Hydraulic track rock loader

A rock loader and crawler technology, which is applied in the field of hydraulic crawler rock loaders, can solve the problems of reduced strength of the gearbox, internal gears and bearings, reduced reliability and service life of the machine, and insufficient power of the motor, so as to save manpower and material resources, Effect of long service life and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

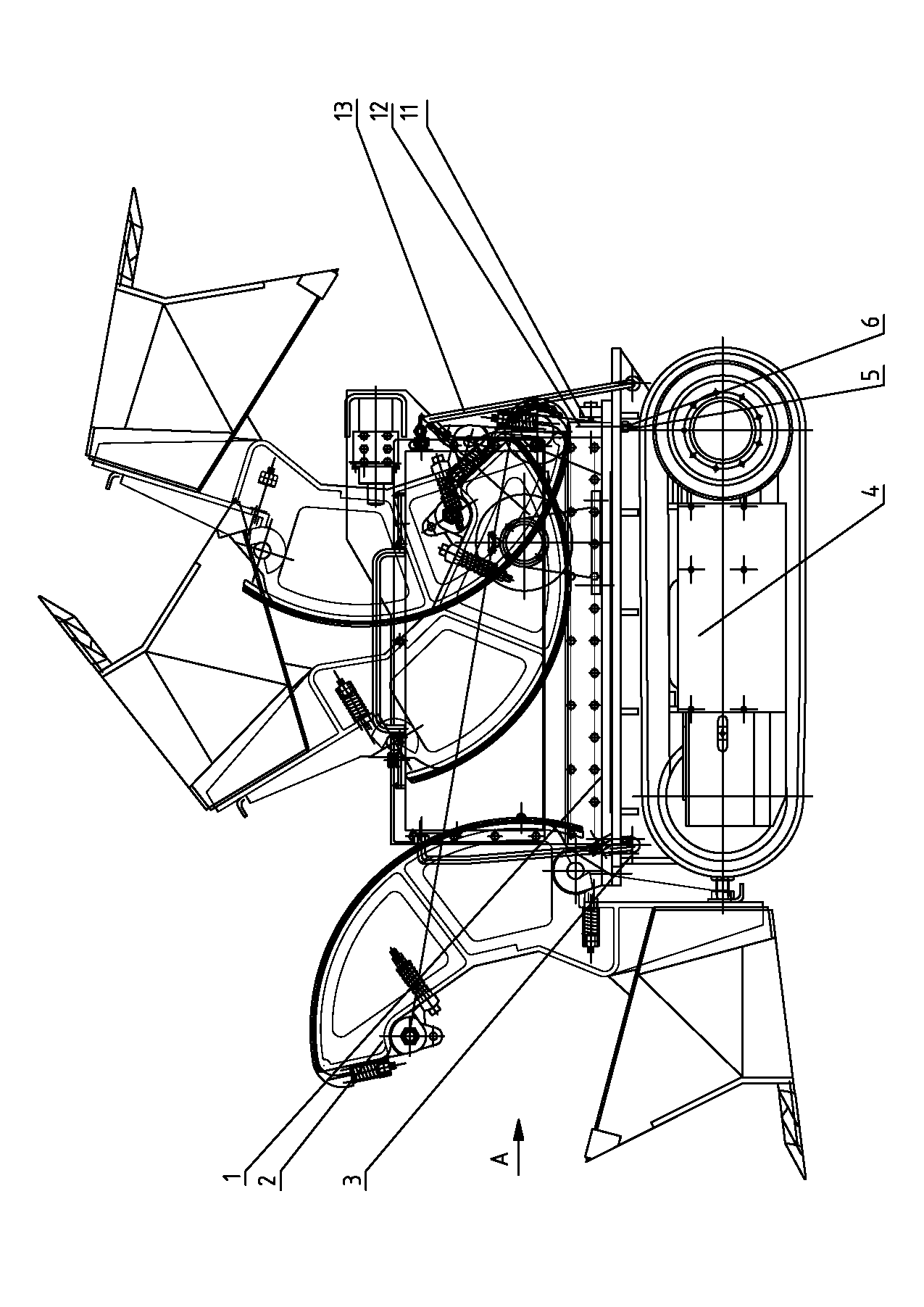

