Automatic stainless steel sheet rolling and packing machine

A technology of stainless steel sheet and wrapping machine, which is applied in packaging, wrapping objects, transportation and packaging, etc., and can solve problems such as cumbersome operation, low intelligence, and poor lamination automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

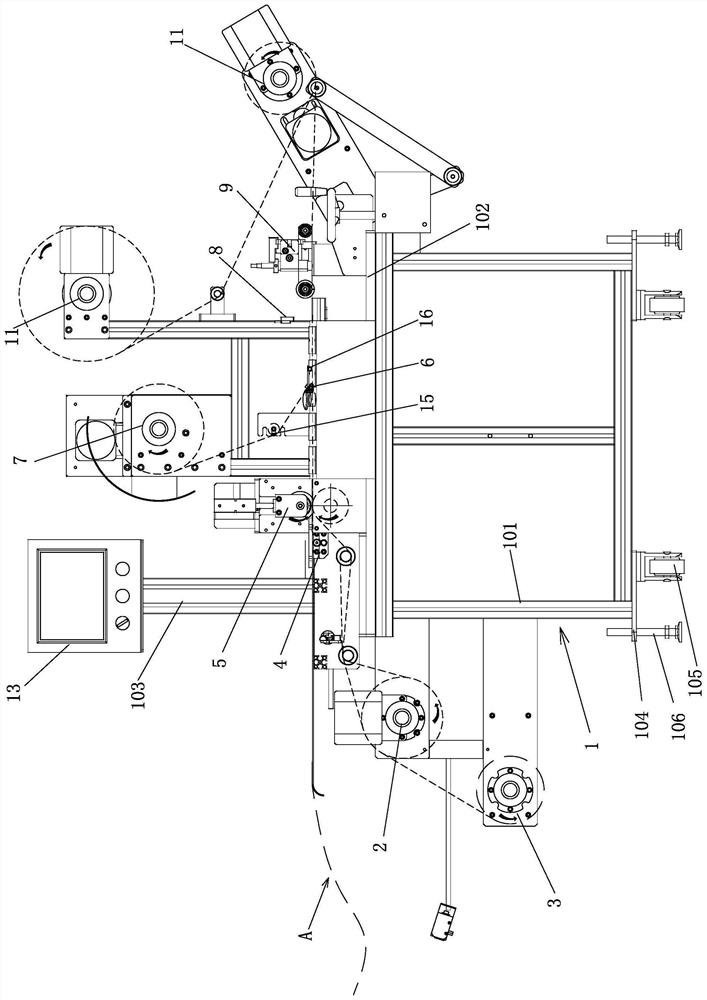

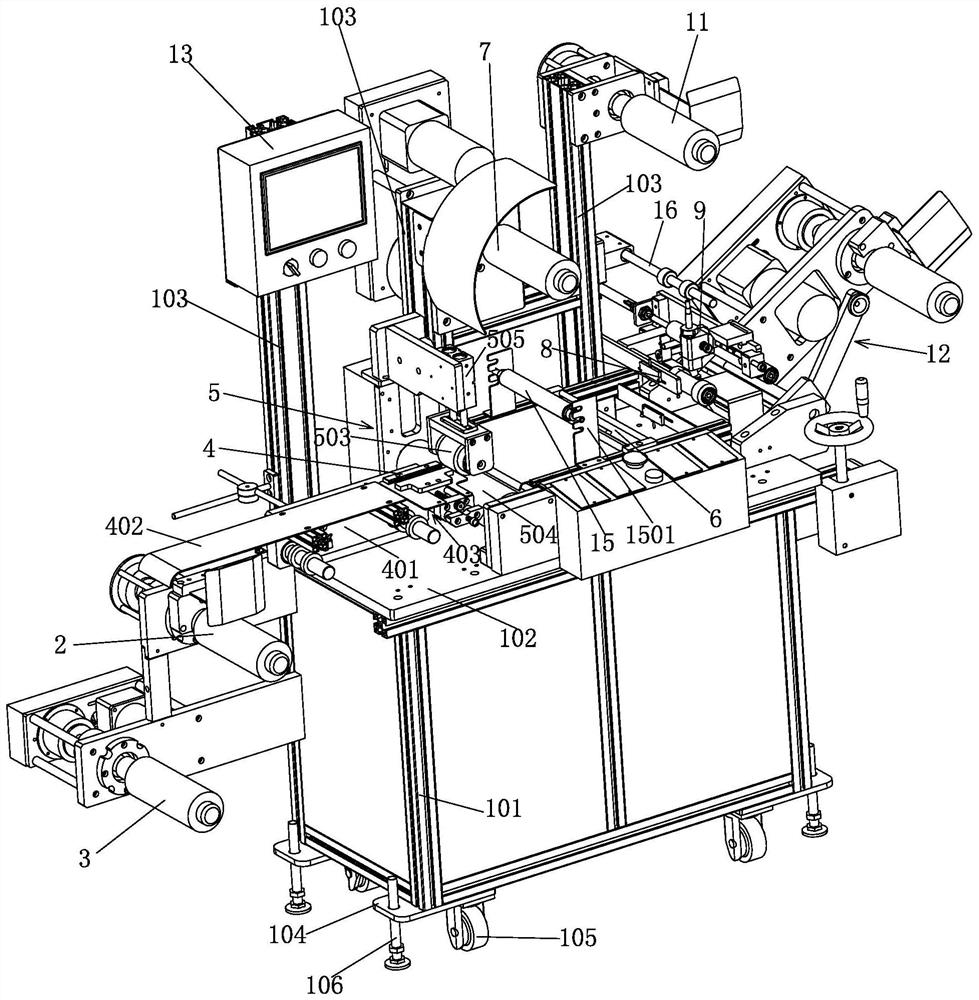

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0040] The invention defines the side where the material of the stainless steel belt enters is the feed side, and the side where the product is rolled up after coating is the discharge side. The direction of the control panel on the winder is the front, and the opposite direction is the rear.

