A kind of processing method of heavy crude oil

A processing method and raw oil technology, which is applied in the processing of hydrocarbon oil, hydrogenation treatment process, petroleum industry, etc., can solve the problems of wasting reactor space, etc., and achieve the effects of preventing asphaltene precipitation, stabilizing the colloidal system, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

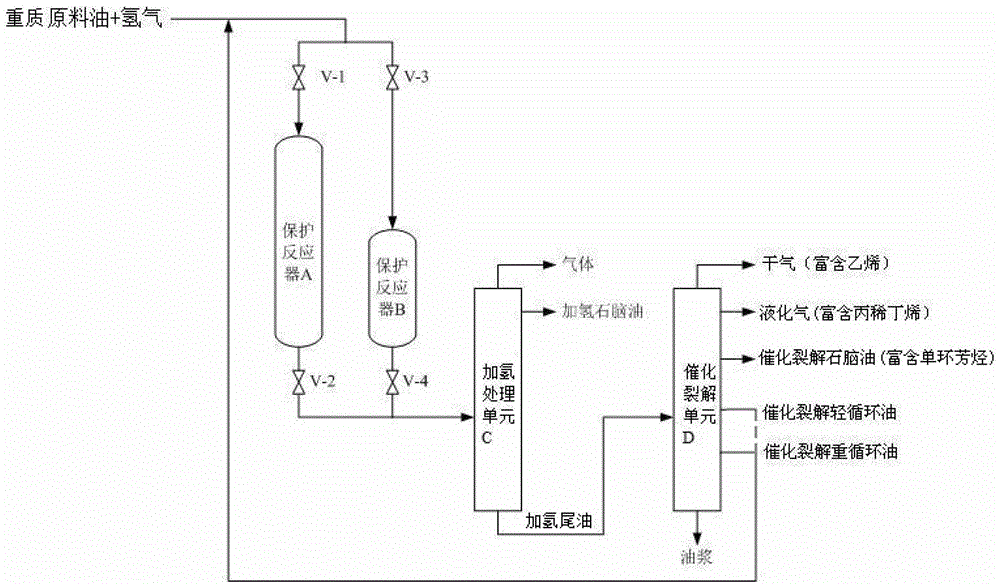

[0068] According to a preferred embodiment of the present invention, the present invention is carried out as follows: catalytic cracking heavy cycle oil from catalytic cracking unit D, catalytic cracking light cycle oil and residue (or wax oil, used in the embodiment is Residuum) mixed with hydrogen together into the hydrogenation protection unit, and then into the hydroprocessing unit C, in the presence of a hydrogenation catalyst for hydroprocessing reaction, separation of hydroprocessing products, to obtain gas, hydrogenated naphtha and hydrogenated Hydrogen tail oil, in which gas and hydrogenated naphtha are drawn separately, and hydrogenated tail oil enters catalytic cracking unit D together with optional vacuum gas oil, reacts in the presence of catalytic cracking catalyst, and separates the reaction products of catalytic cracking , to obtain dry gas rich in ethylene, liquefied gas rich in propylene and butene, catalytic cracking naphtha rich in single-ring aromatics, cat...

Embodiment 1

[0073] In the raw oil treatment device used in this example, the main hydrogenation protection reactor is a protection reactor A, the standby hydrogenation protection reactor is a protection reactor B, and the hydroprocessing unit C is a fixed bed residual oil processing unit. Hydrogen device, the catalytic cracking unit D is a laboratory fixed fluidized bed catalytic cracking device, such as figure 1 shown.

[0074] Among them, 60 mL of RG-30A catalyst, 60 ml of RG-30B catalyst, and 60 ml of RDM-32 catalyst are filled in the main hydrogenation protection reactor A in sequence; 20 mL of RG-30A catalyst, 20 mL of RG-30B catalyst and 20ml of RDM-32 catalyst; 200mL of RDM-32 catalyst and 400mL of RMS-30 catalyst are filled in the fixed-bed residual oil hydrotreating reactor C; Catalysts are all produced by Catalyst Changling Branch.

[0075] A kind of atmospheric residual oil is used as feedstock oil A, a kind of catalytic cracking heavy cycle oil (HCO) is used as feedstock oil...

Embodiment 2

[0089] According to the method of Example 1, the heavy feed oil is processed, the difference is that the heavy feed oil is a separate atmospheric residue A, that is, the catalytic cracking heavy cycle oil (HCO) and the catalytic cracking light cycle oil obtained from the catalytic cracking unit D (LCO) is not returned to be used as a hydrogenation protection unit as a raw material, and the feed amount of heavy crude oil A is 156g / h, the hydrogen-oil volume ratio of the protection unit and the treatment unit are both 1000, and the rest of the conditions are the same.

[0090] The test results are: based on raw material A, the total yield of high-value products (ethylene + propylene + butene + single-ring aromatics) is 42.6%.

[0091] Comparing Example 1 and Example 2, it can be seen that catalytic cracking heavy cycle oil (HCO) and catalytic cracking light cycle oil (LCO) are returned as hydrogenation protection units as raw materials for re-refining, which can be compared with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com