Harmless treatment method of waste burning fly ash

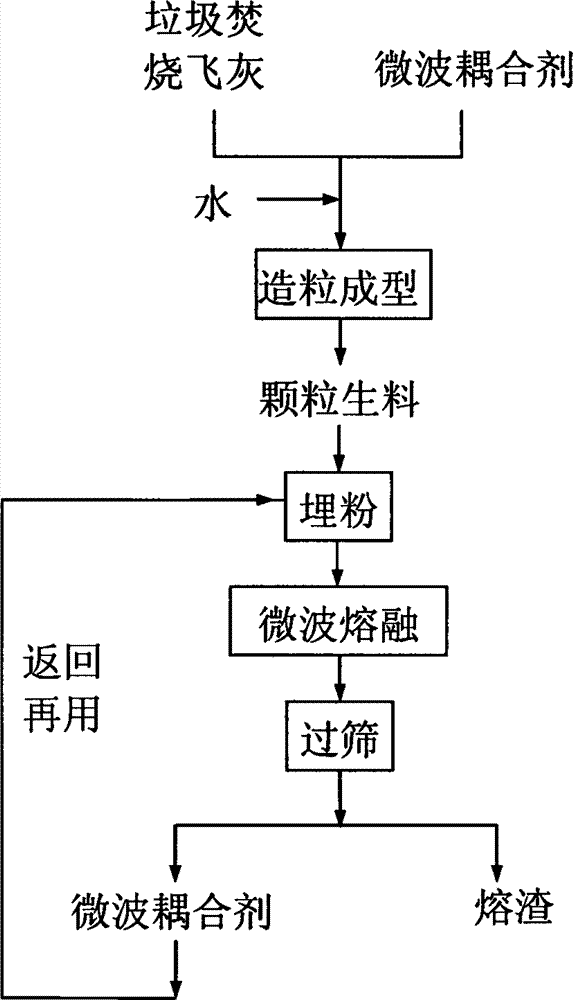

A technology for waste incineration fly ash and harmless treatment, applied in the field of environmental pollution control, can solve the problems of high consumption, high operating cost, large energy consumption, etc., and achieve the effects of speeding up the reaction rate, increasing the contact area, and high energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

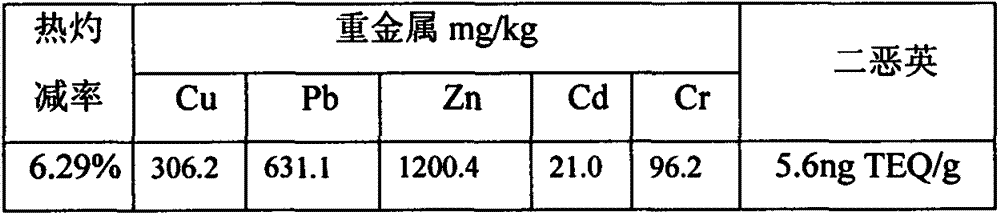

[0016] The chemical composition of municipal solid waste incineration is shown in Table 1, and the heat loss rate of fly ash, heavy metals, dioxins and chlorine content are shown in Table 2. Put the waste incineration fly ash and silicon carbide powder into a mixer at a mass ratio of 20:1 to fully mix, then add deionized water for granulation molding, put the molded particles into a graphite crucible, and add embedded carbon powder ( Particle size≤250μm), put the graphite crucible into an industrial microwave oven for powder fusion. The working frequency of the microwave sintering furnace is 2.45GHz, the power of the microwave oven is 5kW, the heating time is 5 minutes, and the slag is obtained by cooling in the crucible The slag and buried powder are separated by sieving. After separation, the microwave couplant is reserved as buried powder. The concentration of dioxins in the slag is reduced to 0.021ng TEQ / g after testing. The heavy metal leaching toxicity test results of the ...

Embodiment 2

[0024] The waste incineration fly ash is the same as in Example 1. Put the waste incineration fly ash and the carbon powder into a mixer at a mass ratio of 10:1 to fully mix, then add deionized water for granulation and shape, and put the shaped particles into a graphite crucible , And add embedded ferroferric oxide powder (particle size ≤300μm), put the graphite crucible into an industrial microwave oven for powder fusion, the working frequency of the microwave sintering furnace is 0.915GHz, the power of the microwave oven is 30kW, and the heating time is 8 Minutes, the slag is obtained in the crucible after cooling, and the slag is separated from the buried powder by sieving. After separation, the microwave couplant is reserved as buried powder for later use. The concentration of dioxins in the molten slag is reduced to 0.025ng TEQ / g after the separation. The heavy metal leaching toxicity test results of the slag are shown in Table 4. The hazardous concentration in the leachin...

Embodiment 3

[0028] The waste incineration fly ash is the same as in Example 1. Put the waste incineration fly ash and the ferroferric oxide powder in a mixer at a mass ratio of 5:1 to fully mix, then add deionized water to granulate and shape, and put the molded particles into Graphite crucible, and add embedded ferroferric oxide powder (particle size ≤200μm), put the crucible into an industrial microwave oven for embedding powder melting, the working frequency of the microwave sintering furnace is 2.45GHz, the power of the microwave oven is 300kW, heating After 15 minutes, the molten slag is obtained in the crucible after cooling. The molten slag and the buried powder are separated by a sieve. After separation, the microwave coupling agent is reserved as buried powder for later use. The concentration of dioxins in the molten slag is reduced to 0.018ng TEQ / g. The test results of heavy metal leaching toxicity of molten slag are shown in Table 5. The hazardous concentration in the leaching so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com