Patents

Literature

124 results about "Endothermic process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An endothermic process is any process which requires or absorbs energy from its surroundings, usually in the form of heat. It may be a chemical process, such as dissolving ammonium nitrate in water, or a physical process, such as the melting of ice cubes. The term was coined by Marcellin Berthelot from the Greek roots endo-, derived from the word "endon" (ἔνδον) meaning "within", and the root "therm" (θερμ-), meaning "hot" or "warm" in the sense that a reaction depends on absorbing heat if it is to proceed. The opposite of an endothermic process is an exothermic process, one that releases, "gives out" energy in the form of heat. Thus in each term (endothermic & exothermic) the prefix refers to where heat goes as the reaction occurs, though in reality it only refers to where the energy goes, without necessarily being in the form of heat.

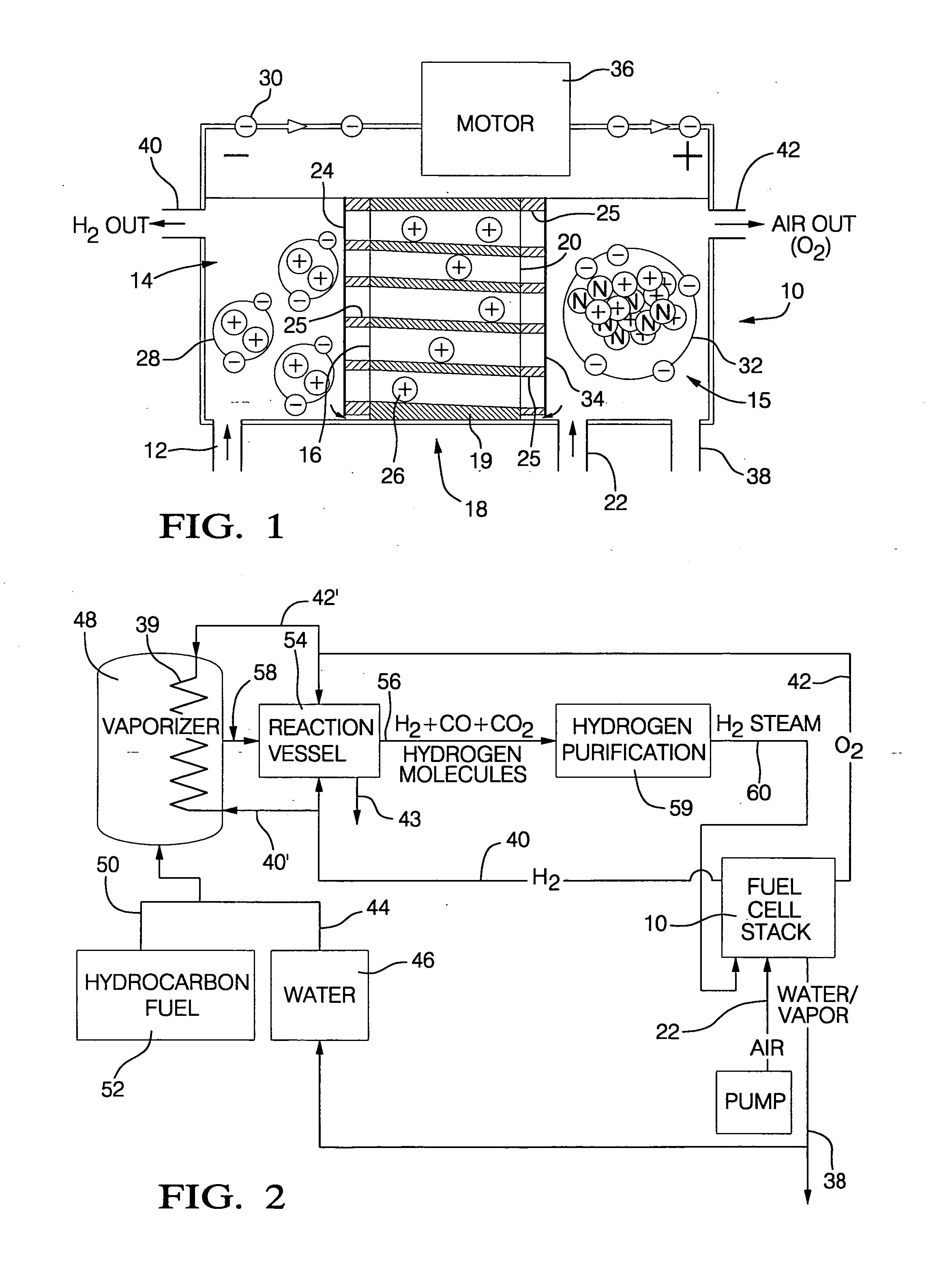

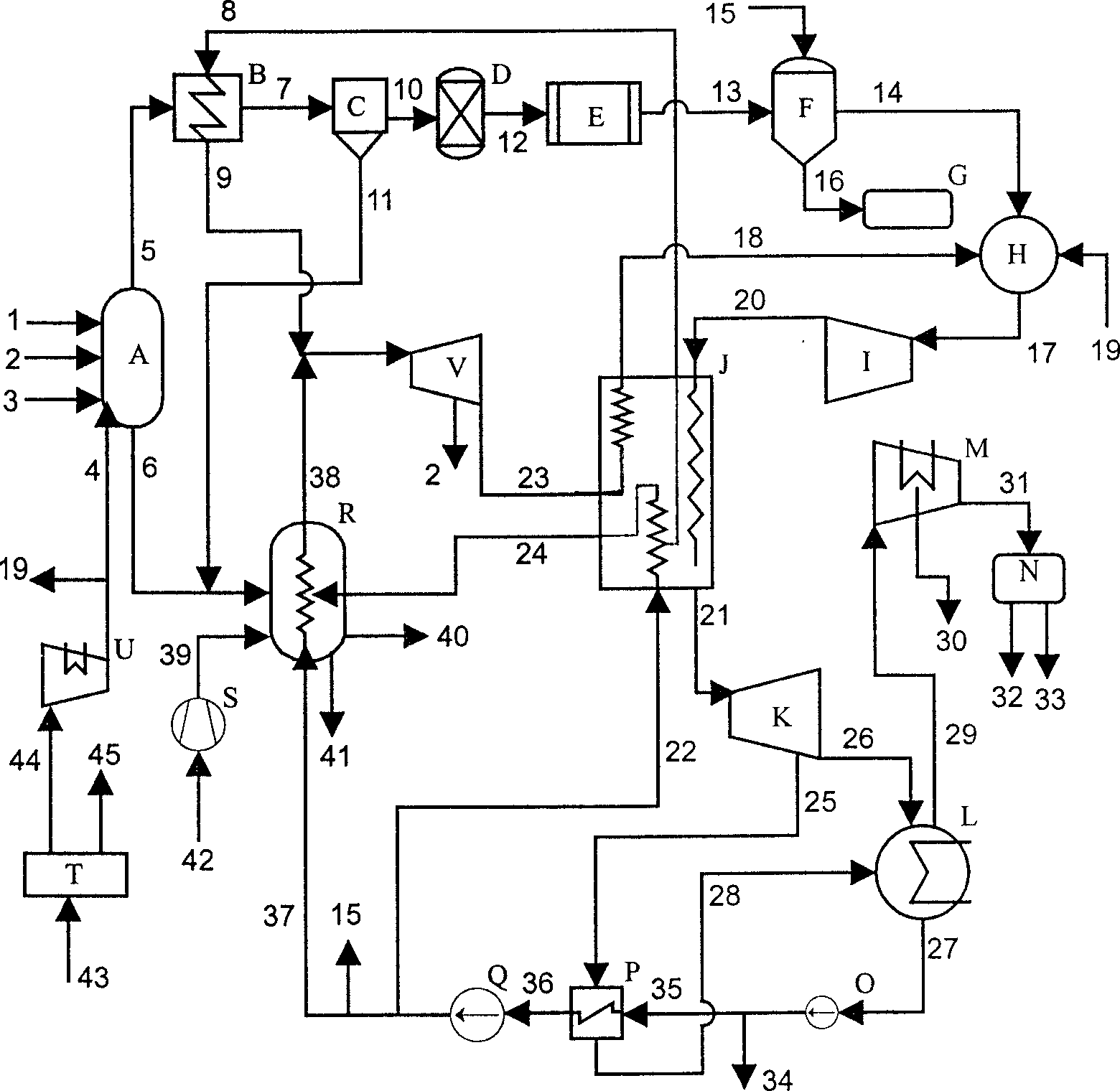

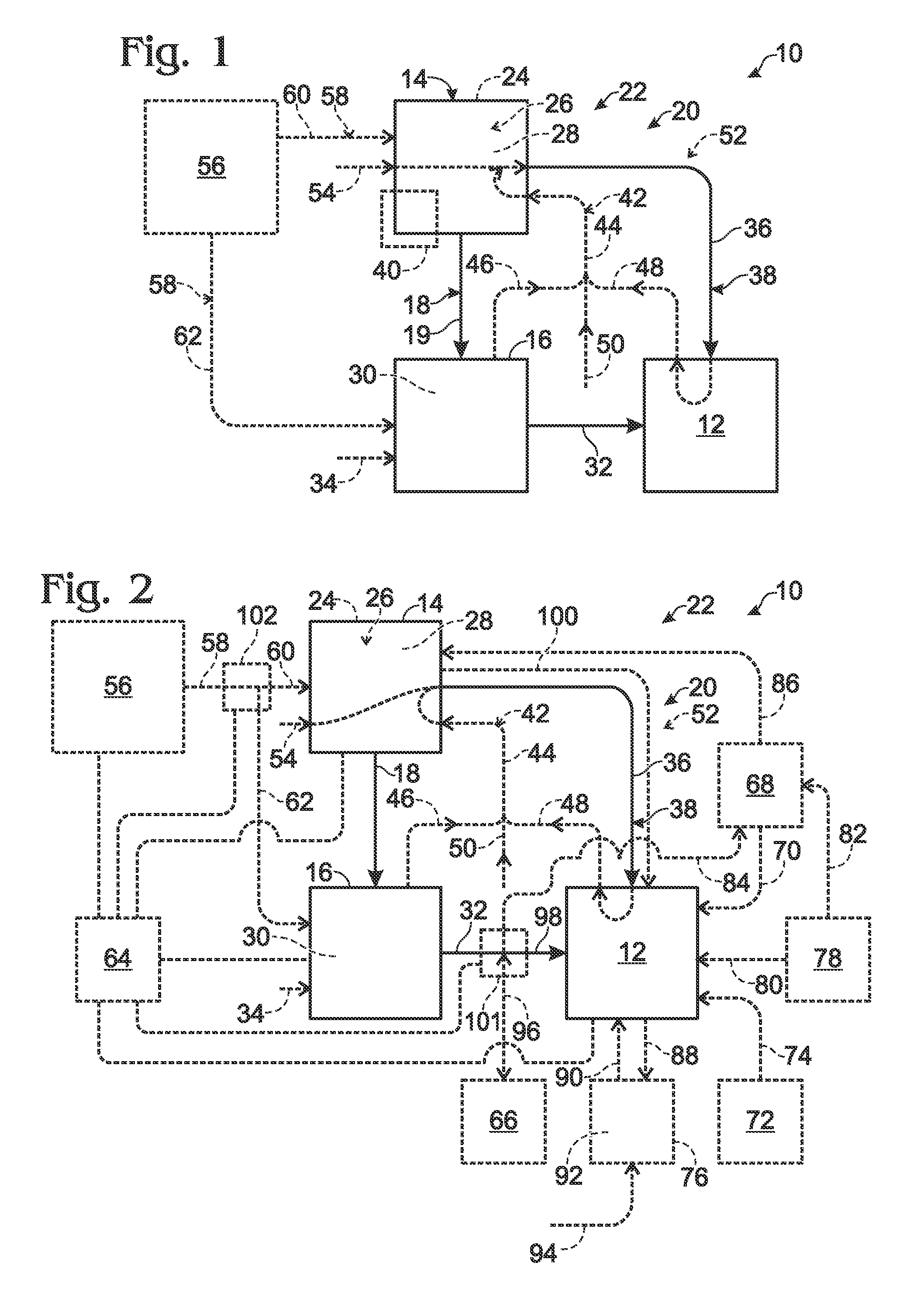

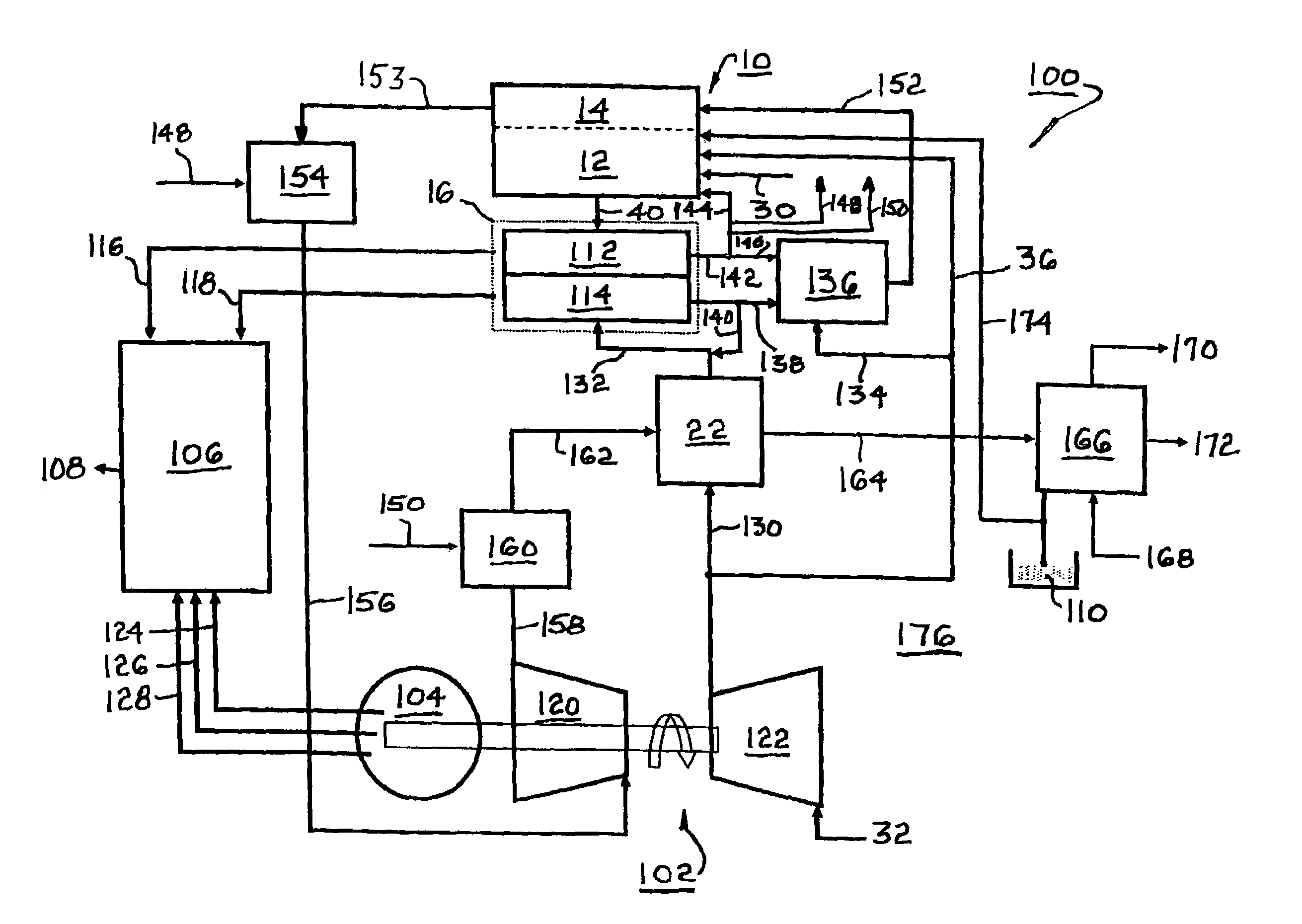

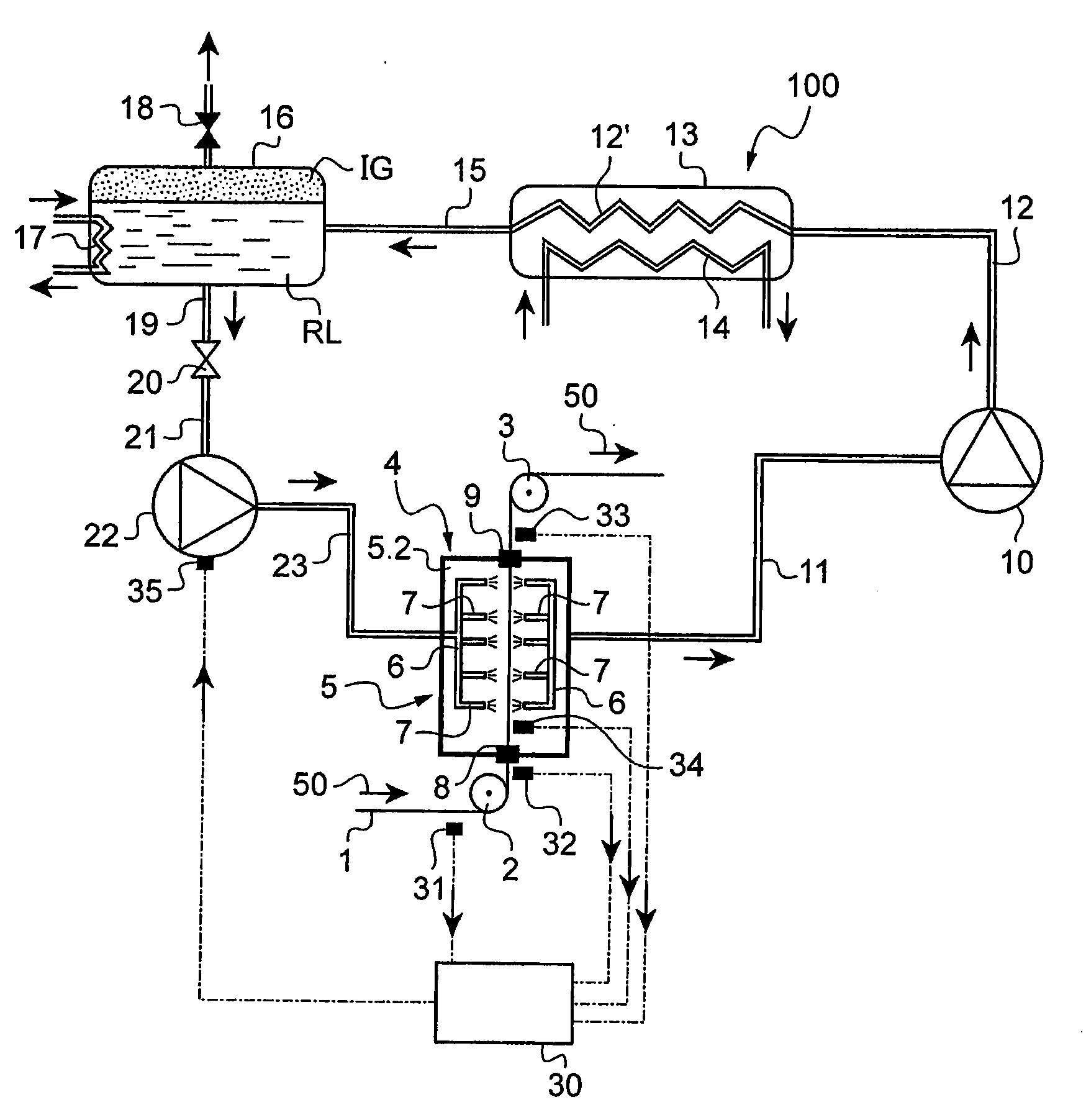

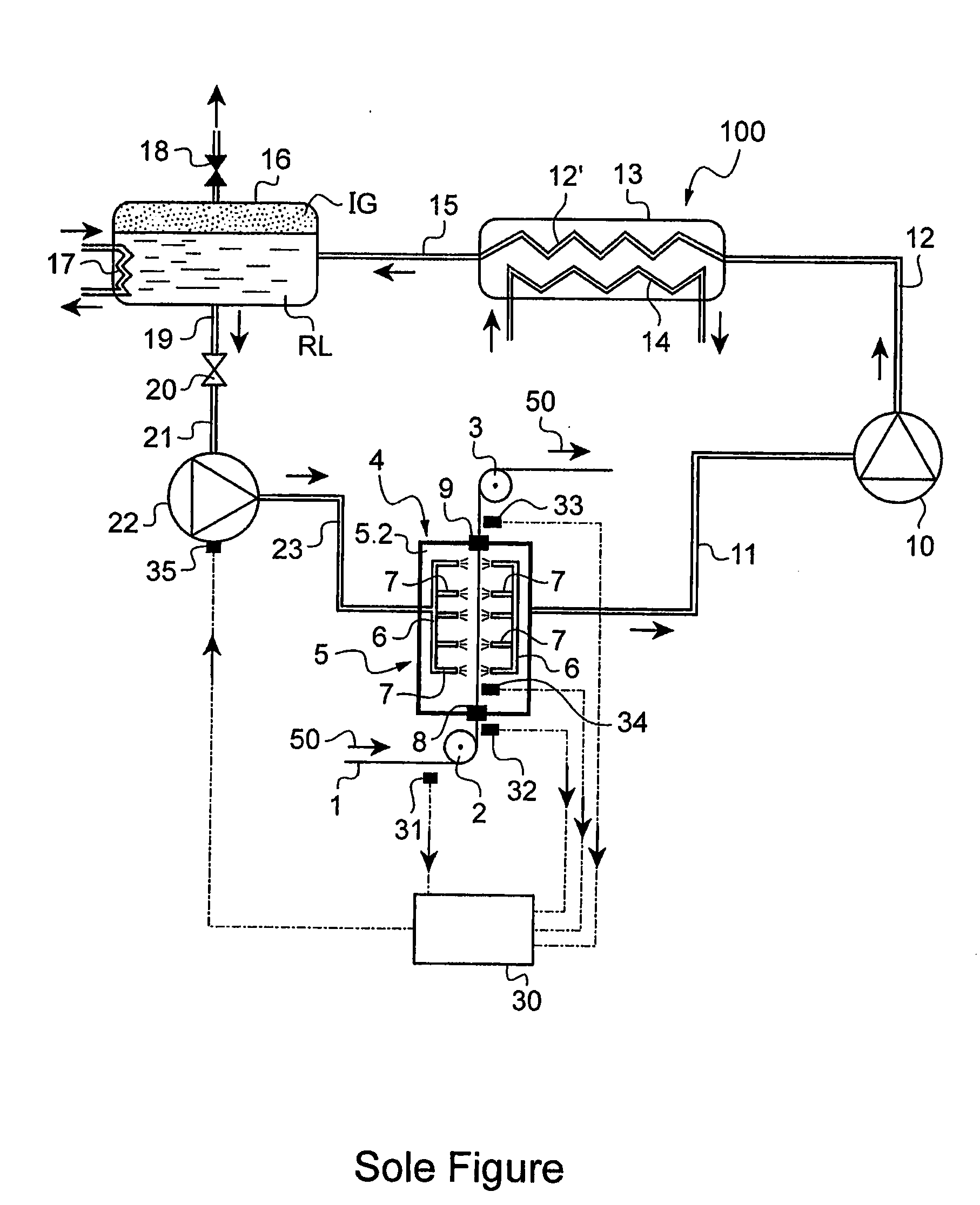

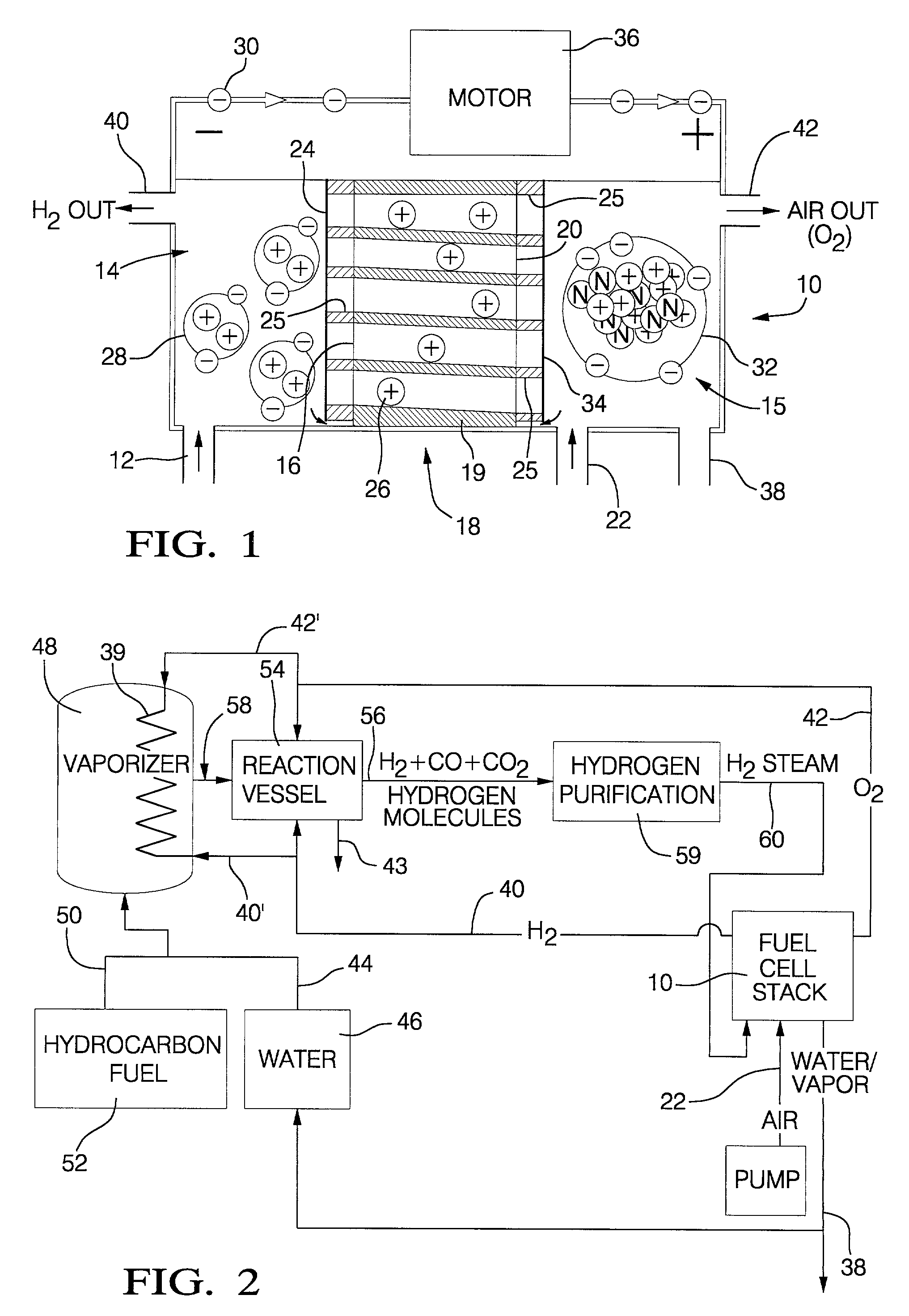

Hybrid power generating system combining a fuel cell and a gas turbine

ActiveUS20050196659A1Avoid overall overheatingOverheating of elements within the stack is preventedAuxillary drivesElectric propulsion mountingElectric power systemHydrocotyle bowlesioides

A system for co-generation of electricity combining a hydrocarbon catalytic reformer, an SOFC assembly and a generator driven by a gas turbine. The fuel cell assembly recycles a high percentage of anode exhaust gas into the reformer. Oxygen for reforming is derived from water in an endothermic process. The stack exit temperature is normally above 800° C. DC power from the fuel cell assembly and AC power from the gas turbine generator are directed to a power conditioner. Anode exhaust gas including carbon monoxide and hydrogen is divided into a plurality of portions by which heat may be added to the reforming, gas turbine, and cathode air heating processes. Water may be recovered from the exhaust. A power system in accordance with the invention is capable of operating at a higher total efficiency than either the fuel cell component or the gas turbine component alone.