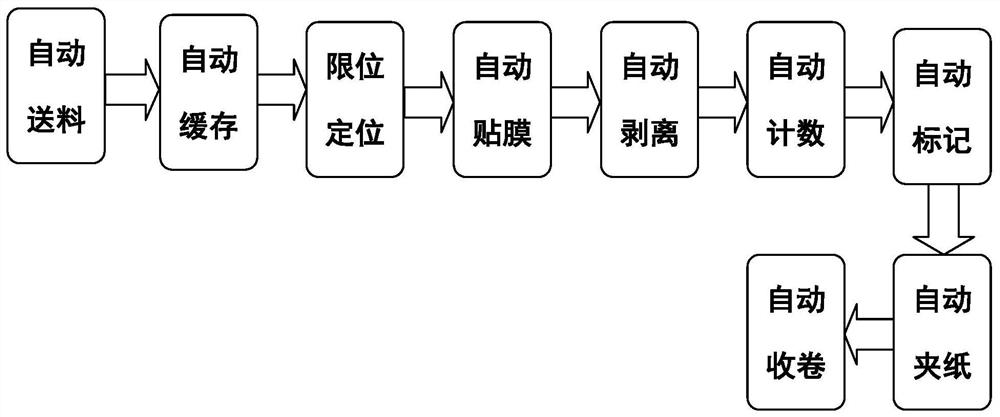

[0041] The present invention relates to a kind of stainless steel sheet automatic wrapping machine (referred to as automatic wrapping machine), such as Figure 2-3As shown, it includes a frame 1, a film release mechanism 2 for releasing the protective film, a waste film collection mechanism 3 for rewinding the release film on the protective film roll on the film release mechanism 2 are installed on the frame 1 , a positioning adjustment mechanism for limit positioning of the stainless steel strip to be filmed 4, a laminating mechanism for laminating th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com