Patents

Literature

134results about How to "Low-temperature fixability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Toner and image forming method using the toner

ActiveUS20060057488A1Excellent hot offset resistanceHigh quality imagingDevelopersImage formationGlass transition

A toner satisfying at least one of the following relationships: 10° C.<(T1−T2)<60° C. and 0<Q2 / Q1<2 / 3 wherein T1 represents a glass transition temperature of the toner and Q1 represents an endothermic quantity at a melting point thereof before melting when heated from −20° C. to 150° C. at a heating speed of 10° C. / min, and T2 represents a glass transition temperature thereof and Q2 represents a an endothermic quantity at a melting point thereof after melting after heated from −20° C. to 150° C. at a heating speed of 10° C. / min, cooled to −20° C. at a cooling speed of 10° C. / min and heated again at a heating speed of 10° C. / min.

Owner:RICOH KK

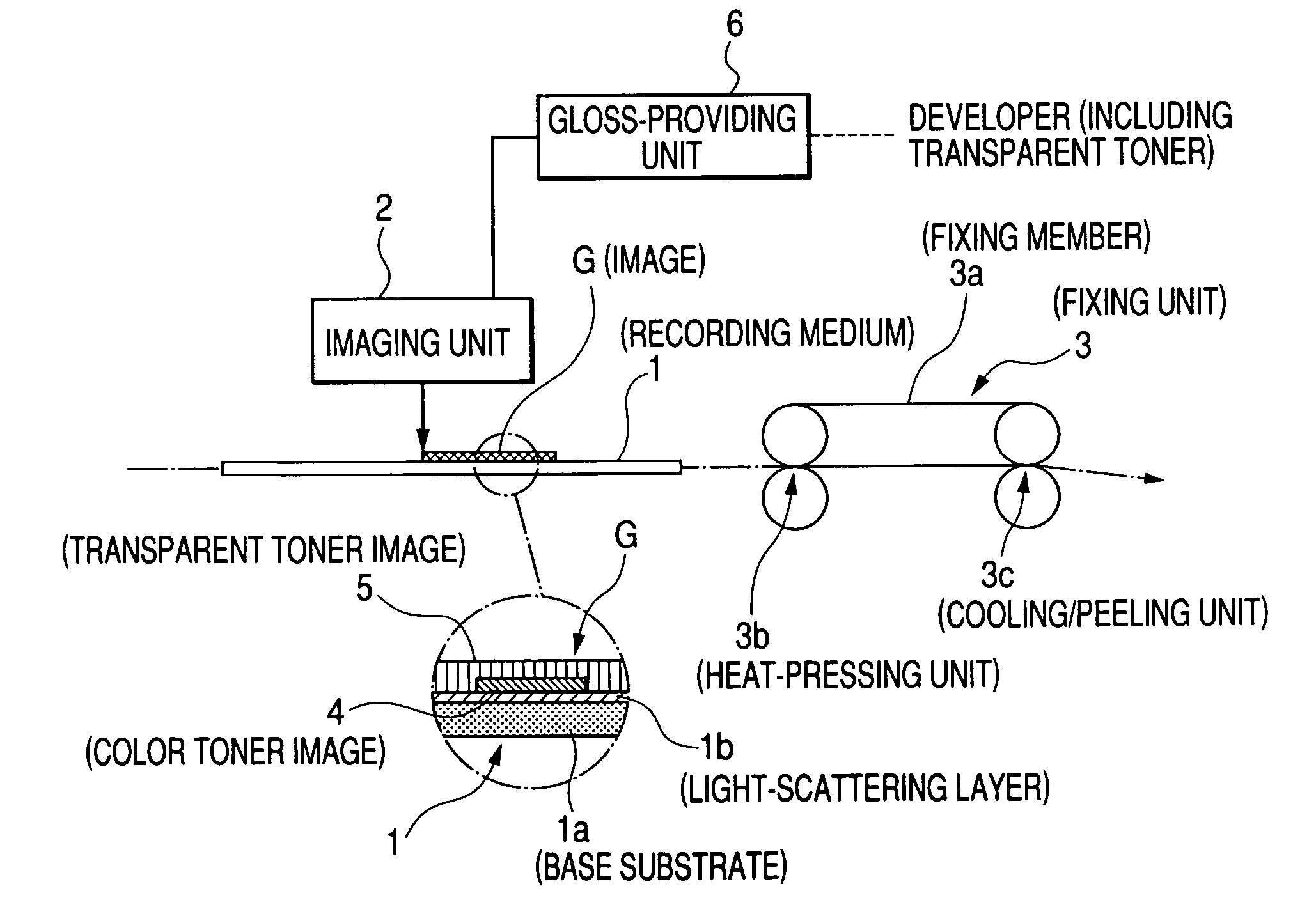

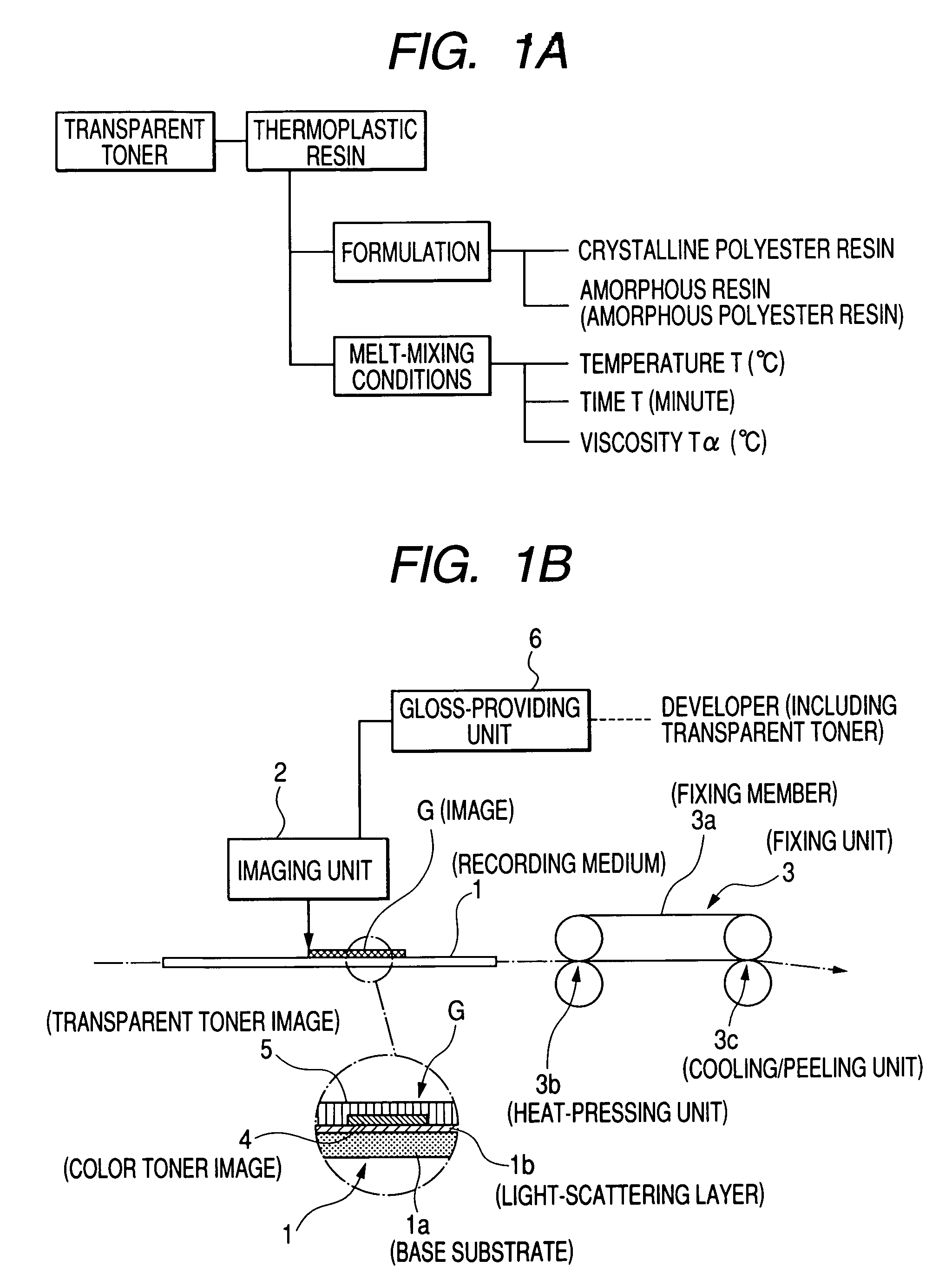

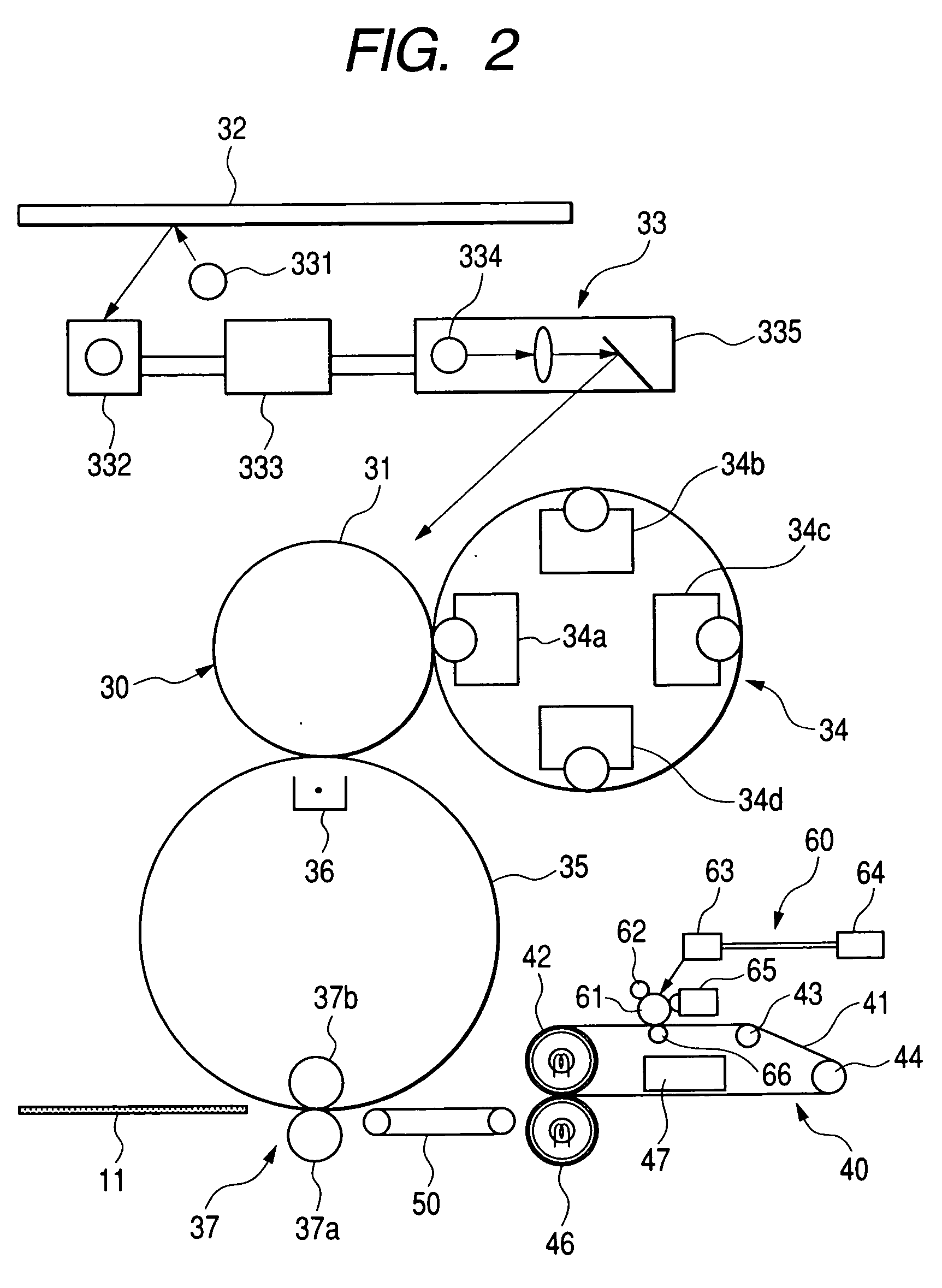

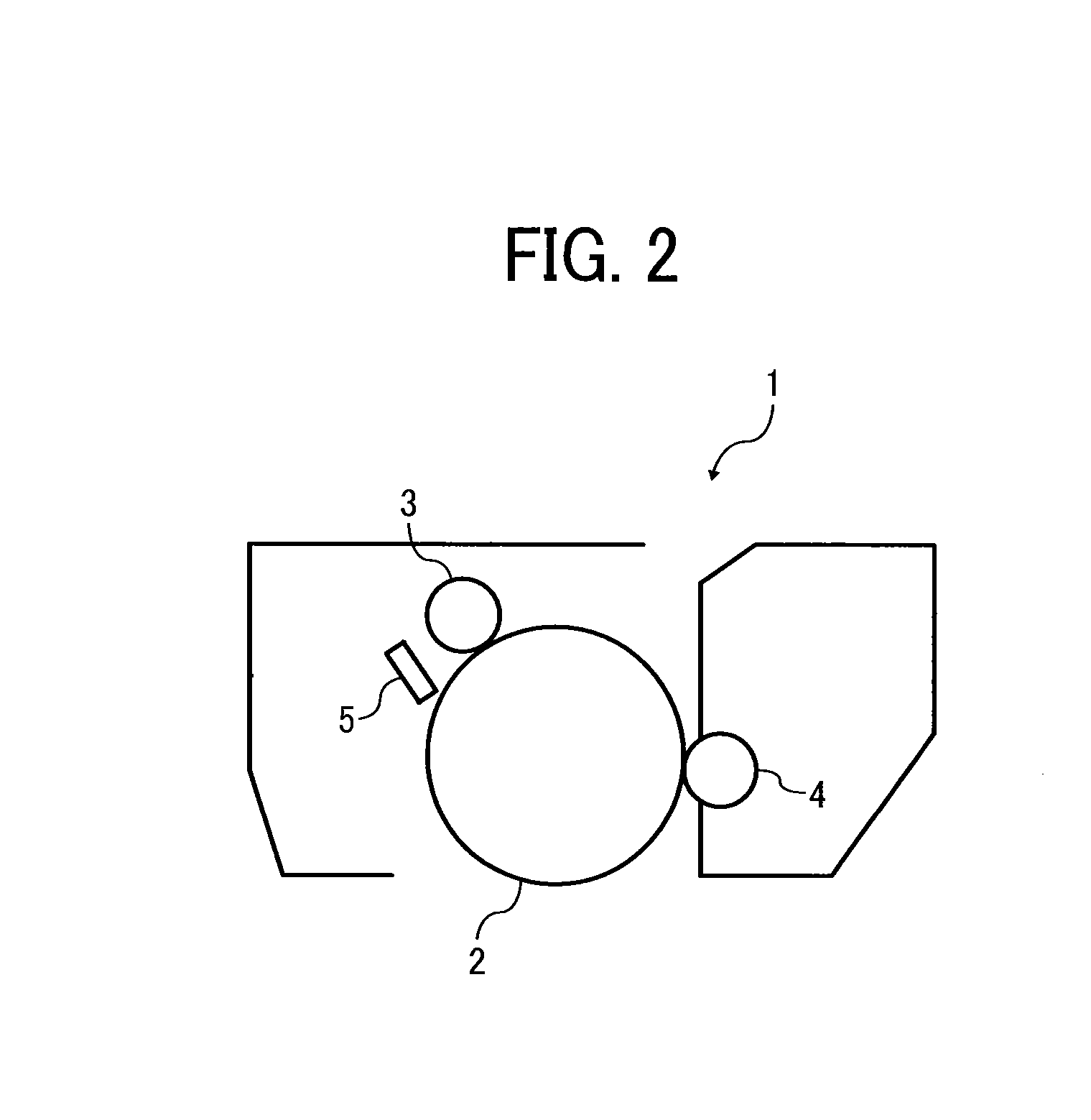

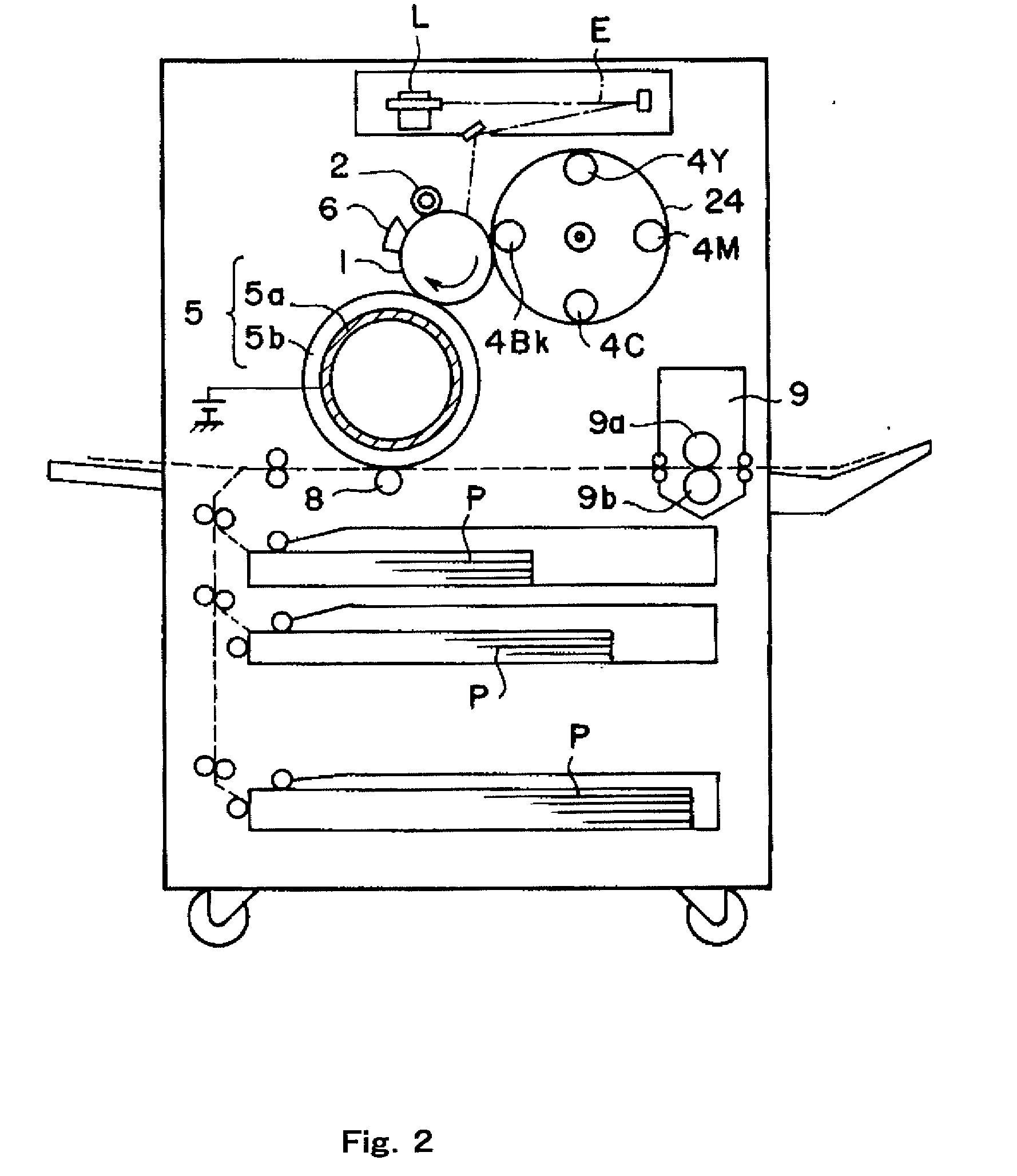

