Tower type solar boiler

A technology of tower-type solar energy and solar reflectors, which is applied in the field of solar energy, can solve the problems of high control precision requirements of heliostat devices, complex thermal process of heat absorbers, and uneven energy flow distribution, so as to improve operation safety and reduce Accuracy requirements and the effect of improving heat collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific examples.

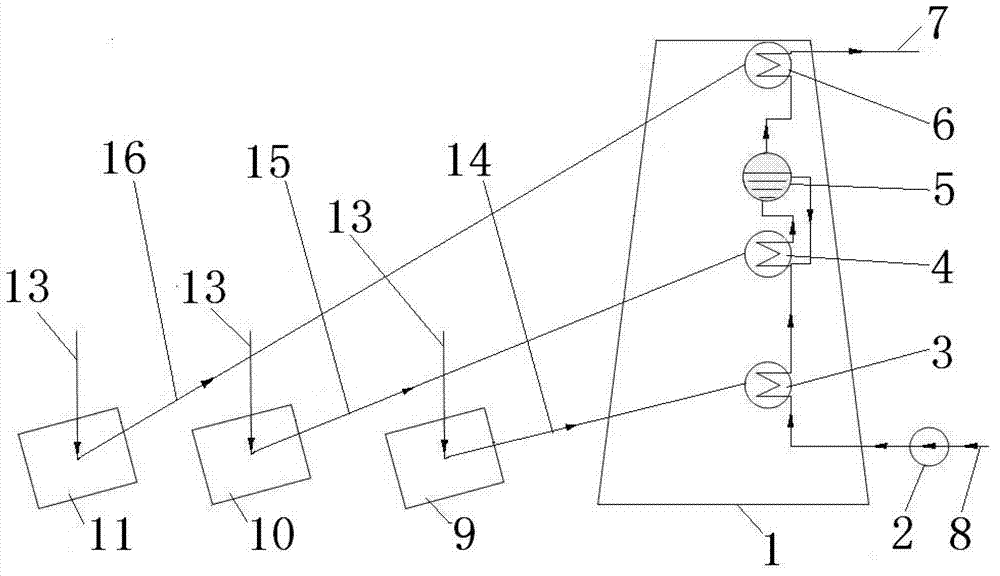

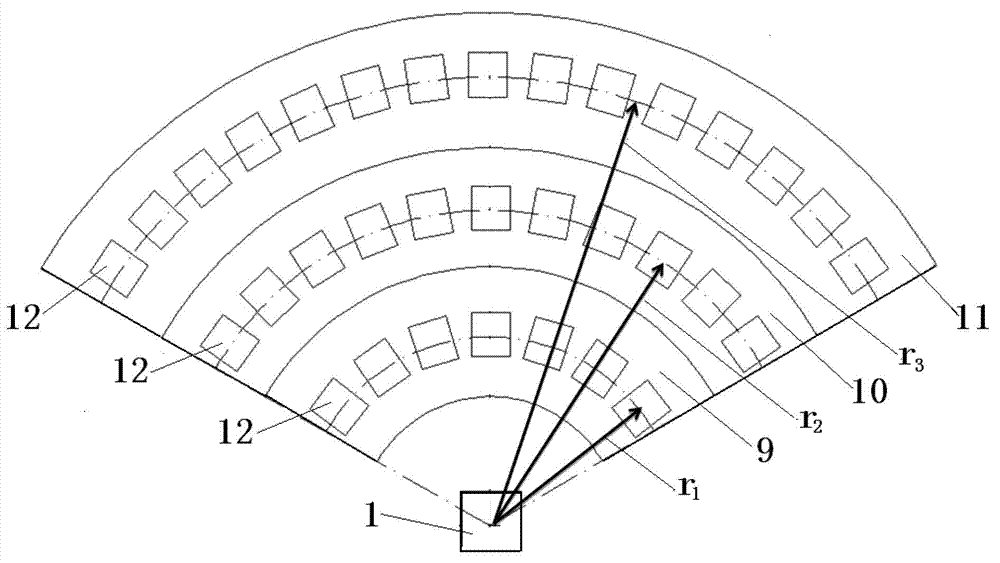

[0031] This embodiment is a 20MW level tower solar boiler. figure 1 Schematic diagram of the arrangement of the heliostat field and its absorption stage of the tower solar boiler, figure 2 It is the top view of the heliostat field and collector tower.

[0032] The setting area of the solar reflector field is the ground in the fan-shaped area with a central angle of 100°-120° in the back-sun direction of the heat collection tower 1. The solar reflector field consists of heliostat field I9, heliostat field II10 and heliostat field In the fan-shaped area of the solar mirror field, there are heliostat field I9, heliostat field II10 and heliostat field III11 in sequence from the inside to the outside.

[0033] Inside the heat collecting tower 1, the lower part is the preheating heat absorbing section, the middle part is the steam generating heat a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com