Multi-main-phase Nd-Fe-B type permanent magnet with high crack resistance and high coercive force and preparation method thereof

A high coercivity, nd-fe-b technology, used in magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve the problem that mechanical properties cannot meet the new needs of application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

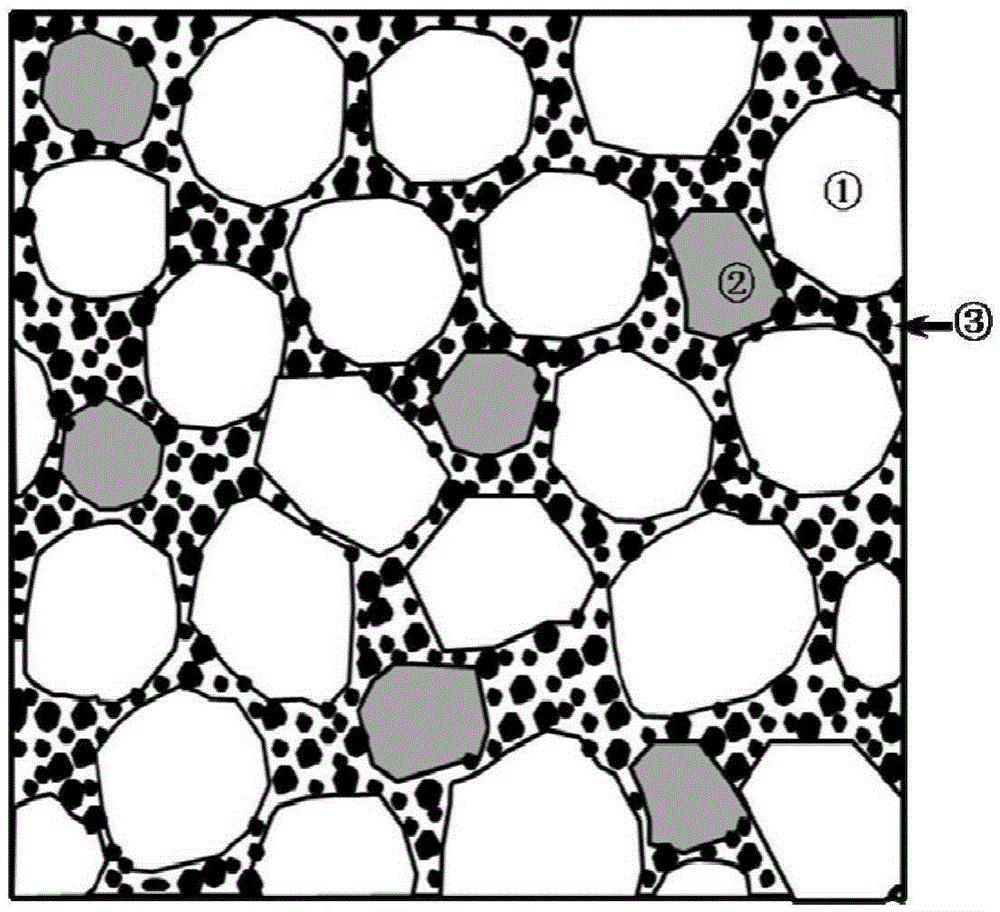

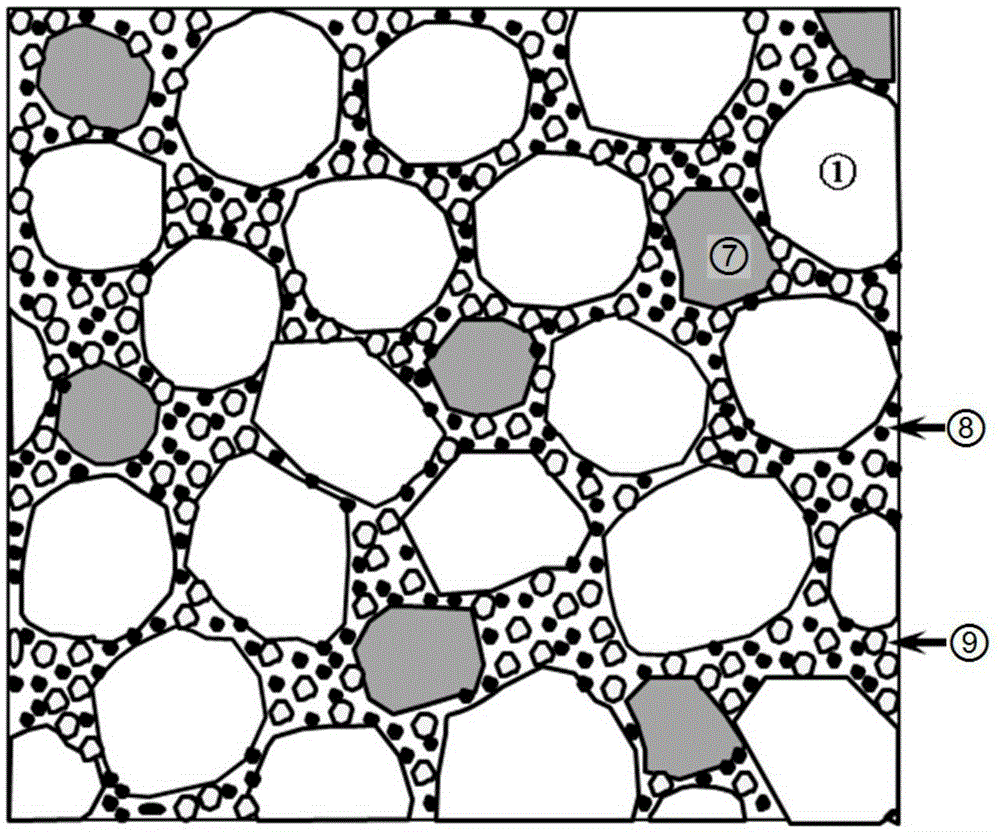

[0067] The invention provides a high crack resistance, multi-main phase Nd-Fe-B type permanent magnet and its preparation method. According to the performance requirements of multi-hard magnetic main phase Nd-Fe-B permanent magnet alloy, the design is different Size, different distribution, different anisotropy field H A The main phase alloy of the main phase alloy determines the phase structure composition of a variety of different multi-hard magnetic main phase Nd-Fe-B type permanent magnets; in the final magnet, Nd is the rare earth element with the most content by mass percentage, and the method includes the following process steps:

[0068] (1) A variety of different hard magnetic main phase alloy raw materials are prepared respectively. These hard magnetic main phases all have a 2:14:1 structure and are composed of the following three types of main phases:

[0069] I) (Nd, Pr)-Fe-B phase: It is a permanent magnetic phase based on rare earth elements Nd and Pr, and does n...

Embodiment 1

[0080] Design composition (Nd 0.65 PR 0.20 Dy 0.09 Tb 0.06 ) 29.6 Fe 68 B 0.9 tm 1.5 (TM=Co, Cu, Nb).

[0081] (1) According to the alloy mass percentage composition (Nd 0.9 PR 0.1 ) 28.6 Fe 69.5 B 0.9 tm 1.0 , (Dy 0.9 PR 0.1 ) 31 Fe 66.1 B 0.9 tm 2 and Tb 30 Fe 67.1 B 0.9 tm 2 Prepare raw materials separately.

[0082] (2) Melt the prepared raw materials separately. The alloy without heavy rare earth is prepared into quick-setting thin strips and then hydrogen crushed, and the alloy containing heavy rare earth is made into quick-quenched thin strips and then hydrogen crushed, then dehydrogenated, and then passed through jet mill or high-energy ball mill to obtain coarse particles with different particle sizes. (Nd 0.9 PR 0.1 ) 28.6 Fe 69.5 B 0.9 tm 1.0 Magnetic powder, fine (Dy 0.9 PR 0.1 ) 31 Fe 66.1 B 0.9 tm 2 Magnetic powder, nanocrystalline Tb 30 Fe 67.1 B 0.9 tm 2 Magnetic powder etc.