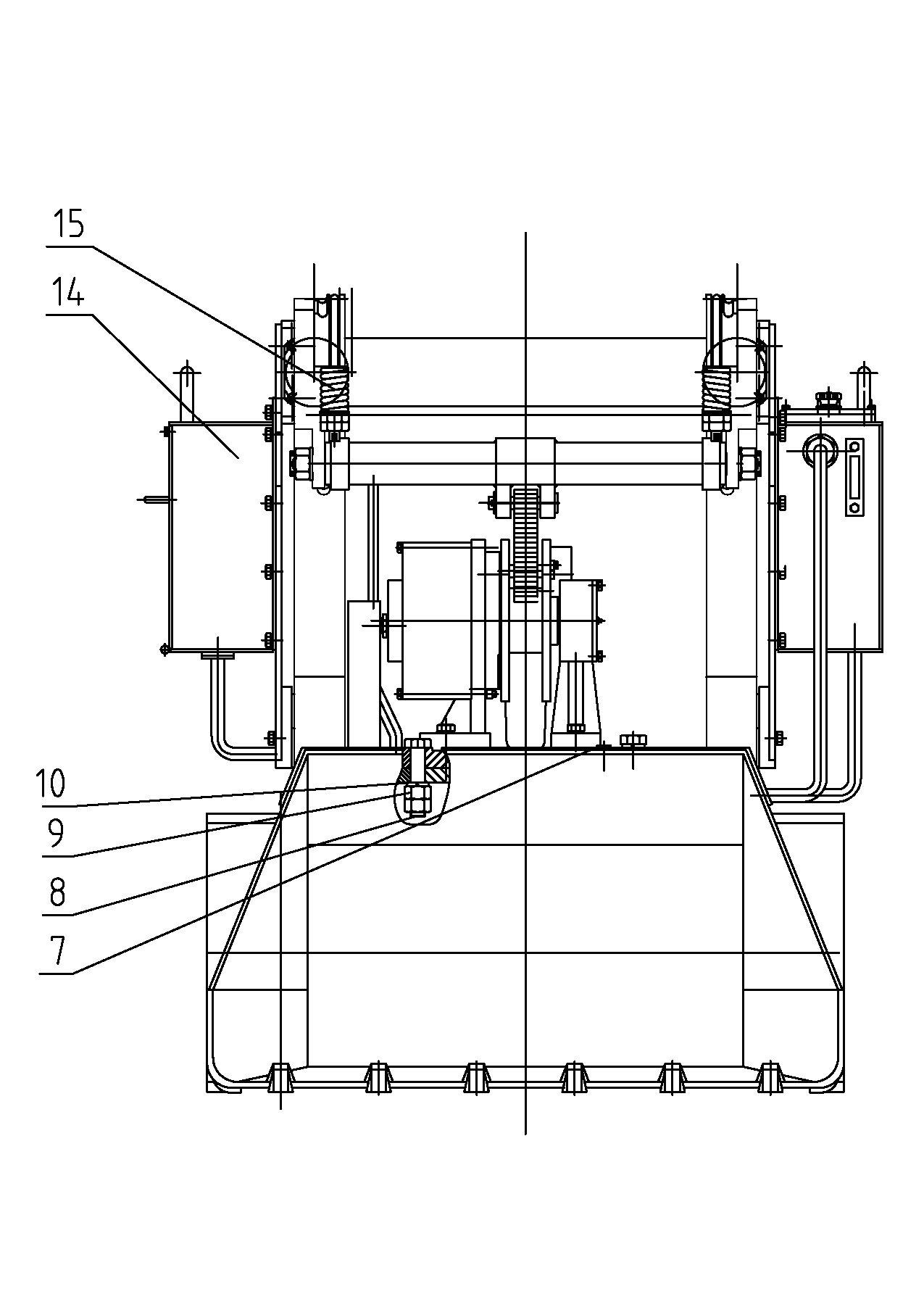

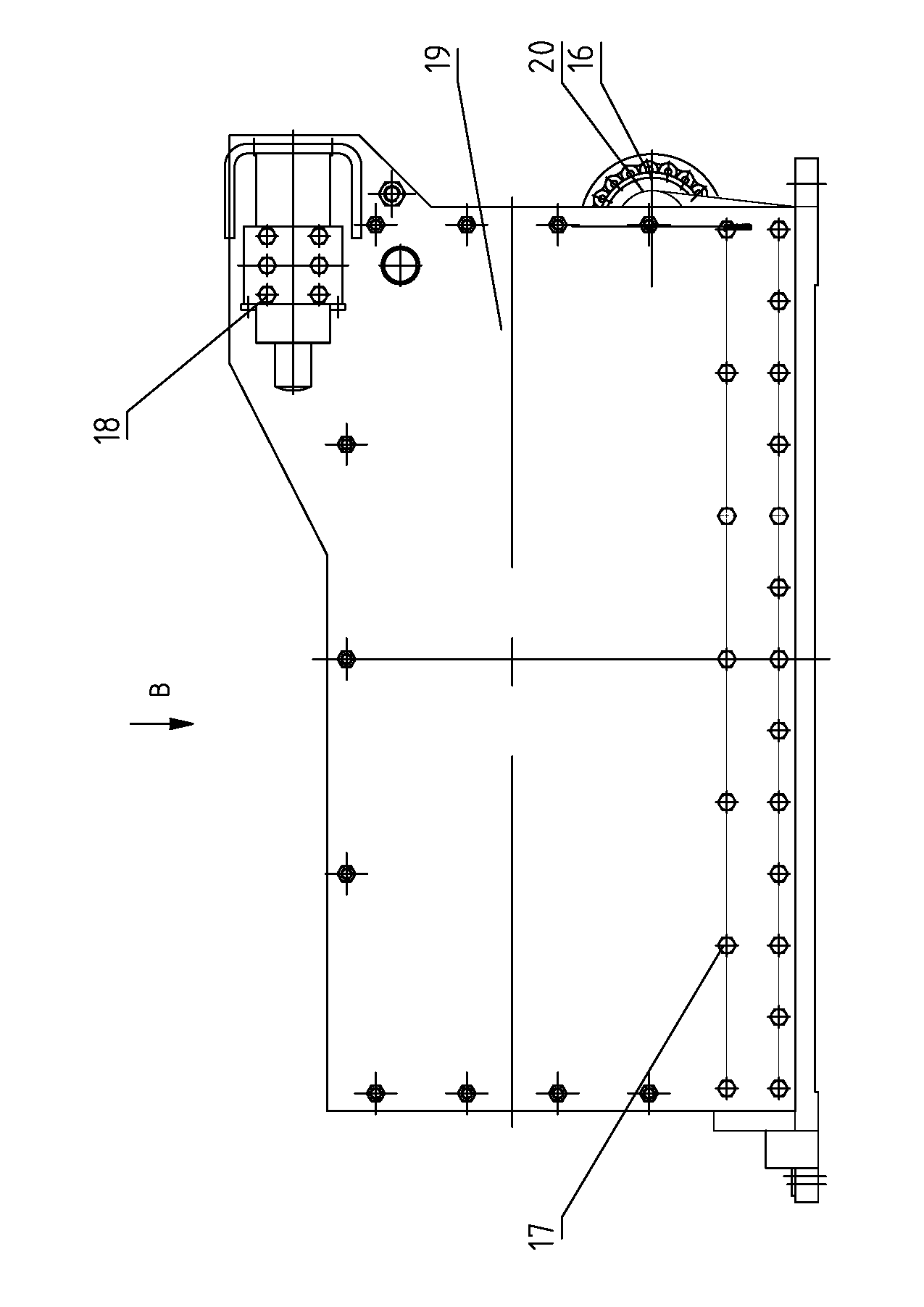

[0043] like figure 1 and 2 As shown, the hydraulic crawler rock loader according to the present invention includes a bucket part 1, a bucket part 2, a wire rope connecting pin 3, a walking part 4, a washer 5, a nut 6, a positioning pin 7, a bolt 8, and a nut 9. Washer 10, wire rope 1 11, wire rope connecting pin 2 12, hydraulic system 13, electrical control system 14, wire rope 2 15, bucket chain 16 and other components.

[0044] The walking part 4 is the basic part of the whole machine, and its function is to complete functions such as advancing, retreating and turning of the machine, and other parts are installed based on it simultaneously.

[0045] The lifting bucket part 1 is installed on the running part 4 through positioning pins 7 , bolts 8 , nuts 9 and washers 10 . Wire rope connection pin one 3 and steel wire rope connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com