Preparation method of perovskite-like varistor ceramic material CaCu3Ti4O12 with high dielectric constant

A technology of high dielectric constant and pressure-sensitive ceramics, applied in chemical instruments and methods, titanium compounds, inorganic chemistry, etc., can solve the problems of high energy consumption, large powder particle size, uneven chemical composition of products, etc., and achieve energy consumption Low, reduced energy consumption, and simple reaction equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. CaCu 3 Ti 4 O 12 Preparation of powder

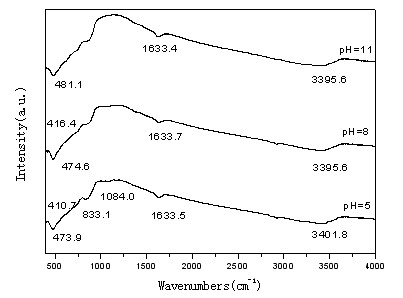

[0030] (1) 2.3139g of tetrabutyl titanate was slowly dropped into ethanol to obtain an ethanol solution with a concentration of 0.1 mol / L, 1.2378g of copper nitrate and 0.4066g of calcium nitrate were dissolved into an aqueous solution and added to the mixture under stirring. In the tetrabutyl titanate ethanol solution, the pH of the solution is adjusted to 5 with ammonia water, and then 5 mL of 6 mol / L mineralizer sodium hydroxide is added, and the resulting solution is fully mixed;

[0031] (2) Stir the mixed solution evenly and seal it in the autoclave with a filling degree of 60% (volume fraction), keep it at 180°C for 12h, and let it cool to room temperature naturally;

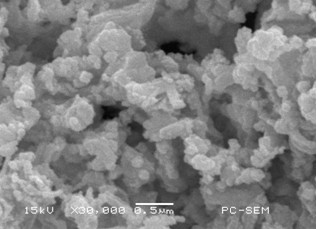

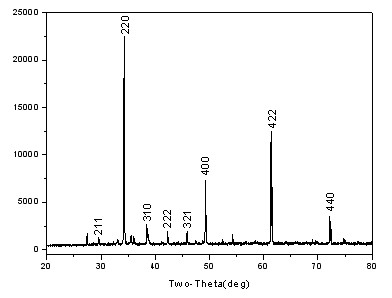

[0032] (3) filter the precipitate obtained in step (2) with suction, fully wash it with deionized water and ethanol to remove impurities, and finally dry it in a vacuum drying oven at 100° C. for 2 hours, take it out and grind it in an agate mortar to ...

Embodiment 2

[0038] In this example, the hydrothermal method was used to prepare CaCu 3 Ti 4 O 12 When powder, the weight of each component is the same as in Example 1, the pH value of the solution is adjusted to 8 with ammonia water, 5 mL of mineralizer sodium hydroxide with a concentration of 8 mol / L is added, the reaction temperature is 200 ° C, and the reaction time is 12 h. Using the same process steps as in Example 1, CaCu with giant dielectric properties was prepared 3 Ti 4 O 12 Pressure-sensitive ceramics, the difference is that the ceramic sintering temperature is 950 °C.

Embodiment 3

[0040] In this example, the hydrothermal method was used to prepare CaCu 3 Ti 4 O 12 When powder, the weight of each component is the same as in Example 1, the pH value of the solution is adjusted with ammonia water at 11, the concentration of the mineralizer sodium hydroxide is 10mol / L, the reaction temperature is 160 ° C, and the reaction time is 24h. The above materials are used and implemented. Example 1 The same process steps were used to prepare CaCu with giant dielectric properties 3 Ti 4 O 12 Pressure-sensitive ceramics, the difference is that the ceramic sintering temperature is 950 °C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com