Transmission mechanism utilizing permanent magnet

A transmission device and permanent magnet technology, applied in the direction of transmission device, electromechanical transmission device, electromechanical device, etc., can solve problems such as undiscovered

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

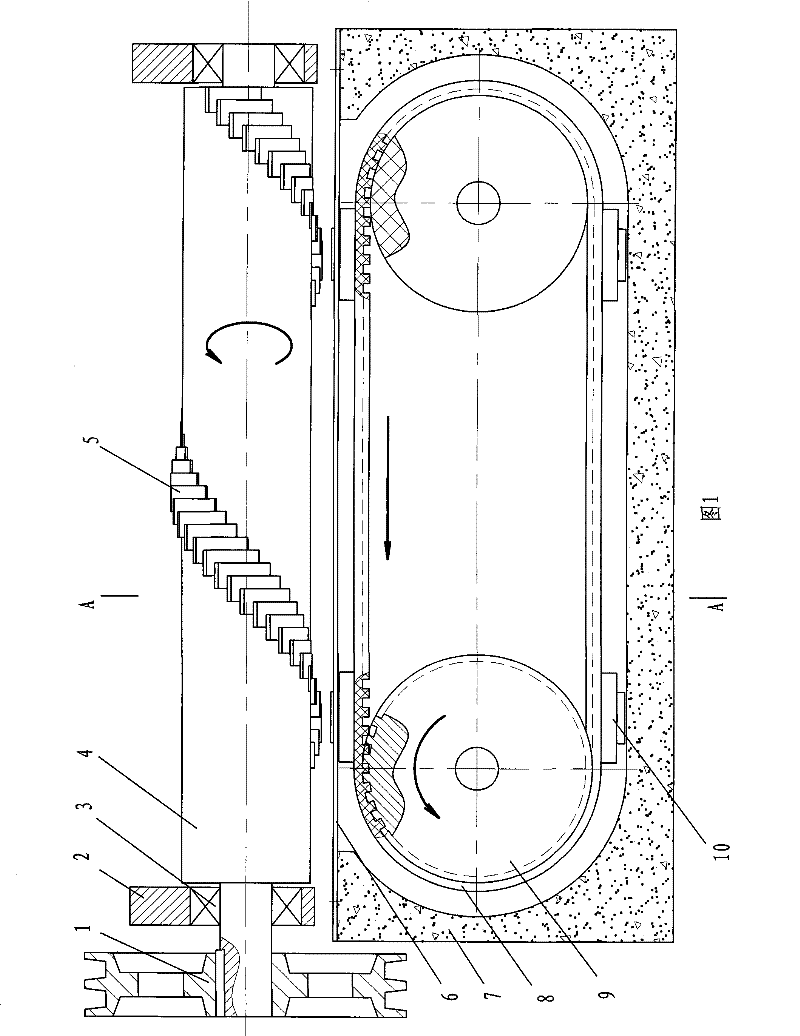

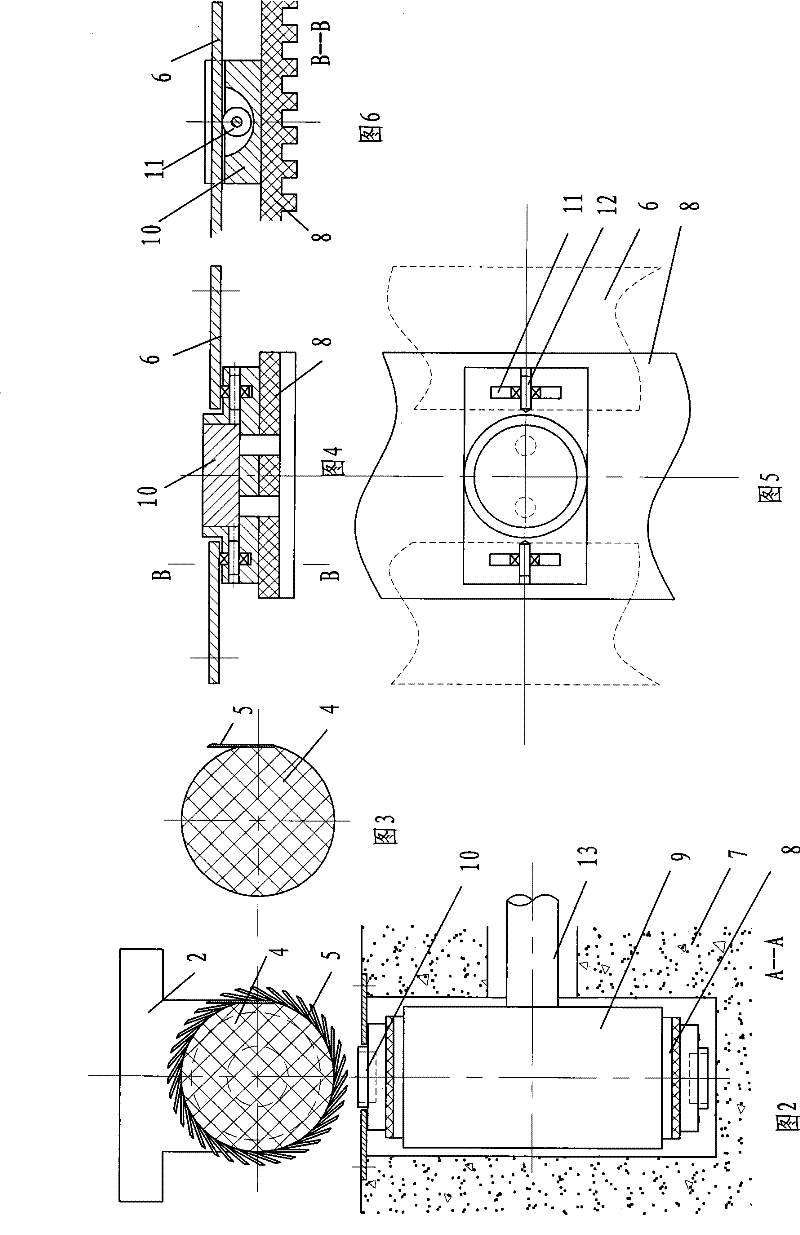

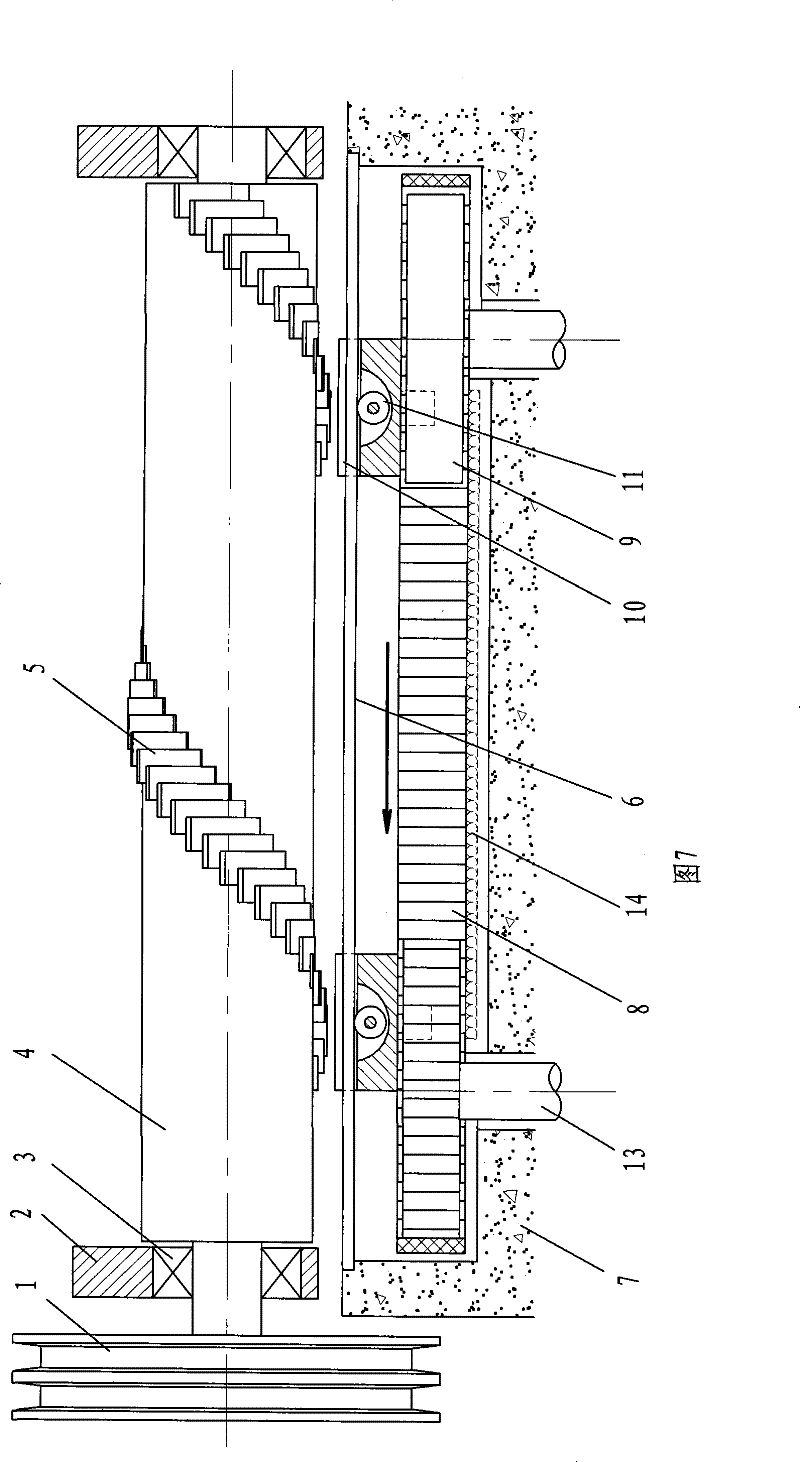

[0016] The technical solution of the present application will be further described below in conjunction with the specific implementation methods shown in the drawings of the description.

[0017] Referring to Fig. 1, it is the first embodiment of the transmission device utilizing permanent magnets, including a power output part and a drive part, wherein the power output part has a non-magnetic main shaft 4 supported on a bearing 3, and the surface of the main shaft 4 is helical in the axial direction A plurality of sucked sheets 5 are fixed in a shape; the driving part has a guide wheel 9 and a transmission belt, and the transmission belt can use a flat belt or a toothed belt. In the embodiment, the toothed belt 8 surrounds two guide wheels 9, and the two guide wheels 9 are fixed on two parallel guide wheel shafts 13 ends, and a plurality of permanent magnets 10 are directly fixed on the outer surface of the toothed belt 8, and the tooth profile in the working area The belt 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com