Owner:APTIV TECH LTD

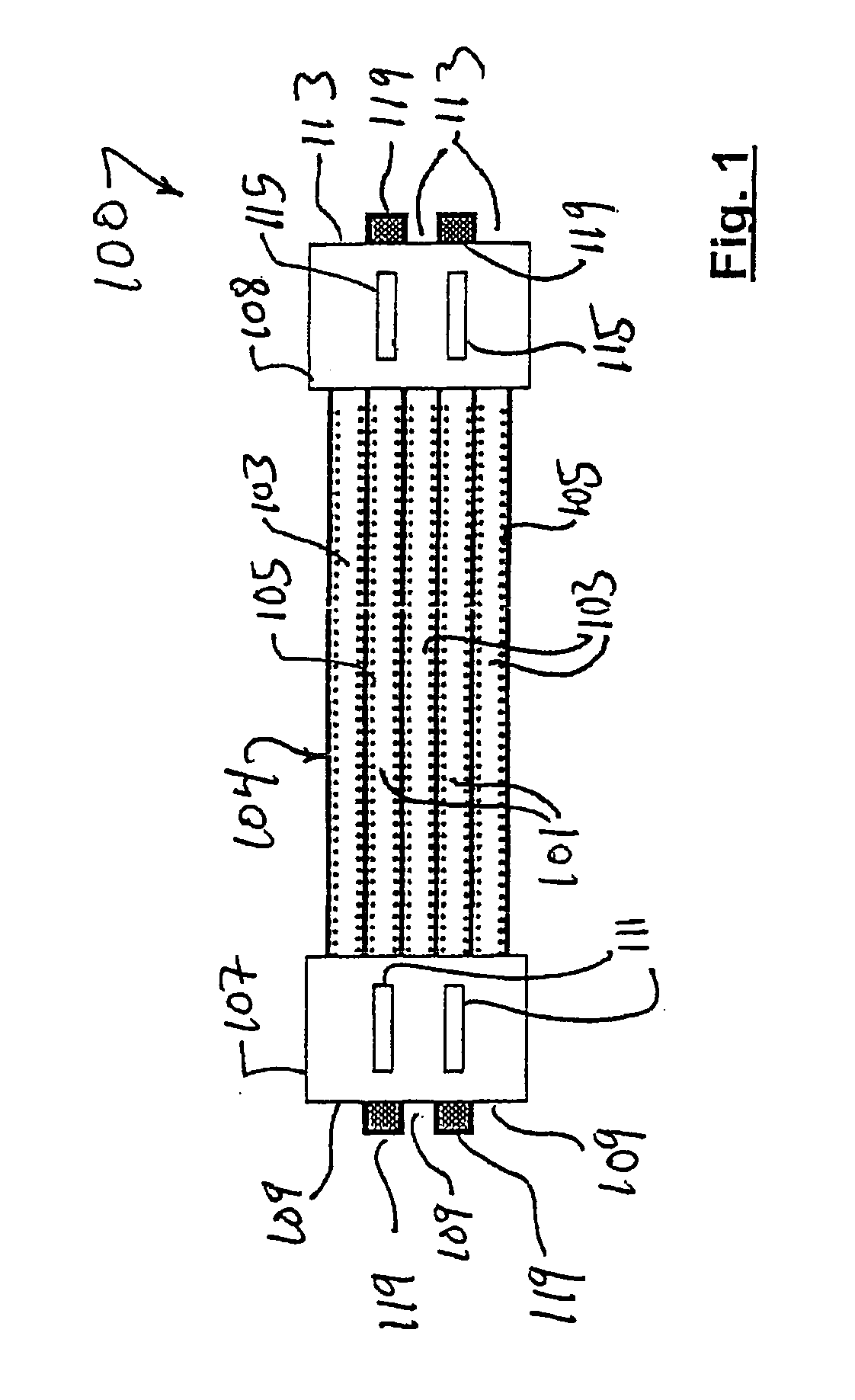

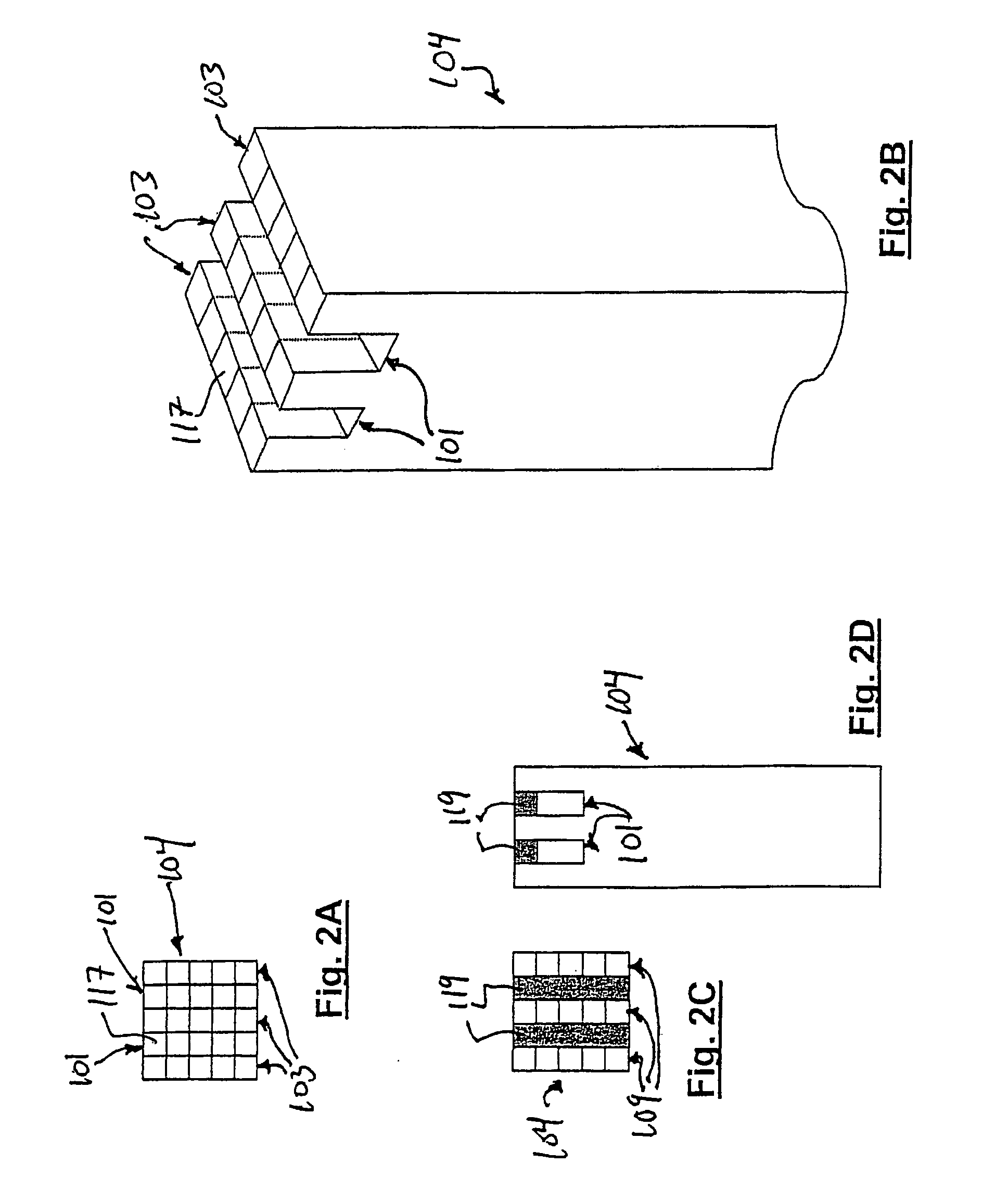

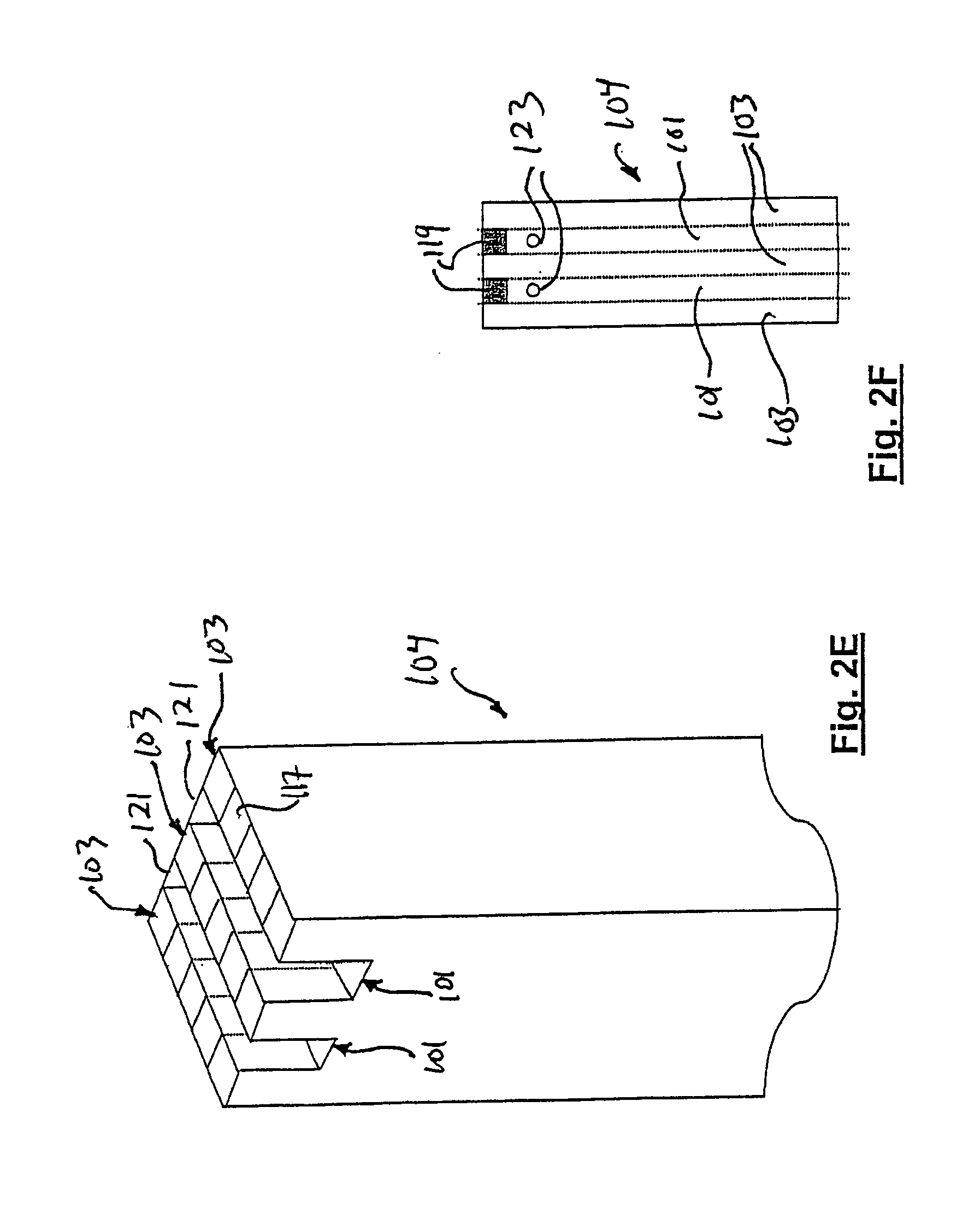

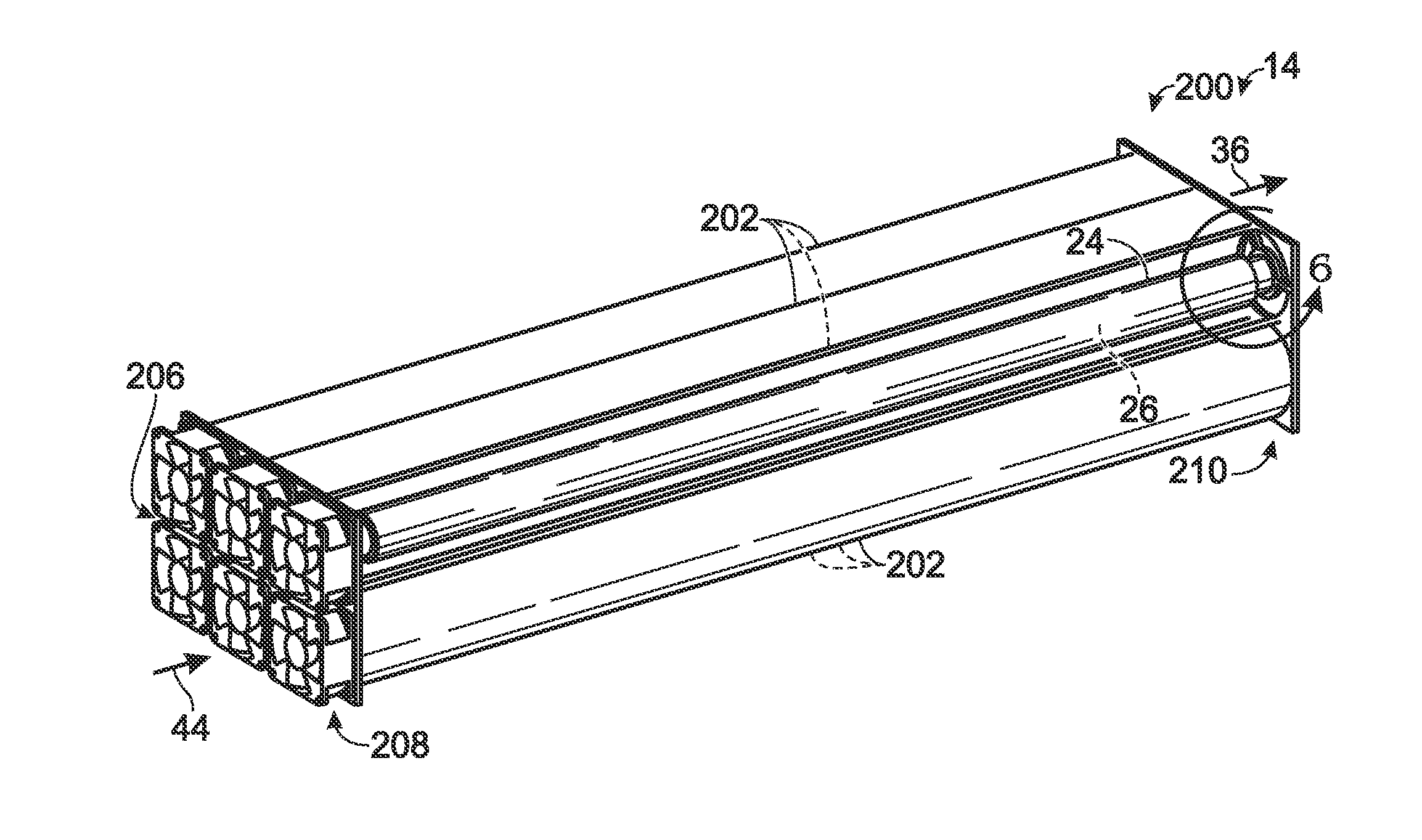

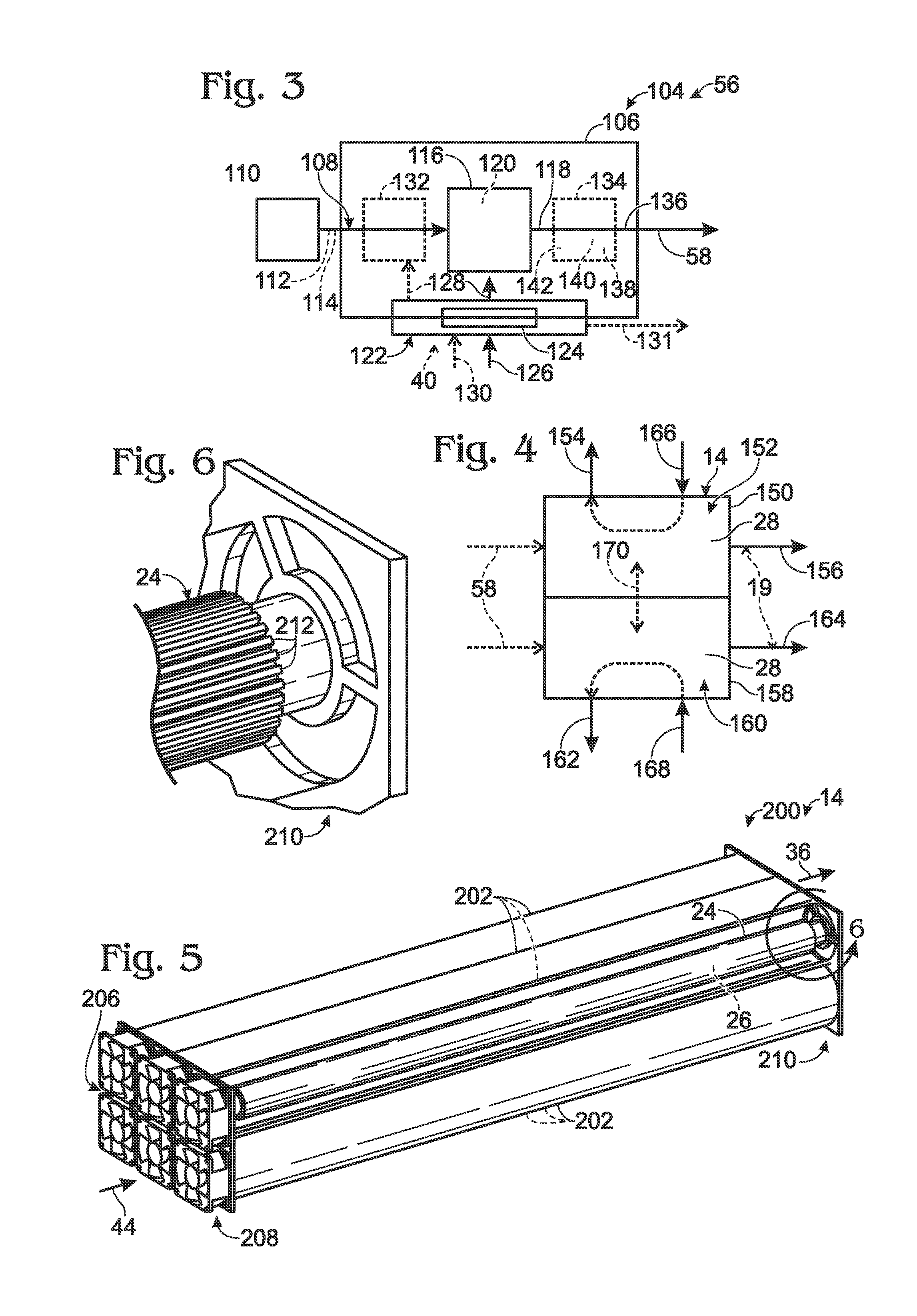

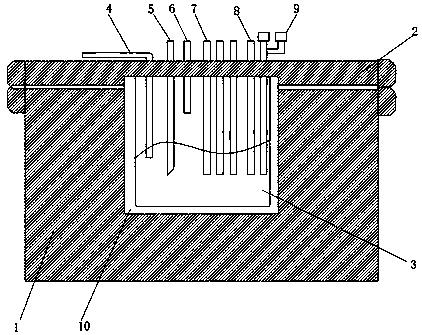

Thermally coupled monolith reactor

InactiveUS20070009426A1Easy to useMaximize heat transferCatalytic gas-gas reactionPhysical/chemical process catalystsChemical treatmentGas phase

The invention comprises, in one form thereof, a chemical processing method to thermally contact an endothermic and an exothermic reaction without mixing the two streams, utilizing a thermally coupled monolith reactor (TCMR). A ceramic or metal monolith is modified to produce a structure containing at least two sets of discrete flow paths and which are separated by a number of common walls. Manifolds are arranged such that one reaction mixture flows through one set of channels and a different reaction mixture flows through the second. Catalytic material, which is active for the relevant reaction, is coated onto the inner walls of each of the sets of channels. The two reactions are chosen such that one is exothermic and one is endothermic, such that the energy required by the endothermic process is supplied directly through the dividing wall from the exothermic process occurring on the opposing side. This method of heat transfer completely decouples the gas phase hydrodynamics from the heat transfer process.

