High-pressure sensor chip with SOI (silicon on insulator) rectangular film structure

A technology of high-voltage sensors and rectangular membranes, which is applied in instruments, measurement of fluid pressure, and measurement of the properties and forces of piezoelectric resistance materials. problems, to achieve the effect of ensuring sensitivity and accuracy, increasing the range and reducing hysteresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The structural principle and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

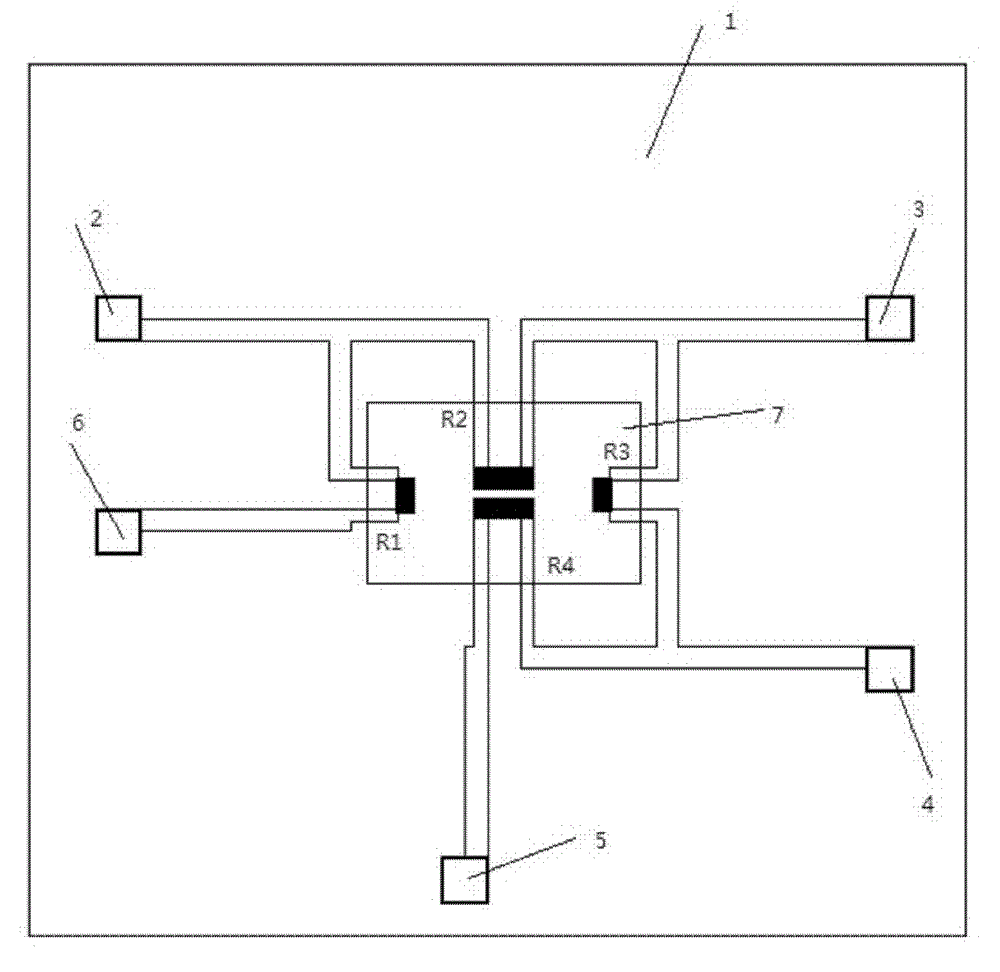

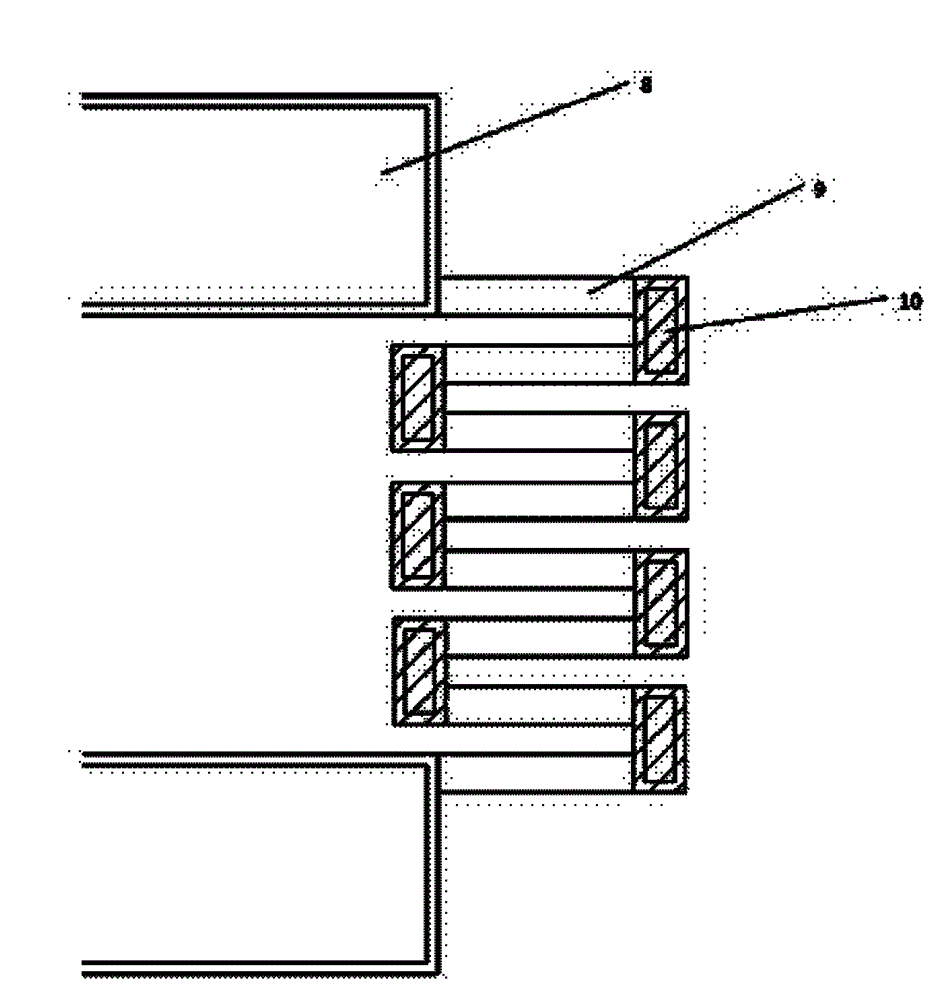

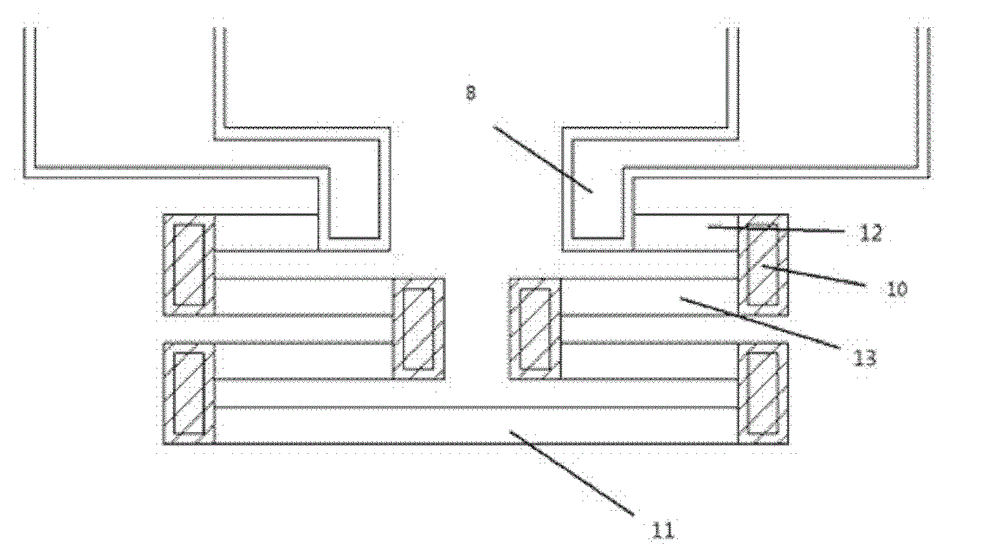

[0020] refer to figure 1 and image 3 , a SOI rectangular film structure high-voltage sensor chip, including a high-voltage sensor chip 1, the central area of the bottom surface of the high-voltage sensor chip 1 is corroded to form a rectangular film 7, on the front of the high-voltage sensor chip 1, along the [110] crystal direction, on the rectangular film The maximum stress on the 7 is arranged with a resistance strip R1, a resistance strip R2, a resistance strip R3 and a resistance strip R4, and a first pressure welding block 2 is arranged between the periphery of the rectangular film 7 and the edge of the high-voltage sensor chip 1, and the second pressure welding Block 3, the third pressure welding block 4, the fourth pressure welding block 5, the fifth pressure welding block 6, one end of the resistance bar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com