mems pressure sensor array, its manufacturing method and pressure measurement method

A technology of a pressure sensor and a manufacturing method, which is applied to the fluid pressure measurement using capacitance change, piezoelectric device/electrostrictive device, piezoelectric/electrostrictive/magnetostrictive device, etc., can solve the problem of large measurement error of the pressure sensor , small measurable range, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

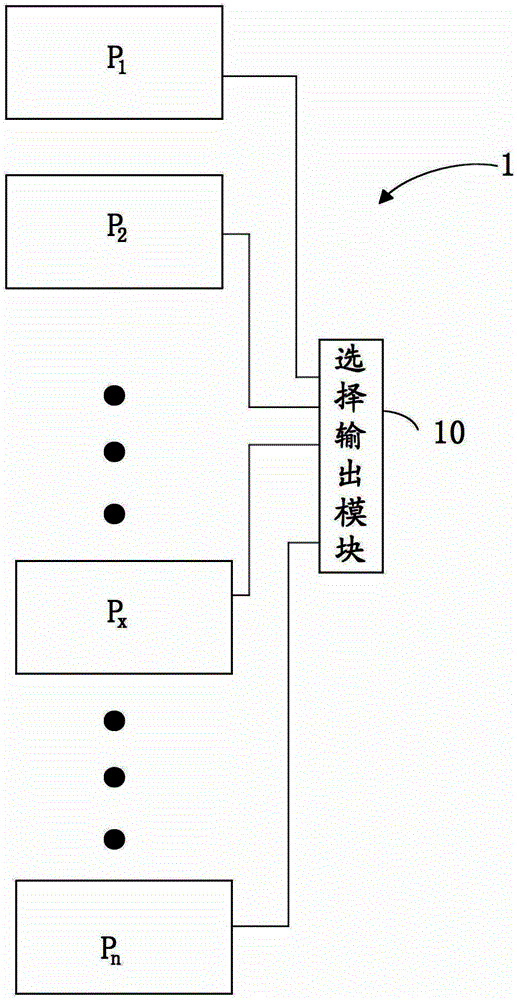

[0092] figure 1 Shown is a simplified diagram of the MEMS pressure sensor array 1 provided in this embodiment. The array 1 consists of:

[0093] n MEMS pressure sensors located on the same chip, n≥2, each of the MEMS pressure sensors has a cavity, and the pressures in the cavities of each MEMS pressure sensor are P 1 ,P 2 …P n , where P 1 ,P 2 ...P n Not equal to each other;

[0094] Select the output module 10 to output the pressure in the cavity as P 1 ,P 2 …P n Among the MEMS pressure sensors, the measured value of the MEMS pressure sensor whose cavity pressure is closest to the environmental pressure P' where the MEMS pressure sensor array is located.

[0095] The following are introduced separately. First, the structure of each MEMS pressure sensor and its fabrication method are introduced.

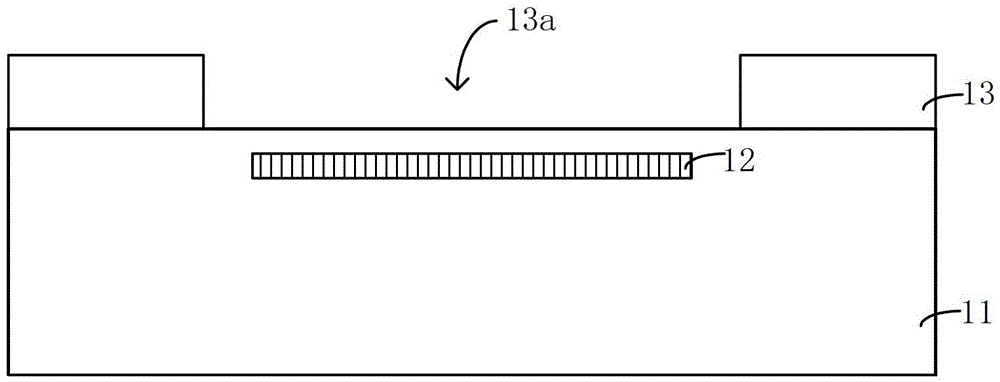

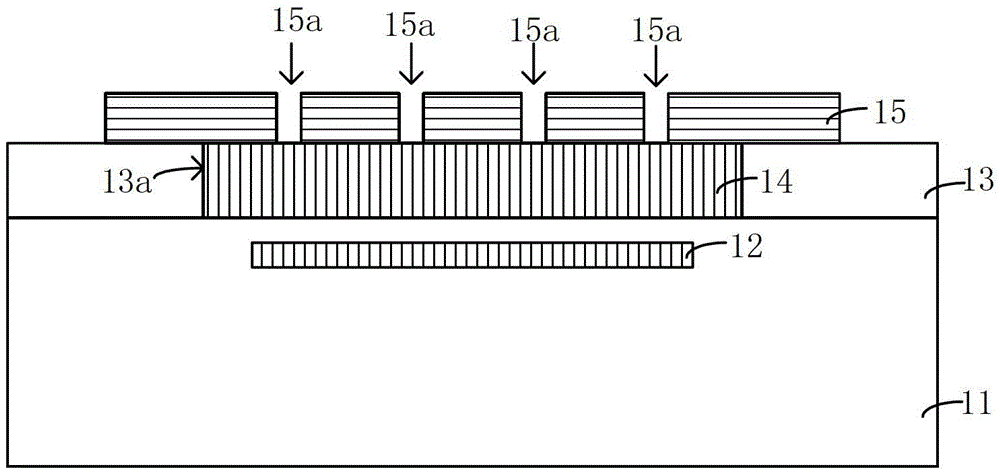

[0096] About the production method: Figure 2 to Figure 4 , Figure 6 to Figure 7 is a cross-sectional view of the structure formed during fabrication, Figure 5 is a ...

Embodiment 2

[0132] refer to Figure 7 As shown, for the single MEMS pressure sensor in the array 1, the manufacturing method needs to reserve an opening 19 for the gas in the cavity 13a to reach a certain pressure. The solution used tends to enter the cavity 13a, causing the sensitive film 15 to stick. In view of the above problems, this embodiment 2 proposes a new MEMS pressure sensor array structure and manufacturing method thereof, so that the solution used for wet cleaning does not directly enter the cavity, thereby reducing the possibility of sensitive film adhesion and improving the production efficiency of MEMS. Yield of the pressure sensor.

[0133] The semiconductor substrate 11, the first electrode 12, the patterned first dielectric layer 13, and the cavity 13a formed in the patterned first dielectric layer 13 in the second embodiment are the same as those in the first embodiment, so the specific process and structure Referring to step S11 and figure 2 shown.

[0134] The f...

Embodiment 3

[0162] The MEMS pressure sensor array provided in the third embodiment, its manufacturing method and pressure measurement method are substantially the same as those in the second embodiment. The difference is: if Figure 20 As shown, the patterned sensitive thin film 15' forming the trench 15b' is disposed on the semiconductor substrate 11 instead of the first dielectric layer 13 in the first embodiment.

[0163] Correspondingly, the method for fabricating the patterned sensitive thin film 15' on the semiconductor substrate 11 includes: first, forming a sacrificial layer on the semiconductor substrate 11; then, etching part of the sacrificial layer until the semiconductor substrate 11 is exposed, leaving The sacrificial layer 14 is used as a support for the sensitive film 15'; afterward, a sensitive film is formed on the sacrificial layer 14 and the semiconductor substrate 11, and part of the sensitive film is etched to form a patterned sensitive film 15'. A trench 15 b ′ is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com