Owner:ZEROPOINT CLEAN TECH

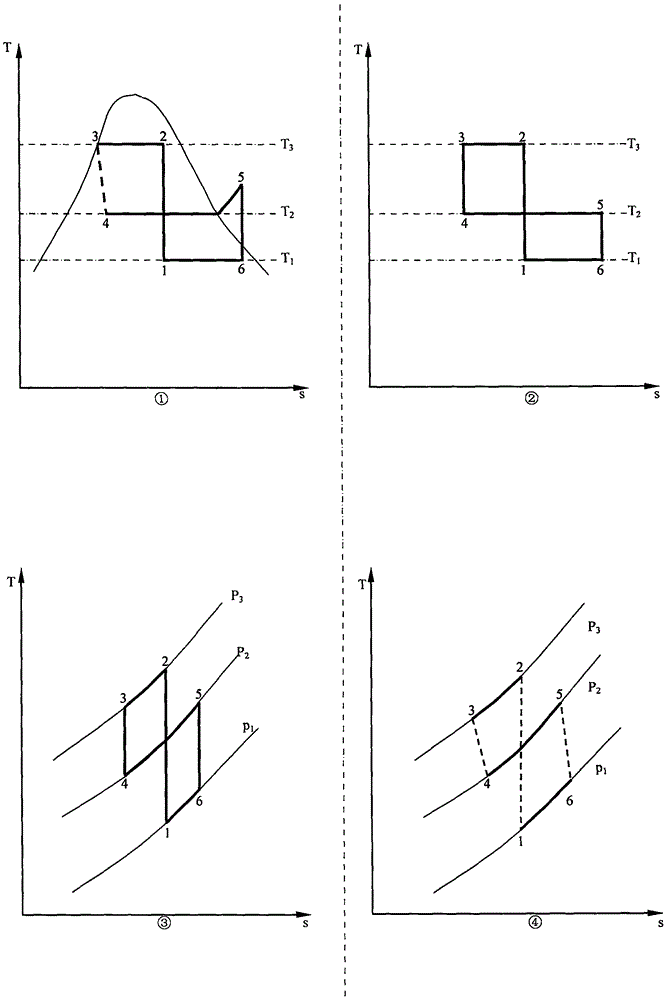

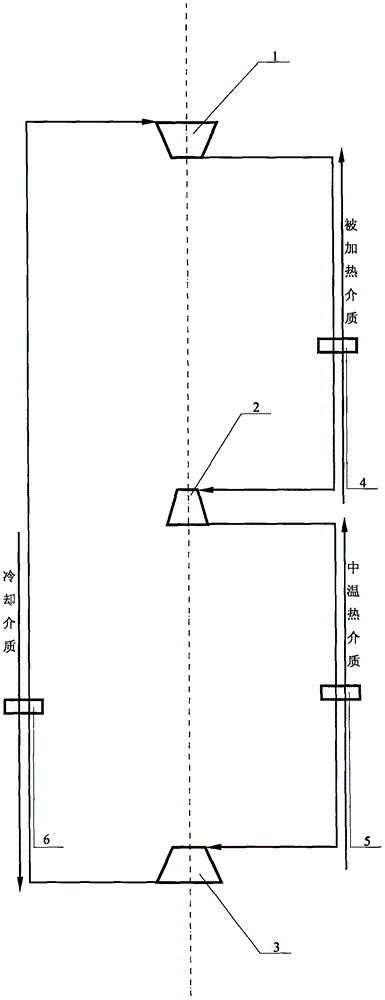

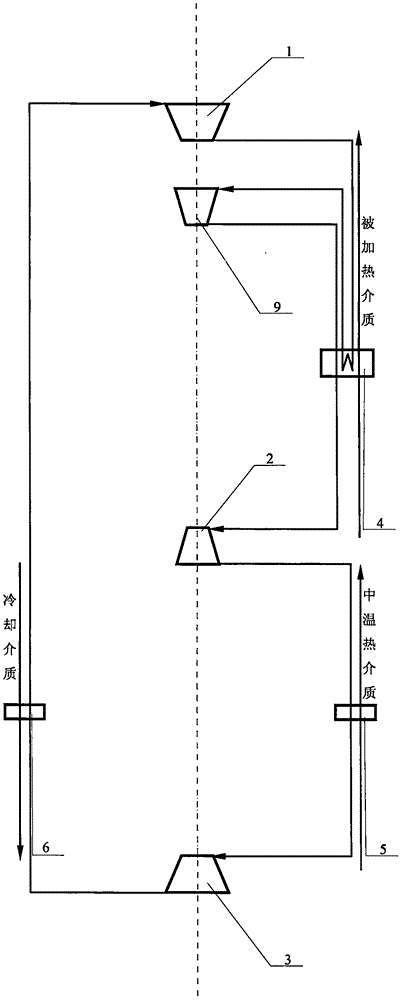

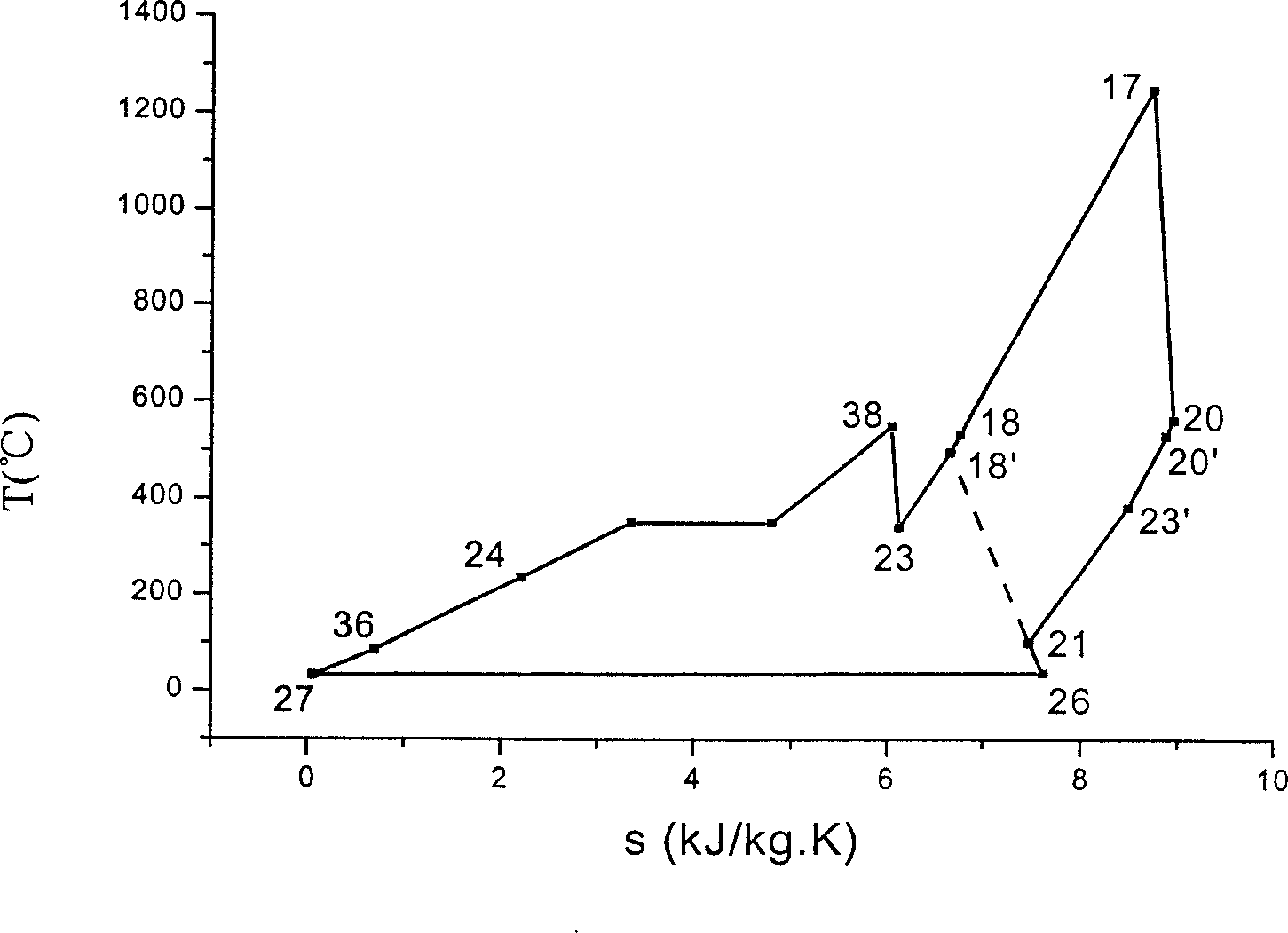

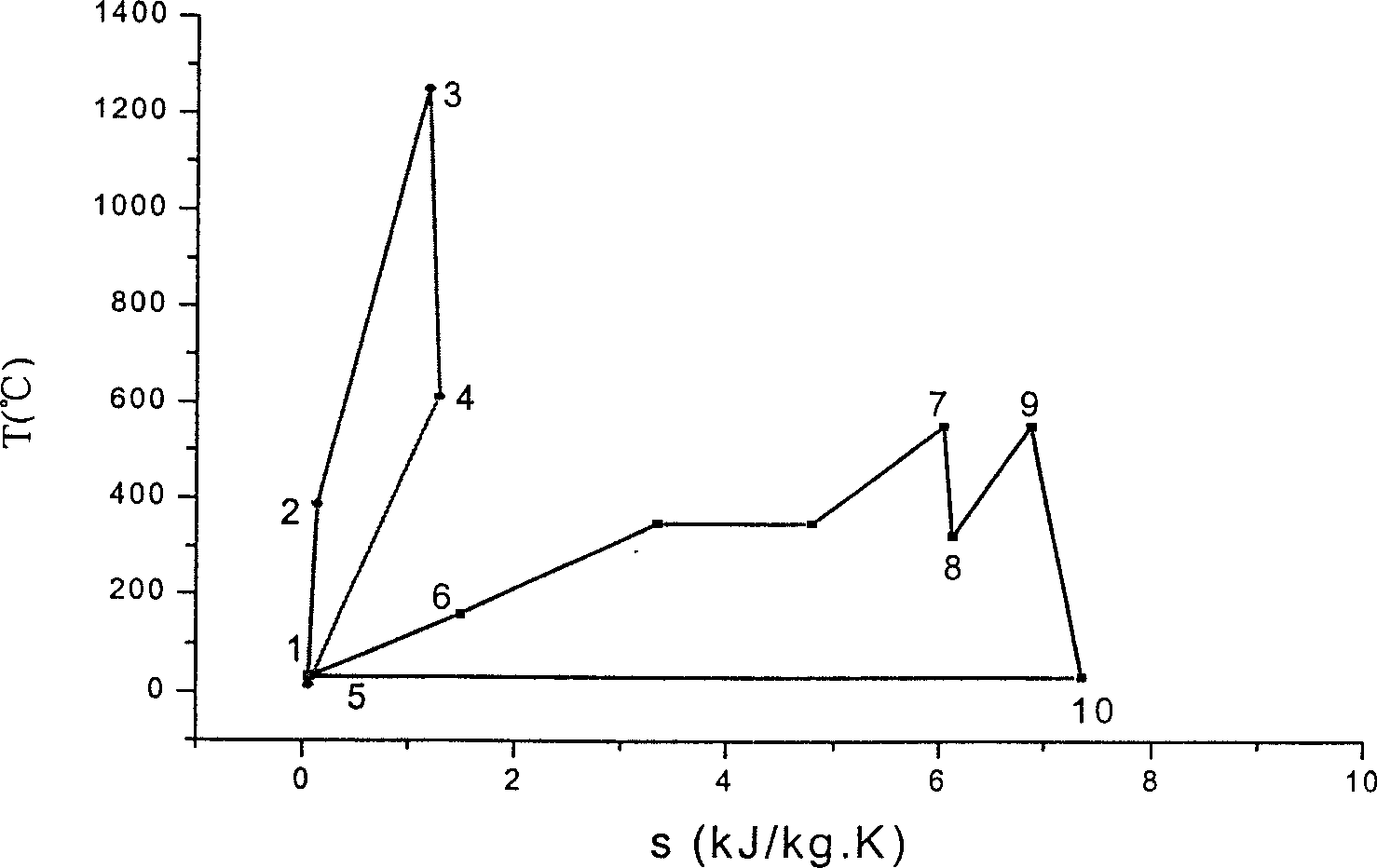

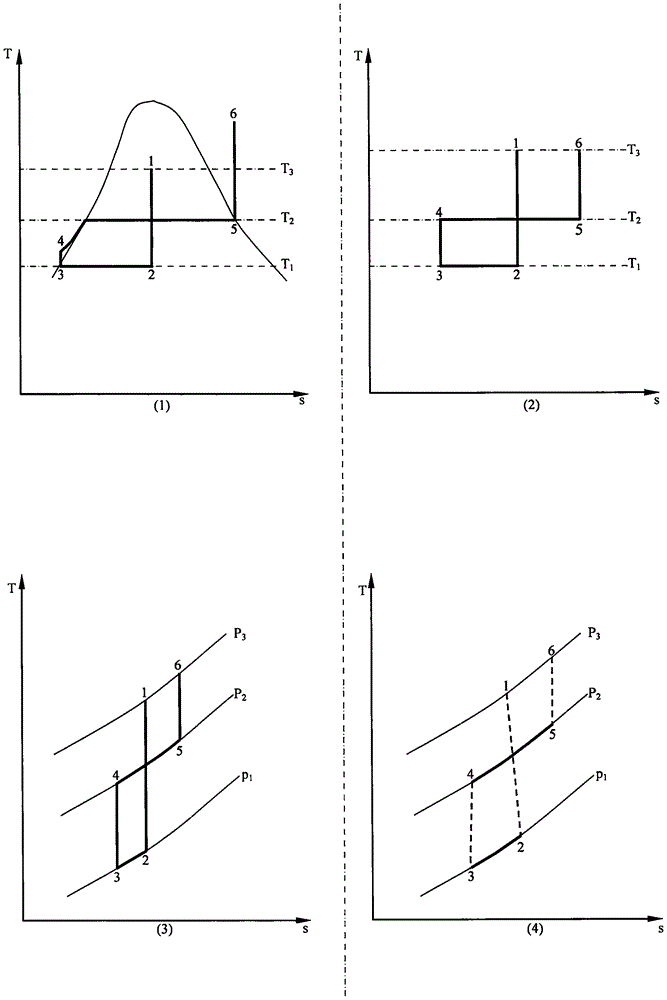

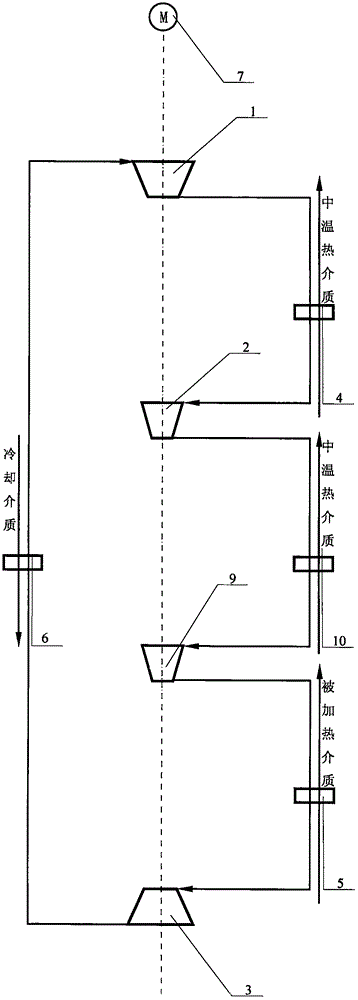

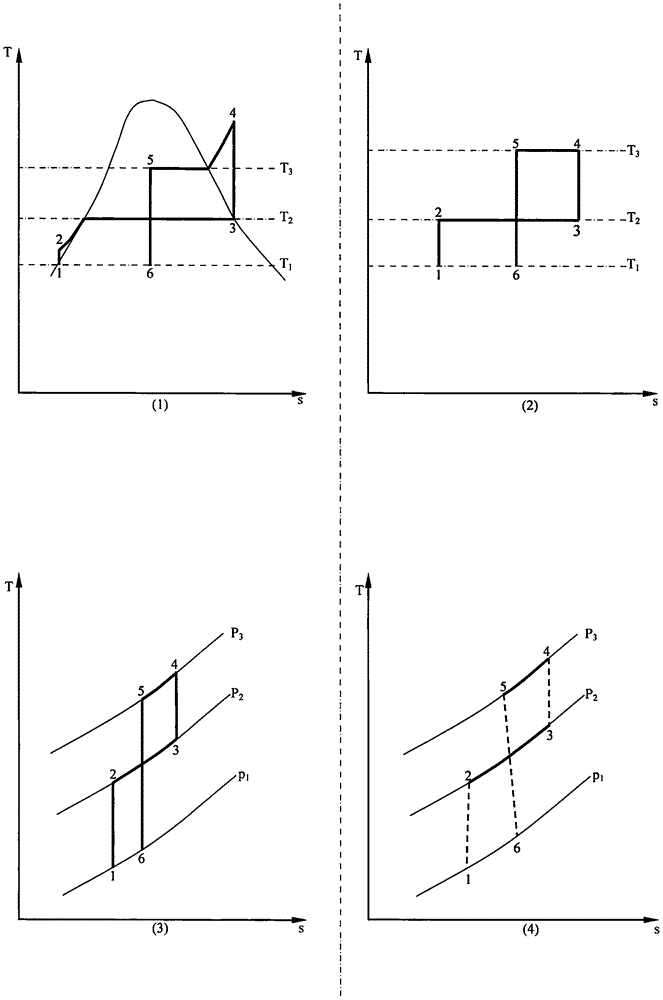

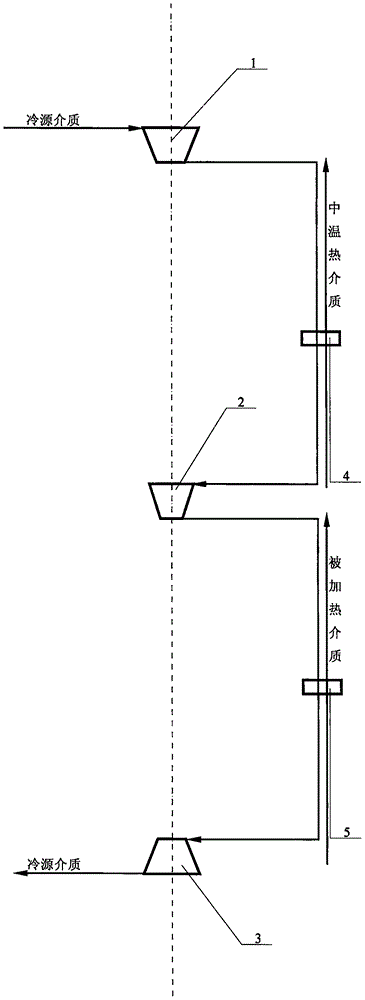

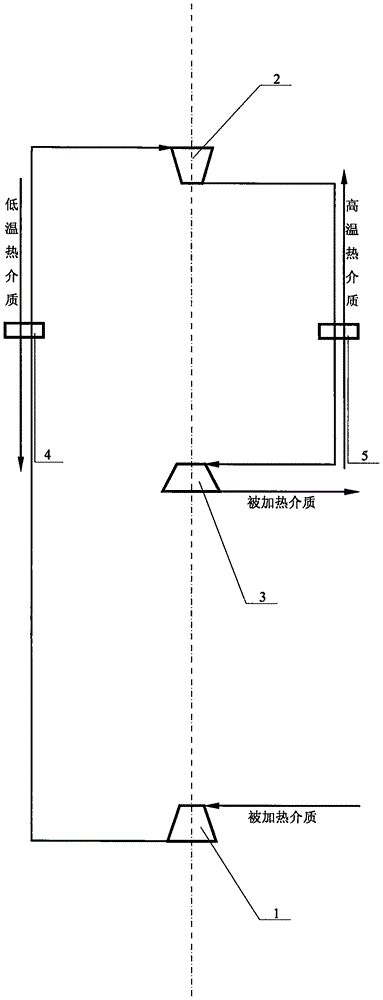

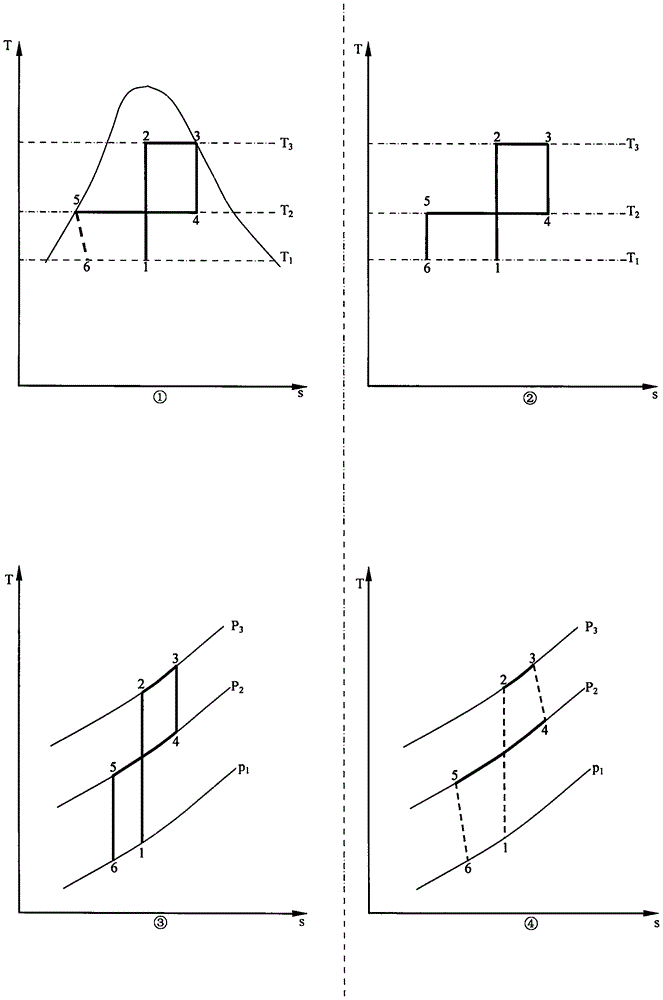

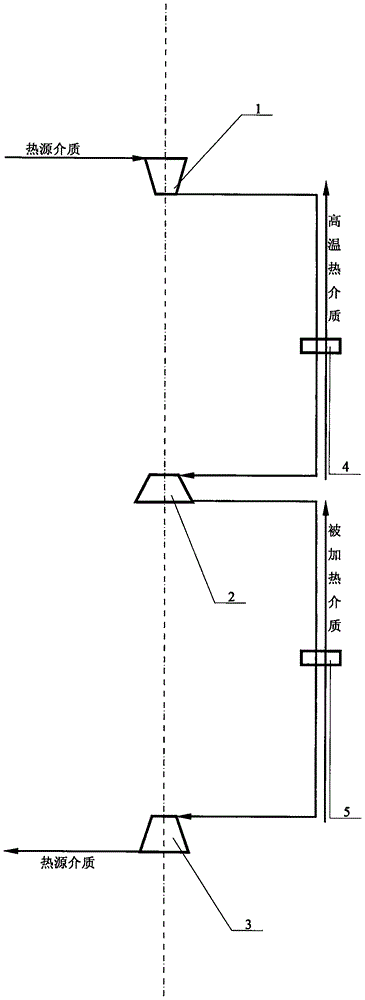

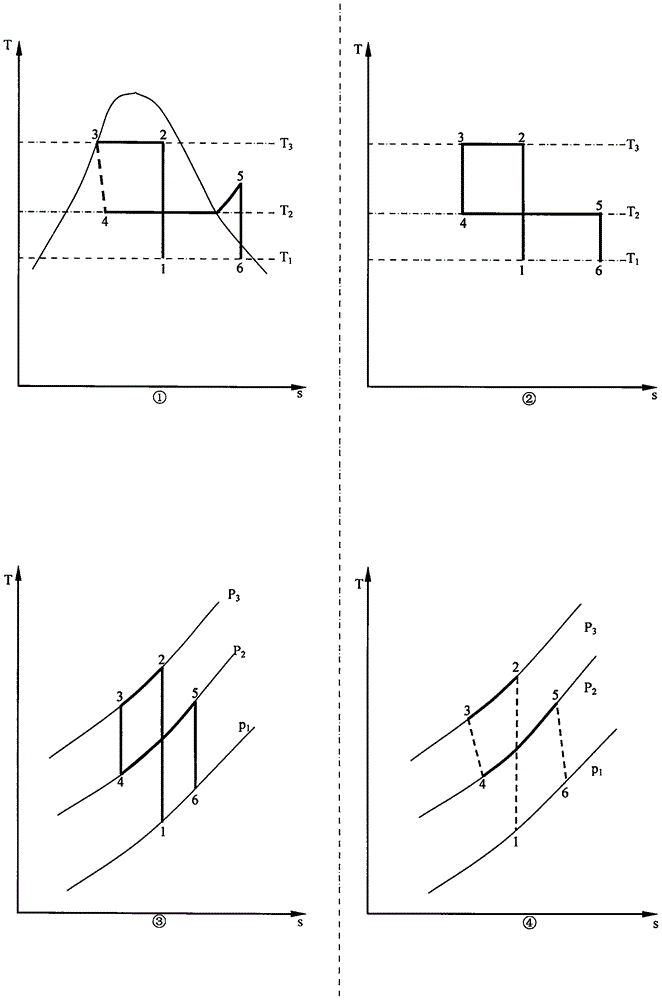

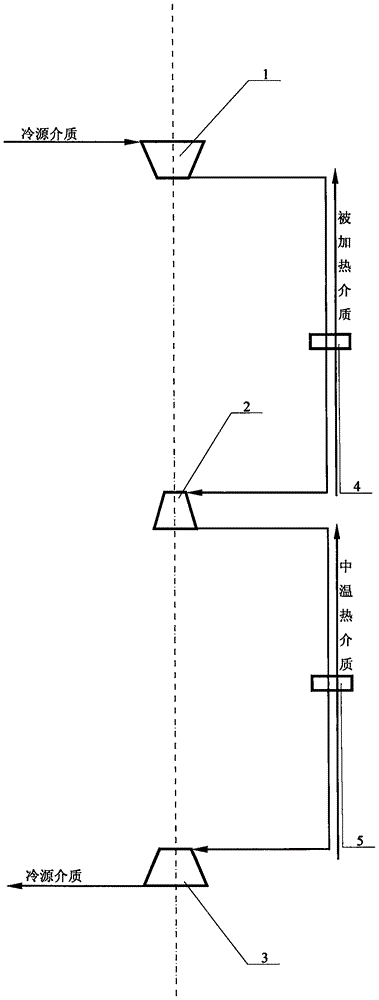

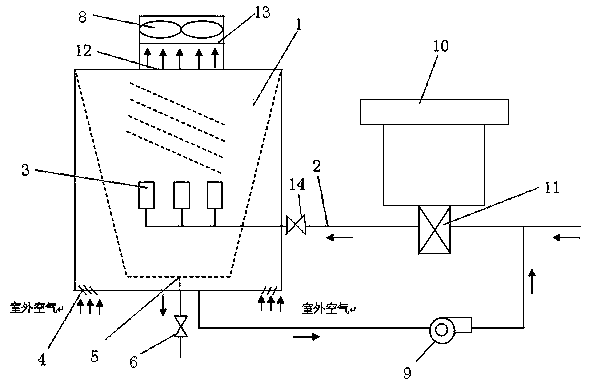

Bidirectional thermal cycle and second type of heat-driven compression heat pump

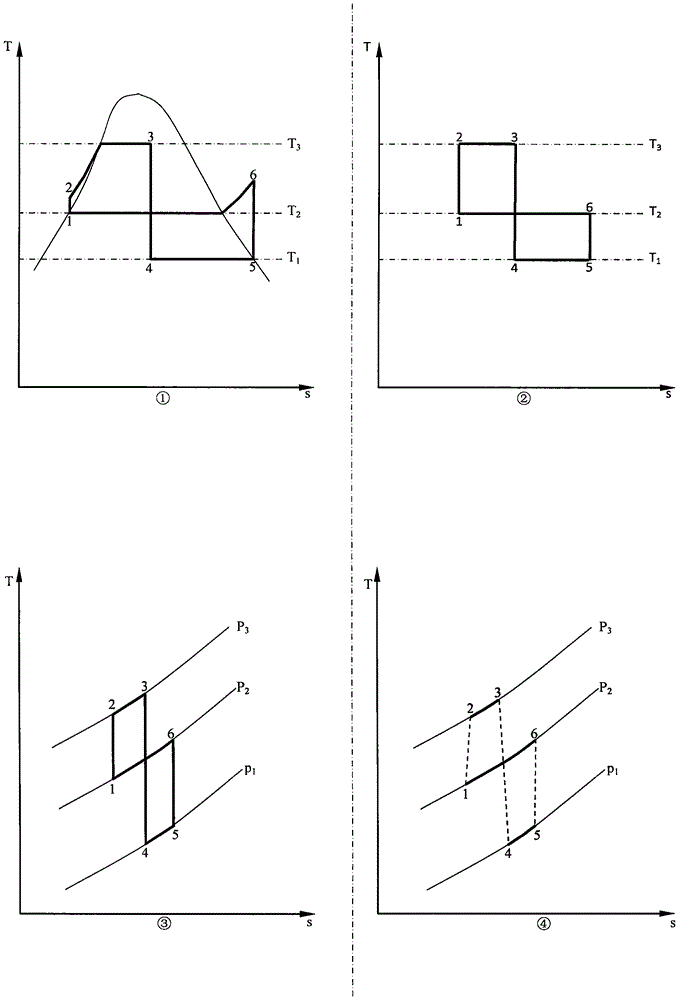

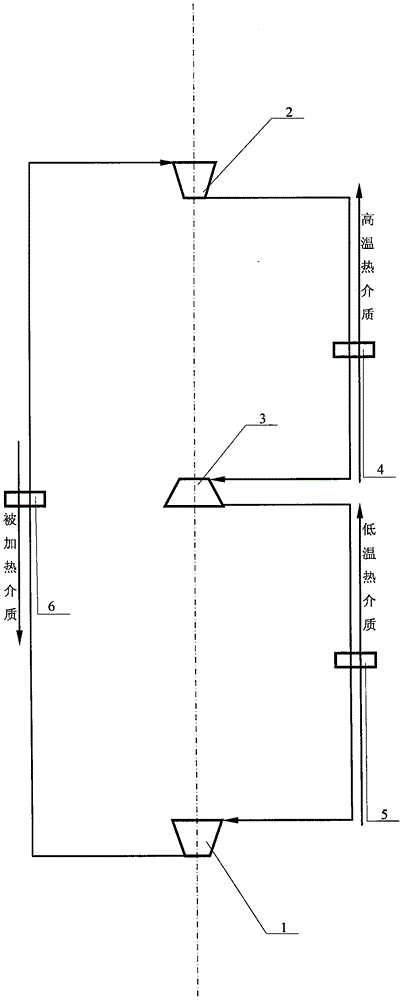

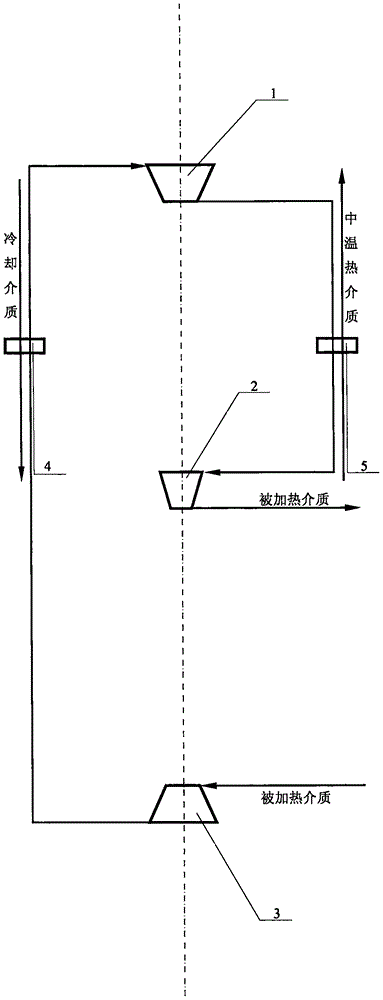

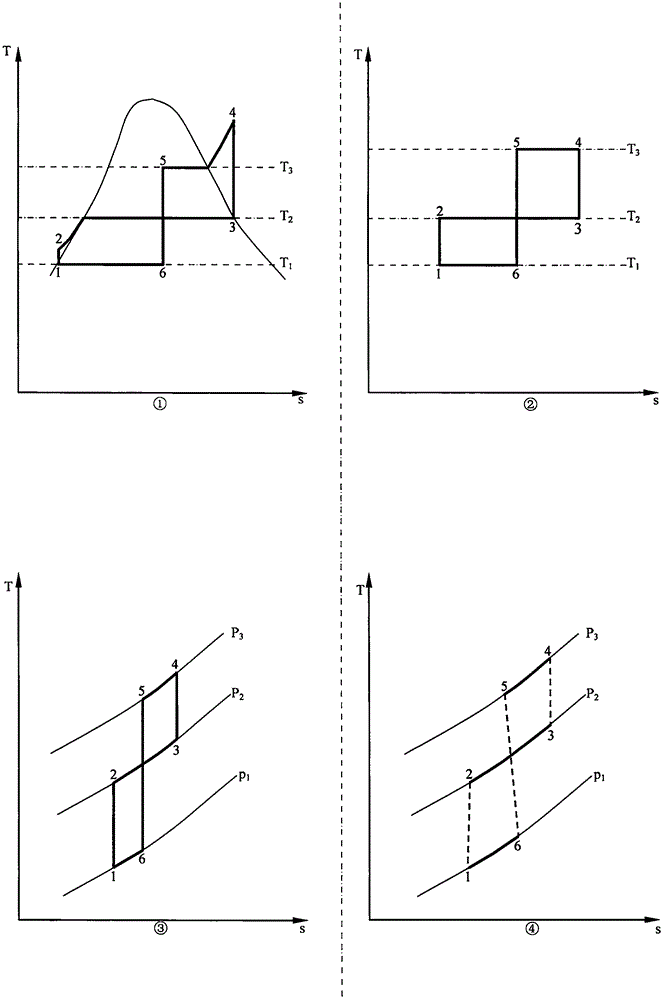

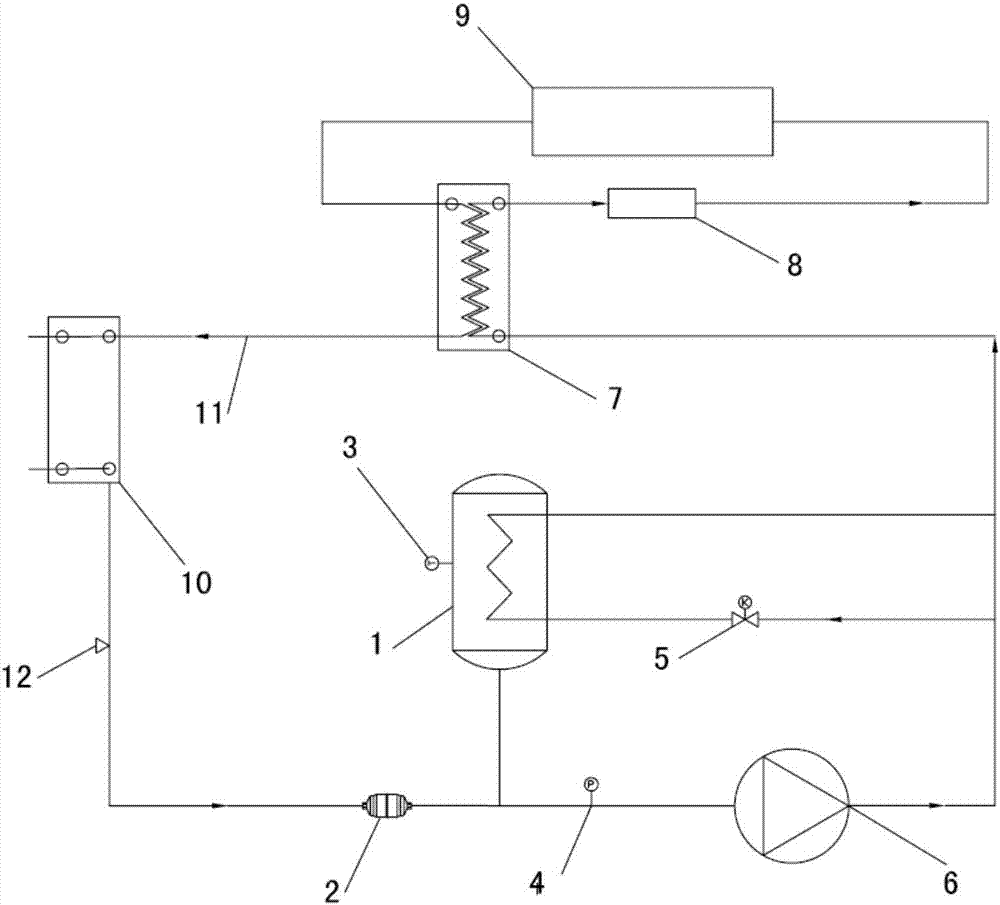

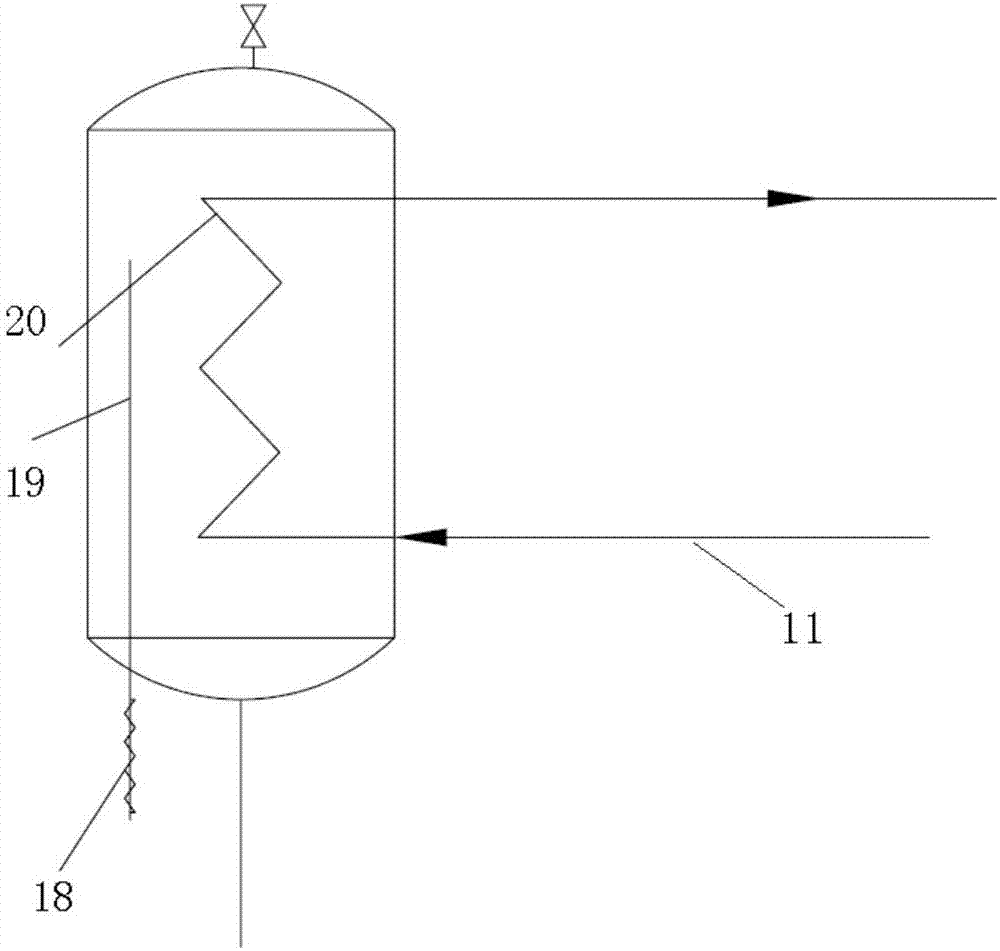

The invention provides a bidirectional thermal cycle and second type of heat-driven compression heat pump, and belongs to the power and heat pump technology field. A bidirectional thermal cycle 1234561 comprises the steps of a working medium boost process 12 that begins from a low temperature; a heat absorption process 23 that absorbs heat from a middle temperature heat source; a boost process 34 that begins from a middle temperature; a heat release process 45 that releases heat to a high temperature heat source; a pressure reduction process 56 that begins from a high temperature; a heat release process 61 that releases heat to a low temperature heat source. A compressor has cycle working medium and is communicates with a second compressor through a heat exchanger; the second compressor has the cycle working medium channel and is communicated with an expander through a heater; the expander has the cycle working medium channel and is communicated with a compressor through a cooler; the heat exchanger has a middle temperature thermal medium channel and is communicated with the outside; the heater has a heated medium channel and is communicated with the outside; the cooler has a cooling medium channel and is communicated with the outside; the expander is connected with the compressor and the second compressor, and is used to transmit power to form the second type of heat-driven compression heat pump.

Owner:李华玉

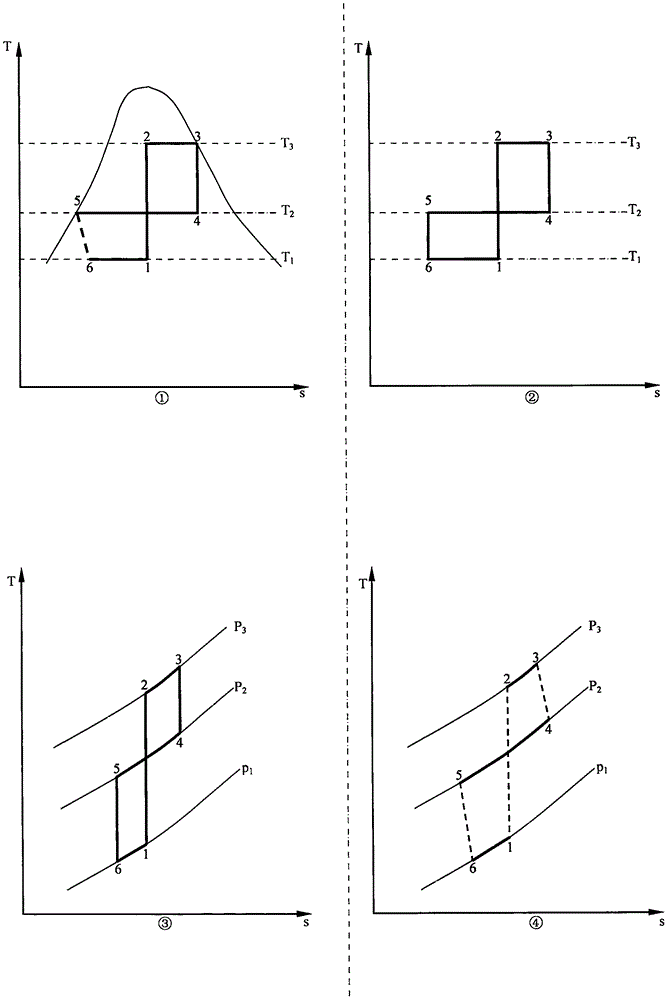

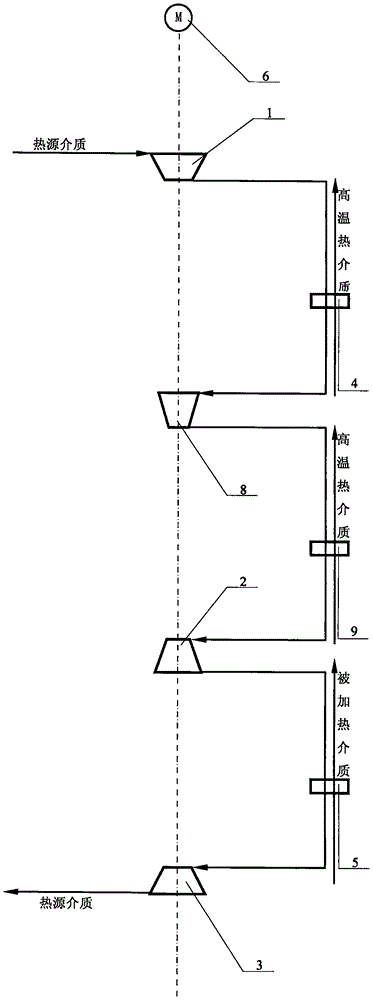

Bidirectional thermal cycle and first type of heat-driven compression heat pump

ActiveCN105953454AMechanical apparatusCompression machines with non-reversible cycleExothermic processEngineering

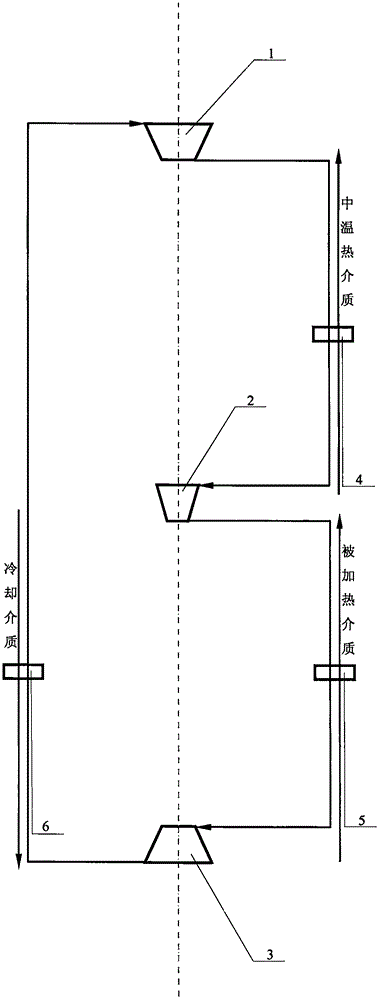

The invention provides a bidirectional thermal cycle and first type of heat-driven compression heat pump, and belongs to the power, refrigeration and heat pump technology field. A bidirectional thermal cycle 1234561 comprises the steps of a working medium boost process 12 that begins from a low temperature; a heat absorption process 23 that absorbs heat from a middle temperature heat source; a boost process 34 that begins from a middle temperature; a heat release process 45 that releases heat to a high temperature heat source; a pressure reduction process 56 that begins from a high temperature; a heat absorption process 6 that absorbs heat from a low temperature heat source. A compressor has cycle working medium and is communicates with an expander through a high temperature heat exchanger; the expander has the cycle working medium channel and is communicated with a second expander through a heater; the second expander has the cycle working medium channel and is communicated with the compressor through a low temperature heat exchanger; the high temperature heat exchanger has a high temperature thermal medium channel and is communicated with the outside; the low temperature heat exchanger has a low temperature thermal medium channel and is communicated with the outside; the heater has a heated medium channel and is communicated with the outside; the expander and the second expander are connected with the compressor to transmit power to form the first type of heat-driven compression heat pump.

