Electrical synergistic heat supply reforming reaction system

A reforming reaction and heating system technology, applied in the chemical industry, can solve the problems that limit the continuous and stable operation of chemical equipment, achieve the effect of reducing material selection requirements, avoiding ultra-high temperature areas, and reducing the generation of NOx gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

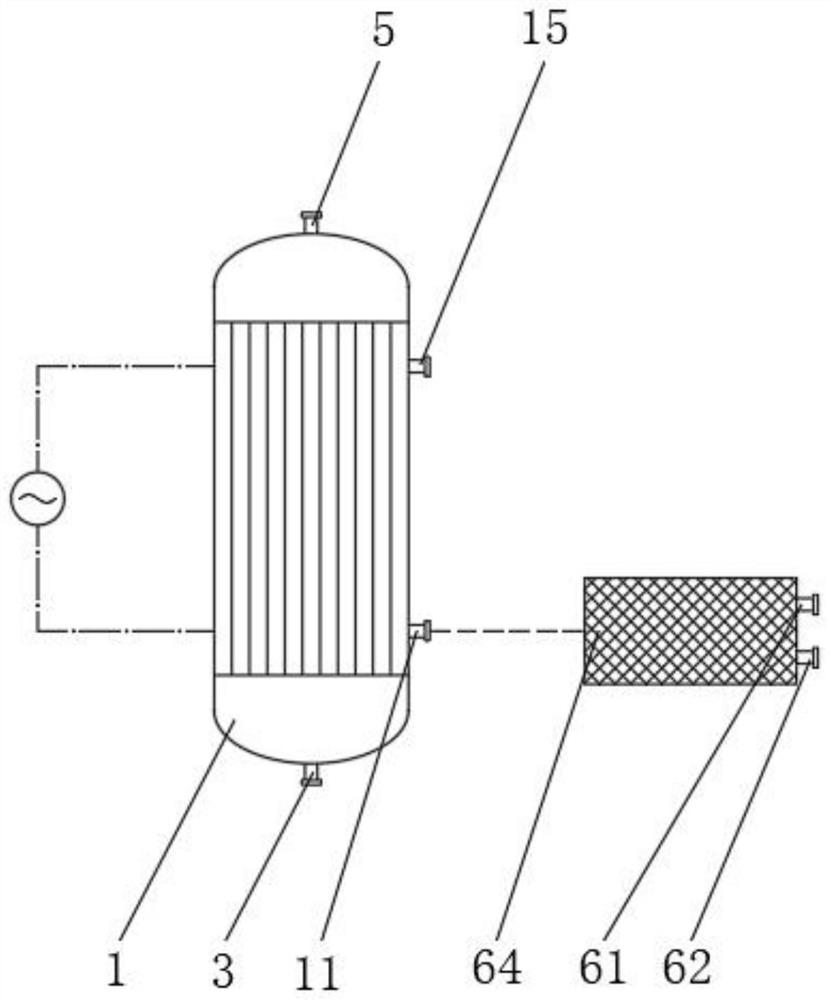

[0058] Example 1: Externally supplied flue gas single-stage induction heating reforming reaction system

[0059] The reforming reactor 1 used by the external flue gas single-stage induction heating reforming reaction system, the high-temperature flue gas transported from the outside to the inside of the reactor and the induction eddy current caused by the single-stage induction coil 52 cooperate to form the reforming reactor 1 heating. To achieve this purpose, the present invention lists the following embodiment.

[0060] Implementation structure:

[0061] Such as Figure 4 and Figure 9 As shown, a plurality of bayonet tubes consisting of the outer tube 22 of the conversion tube and the inner tube 23 of the conversion tube are arranged in an orderly manner around the central flue gas tube 26 . The annular gap between the outer tube 22 of the reforming tube and the inner tube 23 of the reforming tube is filled with the reforming catalyst layer 2 , and the inner tube 23 of ...

