Corrosion scaling experiment detection system and method in geothermal water heat exchange process

A detection system, thermal process technology, applied in the direction of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve the problems of deviation of corrosion and scaling results, poor pertinence, etc., to achieve safe and convenient use, improve accuracy, reduce the effect of interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

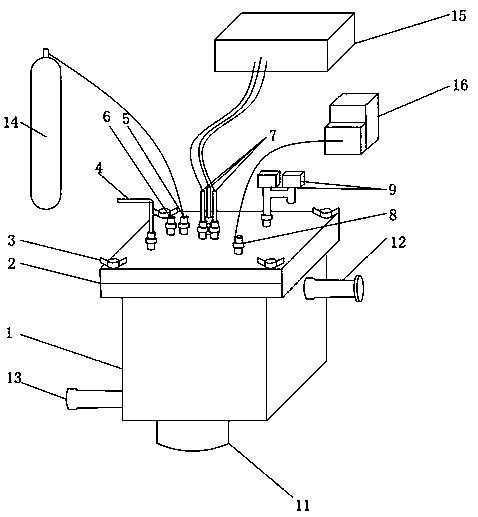

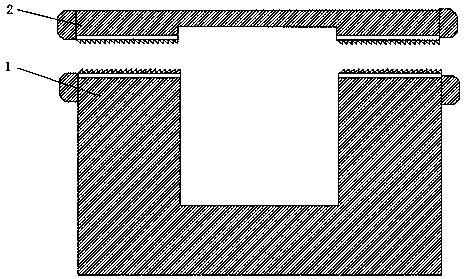

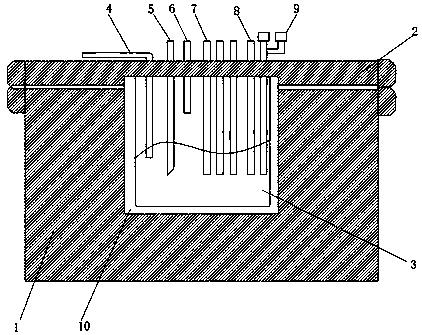

[0039] Embodiment 1: as Figure 1-4 As shown, the present invention provides a technical solution, a corrosion and fouling experimental detection system in the heat exchange process of geothermal water, including a gradient heat transfer simulation system main body 1, and a gradient heat transfer simulation system is installed on the top of the gradient heat transfer simulation system main body 1 Cover plate 2, the four corners of the upper cover plate 2 of the gradient heat transfer simulation system are fixed and installed with the main body 1 of the gradient heat transfer simulation system through fixing nuts;

[0040] The surface of the upper cover plate 2 of the gradient heat exchange simulation system is provided with a liquid inlet 4, an air inlet 5, an exhaust port 6 and a pH adjustment port 8, and the surface of the upper cover plate 2 of the gradient heat exchange simulation system is connected with a three-electrode system 7 and a liquid phase monitoring device 9, a...

Embodiment 2

[0052] Embodiment 2: The present invention provides a technical solution, a method for detecting corrosion and scaling dynamic simulation experiments applicable to geothermal water heat exchange processes, comprising the following steps:

[0053] S1. Install the reaction pool 3 in the upper cover plate 2 of the gradient heat transfer simulation system, apply sealing grease on the interface thread, and fill the liquid metal 10 between the reaction pool 3 and the main body 1 of the gradient heat transfer simulation system to increase To achieve high heat transfer efficiency, apply sealing grease on the PTFE substrate on both sides of the main body 1 of the gradient heat transfer simulation system and the upper cover plate 2 of the gradient heat transfer simulation system, cover the cover plate and fix the seal with bolts in turn, Sealing rubber rings are installed at the joints of the components on the board, and sealing grease is applied to the joints;

[0054] S2. Install the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com