Owner:李华玉

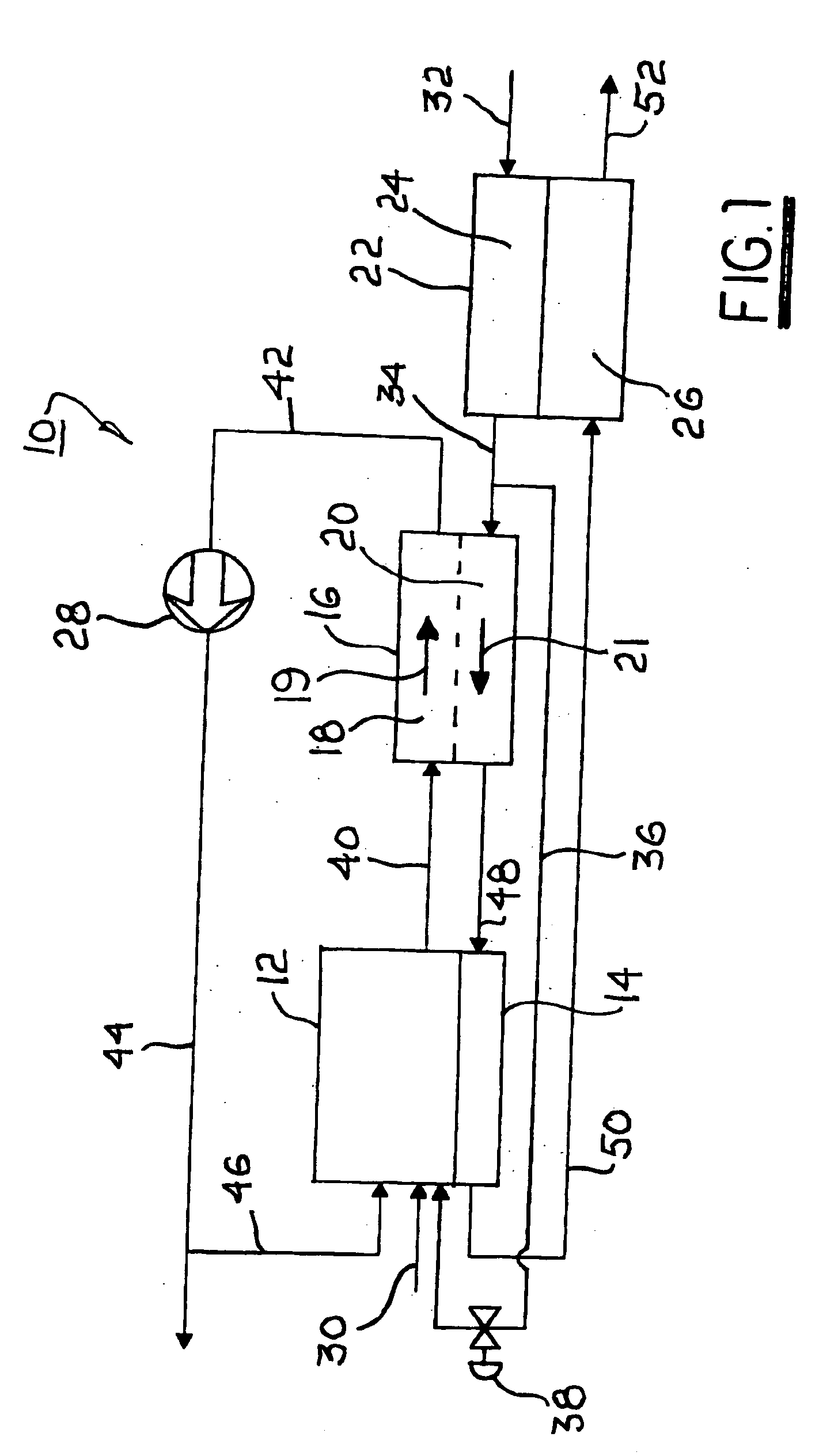

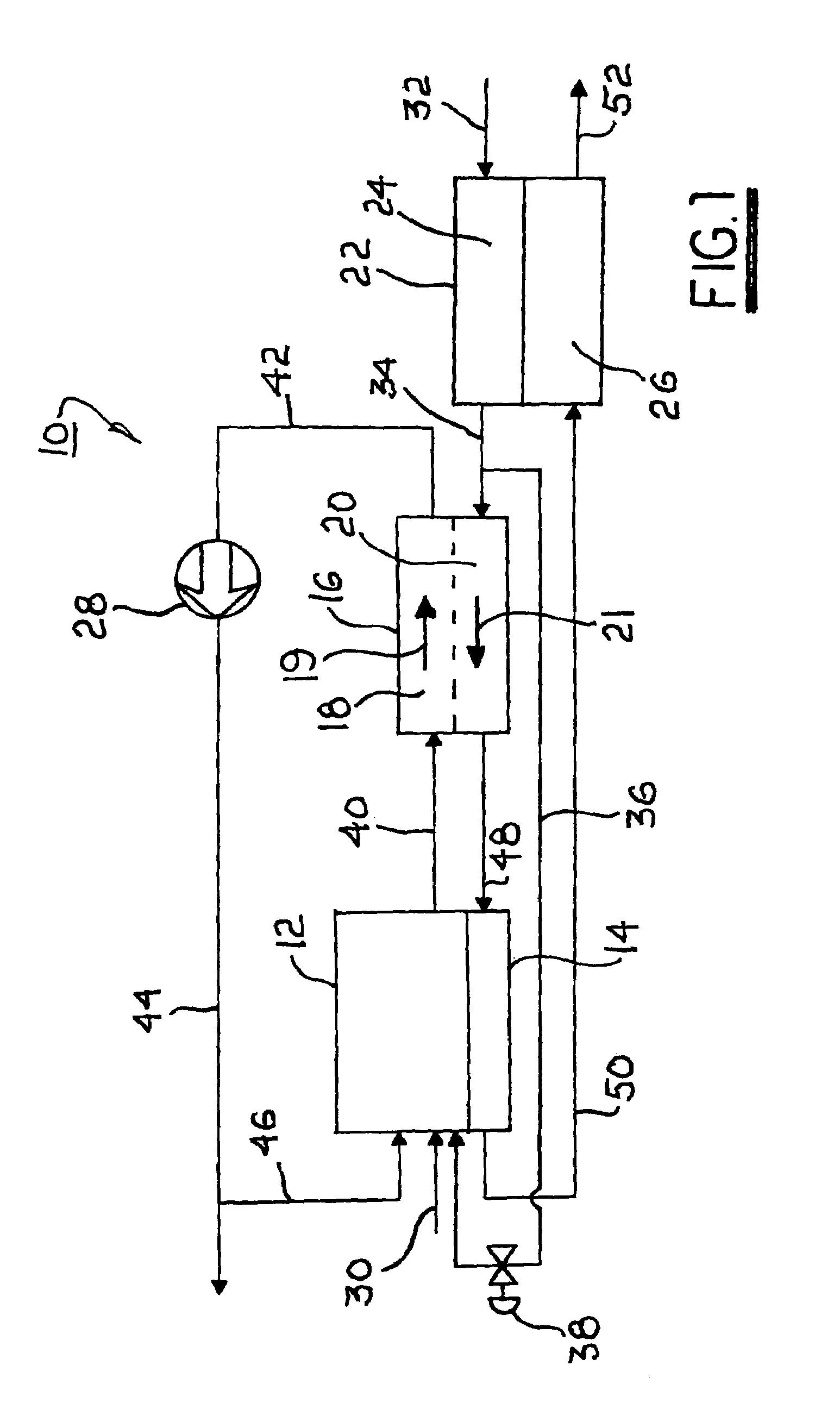

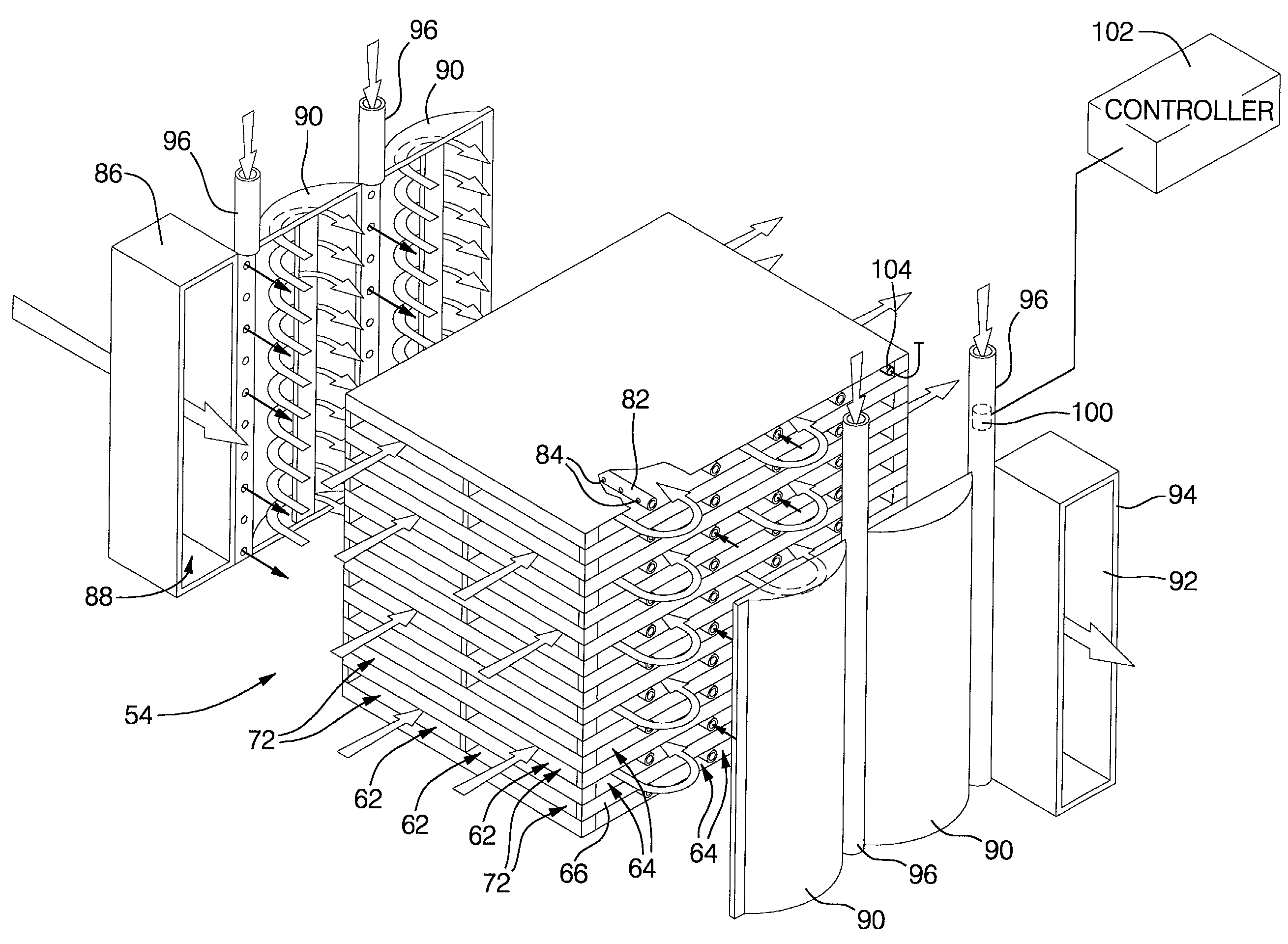

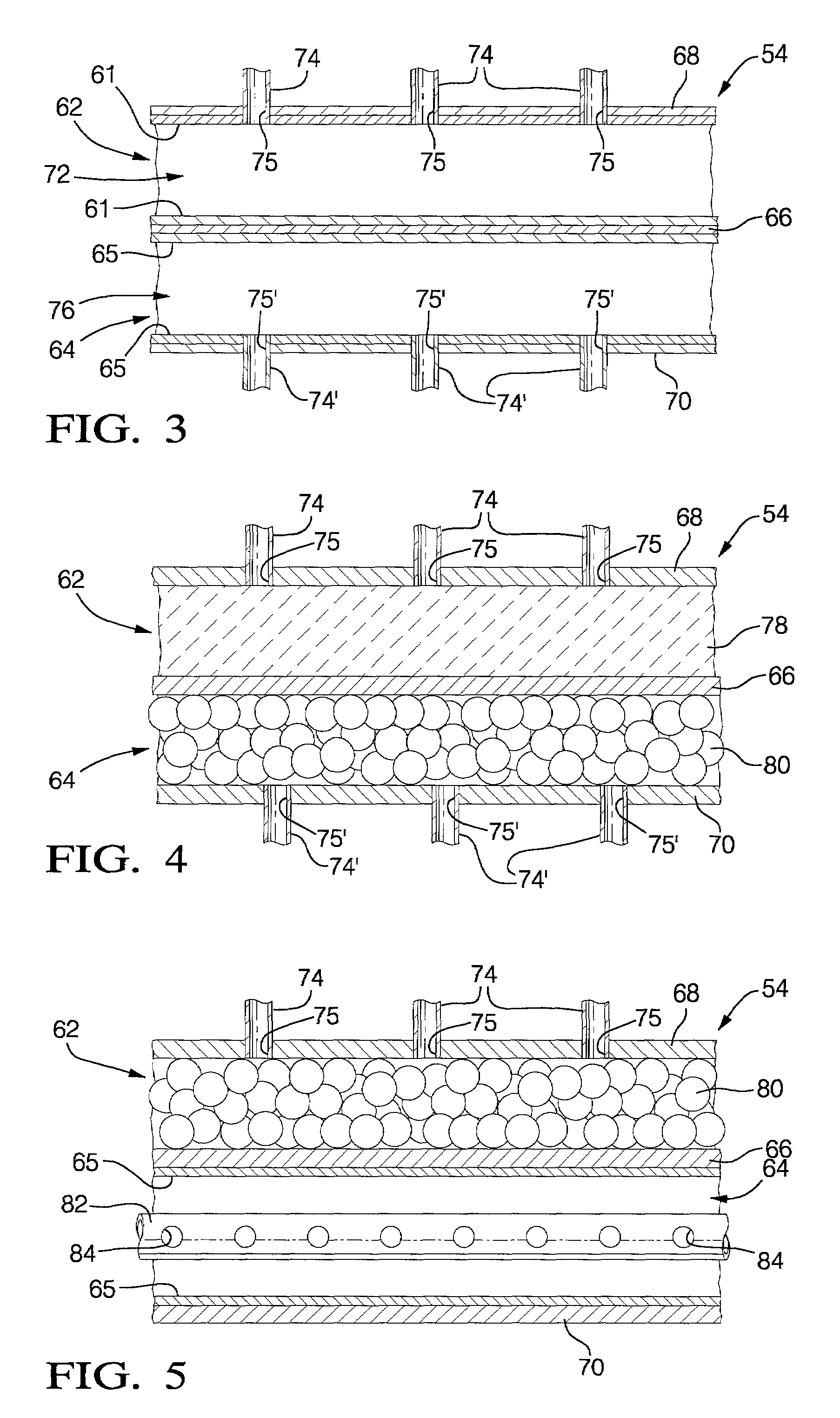

Multiple stage combustion process to maintain a controllable reformation temperature profile

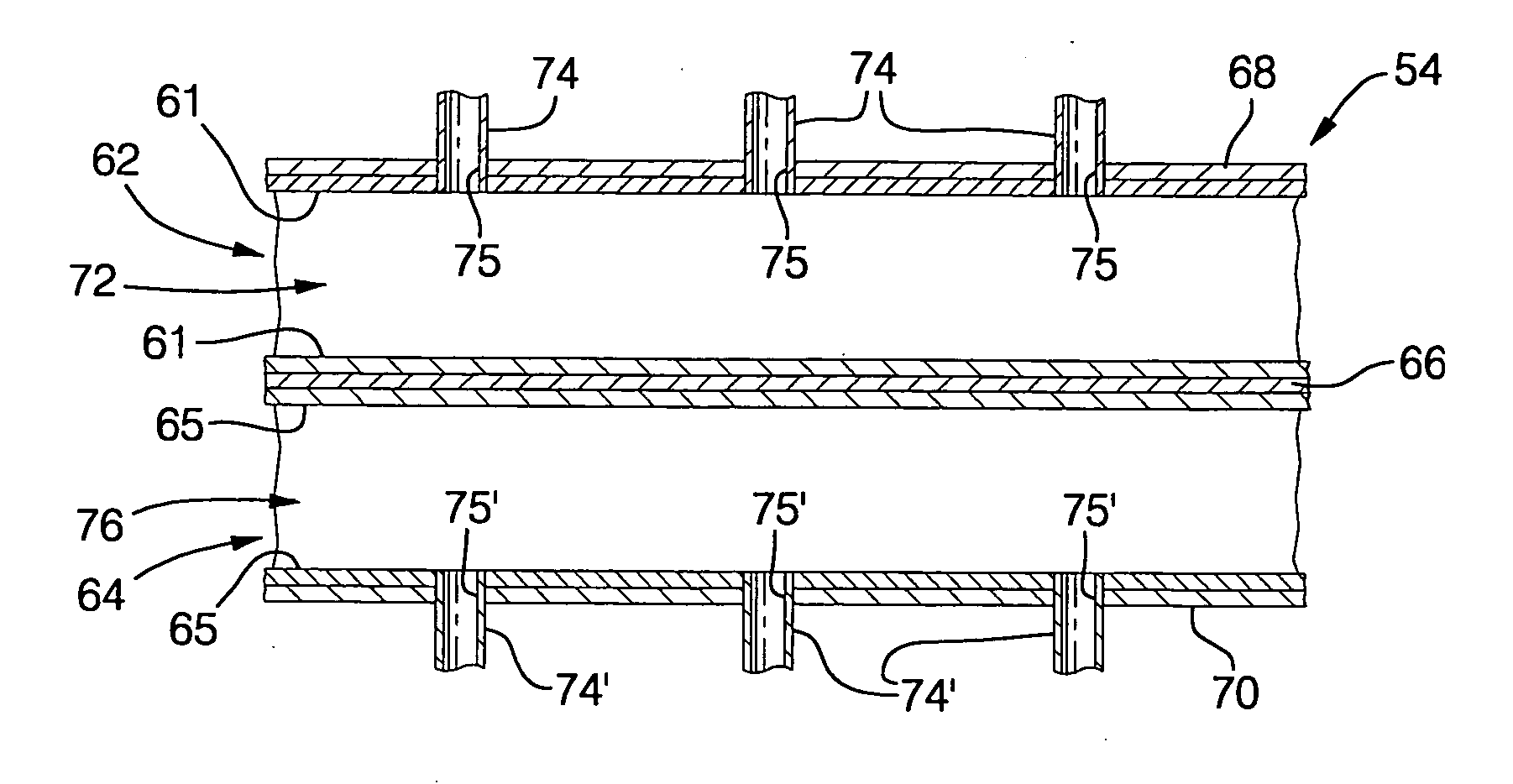

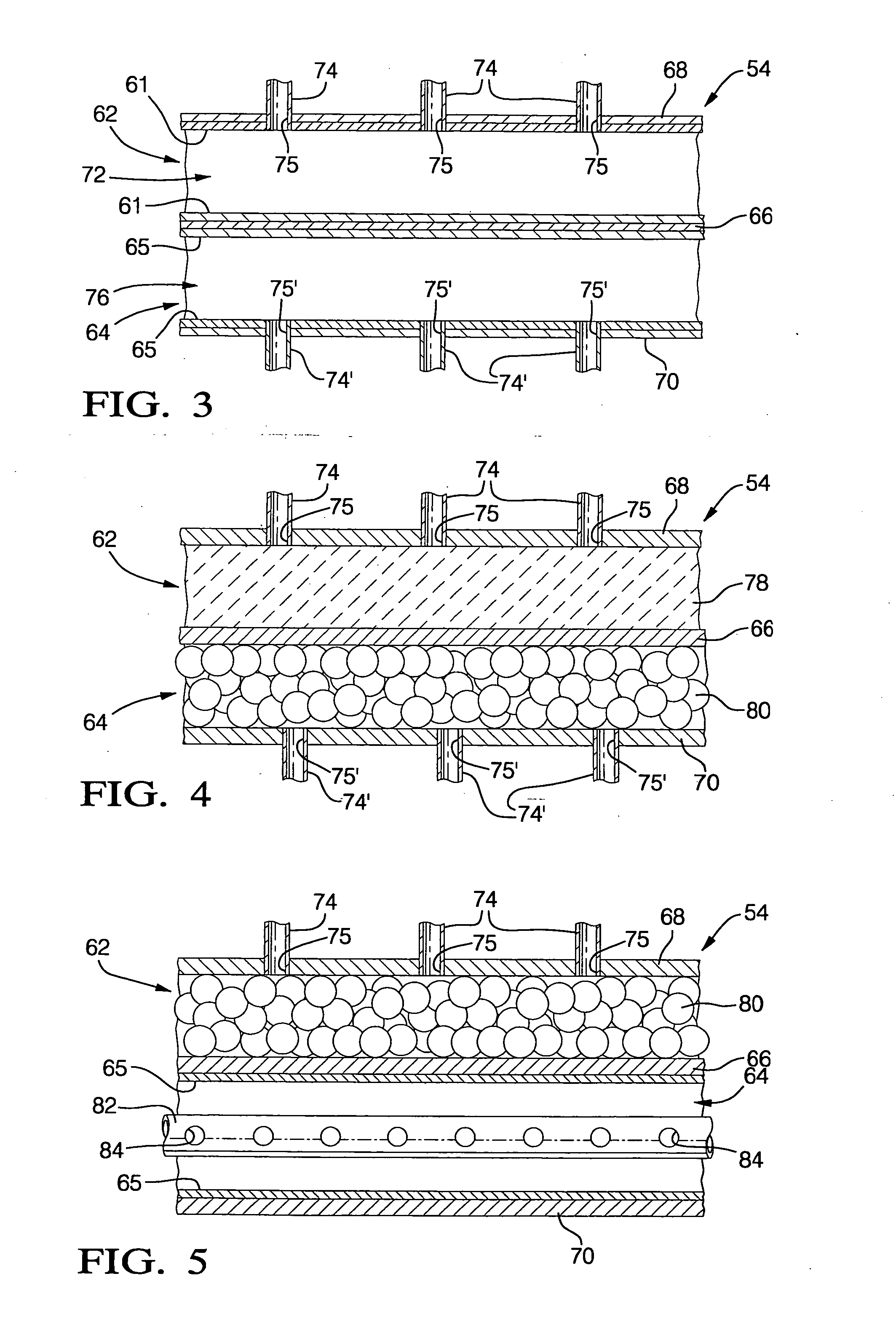

InactiveUS20050048333A1Uniform exchangeGenerate uniformFuel cells groupingFuel cell auxillariesFuel cellsWorking fluid

A reaction vessel that integrates and balances an endothermic process with at least one exothermic process of the fuel cell system. Preferably the exothermic process is conducted in stages to provide more uniform and / or controllable heat generation and exchange, and to produce a uniform and / or controllable temperature profile in the endothermic reaction process. The invention allows for the elimination of the working fluid loop of prior art systems that had unsatisfactory response times at startup, and during transient conditions, and also added to the overall mass and volume of the fuel cell system.

Owner:GM GLOBAL TECH OPERATIONS LLC

Inside and outside burning coal integrative combined cycle generation system and method

InactiveCN1521446AAchieve efficiencyPromote environmental protectionGas turbine plantsSteam generation plantsEngineeringHigh pressure

The invention relates to an external and internal fire coal integrated combination circulation power generating system and process thereof, the power generating system comprises gasification sub-system, power circulation subsystem and carbon dioxide reclamation subsystem. The process according to the invention includes heating up in external-burning mode in the low-temperature stage of the endothermic process in thermodynamic cycle, obtaining the energy through portion coal gasification, and using internal-burning mode heating up in high temperature stage, obtaining the coal gas energy through portion coal gasification. The advantages of the invention are high heat efficiency, environmentally friendliness and good economy property.

