Concrete processing device and method of building outline forming machine

A technology for building outlines and processing equipment, applied in ceramic molding machines, clay preparation devices, chemical instruments and methods, etc., can solve the problems of concrete segregation and "segregation, production efficiency decline, construction cost increase, etc., to shorten the path and time. , avoid pipe bending and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

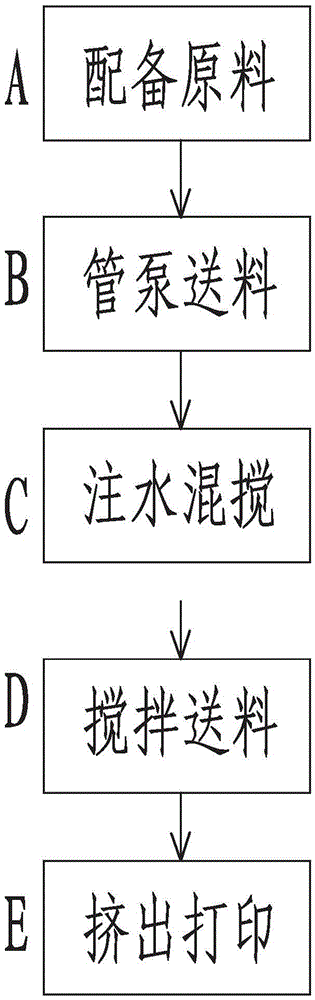

[0030] The following is attached Figures 1 to 3 The given examples further illustrate the specific implementation of the concrete processing equipment and processing method of the building contour forming machine of the present invention. The concrete processing equipment and processing method of the building contour forming machine of the present invention are not limited to the description of the following embodiments.

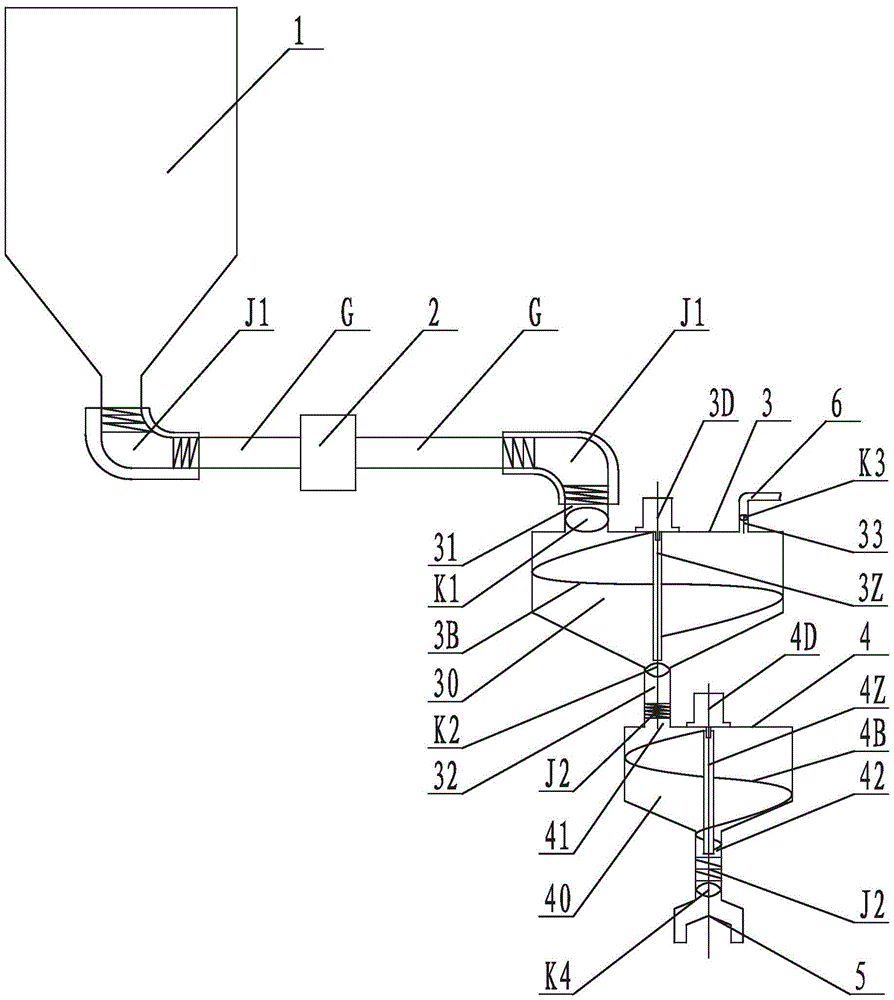

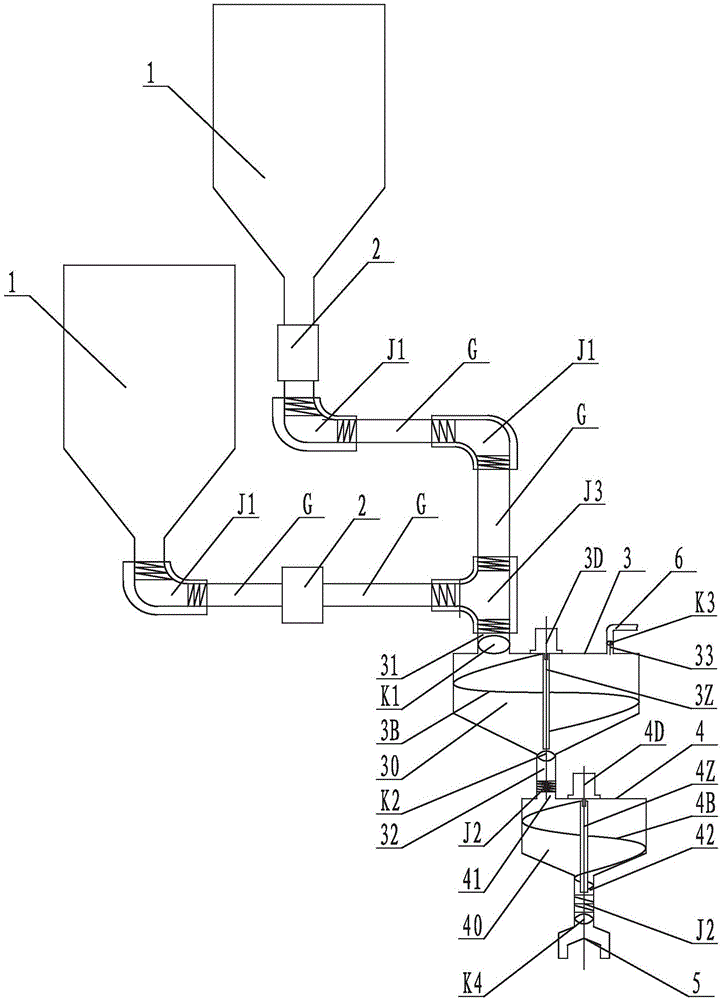

[0031] see figure 1 and figure 2, the concrete processing equipment of the architectural contour forming machine of the present invention includes: a raw material bin 1 for storing solid raw materials; a raw material pump 2 and a delivery pipe G for transporting the solid raw materials in the raw material bin 1 to the stirring integrated machine 3 In the mixing chamber 30; the mixing machine 3 is used to inject liquid raw materials, mix the solid raw materials with the liquid raw materials and then stir them into qualified concrete, and directly transpor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com