Fluid pressure sensing device

A sensing device and fluid pressure technology, which is applied in the direction of fluid pressure measurement involving magnet displacement, can solve the problems of small pressure measurement range, low magnetic field strength, and reduced test sensitivity, so as to increase the pressure measurement range and radial magnetic field. The effect of strengthening the strength and expanding the measurement adaptation surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

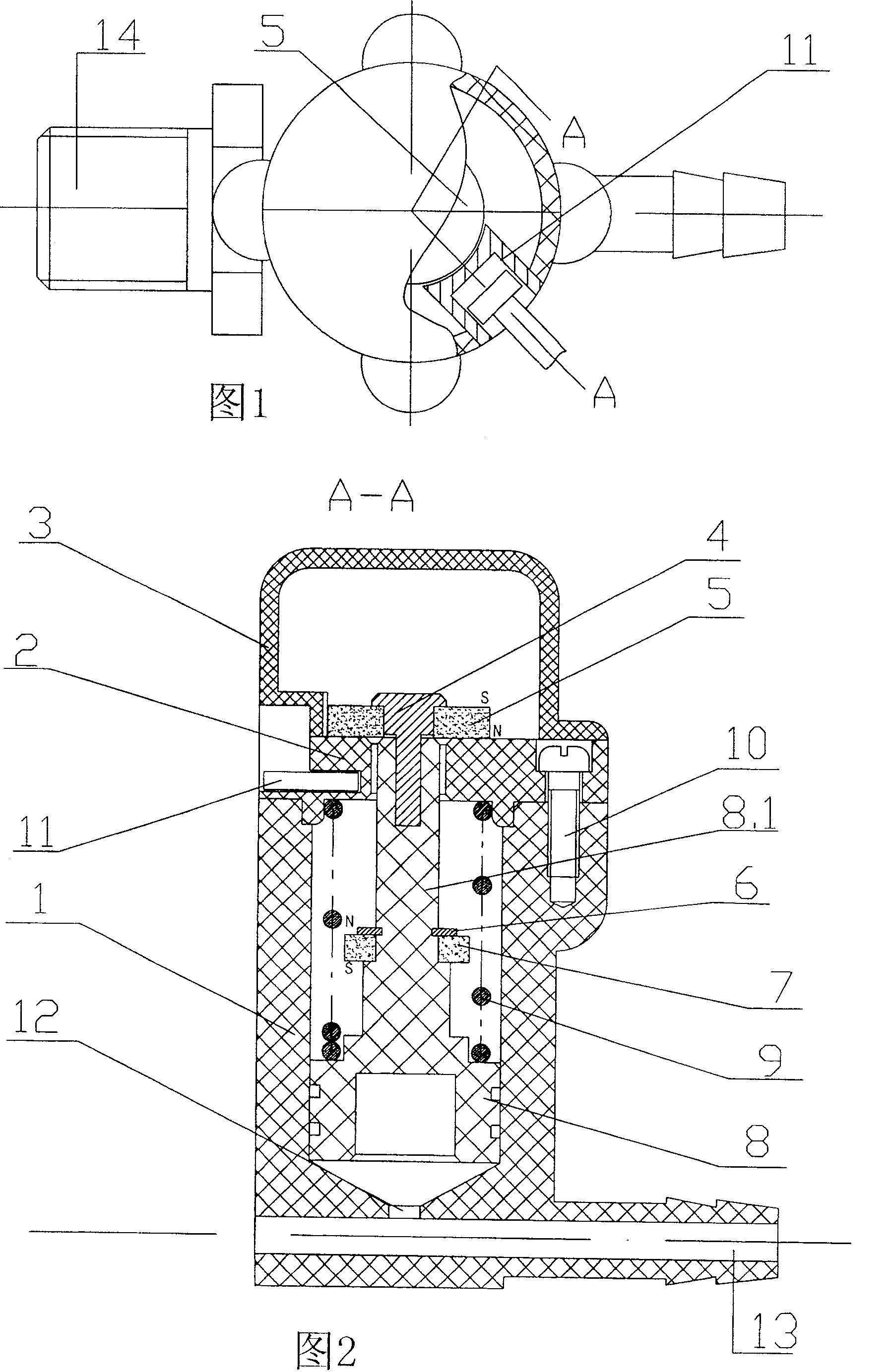

[0014] Refer to attached picture. Embodiment The housing is made into a barrel shape, and the housing 1 is integrated with a tubular object with an inlet 13 and an outlet 14 at the bottom, and the tubular object communicates with the inner cavity of the housing through a through hole 12, so that the measured fluid enters the inner cavity of the housing . The upper edge of the housing 1 and the end cover 2 are fastened by screws 10 and bonded to the upper cover 3 , or the upper cover 3 , the end cover 2 and the housing 1 are fastened together by the screws 10 . The housing 1 is equipped with a piston 8, and the top end of the piston rod 8.1 made of the piston 8 is fixed with a screw 4 to fix the ring-shaped upper magnet 5 and is located on the upper surface of the end cover 2, and the step made in the middle of the piston rod 8.1 is provided by a circlip 6. Fix the ring-shaped lower magnet 7, and the two magnets are arranged with polarities repelling each other, as shown in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com