Transparent toner, developer including same, gloss-providing unit and image forming device

InactiveUS20050214669A1High general qualityLow temperature fixabilityDevelopersElectrographic process apparatusChemistryReflectivity

A transparent toner to be used for a transparent toner image formed with a color toner image, wherein a thermoplastic resin constituting the transparent toner is made of a resin obtained by melt-mixing a crystalline polyester resin and an amorphous resin under the conditions such that supposing that T0 (° C.) is the temperature at which the visual reflectance Y of 20 μm thick film formed by the resin obtained by melt-mixing the crystalline polyester resin and the amorphous resin for a period of time t0 (minute) is 1.5%, the melt-mixing temperature is T (° C.) and the melt-mixing time is t (minute), T (° C.) is predetermined to be from T0 to (T0+30), t (minute) is predetermined to be from t0 to (10×t0) and the temperature Tα at which the viscosity of the thermoplastic resin is 103 Pa·s is from 70° C. to 110° C.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Toner, developer, image forming method, and toner container

ActiveUS20070015077A1Quality improvementHigh color reproductionDevelopersElectrographic processes using charge patternPolyesterParticulates

A toner is provided manufactured by a method having the steps: dispersing toner constituents including a resin, in an aqueous medium containing a particulate resin, wherein the resin has a polyester skeleton formed by a ring-opening addition reaction of a cyclic ester with a first compound having an active hydrogen group; and a developer and an image forming method using the toner, and a toner container containing the toner.