Owner:中科思道(南京)储能技术有限公司

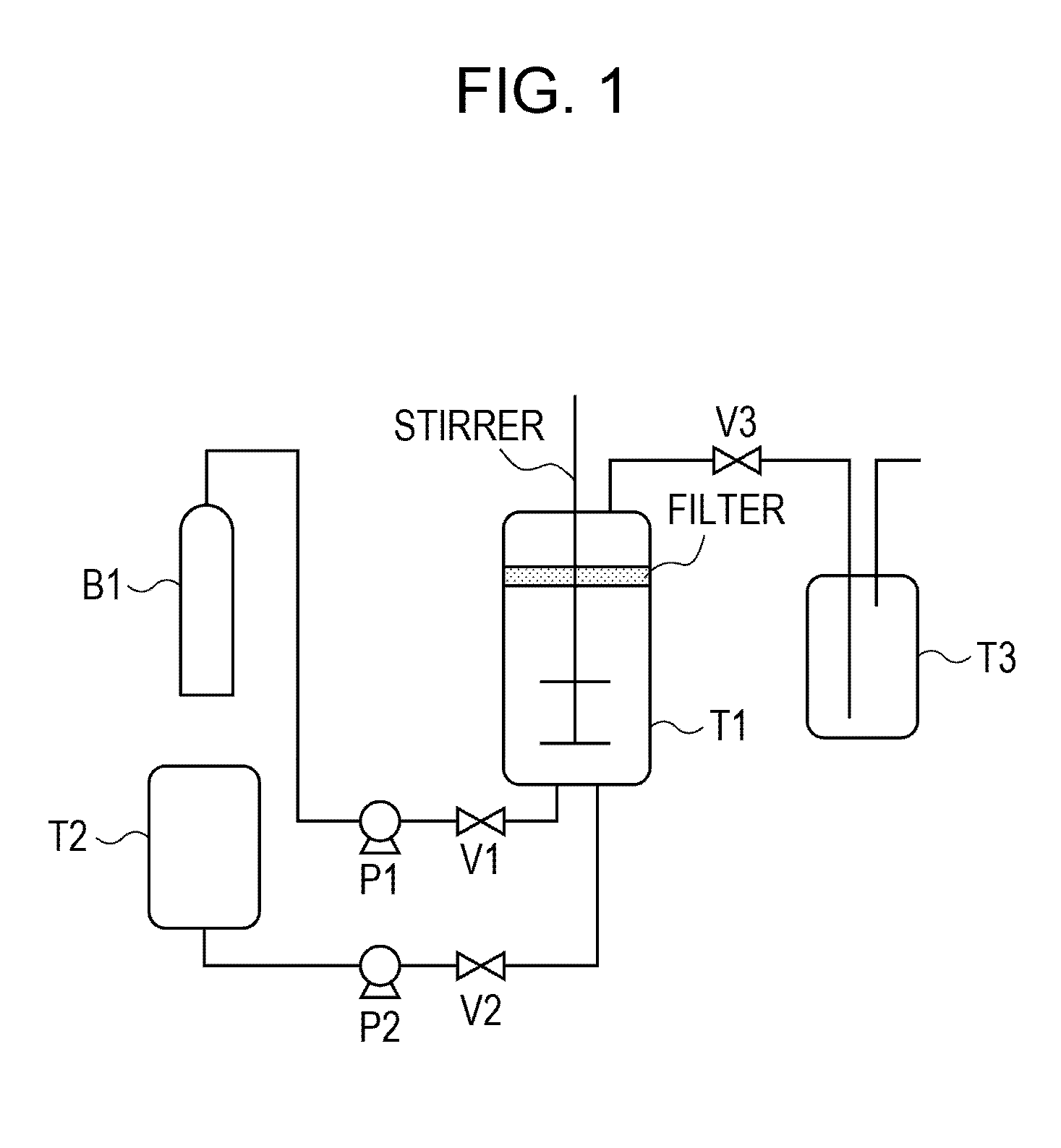

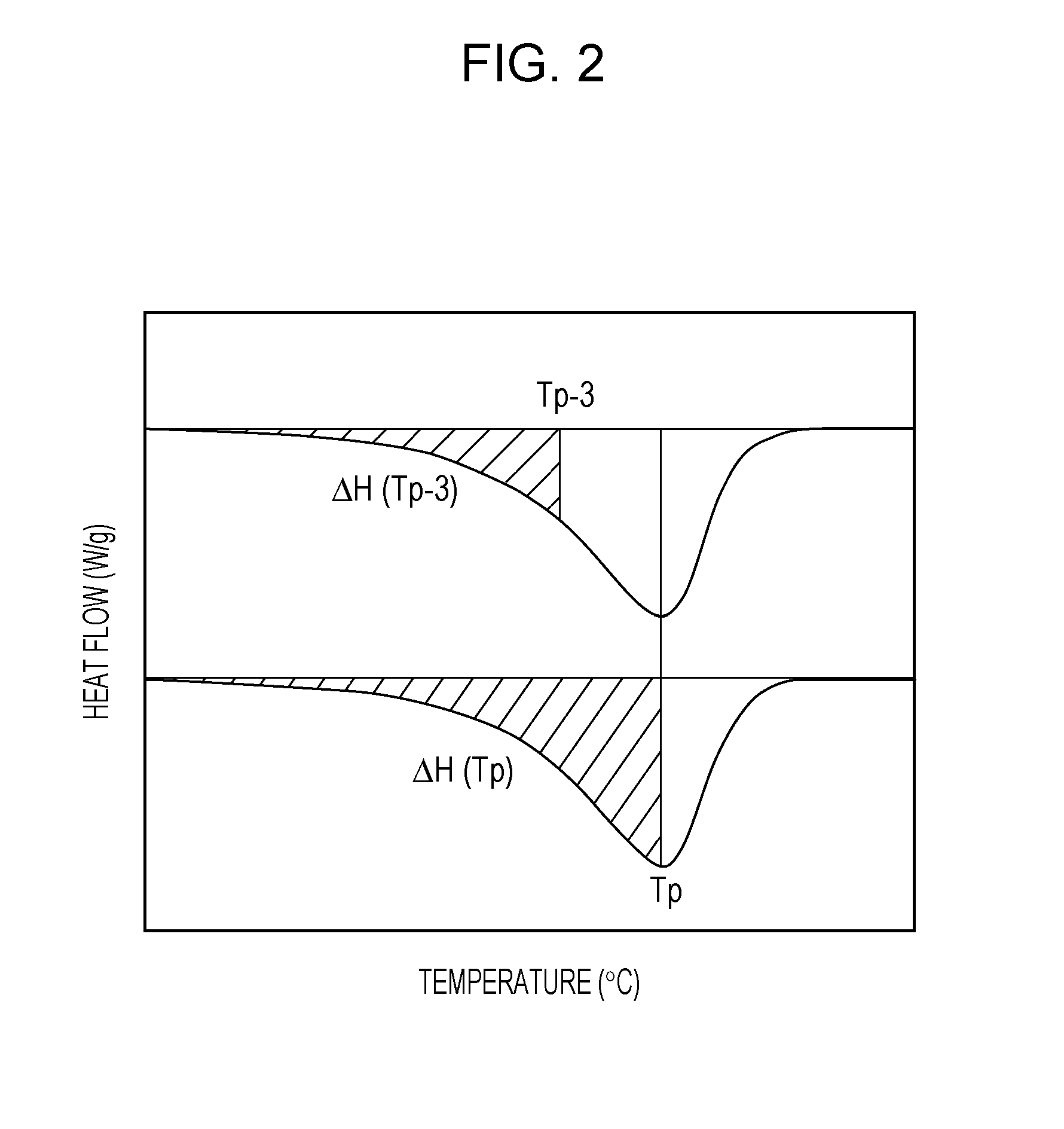

Toner

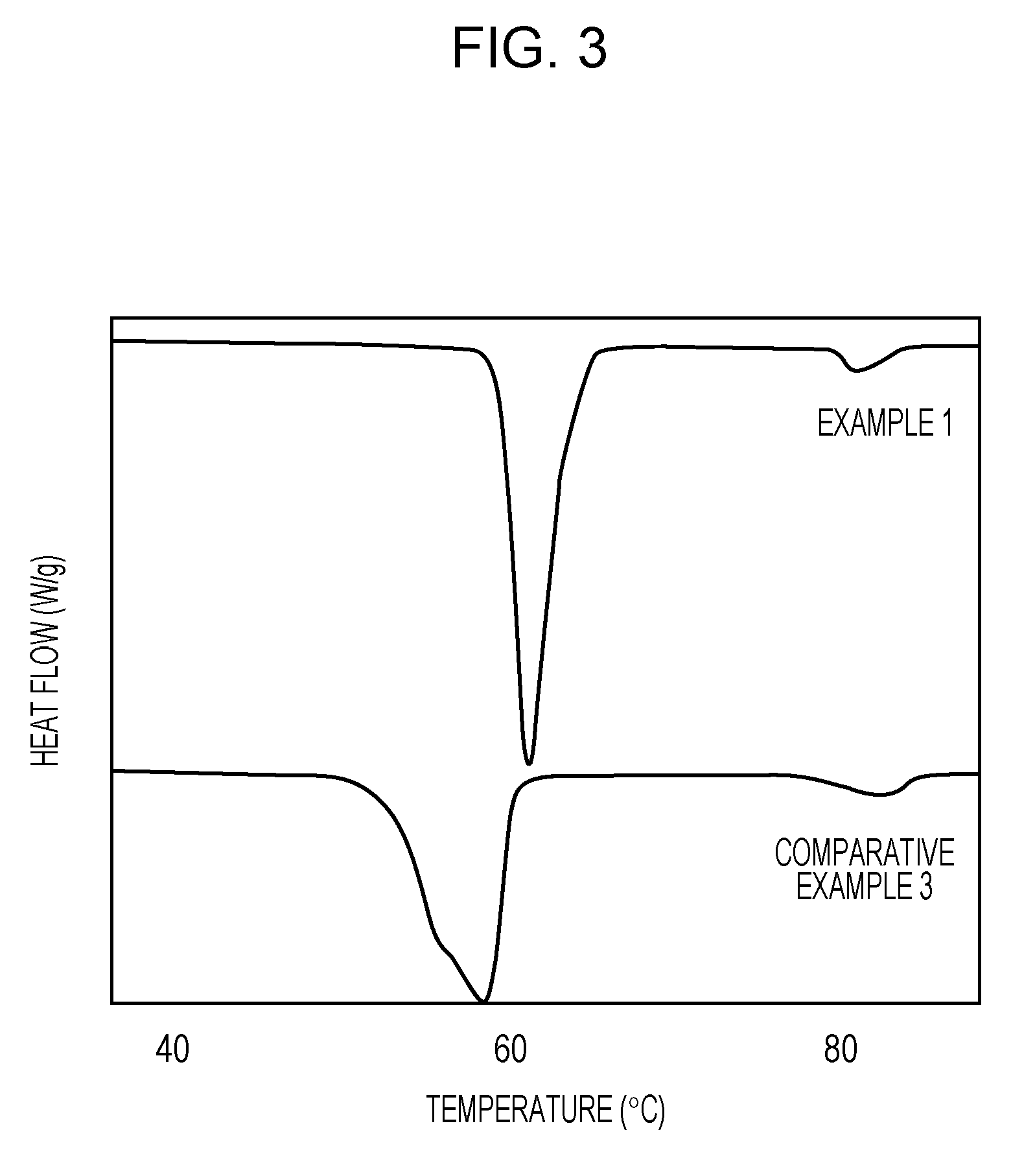

InactiveUS20130130169A1Maintain good propertiesLow-temperature fixabilityDevelopersMaterials scienceEndothermic process

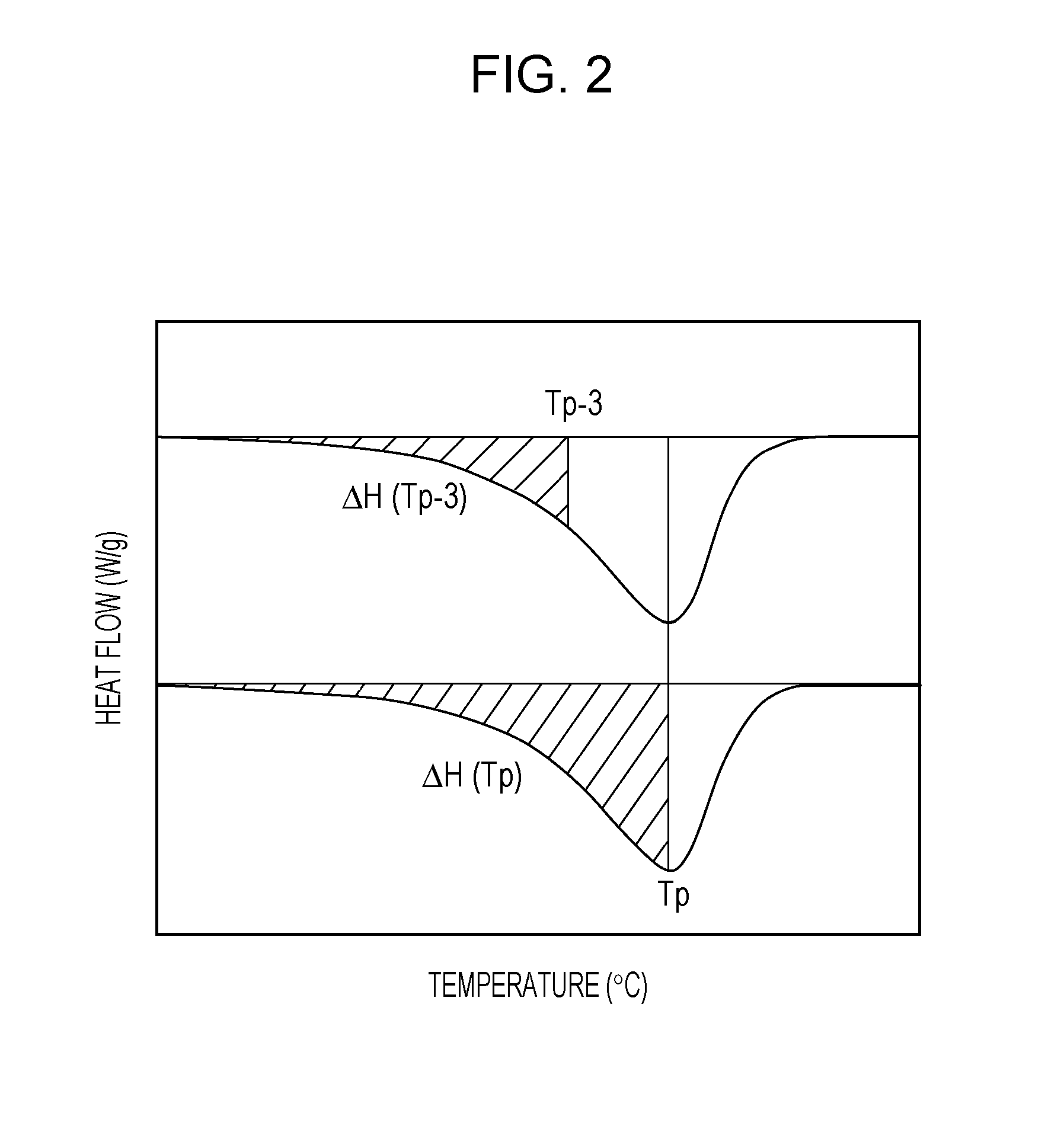

In the measurement of an endothermic amount of a toner, (1) an endothermic peak temperature (Tp) derived from the binder resin is 50° C. or higher and 80° C. or lower; (2) a total endothermic amount (ΔH) derived from the binder resin is 30 [J / g] or more and 125 [J / g] or less based on mass of the binder resin; (3) when an endothermic amount derived from the binder resin from an initiation temperature of an endothermic process to Tp is represented by ΔHTp [J / g], ΔH and ΔHTp satisfy formula (1) below; and (4) when an endothermic amount derived from the binder resin from the initiation temperature of an endothermic process to a temperature 3.0° C. lower than Tp is represented by ΔHTp-3 [J / g], ΔH and ΔHTp-3 satisfy formula (2) below.0.30≦ΔHTp / ΔH≦0.50 (1)0.00≦ΔHTp-3 / ΔH≦0.20 (2)

Owner:CANON KK

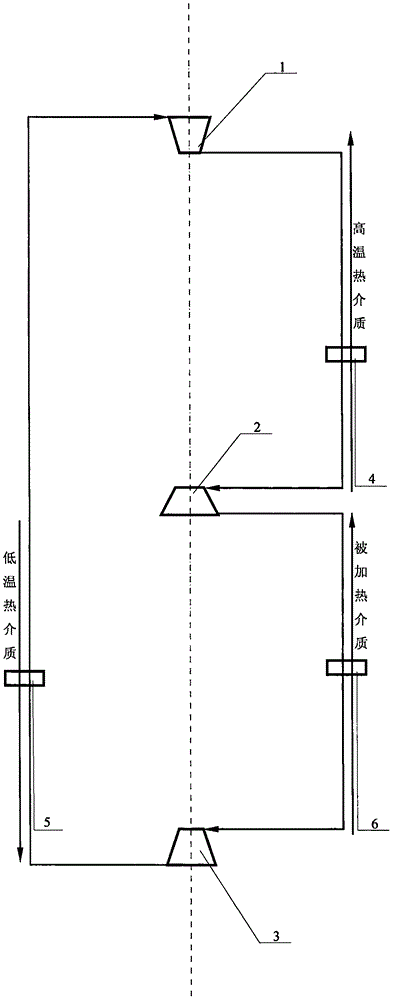

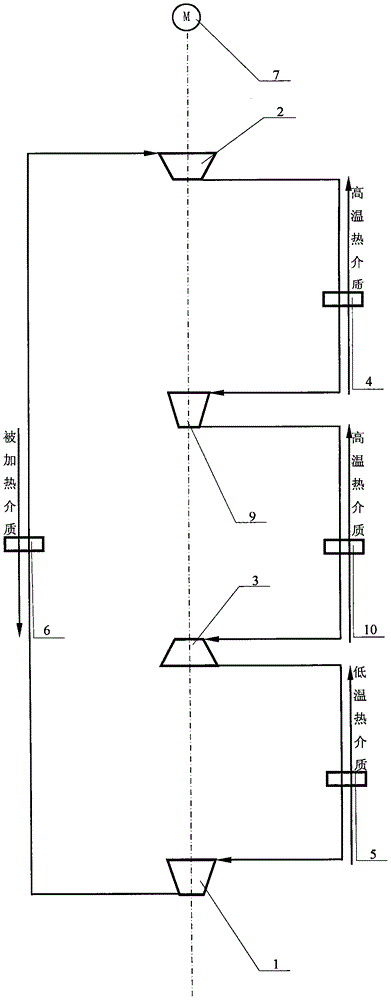

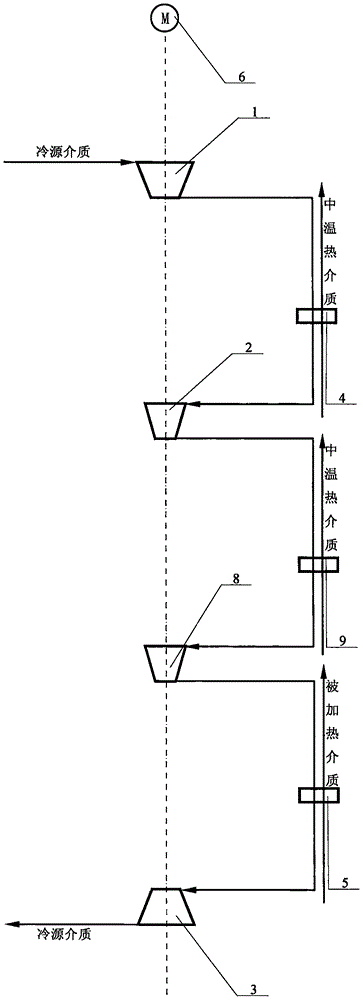

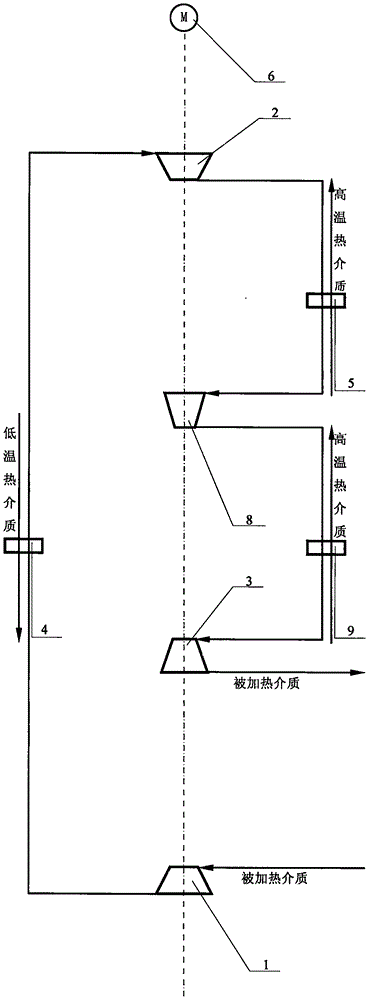

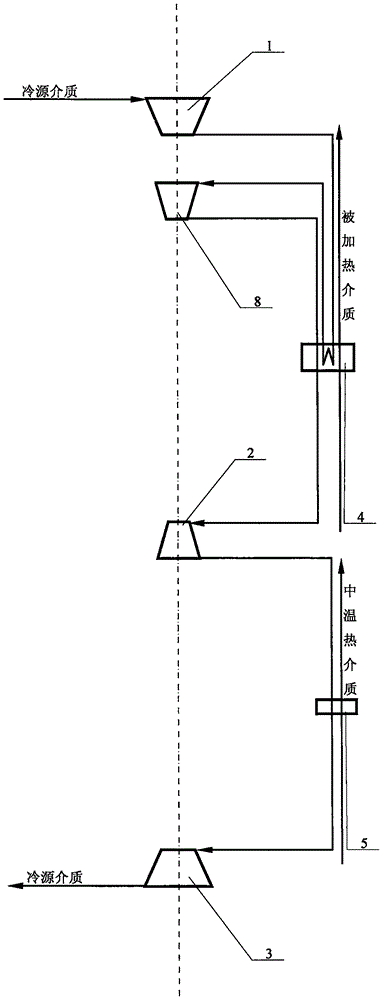

Dual-way thermodynamic cycle and first-type thermal-drive compression heat pump

ActiveCN105953453ACompression machines with non-reversible cycleFluid circulation arrangementThermodynamic cycleEngineering

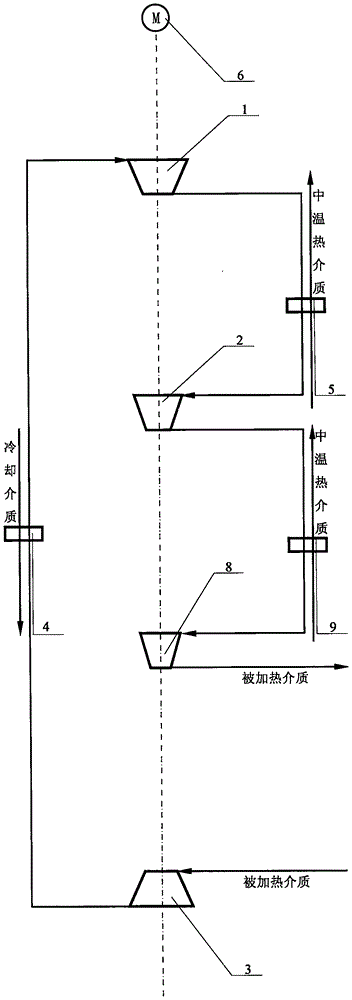

The invention provides a dual-way thermodynamic cycle and a first-type thermal-drive compression heat pump and belongs to the technical field of dynamics, refrigeration and heat pumps. The dual-way thermodynamic cycle 1234561 is composed of a course 12 in which a working medium is boosted from a middle temperature, a course 23 in which the working medium absorbs heat from a high-temperature heat source, a course 34 in which the working medium is decompressed from a high temperature, a course 45 in which the working medium absorbs heat from a low-temperature heat source, a course 56 in which the working medium is boosted from a low temperature, and a course 61 in which the working medium releases heat to a middle-temperature heat source. A compressor is equipped with a circulating medium channel which communicates with a second compressor by a heat supply device; the second compressor is equipped with a circulating medium channel which communicates with an expansion machine via a high-temperature heat exchanger; the expansion machine is equipped with a circulating medium channel which communicates with the compressor via a low-temperature heat exchanger; the high-temperature heat exchange is equipped with a high-temperature thermal medium pipeline which communicates with the external environment; the low-temperature heat exchange is equipped with a low-temperature thermal medium pipeline which communicates with the external environment; the heat supply device is equipped with a heated medium pipeline which communicates with the external environment; and the expansion machine is connected to the compressor and the second compressor and transmits power. In this way, the first-type thermal-drive compression heat pump is formed.

Owner:李华玉

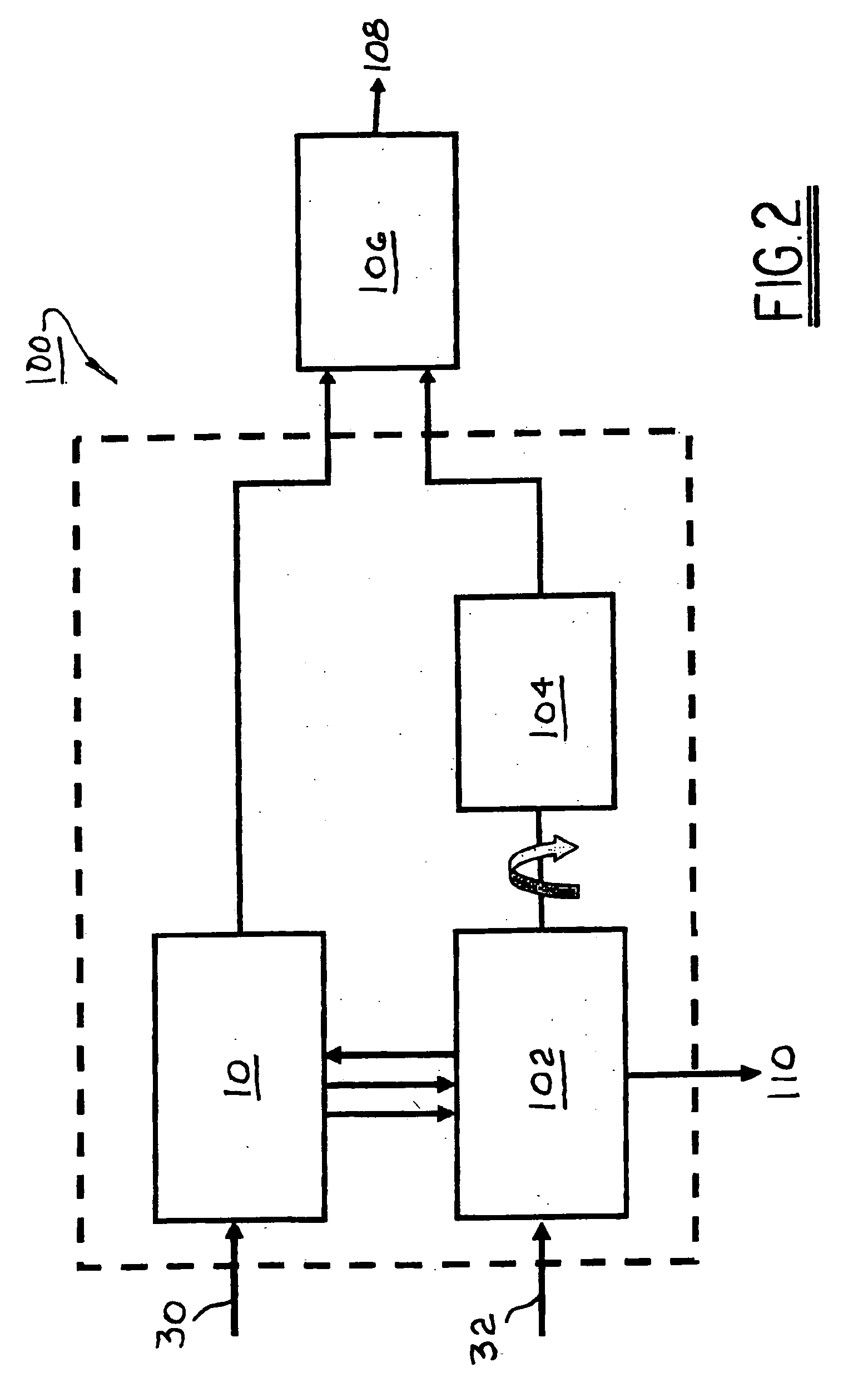

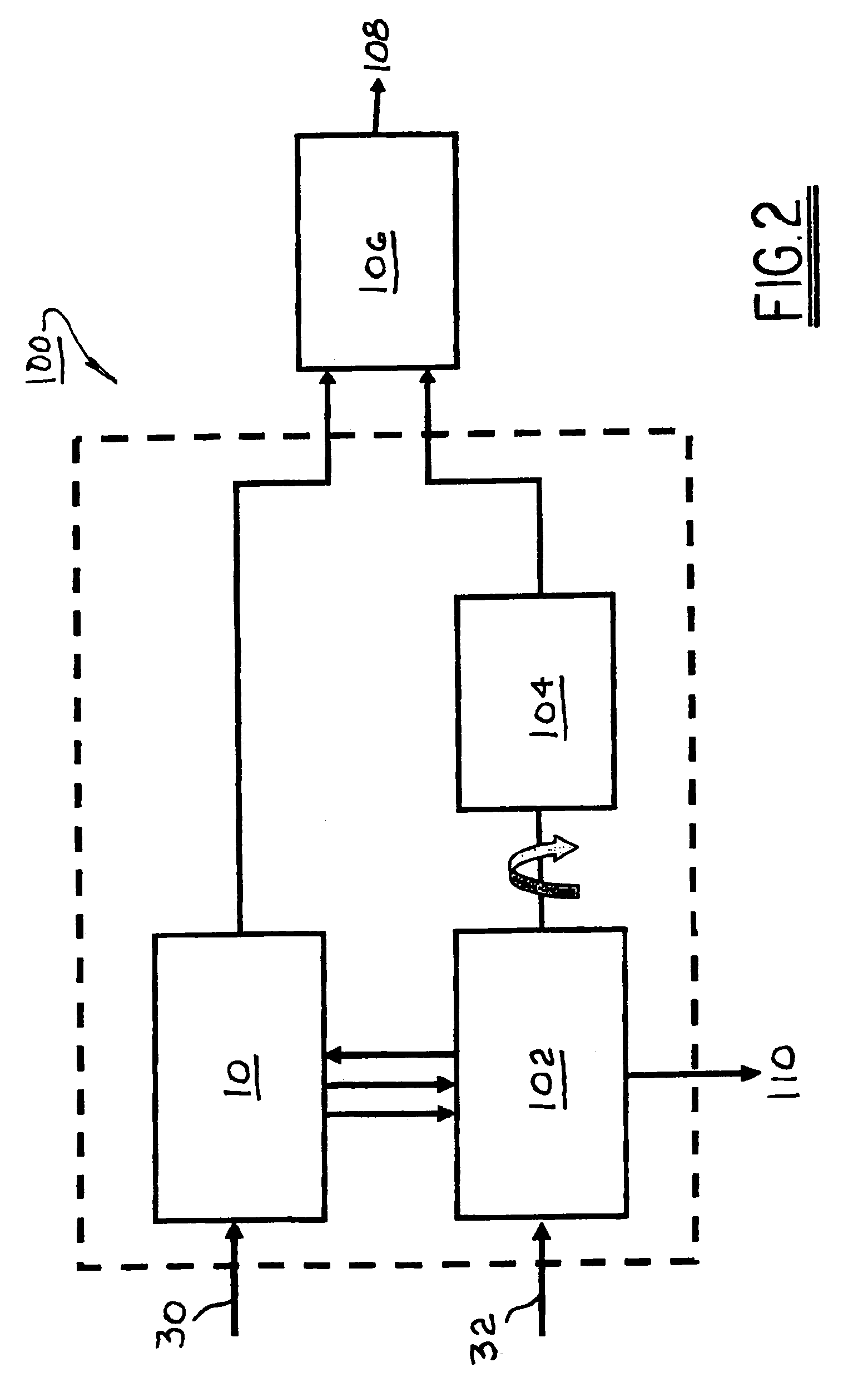

Fuel cell systems and methods for providing power and cooling to an energy-consuming device

Fuel cell systems and methods for providing power to an energy-consuming device and cooling of the energy-consuming device utilizing the endothermic process of desorbing hydrogen gas from a hydride bed. Fuel cell systems include a fuel cell stack, a hydrogen storage device having a volume of a hydrogen storage material, and a heat exchange system operatively connected to the hydrogen storage device and configured to heat the hydrogen storage material to desorb hydrogen gas therefrom for delivery to the fuel cell stack. The heat exchange system is further configured to deliver a cooled fluid stream to the energy-consuming device for cooling thereof. The cooled fluid stream may be produced, or cooled, by the endothermic desorption of hydrogen gas from the hydrogen storage device. In some fuel cell systems, the heat exchange system utilizes heat from the energy-consuming device to heat the hydrogen storage material for desorption of hydrogen gas therefrom.

Owner:DCNS SA

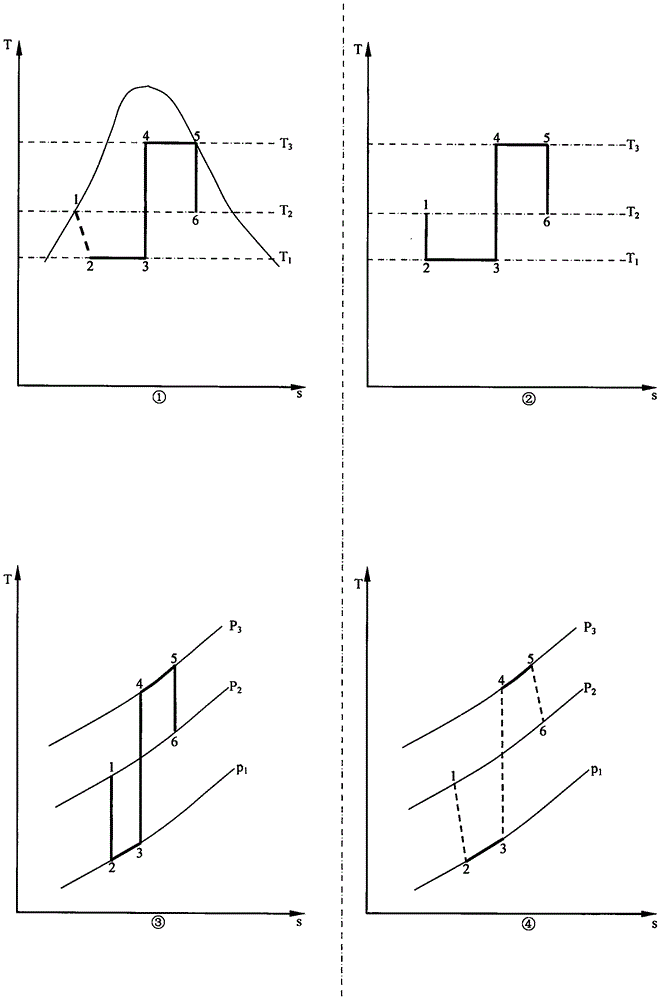

Open-type bidirectional thermodynamic cycle and second-class thermally-driven compression heat pump

ActiveCN105865068ACompression machines with non-reversible cycleFluid circulation arrangementThermodynamic cycleChiller

The invention provides an open-type bidirectional thermodynamic cycle and a second-class thermally-driven compression heat pump belonging to the technical fields of heat energy utilization and heat pumps. The open-type bidirectional thermodynamic cycle is formed by a process 12 of heated medium pressure reduction beginning from a high temperature, a process 23 of releasing heat towards a low-temperature heat source, a process 34 of pressure rise beginning from a low temperature, a process 45 of absorbing heat from a medium-temperature heat source and a process 56 of pressure rise beginning from a medium temperature. The outside communicates with an expansion machine by virtue of a heated medium channel; the expansion machine communicates with a compressor through a cooler by virtue of a heated medium channel; the compressor communicates with a second compressor through a heat exchanger by virtue of a heated medium channel; the second compressor communicates with the outside by virtue of a heated medium channel; the cooler communicates with the outside by virtue of a cooling medium channel; the heat exchanger communicates with the outside by virtue of a medium-temperature heat medium channelA heated medium channel which communicates with an expansion machine is arranged at the outside; the expansion machine is provided with a heated medium channel which communicates with a compressor through a cooler; the compressor is provided with a heated medium channel which communicates with a second compressor through a heat exchanger; the second compressor is provided with a heated medium channel which communicates with the outside; the cooler is provided with a cooling medium channel which communicates with the outside; the heat supply device is provided with a heated medium channel which communicates with the outside; the heat exchanger is internally provided with a medium-temperature heat medium channel which communicates with the outside; and the expansion machine is connected with the compressor and the second compressor and is used for transmitting power, so that the second-class thermally-driven compression heat pump is formed.

