, the outer side of the housing 4 is fixedly connected with a support ring 8, and the center of the lower part of the housing 4 is provided with a high-precision lower angular contact ceramic ball bearing sleeve 9. The bottom end of 4 is detachably connected with the top of the feed materia...

Embodiment 2

[0036] Embodiment 2 is not described in detail for the same part as Embodiment 1. The difference is that in order to prevent the slurry from adhering to the upper surface of the atomizing disc 12 after solidification and affecting the dynamic balance of the atomizing disc 12, flushing water is poured into the feed pipe 15. The feed distributor 11 sprays water into the atomizing pan 12 to directly wash away the overflowing slurry. At the same time, in order to prevent the overflowing slurry from entering the interior of the housing 4, the shaft flushing water is poured into the rotor 5 to flush the rotor 5 to realize synchronous flushing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com