Owner:RICOH KK

Toner, method for preparing the toner, and developer including the toner

A toner including a binder resin comprising a polyester resin in an amount of from 50 to 100% by weight, wherein the polyester resin includes an unsaturated polyester resin which is preferably a crystalline polyester resin; a colorant; and a fatty acid metal salt which is preferably microencapsulated. A method for preparing a toner including forming particles of a toner composition including at least a binder resin including a polyester resin in an amount of from 50 to 100% by weight and a colorant, in an aqueous medium to prepare a dispersion of a particulate material, wherein the polyester resin includes an unsaturated polyester resin; drying the particulate material; and mixing a fatty acid metal salt with the particulate material to subject double bonds of the unsaturated polyester resin to oxidation polymerization.

Owner:RICOH KK

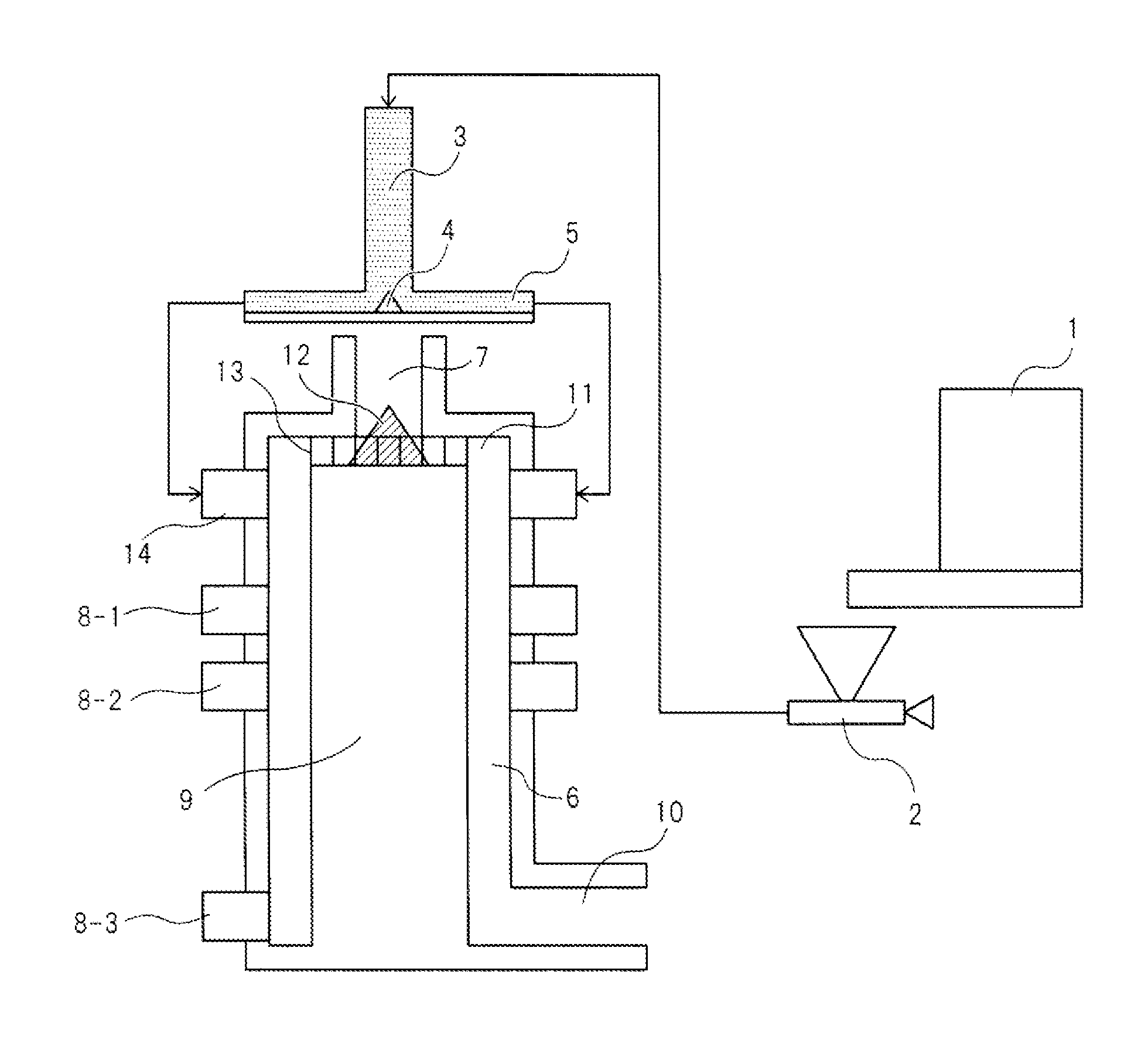

Method for preparing resin and particulate material, toner prepared by the method, developer including the toner, toner container, and process cartridge, image forming method and apparatus using the developer