Owner:李华玉

Bidirectional thermal cycle and second type of heat-driven compression heat pump

The invention provides a bidirectional thermal cycle and second type of heat-driven compression heat pump, and belongs to the power and heat pump technology field. A bidirectional thermal cycle 1234561 comprises the steps of a working medium boost process 12 that begins from a low temperature; a heat absorption process 23 that absorbs heat from a middle temperature heat source; a boost process 34 that begins from a middle temperature; a heat release process 45 that releases heat to a high temperature heat source; a pressure reduction process 56 that begins from a high temperature; a heat release process 61 that releases heat to a low temperature heat source. A compressor has cycle working medium and is communicates with a second compressor through a heat exchanger; the second compressor has the cycle working medium channel and is communicated with an expander through a heater; the expander has the cycle working medium channel and is communicated with a compressor through a cooler; the heat exchanger has a middle temperature thermal medium channel and is communicated with the outside; the heater has a heated medium channel and is communicated with the outside; the cooler has a cooling medium channel and is communicated with the outside; the expander is connected with the compressor and the second compressor, and is used to transmit power to form the second type of heat-driven compression heat pump.

Owner:李华玉

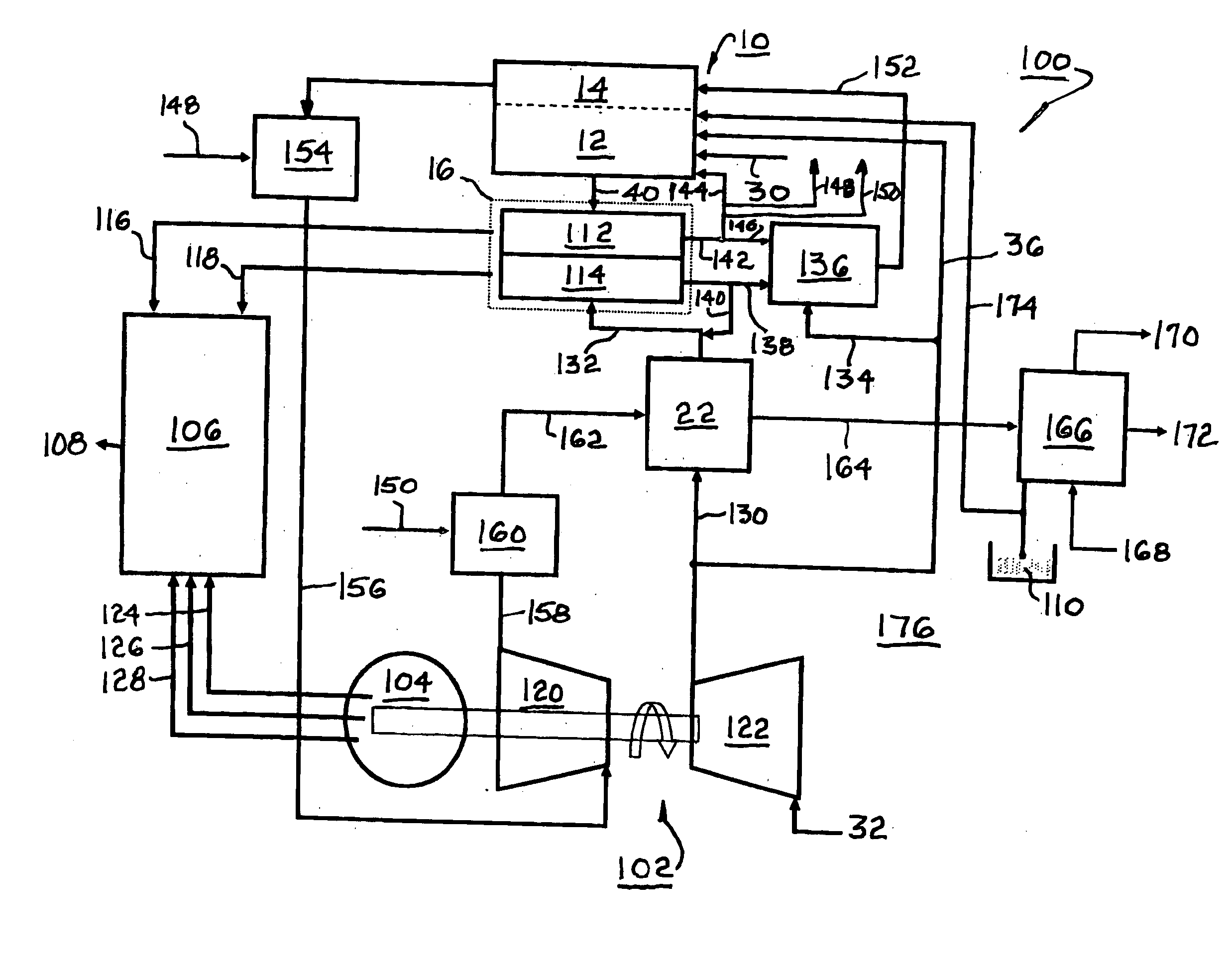

Hybrid power generating system combining a fuel cell and a gas turbine

ActiveUS7306871B2Overheating of elements within the stack is preventedAvoid overall overheatingAuxillary drivesElectric propulsion mountingOxygenCo generation

A system for co-generation of electricity combining a hydrocarbon catalytic reformer, an SOFC assembly and a generator driven by a gas turbine. The fuel cell assembly recycles a high percentage of anode exhaust gas into the reformer. Oxygen for reforming is derived from water in an endothermic process. The stack exit temperature is normally above 800° C. DC power from the fuel cell assembly and AC power from the gas turbine generator are directed to a power conditioner. Anode exhaust gas including carbon monoxide and hydrogen is divided into a plurality of portions by which heat may be added to the reforming, gas turbine, and cathode air heating processes. Water may be recovered from the exhaust. A power system in accordance with the invention is capable of operating at a higher total efficiency than either the fuel cell component or the gas turbine component alone.

Owner:APTIV TECH LTD

Open-type bidirectional thermodynamic cycle and second-class thermally-driven compression heat pump

ActiveCN105865067AMechanical apparatusCompression machines with non-reversible cycleExothermic processEngineering

The invention provides an open-type bidirectional thermodynamic cycle and a second-class thermally-driven compression heat pump belonging to the technical fields of heat energy utilization and heat pumps. The open-type bidirectional thermodynamic cycle is formed by a process 12 of cold source medium pressure rise beginning from a low temperature, a process 23 of absorbing heat from a medium-temperature heat source, a process 34 of pressure rise beginning from a medium temperature, a process 45 of releasing heat towards a high-temperature heat source and a process 56 of pressure reduction beginning from a high temperature. The outside communicates with a compressor by virtue of a cold source medium channel; the compressor communicates with a second compressor through a heat exchanger by virtue of a cold source medium channel; the second compressor communicates with an expansion machine through a heat supply device by virtue of a cold source medium channel; the expansion machine communicates with the outside by virtue of a cold source medium channel; the heat exchanger communicates with the outside by virtue of a medium-temperature heat medium channel; the heat supply device communicates with the outside by virtue of a heated medium channelA cold source medium channel which communicates with a compressor is arranged at the outside; the compressor is provided with a cold source medium channel which communicates with a second compressor through a heat exchanger; the second compressor is provided with a cold source medium channel which communicates with an expansion machine through a heat supply device; the expansion machine is provided with a cold source medium channel which communicates with the outside; the heat exchanger is internally provided with a medium-temperature heat medium channel which communicates with the outside; the heat supply device is provided with a heated medium channel which communicates with the outside; and the expansion machine is connected with the compressor and the second compressor and is used for transmitting power, so that the second-class thermally-driven compression heat pump is formed.

Owner:李华玉

Open type both-way thermodynamic cycle and first-kind heat drive compression type heat pump

ActiveCN105841383ACompression machines with non-reversible cycleFluid circulation arrangementPressure decreasePlate heat exchanger

The invention provides an open type both-way thermodynamic cycle and a first-kind heat drive compression type heat pump, and belongs to the technical field of power, refrigerating and heat pumps. The open type both-way thermodynamic cycle is formed through the heated medium pressure decreasing process 12 starting from the intermediate temperature, the heat absorbing process 23 starting from a low temperature heat source, the pressure increasing process 34 starting from the low temperature, the heat absorbing process 45 starting from a high-temperature heat source and the pressure decreasing process 56 starting from the high temperature. An outer portion is provided with a heated source medium channel to communicate with an expansion machine, and the expansion machine is further provided with a heated medium channel to communicate with a compressor through a low-temperature heat exchanger. The compressor is further provided with a heated medium channel to communicate with a second expansion machine through a high-temperature heat exchanger. The second expansion machine is further provided with a heated medium channel to communicate with the outer portion. The low-temperature heat exchanger is further provided with a low-temperature heat medium channel to communicate with the outer portion. The high-temperature heat exchanger is further provided with a high-temperature heat medium channel to communicate with the outer portion. The expansion machine and the second expansion machine are connected with the compressor and transmit power. Accordingly, the first-kind heat drive compression type heat pump is formed.

Owner:李华玉

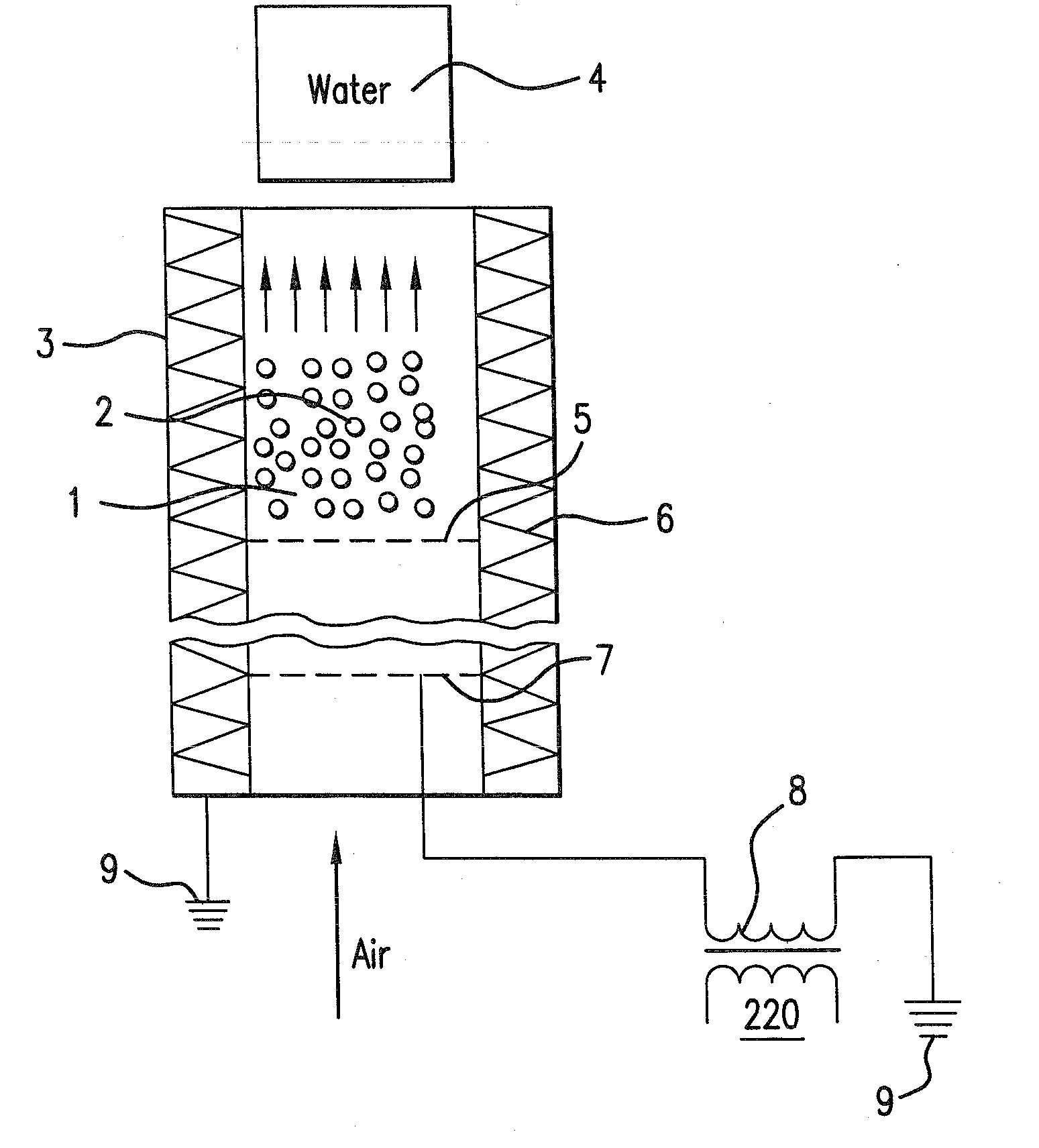

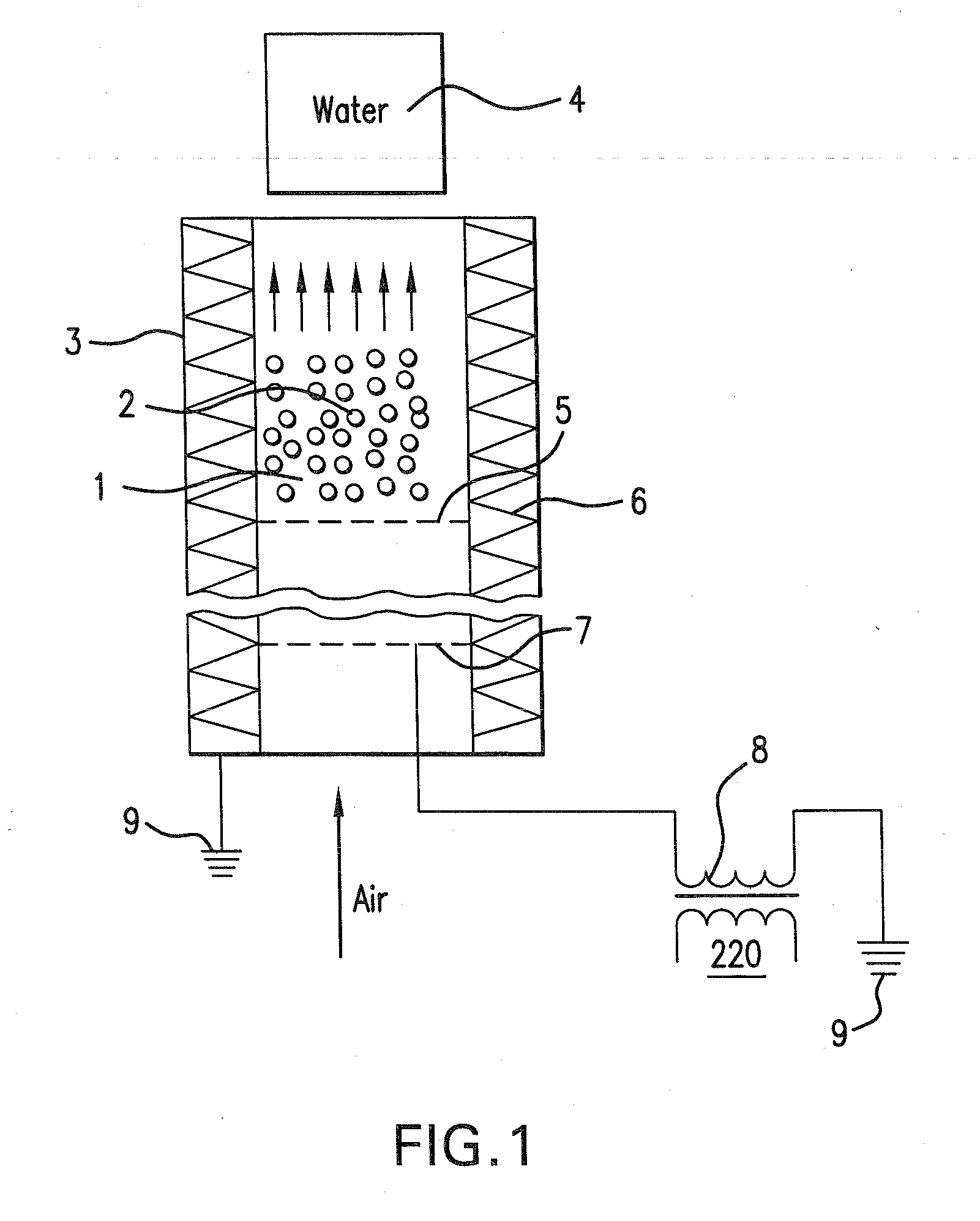

Method of solid fuel combustion intensification

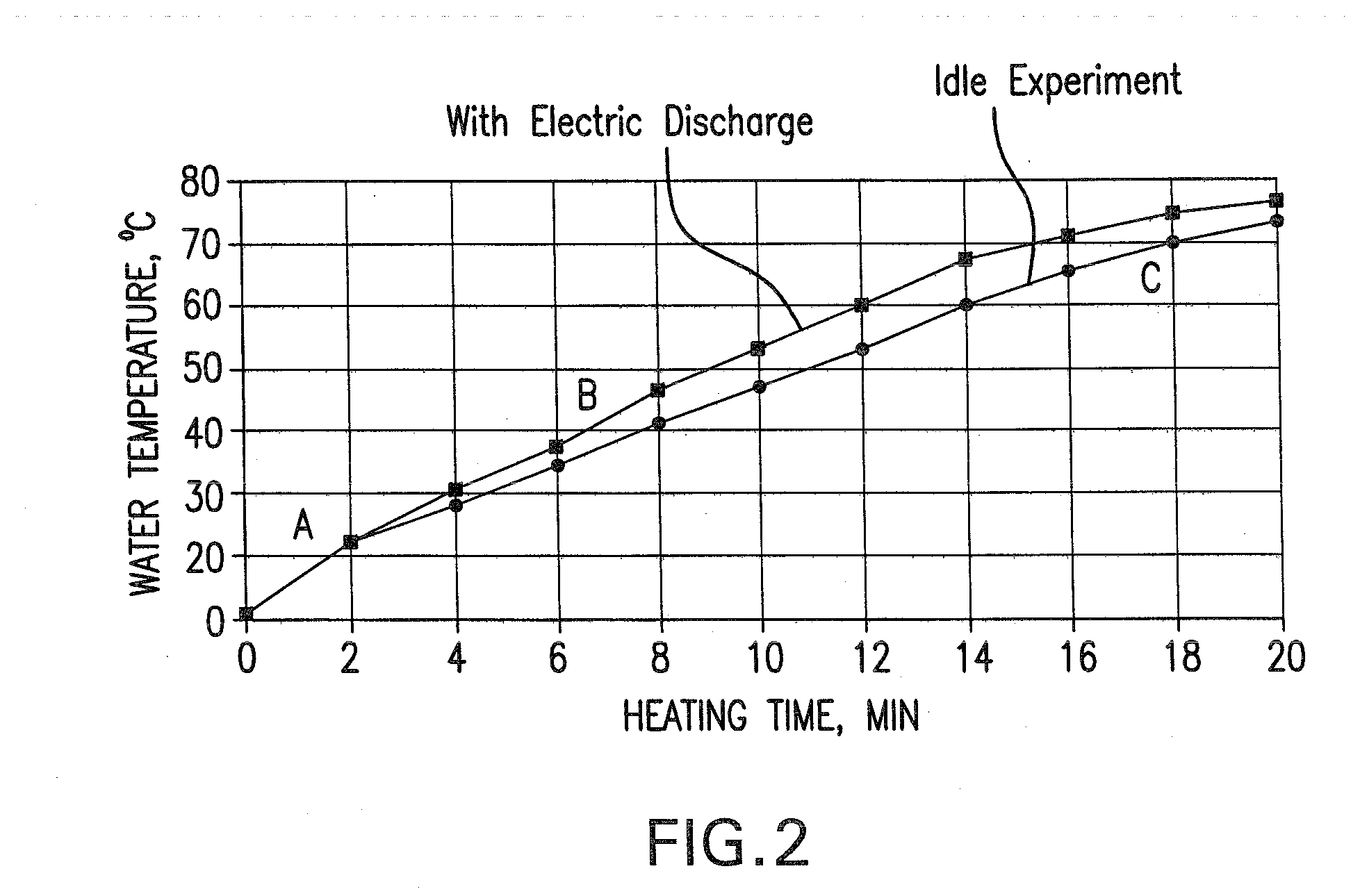

InactiveUS20080044781A1Increase oxidation rateDegree of improvementIncandescent ignitionCatalytic ignitersOxygenEnergy expenditure

The substance of the invention consists in the combustion of the fuel-air mixture in the electric field by means of the catalyst located in the combustion zone and to which high voltage is applied, which results in reduction of activation energies of all endothermic combustion phases due to the formation of oxygen atoms, carbon radicals and oxygen-containing radicals.Technical result: introduction of the catalyst in the combustion zone minimizes energy expenditure for creation of the low-temperature plasma, allows to increase the temperature in the combustion zone, to reduce activation energy of all endothermic processes taking place at the initial phase of combustion and to reduce carbon content in the ash and to achieve considerable fuel economy.

Owner:LIMITED LIABILITY RES AND PRODION COMPANY UKRTRANSKOM +1

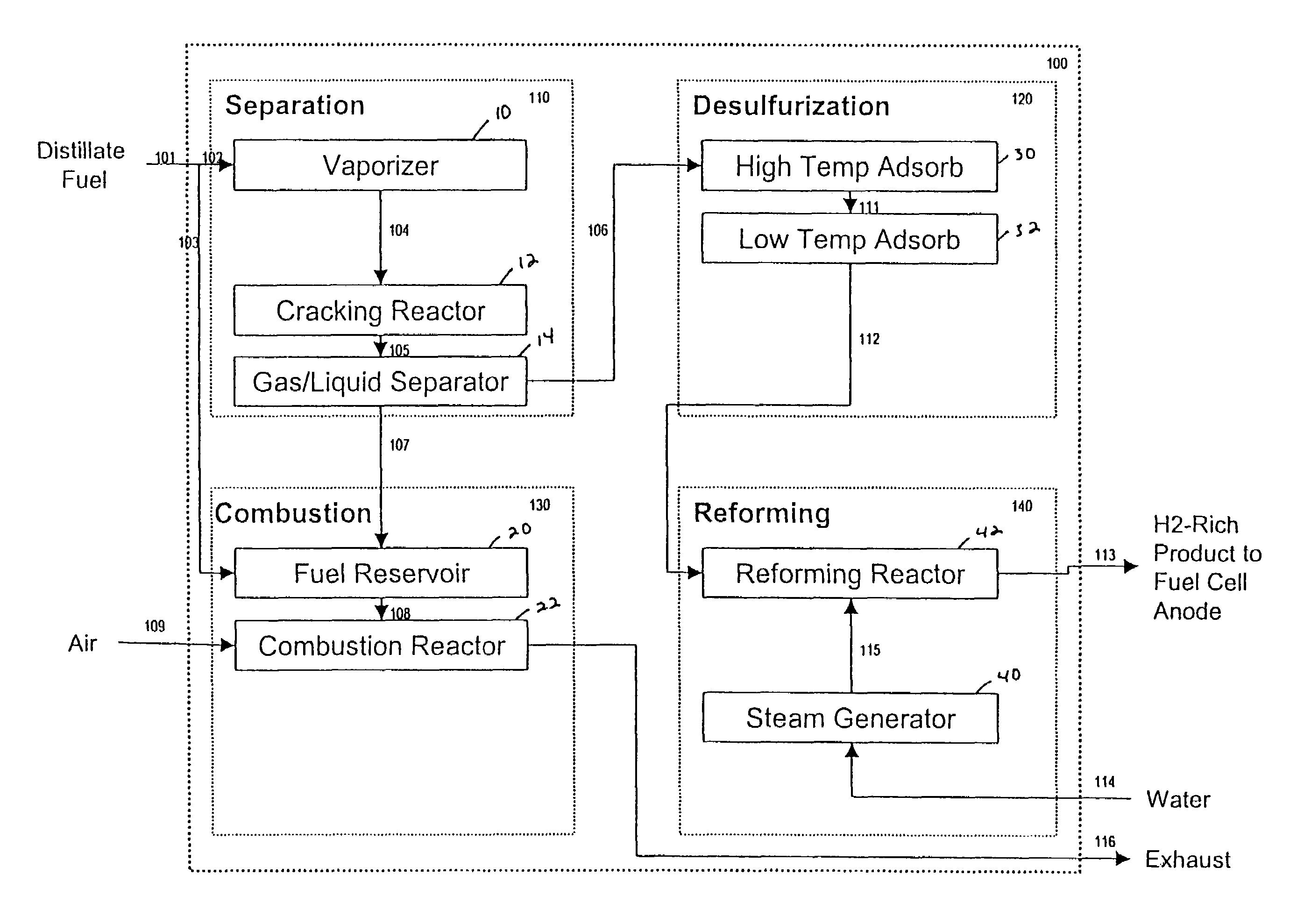

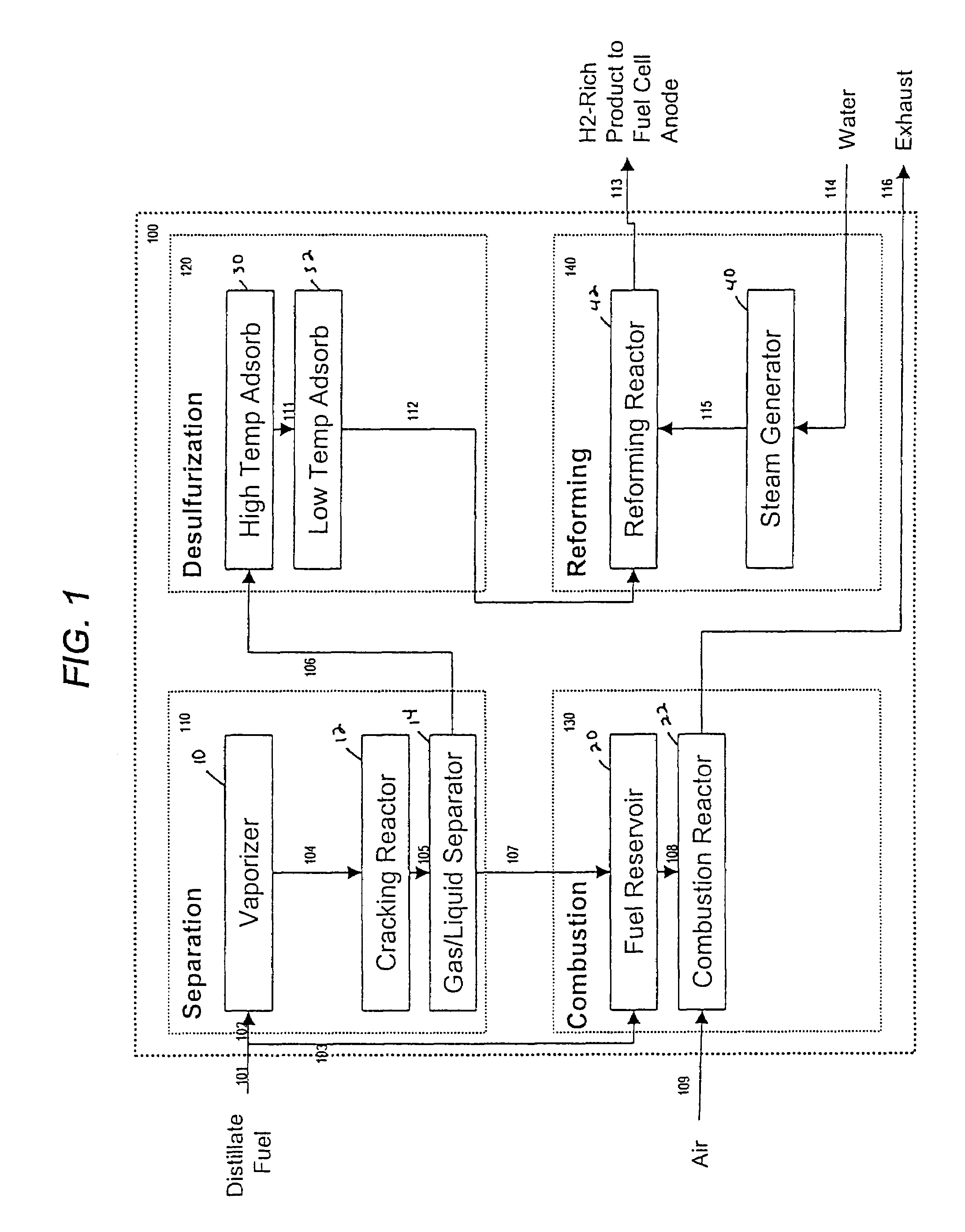

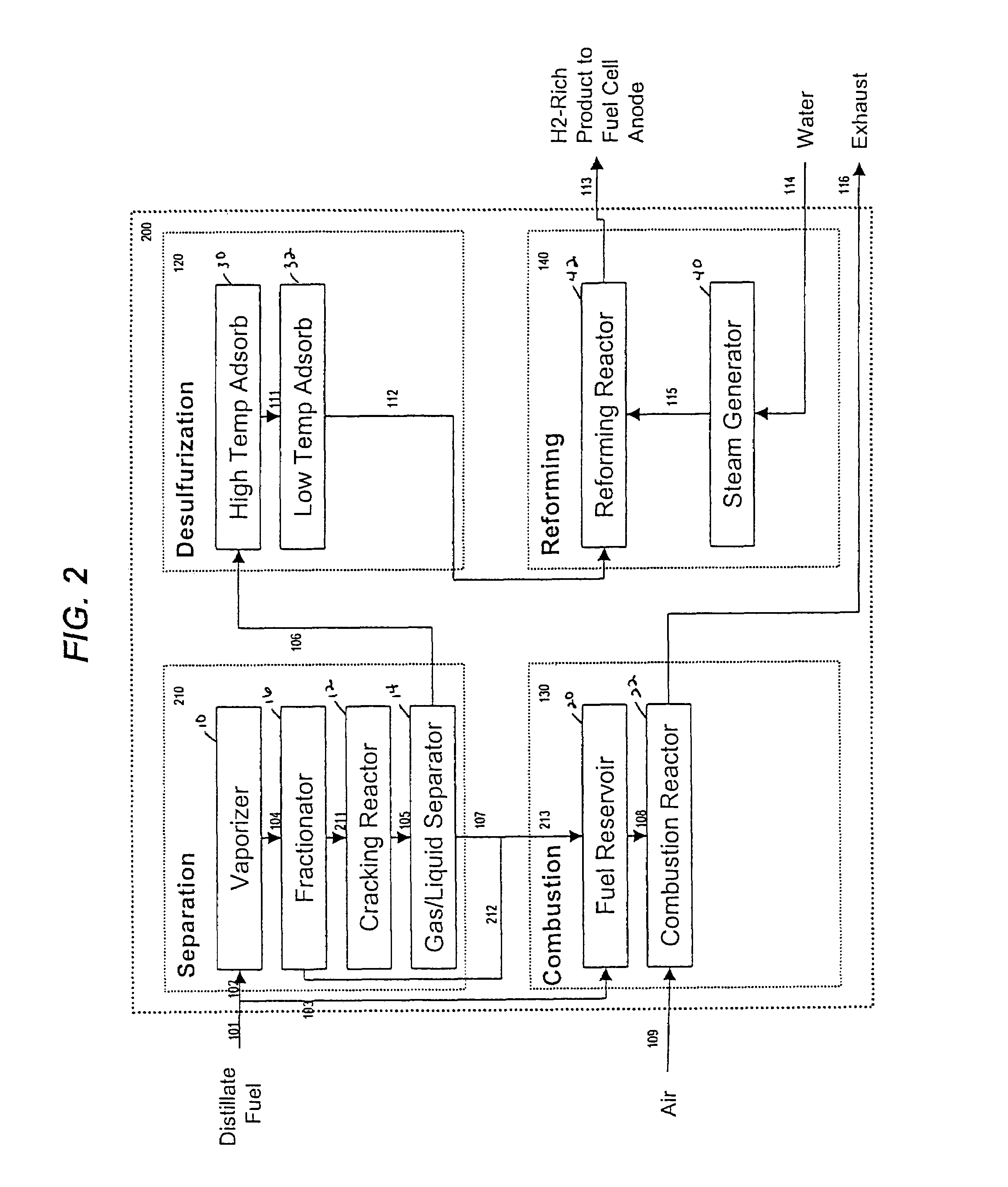

Compact distillates fuel processor with effective sulfur removal process

InactiveUS7318845B2Highly effectiveHigh overall process thermal efficiencyGas modification by gas mixingRefining with acid-containing liquidsSteam reformingHydrogen

A distillate fuel steam reformer system in which a fuel feed stream is first separated into two process streams: an aliphatics-rich, sulfur-depleted gas stream, and an aromatics- and sulfur-rich liquid residue stream. The aliphatics-rich gas stream is desulfurized, mixed with steam, and converted in a reforming reactor to a hydrogen-rich product stream. The aromatics-rich residue stream is mixed with air and combusted to provide heat necessary for endothermic process operations. Reducing the amounts of sulfur and aromatic hydrocarbons directed to desulfurzation and reforming operations minimizes the size and weight of the overall apparatus. The process of the invention is well suited to the use of microchannel apparatuses for heat exchangers, reactors, and other system components, which may be assembled in slab configuration, further reducing system size and weight.