[0083] (3) According to the equivalent compo...

Embodiment 2

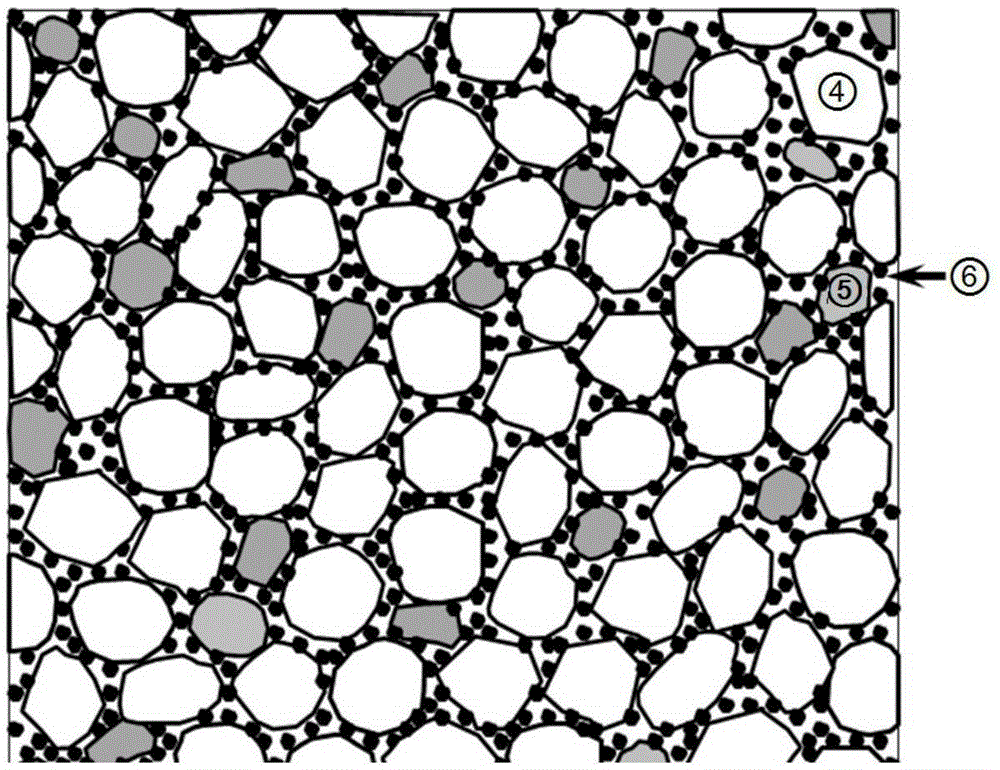

[0089] Design composition (Nd 0.87 PR 0.1 Dy 0.03 ) 29 Fe 68.1 B 0.9 tm 2 (TM = Ga, Co, Cu, Nb).

[0090] (1) According to the alloy mass percentage composition Nd 29 Fe 68.1 B 0.9 tm 2 , Pr 29 Fe 68.1 B 0.9 tm 2 and Dy 29 Fe 68.1 B 0.9 tm 2 Prepare raw materials separately.

[0091] (2) Melt the prepared raw materials separately. The alloy without heavy rare earth is prepared into quick-setting thin strips and then hydrogen crushed, and the alloy containing heavy rare earths is prepared into quick-quenched thin strips and then hydrogen crushed, then dehydrogenated, and then passed through jet mill or high-energy ball mill to obtain different particle sizes. Coarse Nd 29 Fe 68.1 B 0.9 tm 2 Magnetic powder, fine Pr 29 Fe 68.1 B 0.9 tm 2 Magnetic powder, nanocrystalline Dy 29 Fe 68.1 B 0.9 tm 2 Magnetic powder etc.

[0092] (3) According to the equivalent composition (Nd 0.87 PR 0.1 Dy 0.03 ) 29 Fe 68.1 B 0.9 tm 2 (TM=Ga, Co, Cu, Nb), respe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com