Multifunctional sensing flexible sensor and preparation method thereof

A flexible sensor and multi-functional technology, applied in the field of flexible sensors, can solve the problems of response and poor adaptability of traditional processes, and achieve the effects of reducing gaps, improving sensitivity, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

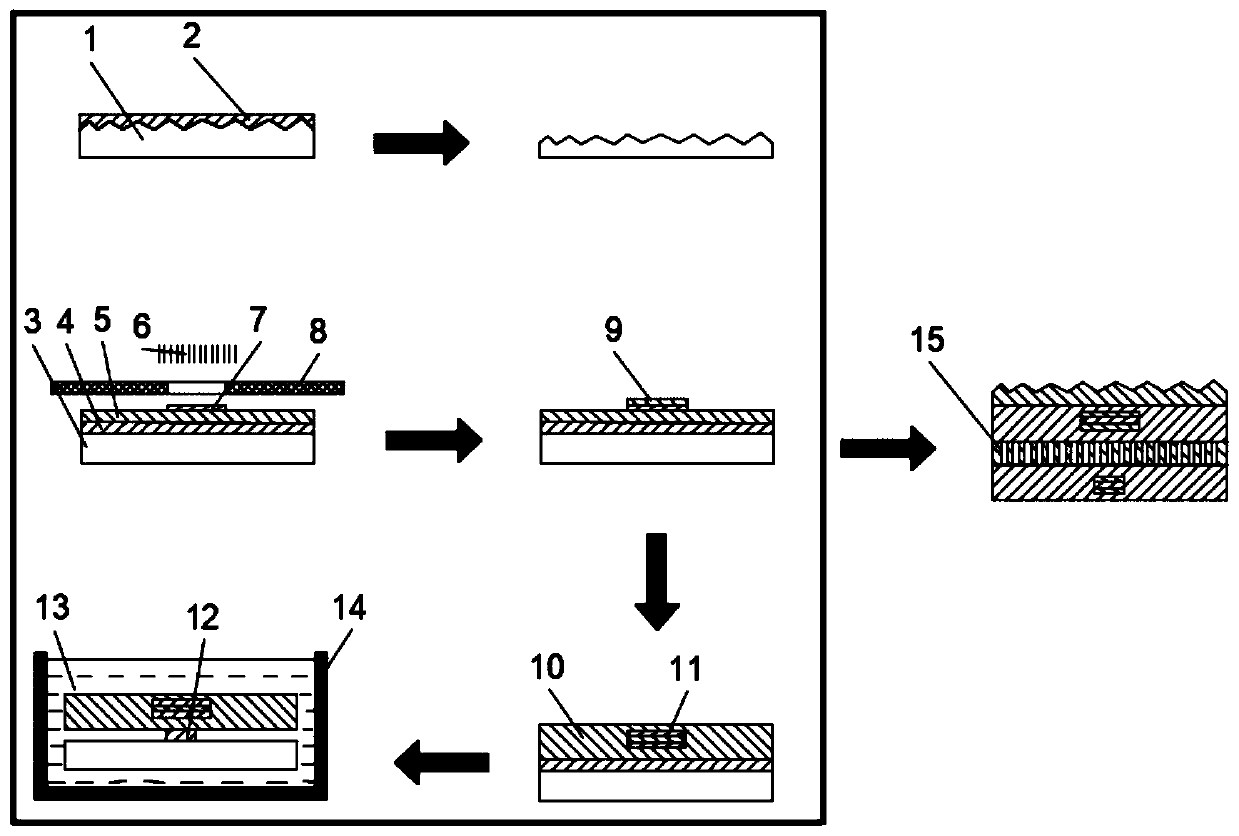

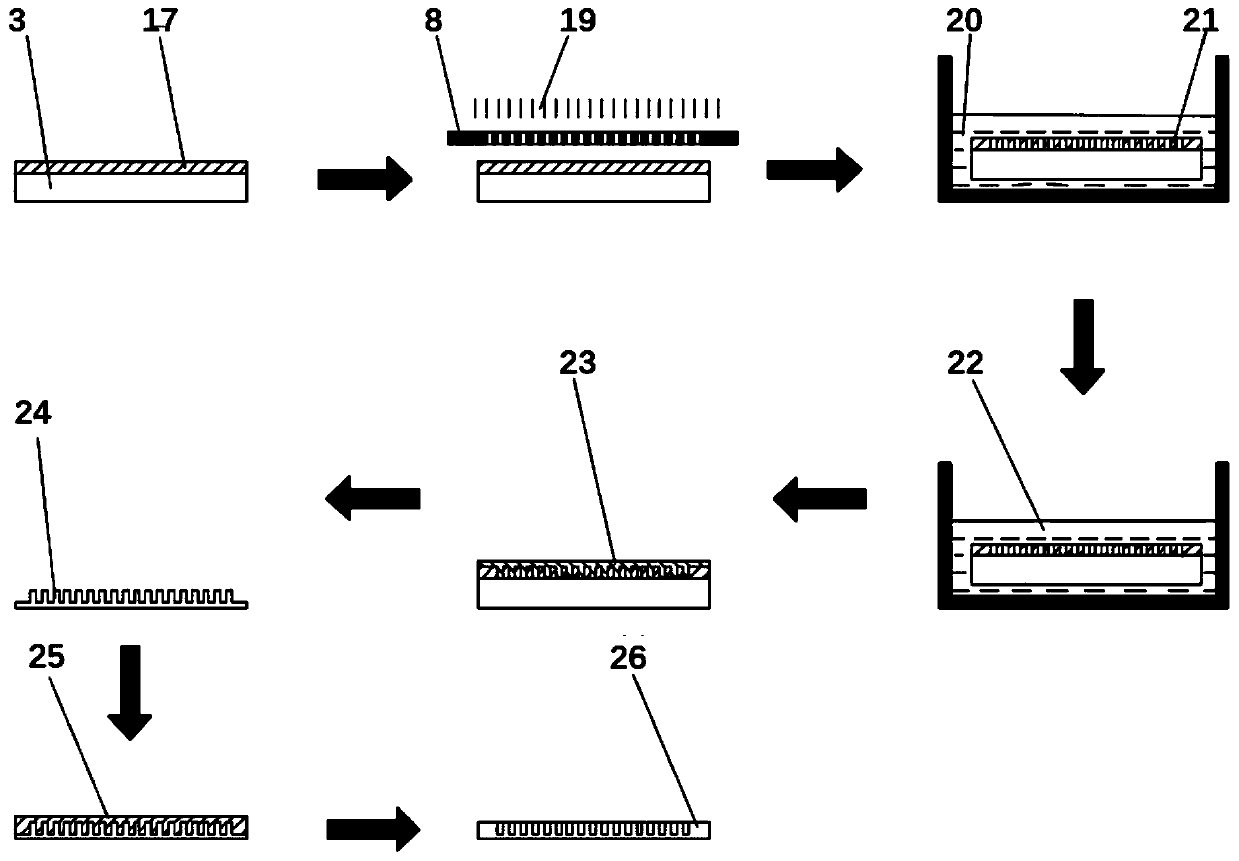

[0040] In order to improve the manufacturing success rate and quality of the sensor, a method for preparing a flexible sensor with a multi-functional sensing principle mainly includes a micro-column hole process, an electrode process, a sacrificial layer process and a reactive ion etching process. Among them, the micro-pillar hole process is used to prepare the intermediate dielectric layer, the electrode process is used to prepare the upper electrode layer and the lower electrode layer, the sacrificial layer process is used to release the sensor from the silicon wafer, and the reactive ion etching process is used for the upper electrode. layer, the middle dielectric layer and the bonded package of the bottom electrode layer. The micro-hole process adopts the method of photolithography and secondary inversion to prepare micron column holes with different diameters on polydimethylsiloxane. Photolithography ensures the stability and precision of the process; the mold of the secon...

Embodiment 1

[0077] (1) Clean the polished surface of the 4-inch silicon wafer with acetone, isopropanol and deionized water in sequence, and then dry it with nitrogen;