Owner:APPLIED RES ASSOCS INC

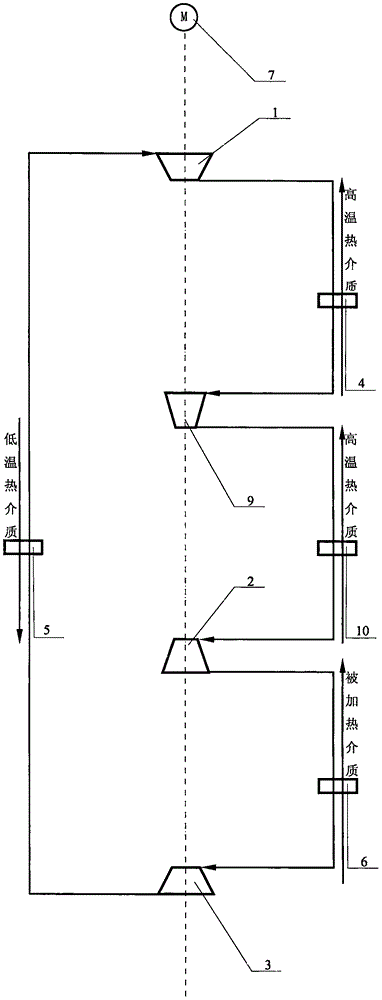

Open type bidirectional thermal cycle and first kind thermal driving compression heat pump

The invention provides an open type bidirectional thermal cycle and first kind thermal driving compression heat pump, and belongs to the power, refrigeration and heat pump technical field; a boost process 12 of a low temperature thermal medium from low temperature, a heat absorption process 23 from a high temperature heat source, a pressure reduction process 34 from high temperature, a heat release process 45 to a middle temperature heat source and a pressure reduction process 56 from middle temperature can form the open type bidirectional thermal cycle; an external heat source medium channel is connected with a compressor; the compressor uses the heat source medium channel to connect with an expander through a high temperature heat exchanger; the expander uses the heat source medium channel to connect with a second expander through a heater; the second expander uses the heat source medium channel to connect with the outer side; the high temperature heat exchanger is connected with the outer side through a high temperature thermal medium channel; the heater is connected with the outer side through a heated medium channel; the expander and the second expander are connected with the compressor so as to transfer power, thus forming the first kind thermal driving compression heat pump.

Owner:李华玉

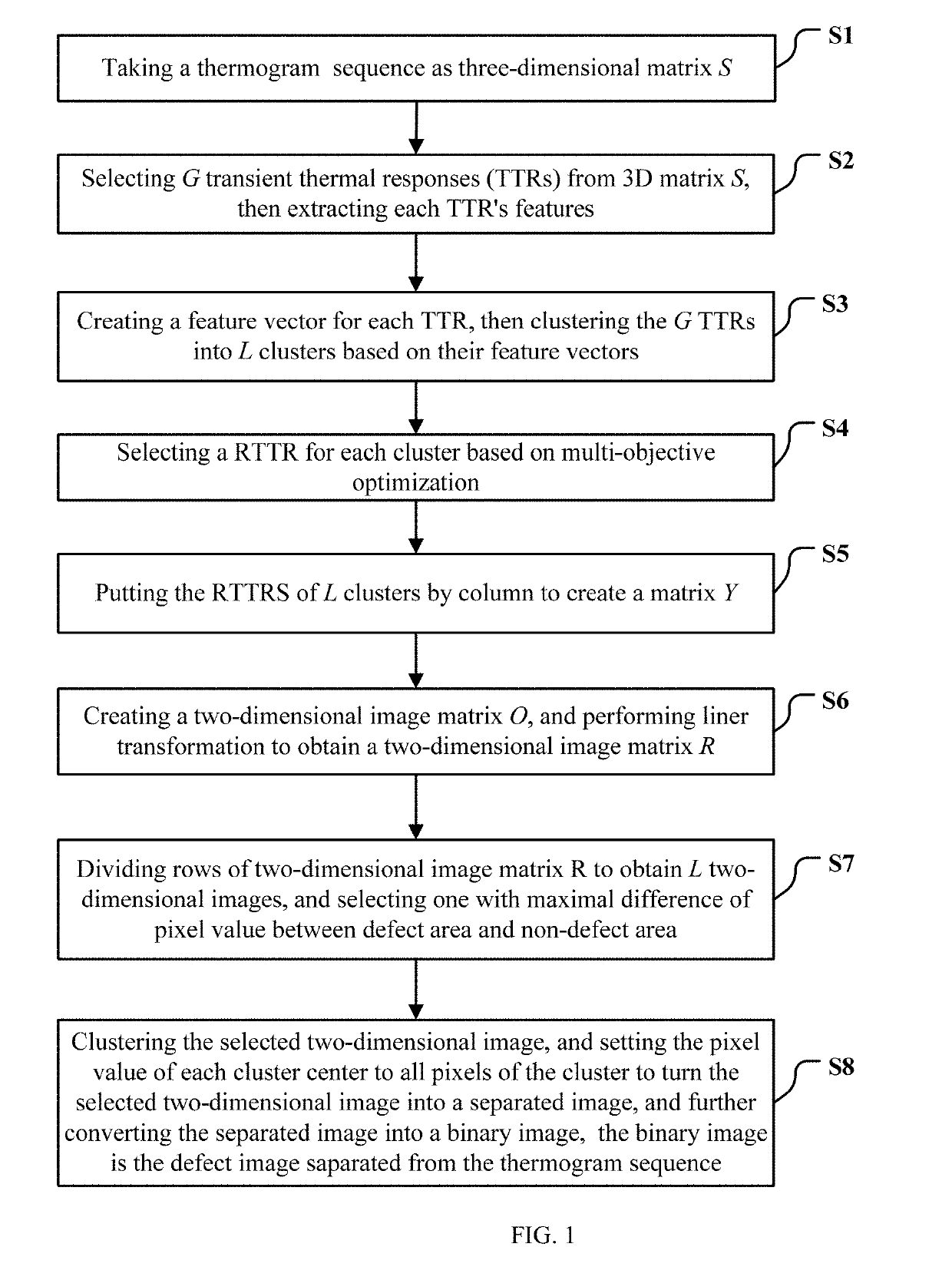

Method for separating out a defect image from a thermogram sequence based on feature extraction and multi-objective optimization

ActiveUS20190228517A1Improve accuracyGuaranteed accuracyImage enhancementImage analysisFeature vectorFeature extraction

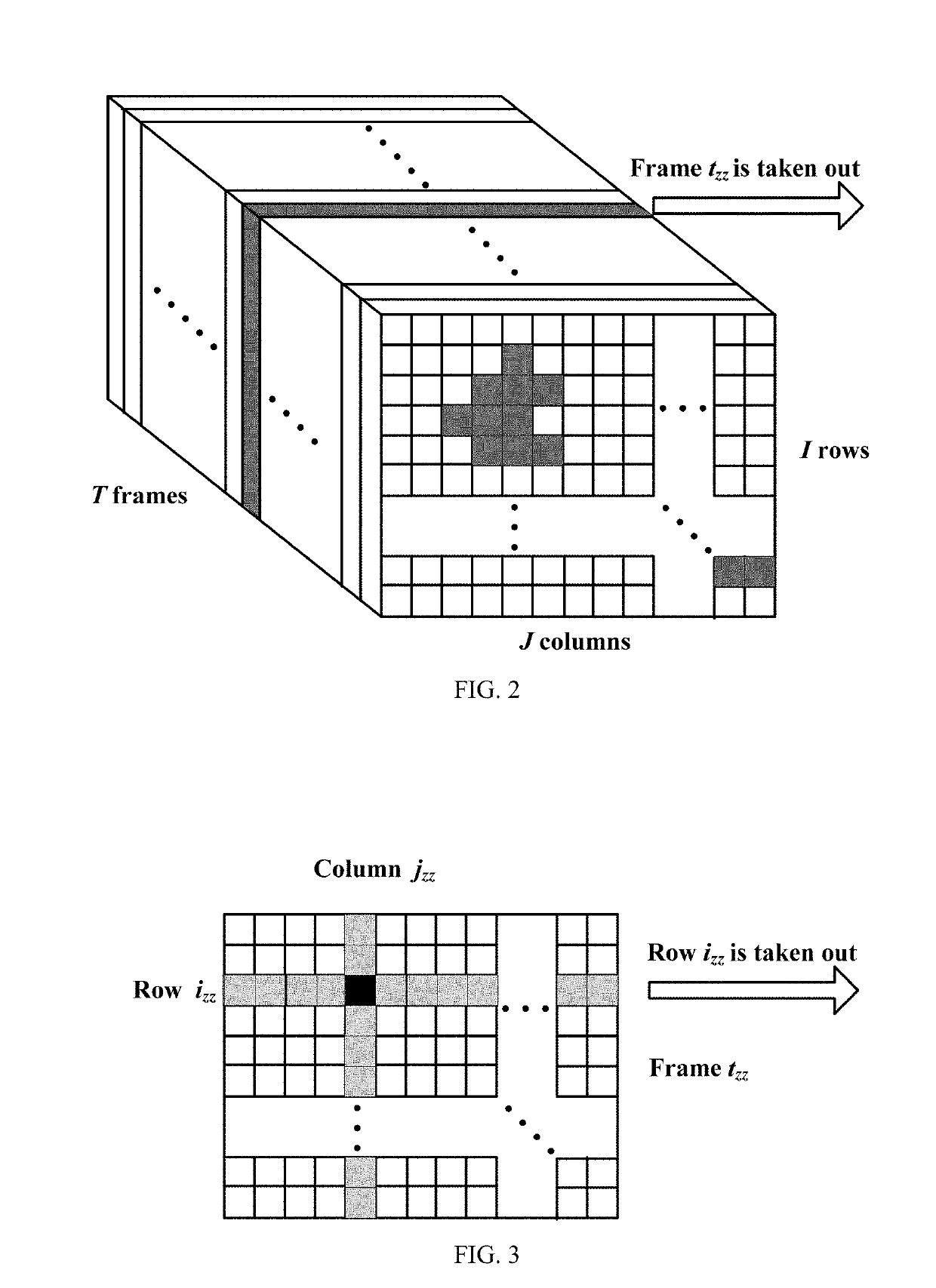

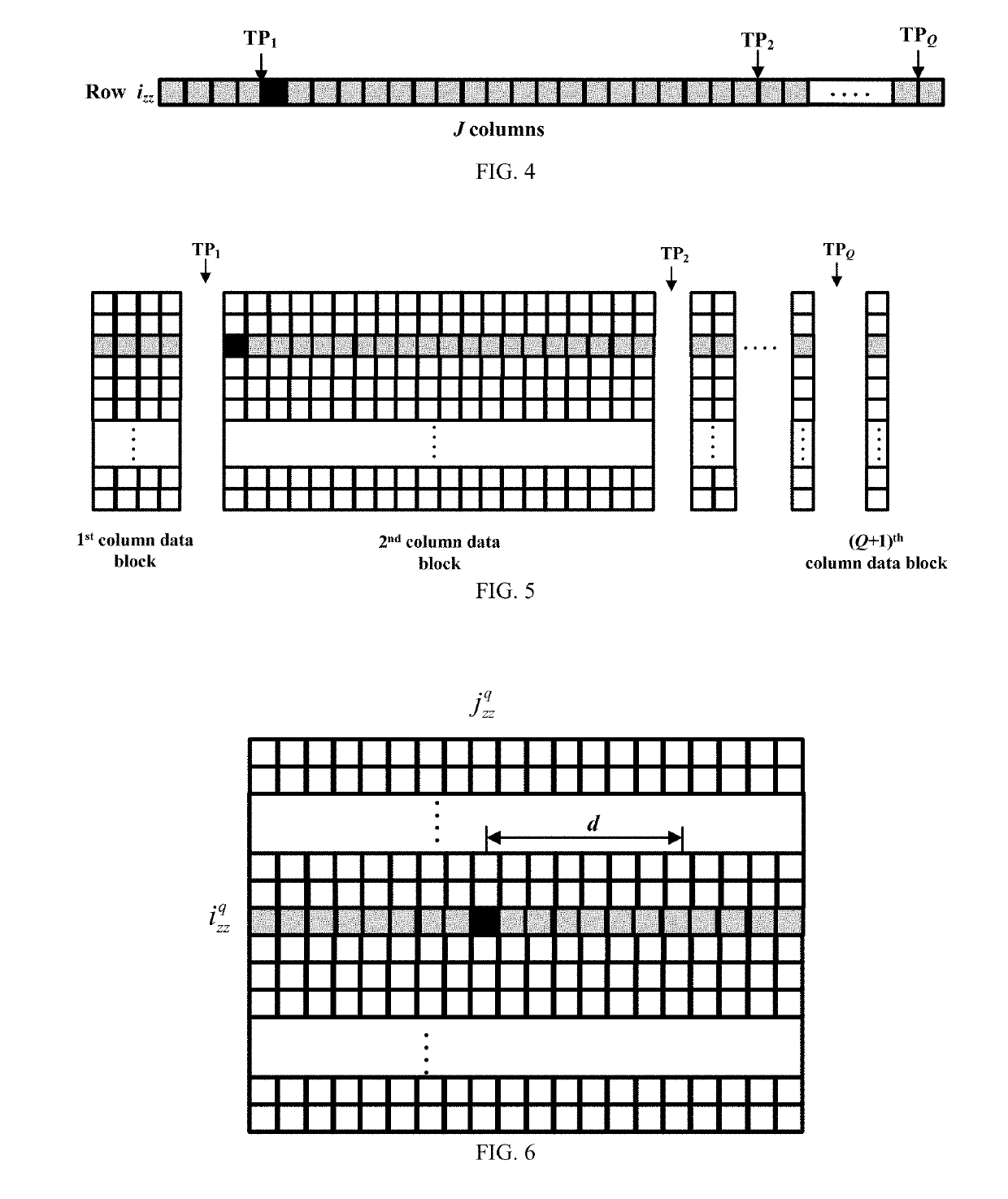

The present invention provides a method for separating out a defect image from a thermogram sequence based on feature extraction and multi-objective optimization, we find that different kinds of TTRs have big differences in some physical quantities, such as the energy, temperature change rate during endothermic process, temperature change rate during endothermic process, average temperature, maximum temperature. The present invention extract these features (physical quantities) and cluster the selected TTRs into L clusters based on their feature vectors, which deeply digs the physical meanings contained in each TTR, makes the clustering more rational, and improves the accuracy of defect separation. Meanwhile, the present invention creates a multi-objective function to select a RTTR for each cluster based on multi-objective optimization. The multi-objective function does not only fully consider the similarities between the RTTR and other TTRs in the same cluster, but also considers the dissimilarities between the RTTR and the TTRs in other clusters, the RTTR is more representative, which guarantees the accuracy of describing the defect outline.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

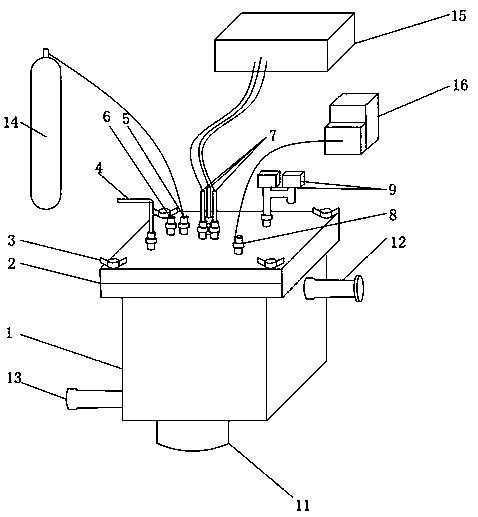

Pump-driven two-phase circuit device for heat dissipation of high heat flux electronic device

ActiveCN107454797AMeet job needsImprove cooling effectDigital data processing detailsCooling/ventilation/heating modificationsHeat fluxEvaporation

The invention provides a pump-driven two-phase circuit device for heat dissipation of a high heat flux electronic device. Heat is collected and transported by using an endothermic process in evaporation and an exothermic process in condensation during a circulation flow process of a working medium. An evaporator for the circuit device comprises micro-channels and fins. In an area of high heat flux, the micro-channels are used to dissipate heat and increase a heat transfer coefficient of a partial area, while in an area of low heat flux, the fins are used. Due to great area difference between the micro-channel area and the fin area in the evaporator, when the working medium in the micro-channels enters the fin area, volume quickly expands and temperature of the working medium reduces, so as to help heat dissipation of the device in the fin area. By using different structures and with little resources, heat dissipation problems of devices with different powers are solved. The pump-driven two-phase circuit device for heat dissipation of the high heat flux electronic device can adapt to heat dissipation of electronic devices with different heat flux densities and can satisfy working requirements of electronic devices with a heat flux density of 50 W / cm<2> or above.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

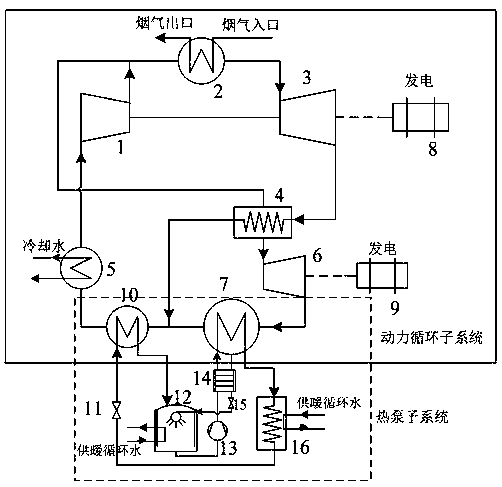

Transcritical carbon dioxide power cycle and absorption heat pump combined heat and power cogeneration system for high temperature flue gas waste heat recovery

ActiveCN108775266AImprove heat transfer matchingImprove utilization efficiencySteam engine plantsTranscritical cyclePower cycle

The invention discloses a CO2 power cycle and absorption heat pump combined heat and power cogeneration system for high temperature flue gas waste heat recovery. The CO2 power cycle and absorption heat pump combined heat and power cogeneration system realizes combined heat and power cogeneration by integrating high and low temperature power cycle and absorption heat pump cycle. The power cycle uses CO2 as the working medium, the endothermic process is located at the supercritical pressure, the exothermic process to a cold source is located at the subcritical pressure, and a transcritical cycleform is achieved. The high-temperature power cycle uses high-temperature flue gas as a heat source, and the low-temperature power cycle absorbs heat from dead steam of the high-temperature power cycle. An absorption heat pump system uses low-temperature power cycle high-temperature dead steam as a driving heat source and a low-temperature dead steam as a low temperature heat source, the waste heat resources are fully used as far as possible, and the COP of the absorption heat pump cycle is increased. The CO2 power cycle and absorption heat pump combined heat and power cogeneration system improves the heat exchange matching between the circulation and the variable temperature heat source, effectively utilizes the recycled dead steam heat, realizes the cascade utilization of different tasteresidual heat energy, and improves the overall energy utilization efficiency of the system.

Owner:山西山安蓝天节能科技股份有限公司

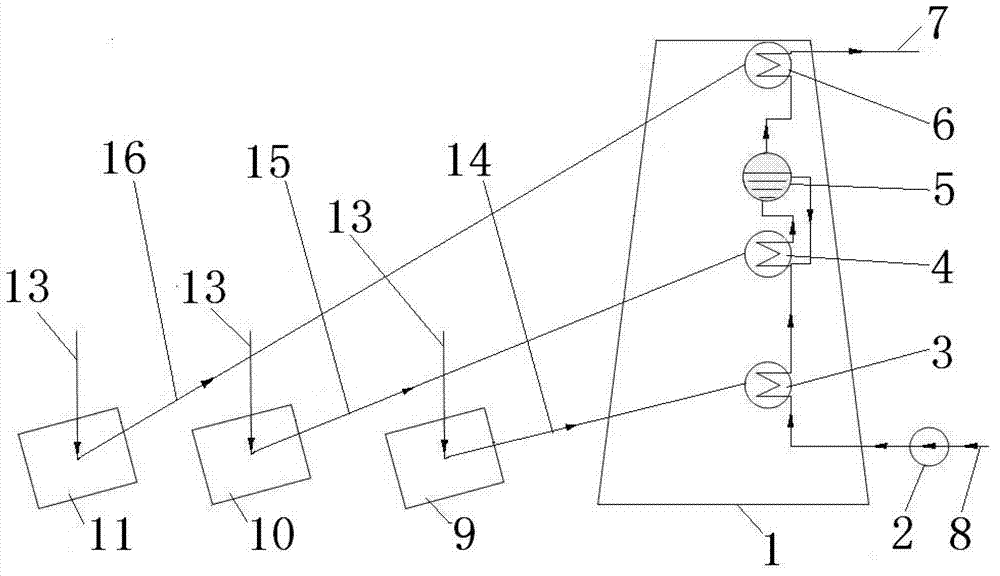

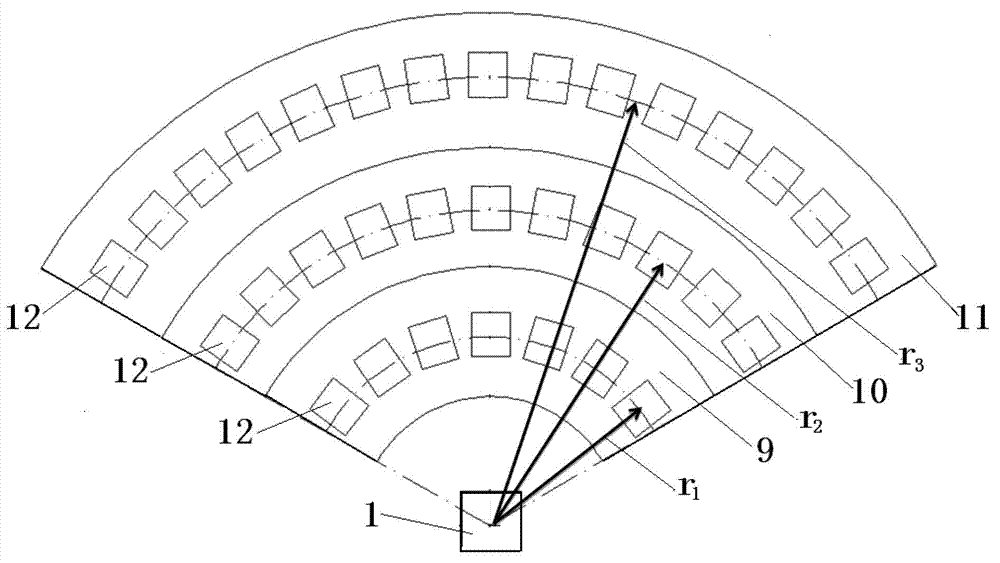

Tower type solar boiler

InactiveCN102889694AOvercome the spot fluctuation on the heating surfaceOvercome uniformity issuesSolar heating energySteam generation heating methodsWater vaporEnergy flux

The invention belongs to the solar field and relates to a tower type solar boiler. The solar boiler consists of a solar reflector field and a three-section type staged and zonal heat collection tower, wherein the solar reflector field consists of three fan-shaped heliostat fields from the interior to the exterior, and solar radiation is reflected to three stages of heat absorbers respectively by the three heliostat fields to produce saturated water, dry saturated vapor and superheated vapor. Due to the adoption of miniature heliostats, on one hand, the uniformity and the controllability of the energy flux density of light spots are improved, and the efficiency is largely improved; and on the other hand, the accuracy requirement of a heliostat tracking control system is lowered, and the cost is lowered. The heat absorbers are divided into three sections according to the heating power properties of the water and the vapor in different heat absorption processes. Meanwhile, the heliostat fields are designed according to the energy flux distribution requirements of all the heat absorbers, and the problems that two-phase flow in a single stage of heat absorber or two stages of heat absorbers causes instable heat exchange and nonuniform heat stress distribution on the surface of the heat absorber are solved. The solar boiler is suitable for solar power stations.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