Embodiment 2

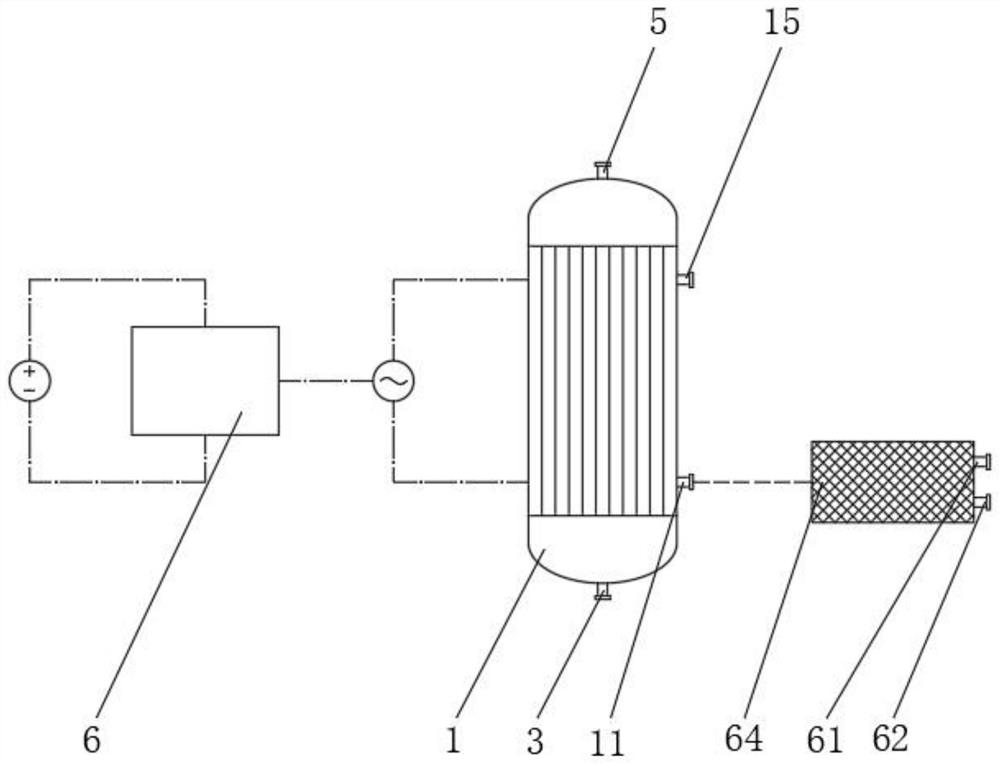

[0071] Example 2: Internally supplied flue gas single-stage induction heating reforming reaction system

[0072] The reforming reactor 1 used in the flue gas single-stage induction heating reforming reaction system, the high-temperature flue gas generated by catalytic combustion inside the reactor and the induction eddy current caused by the single-stage induction coil 52 cooperate to provide heat for the reforming reactor 1 . To achieve this purpose, the present invention lists the following embodiment.

[0073] Implementation structure:

[0074] Such as Figure 5 and Figure 9As shown, a plurality of bayonet tubes consisting of the outer tube 22 of the conversion tube and the inner tube 23 of the conversion tube are arranged in an orderly manner around the central flue gas tube 26 . The annular gap between the outer tube 22 of the reforming tube and the inner tube 23 of the reforming tube is filled with the reforming catalyst layer 2 , and the inner tube 23 of the reform...

Embodiment 3

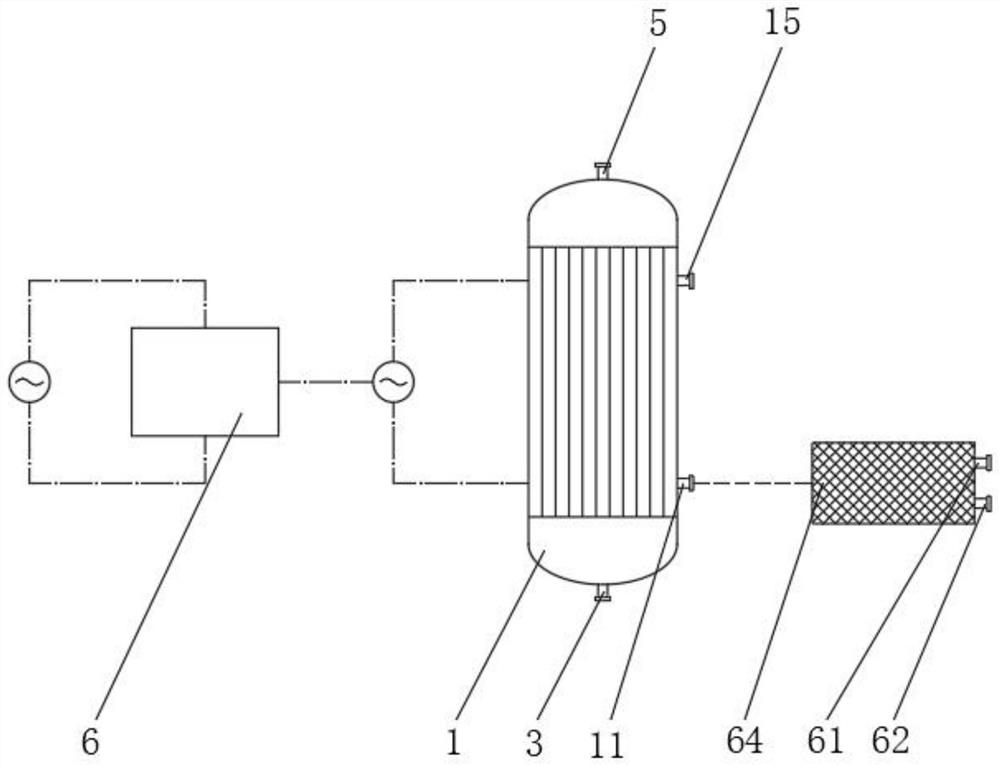

[0083] Example 3: Internally supplied flue gas multi-stage induction heating reforming reaction system

[0084] In the reforming reactor 1 used by the flue gas multi-stage induction heating reforming reaction system, the high-temperature flue gas generated by catalytic combustion inside the reactor and the induction eddy current caused by the multi-stage induction coil 52 cooperate to provide heat for the reforming reactor 1 . To achieve this purpose, the present invention lists the following embodiment.

[0085] Implementation structure:

[0086] like Figure 6 and Figure 9 As shown, a plurality of bayonet tubes consisting of the outer tube 22 of the conversion tube and the inner tube 23 of the conversion tube are arranged in an orderly manner around the central flue gas tube 26 . The annular gap between the outer tube 22 of the reforming tube and the inner tube 23 of the reforming tube is filled with the reforming catalyst layer 2 , and the inner tube 23 of the reforming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com