[0078] (2) 10% polyvinyl alcohol aqueous solution is spin-coated on the polished surface of the silicon crystal element, the spin-coating speed is 500 rpm, and the spin-coating time is 10 minutes, and then the silicon crystal element is placed on a hot plate to heat, The heating temperature is 80°C, the time is 20 minutes, and the polyvinyl alcohol is cured to form a film;

[0079] (3) Spin-coat polydimethylsiloxane on the silicon wafer coated with a sacrificial layer at a spin-coating speed of 800 rpm for 100 seconds, then place the silicon wafer on a hot plate for heating , the heating temperature is 80°C, the heating time is 30 minutes, and the polydimethylsiloxane is cured to form a film;

[0080] (4) Attach the mask plate to the surface of polydimethylsiloxane, then place the wafer coated with polydimethylsiloxane a...

Embodiment 2

[0102] (1) Clean the polished surface of the 4-inch silicon wafer with acetone, isopropanol and deionized water in sequence, and then dry it with nitrogen;

[0103] (2) 10% polyvinyl alcohol aqueous solution is spin-coated on the polished surface of the silicon wafer, the spin coating speed is 1000 rpm, and the spin coating time is 1 minute, and then the silicon wafer is placed on a hot plate to heat, The heating temperature is 100°C, the time is 5 minutes, and the polyvinyl alcohol is cured to form a film;

[0104] (3) Spin-coat polydimethylsiloxane on the silicon wafer coated with a sacrificial layer at a spin-coating speed of 1000 rpm for 50 seconds, then place the silicon wafer on a hot plate for heating , that is, the heating temperature is 100°C, the heating time is 10 minutes, and the polydimethylsiloxane is cured to form a film;

[0105] (4) Attach the mask plate to the surface of polydimethylsiloxane, then place the wafer coated with polydimethylsiloxane and sacrific...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com