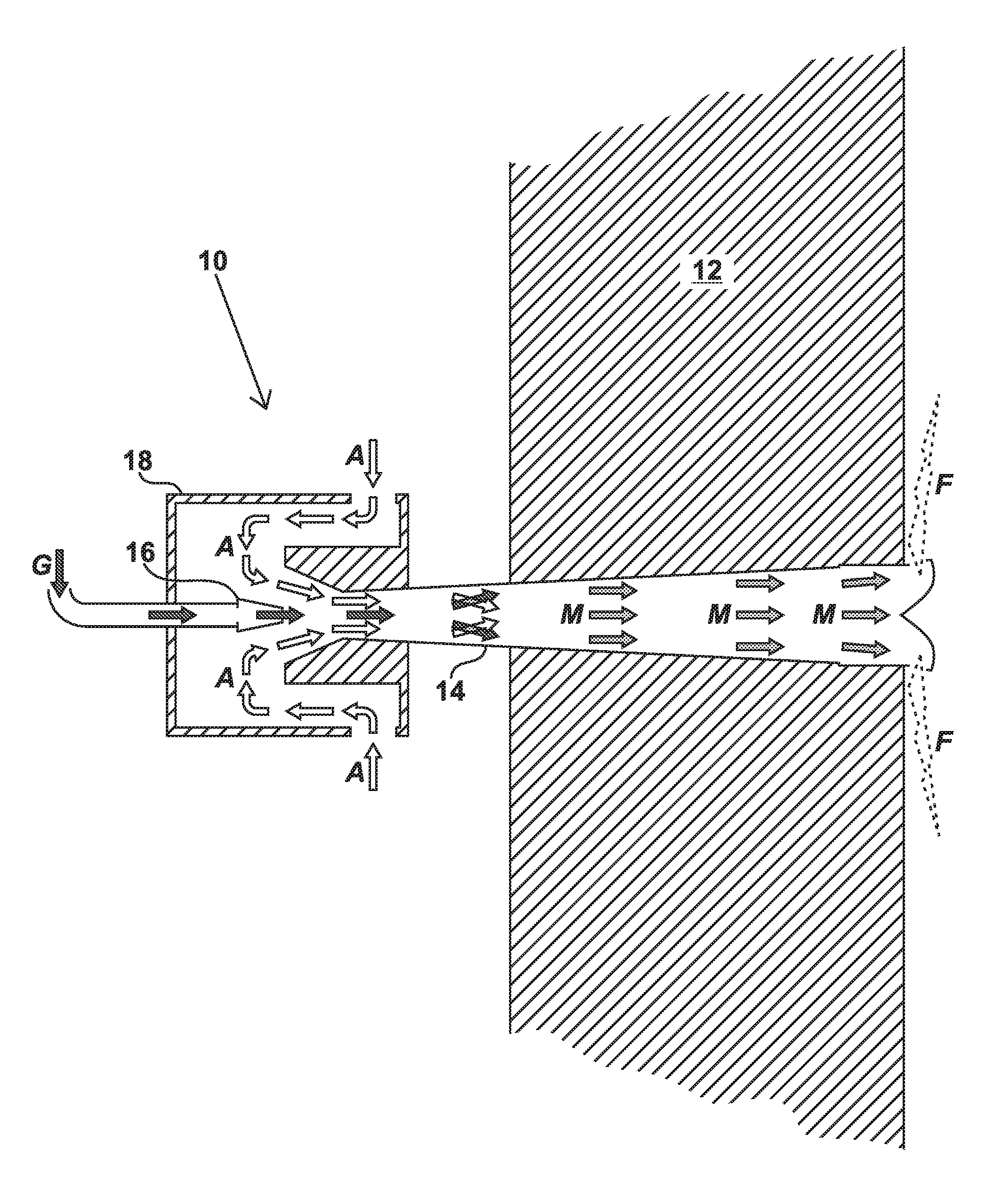

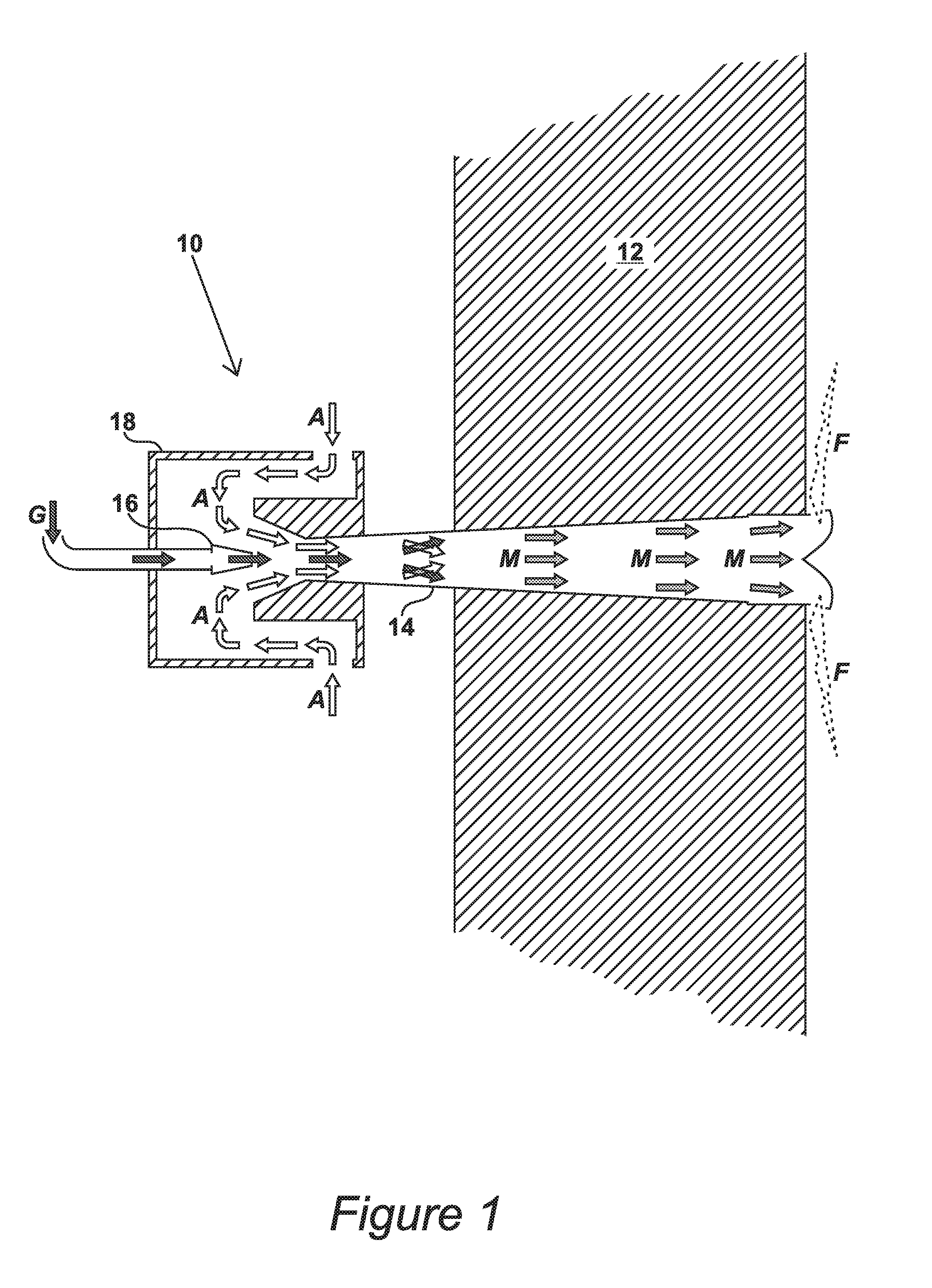

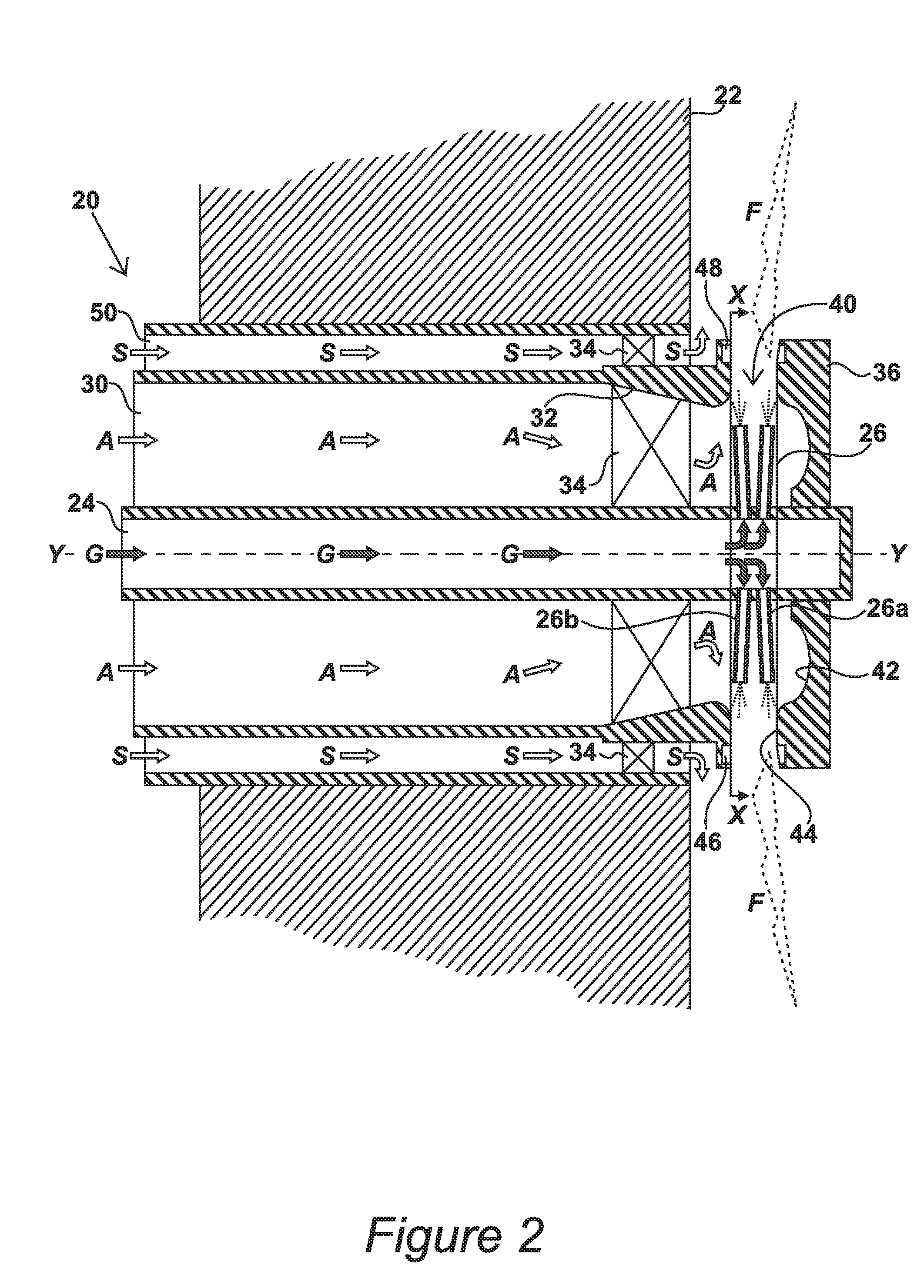

Burners

InactiveUS20120231400A1Easy to operateReduce riskCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorHydrogen

The invention provides a nozzle-mixed burner for use in an endothermic process such as hydrogen reforming or ammonia reforming or ethylene cracking or EDC cracking. The burner comprises a fuel duct extending axially through a wall of the furnace. The fuel duct delivers gaseous fuel to an array of nozzles extending laterally to spray the fuel outwardly into an annular chamber defined by a cap. Combustion air is delivered to the chamber by way of a primary air duct. A convergent-divergent section of the duct and an outwardly divergent section of the chamber together form a radially extending venturi. Combustion of the fuel, supplemented by the venturi effect, draws the air through the duct by natural inspiration.

Owner:HAMWORTHY COMBUSTION ENG LTD

Method of cooling a metal strip traveling through a cooling section of a continuous heat treatment line, and an installation for implementing said method

ActiveUS20100218516A1Avoid disadvantagesGreat ease of implementing and controllingCompression machines with non-reversible cycleStationary refrigeration devicesMetal stripsEngineering

The invention relates to a method of cooling a metal strip traveling through a cooling section in a continuous heat treatment line. In accordance with the invention, the method consists in projecting a refrigerant medium into the cooling section (4) onto the surface of the strip (1) to be cooled, the medium being constituted for the most part by a phase-change substance that passes into the gaseous phase at a temperature that is lower than the temperature of the strip (1) and without oxidizing said strip so that energy is exchanged within an endothermic process by a change in the phase of said phase-change substance.

Owner:COCKERILL MAINTENANCE & INGIE

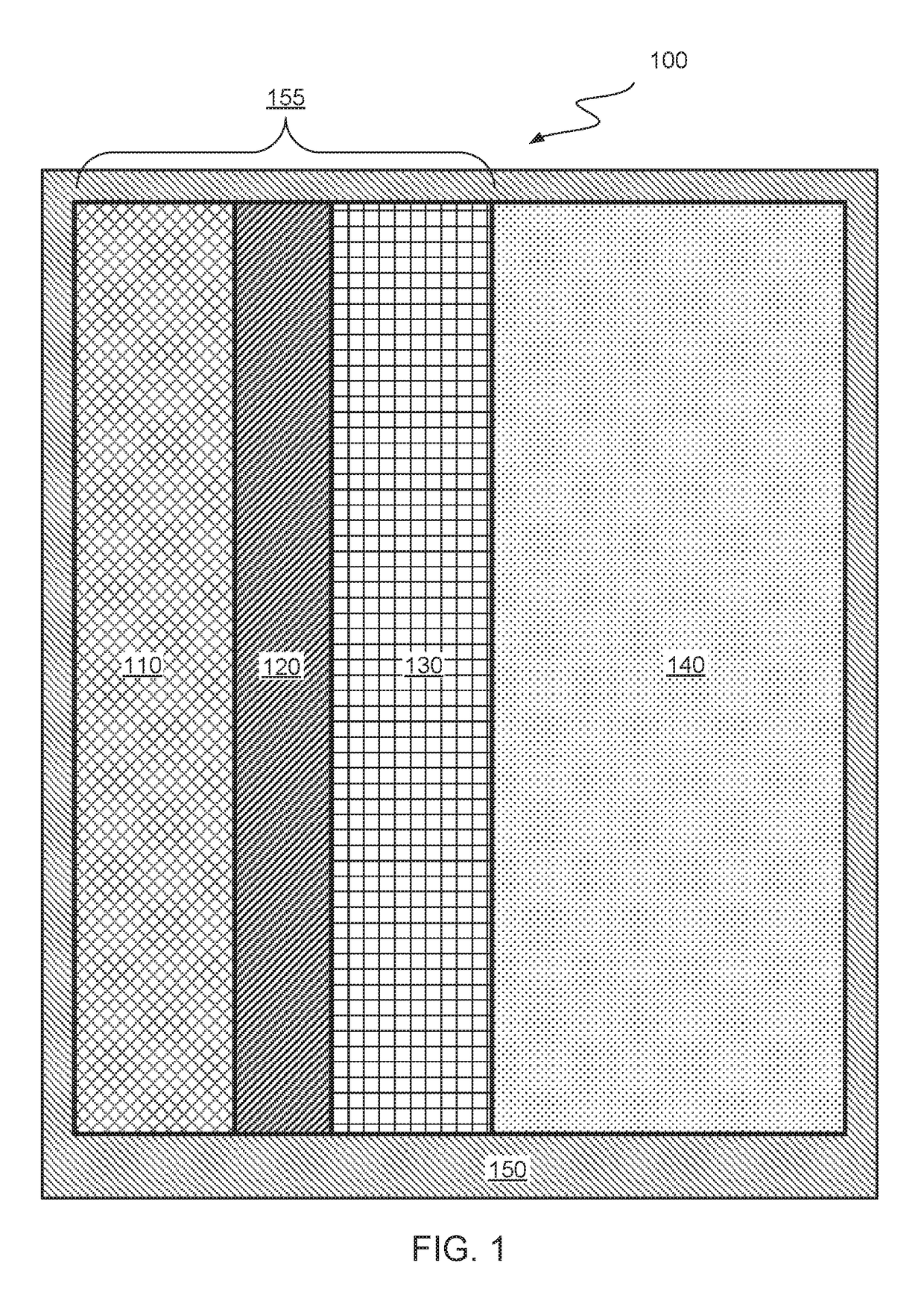

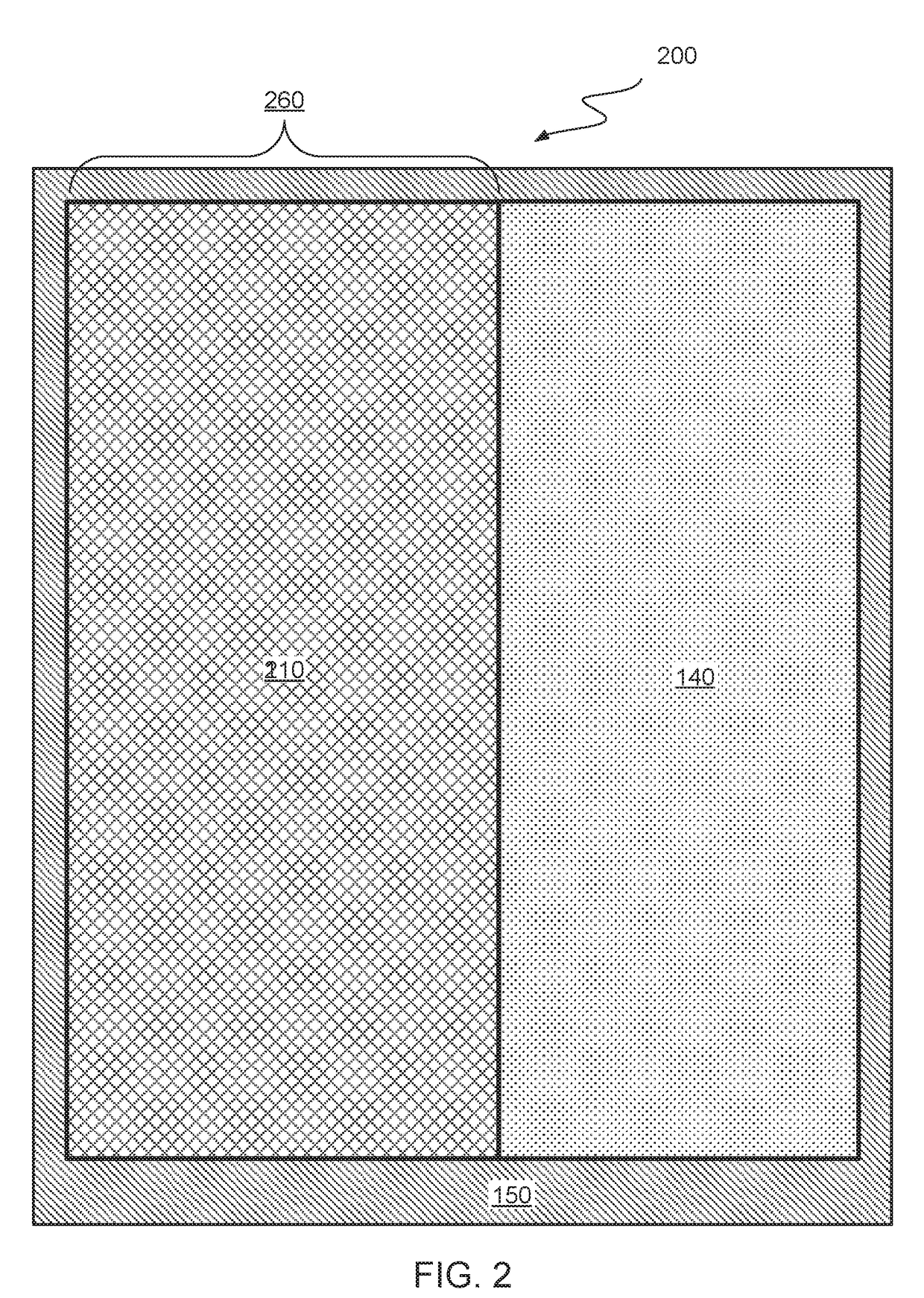

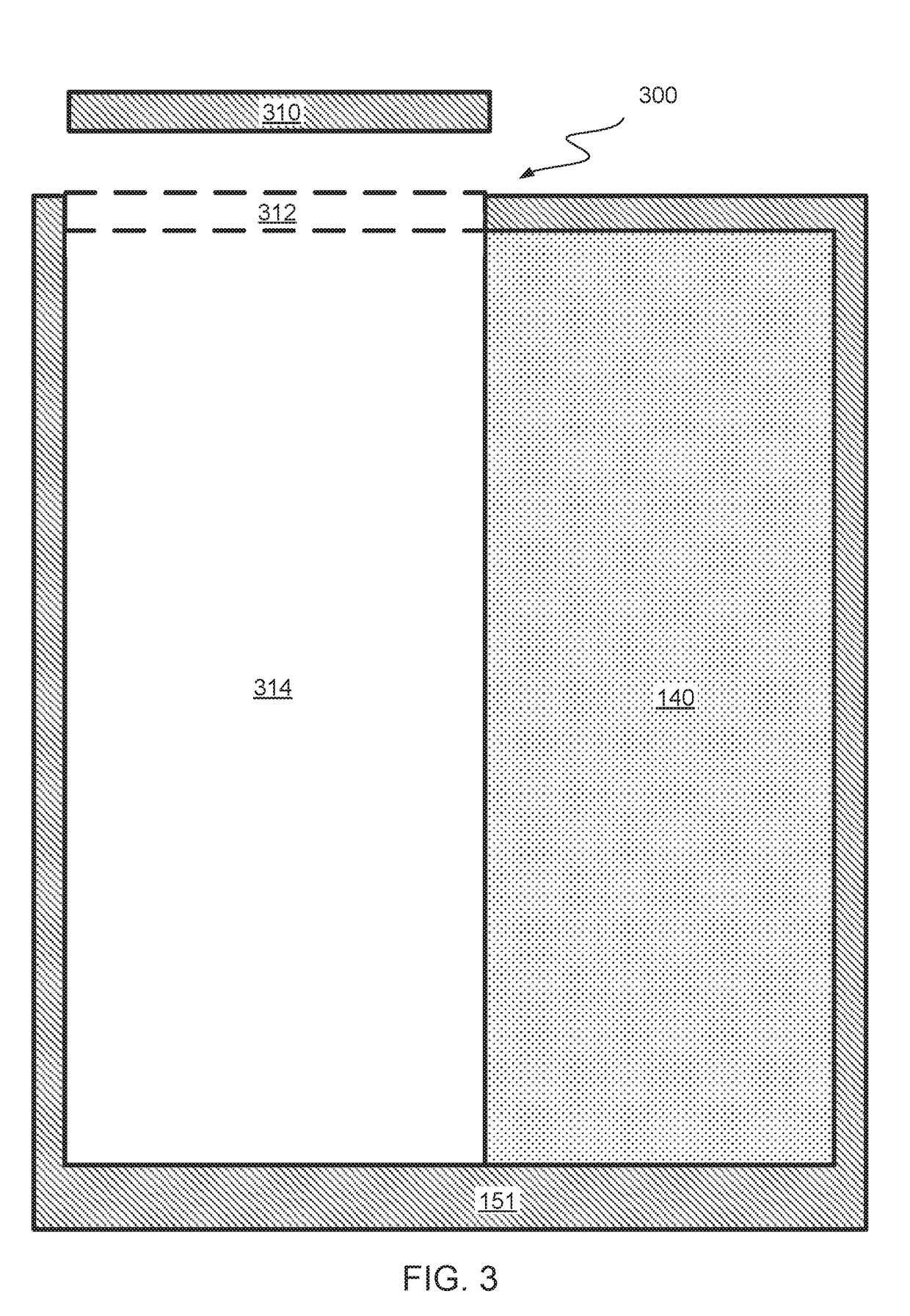

Battery thermal run-away and combustion prevention system

InactiveUS20190020077A1Preventing thermal run-awayThermometers using physical/chemical changesElectric powerCombustionEngineering

A device for preventing thermal run-away in a battery. The device includes a main compartment that is divided into a plurality of sub-compartments. A layer of material separates (i) a first sub-compartment containing a first chemical from (ii) a second sub-compartment containing a second chemical. In the event that a thermal run-away event is either detected or predicted, the layer of material degrades / is degraded and allows the chemicals to mix. The chemicals form an endothermic process that cools the battery, which at least delays the thermal run-away event. The device determines a delay period before thermal runaway is likely to occur and communicates that to a user.

Owner:IBM CORP

Multiple stage combustion process to maintain a controllable reformation temperature profile

InactiveUS7081312B1Uniform exchangeGenerate uniformHydrogen separation using solid contactCell electrodesWorking fluidFuel cells

A reaction vessel that integrates and balances an endothermic process with at least one exothermic process of the fuel cell system. Preferably the exothermic process is conducted in stages to provide more uniform and / or controllable heat generation and exchange, and to produce a uniform and / or controllable temperature profile in the endothermic reaction process. The invention allows for the elimination of the working fluid loop of prior art systems that had unsatisfactory response times at startup, and during transient conditions, and also added to the overall mass and volume of the fuel cell system.

Owner:GM GLOBAL TECH OPERATIONS LLC

Open type bidirectional thermal cycle and second kind thermal driving compression heat pump

ActiveCN105910324ACompression machines with non-reversible cycleFluid circulation arrangementThermal energyEngineering

The invention provides an open type bidirectional thermal cycle and second kind thermal driving compression heat pump, and belongs to the heat energy utilization and heat pump technical field; a boost process 12 of a cold source medium from low temperature, a heat release process 23 to a high temperature heat source, a pressure reduction process 34 from high temperature, a heat absorption process 45 from a middle temperature heat source and a pressure reduction process 56 from middle temperature can form open type bidirectional thermal cycle; an external cold source medium channel is connected with a compressor; the compressor uses the cold source medium channel to connect with an expander through a heater; the expander uses the cold source medium channel to connect with a second expander through a heat exchanger; the second expander is connected with the outer side through the cold source medium channel; the heater is connected with the outer side through a heated medium channel; the heat exchanger is connected with the outer side through a middle temperature medium channel; the expander and the second expander are connected with the compressor so as to transfer power, thus forming the second kind thermal driving compression heat pump.

Owner:李华玉

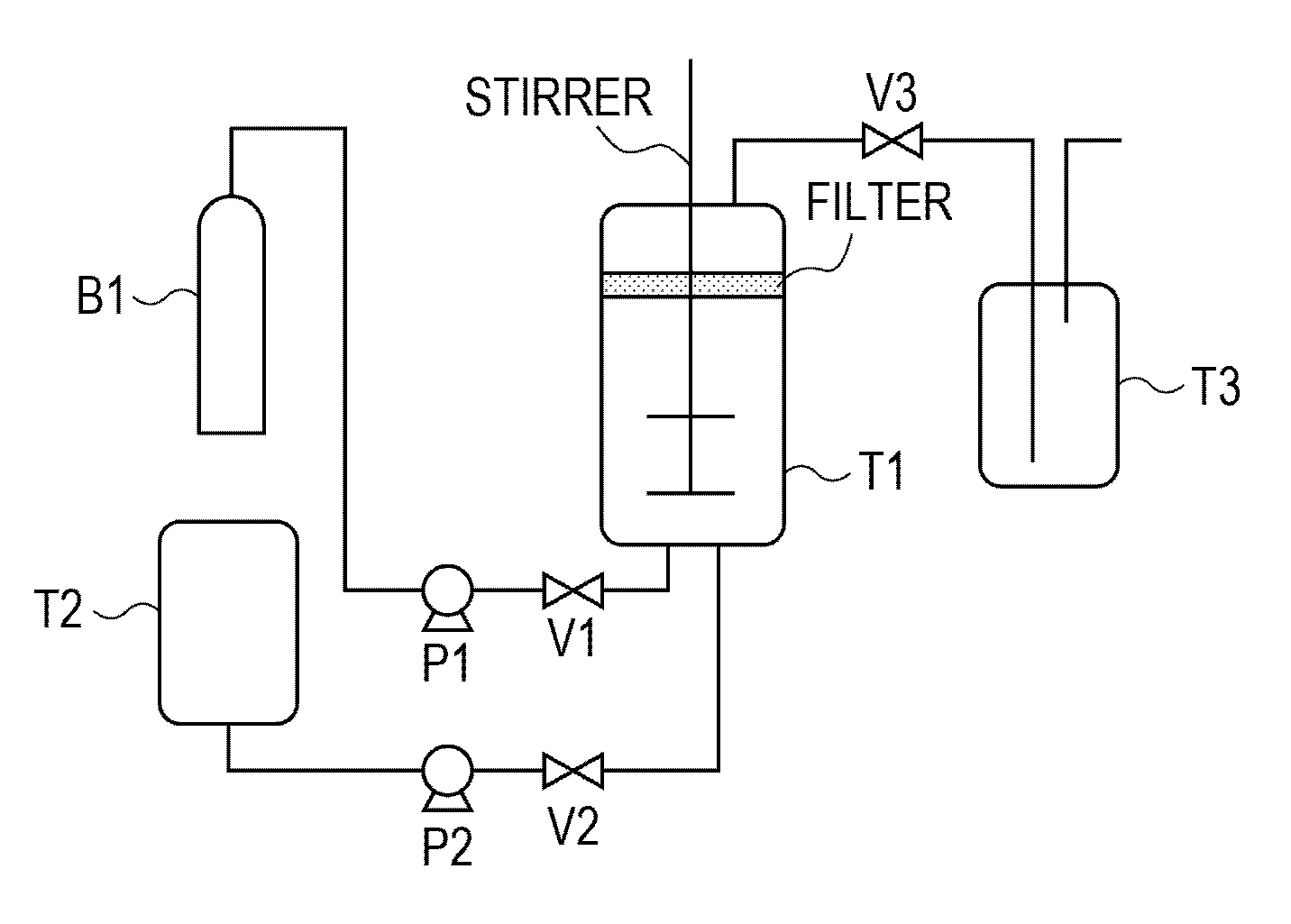

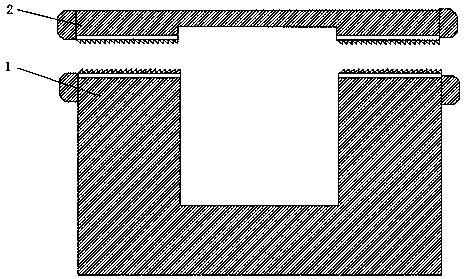

Corrosion scaling experiment detection system and method in geothermal water heat exchange process

InactiveCN111024604AScientific and reasonable structureEasy to useWeather/light/corrosion resistanceThermodynamicsEngineering

The invention discloses a corrosion scaling experiment detection system in a geothermal water heat exchange process. The system comprises a gradient heat exchange simulation system body. A gradient heat exchange simulation system upper cover plate is mounted at the top end of the gradient heat exchange simulation system main body; four corners of the gradient heat exchange simulation system uppercover plate are fixedly mounted with the gradient heat exchange simulation system main body through fixing nuts; a liquid inlet, an air inlet, an air outlet and a pH adjusting opening are formed in the surface of the gradient heat exchange simulation system upper cover plate. The surface of the gradient heat exchange simulation system upper cover plate is connected with a three-electrode system and a liquid phase monitoring device. The corrosion scaling experiment detection system is scientific and reasonable, safe and convenient to use, according to the invention, not only can the heat absorption process in liquid heat exchange be effectively simulated, but also the heat release process can be accurately simulated, the dynamic change of parameters such as temperature, flow velocity, pH value and gas content in the process can be accurately controlled, related conditions can be measured in real time, and corrosion scaling electrochemical results can be acquired.

Owner:韦正楠

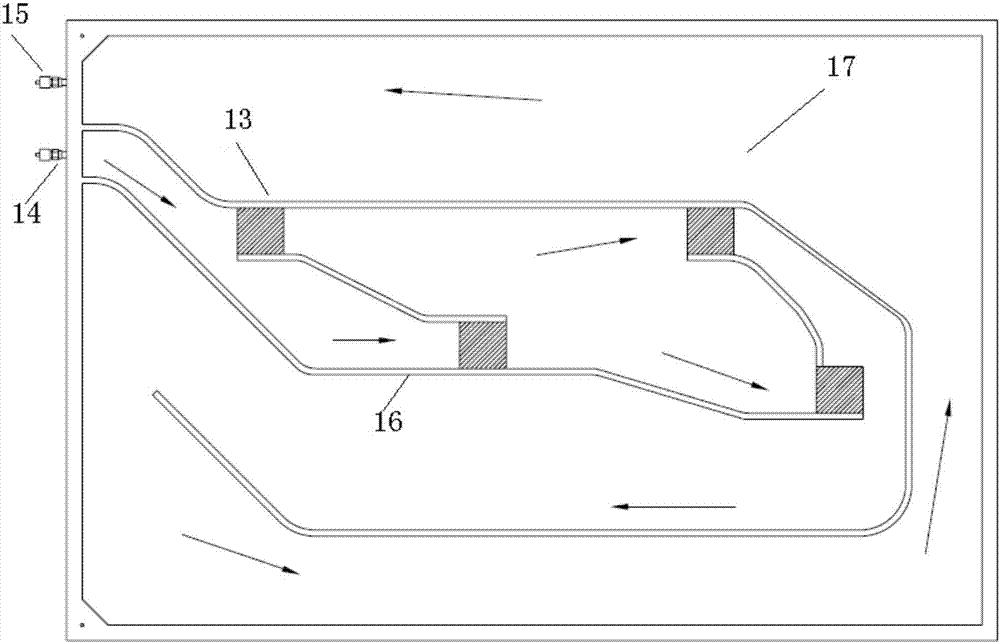

Regenerating device for cyclone-type ultrasonic atomizing solution dehumidification

InactiveCN103968474AIncrease temperatureAffect mass transfer kineticsLighting and heating apparatusAir conditioning systemsWater vaporEngineering

The invention discloses a regenerating device for cyclone-type ultrasonic atomizing solution dehumidification. The regenerating device comprises a regenerating container, a heat exchange heater and a dilute solution feed device, an air outlet and an air inlet are arranged on the regenerating container, a concentrated solution outlet is arranged on the lower portion of the regenerating container, the dilute solution feed device comprises a dilute solution incoming pipe and ultrasonic atomizers used for atomizing a dilute solution, and the ultrasonic atomizers are positioned inside the regenerating container and connected on the dilute solution incoming pipe. The regenerating device has the advantages that temperature of the dilute solution is increased by 5-10 DEG C more than air temperature, so that influence on mass transfer power between the solution and air due to the fact that a difference between steam partial pressure on the surface of the solution and that in the air is influenced caused by lowering of the temperature of the dilute solution in the process when steam gasifies and absorbs heat can be avoided. Low-grade heat energy is adopted, so that utilization of waste heat is facilitated.

Owner:上海誉德动力技术集团股份有限公司 +1

Toner

InactiveUS20150355563A1Good fixabilityMaintain good propertiesDevelopersMaterials scienceEndothermic process

In the measurement of an endothermic amount of a toner, (1) an endothermic peak temperature (Tp) derived from the binder resin is 50° C. or higher and 80° C. or lower; (2) a total endothermic amount (ΔH) derived from the binder resin is 30 [J / g] or more and 125 [J / g] or less based on mass of the binder resin; (3) when an endothermic amount derived from the binder resin from an initiation temperature of an endothermic process to Tp is represented by ΔHTp [J / g], ΔH and ΔHTp satisfy formula (1) below; and (4) when an endothermic amount derived from the binder resin from the initiation temperature of an endothermic process to a temperature 3.0° C. lower than Tp is represented by ΔHTp-3 [J / g], ΔH and ΔHTp-3 satisfy formula (2) below.0.30≦ΔHTp / ΔH≦0.50 (1)0.00≦ΔHTp-3 / ΔH≦0.20 (2)

Owner:CANON KK

Cooling agent for cold packs and food and beverage containers

ActiveUS9039924B2Easy to useSuppress explosivityOther chemical processesHeat-exchange elementsParticulatesDiammonium phosphate

Safe, stable, non-toxic and recyclable cooling compositions comprising solid particulate compounds that undergo an endothermic process when mixed with water such that the resulting mixture is useful for cooling surfaces, liquids and solids. The compositions always include one or more compounds from a group consisting of endothermic compounds that contain potassium; one or more compounds from a group of endothermic compounds that contain nitrogen; and at least one compound from a group consisting of ammonium phosphate, diammonium phosphate, ammonium polyphosphate, ammonium pyrophosphate and ammonium metaphosphate such that the compound or mixture of compounds in this group is at least 1% by weight of the final composition.

Owner:FROSTY TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com