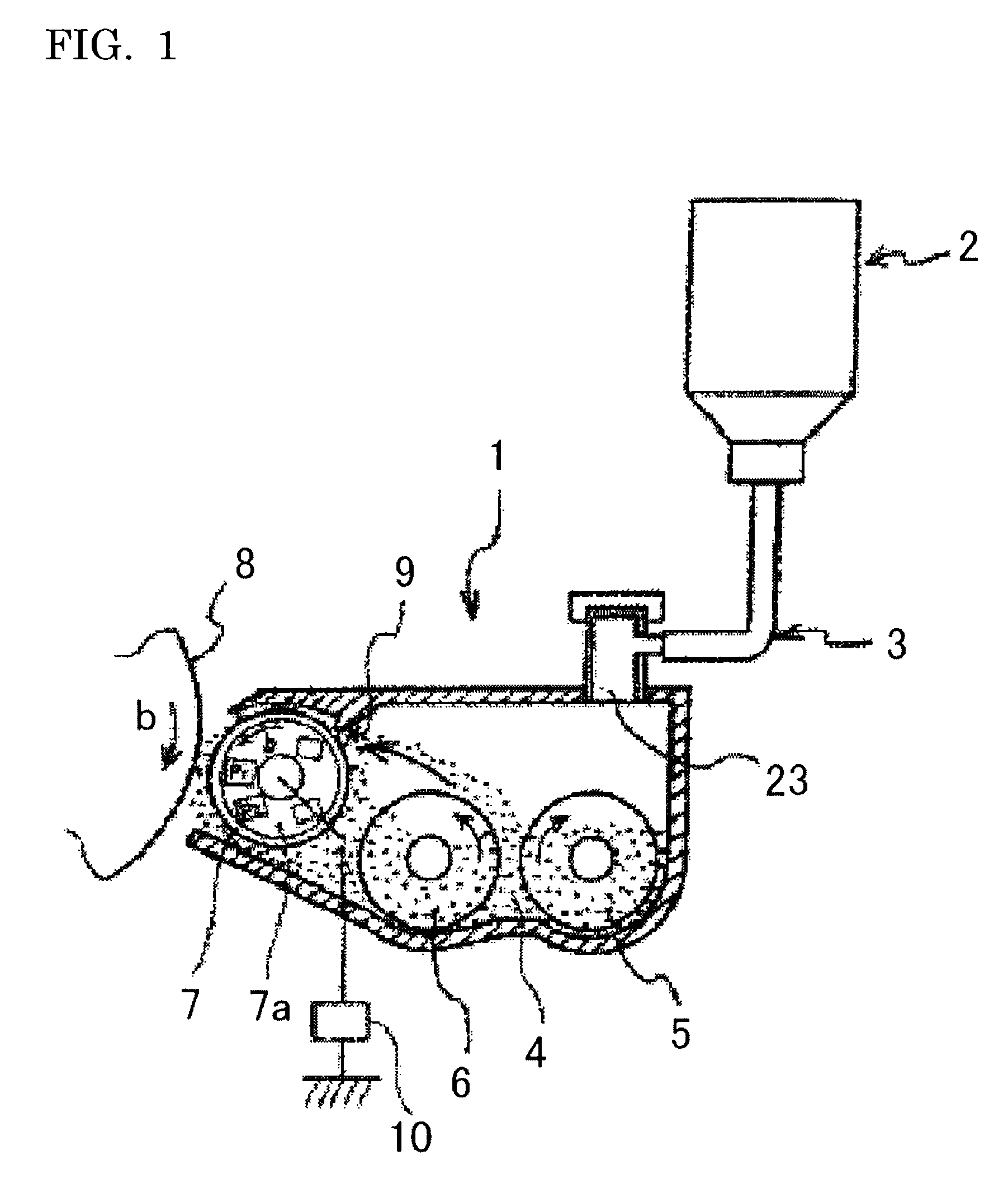

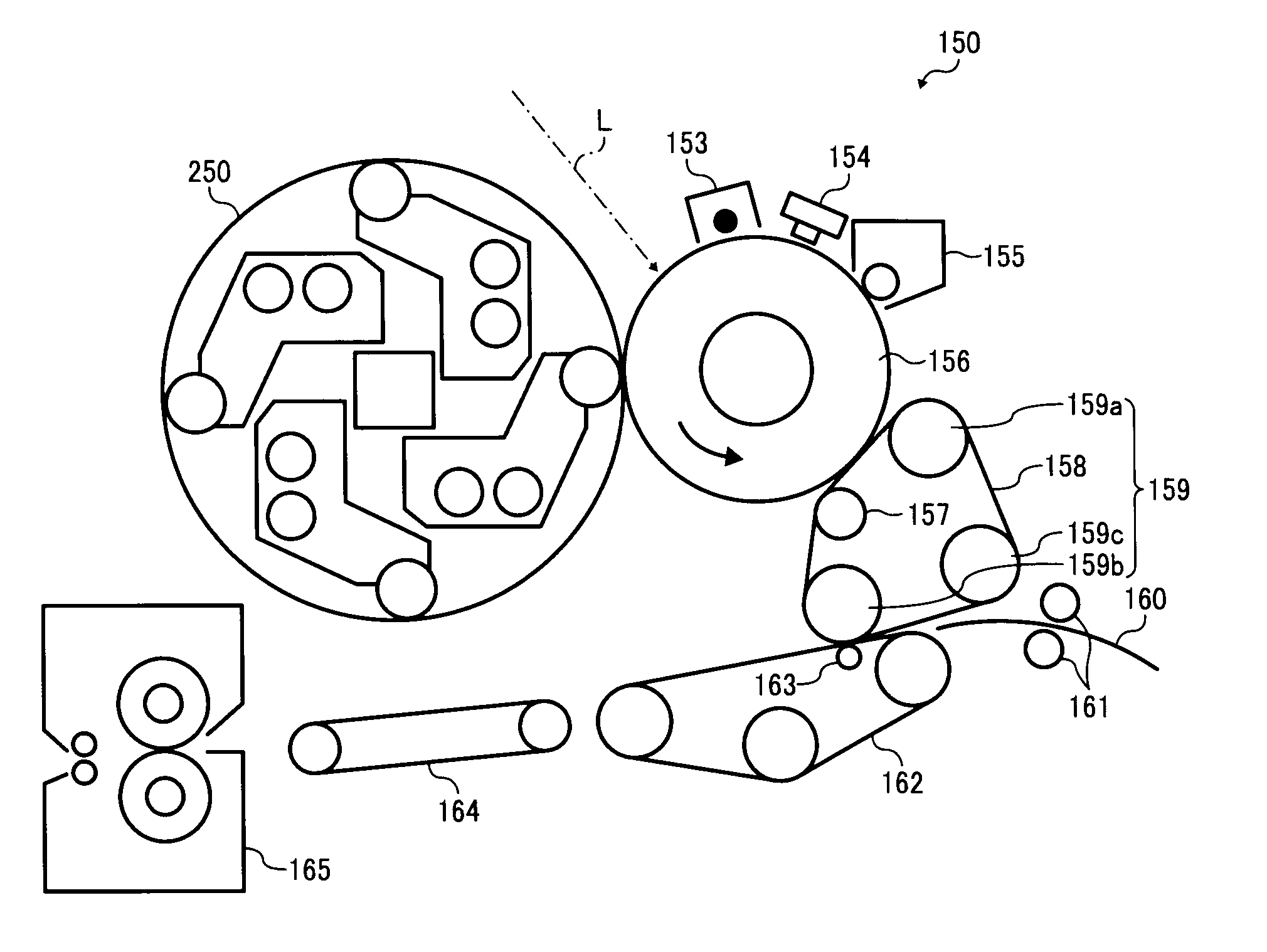

A method for preparing a particulate image forming material such as toner, which includes providing a particulate material including a chain transfer agent; and contacting the particulate material with at least one of a supercritical fluid and a sub-critical fluid under pressure to remove the chain transfer agent from the particulate material. A toner prepared by the method. A toner container containing the toner. A developer including the toner. An image forming method including preparing an electrostatic latent image and developing the latent image with the developer. An image forming apparatus including an image bearing member configured to bear an electrostatic latent image, a developing device configured to develop the electrostatic latent image with the developer to form a toner image on the surface of the image bearing member, a transfer device, a fixing device, and a cleaner configured to clean the image bearing member.

Owner:RICOH KK

Toner

The present invention relates to a toner including a toner particle containing a binder resin, wherein the binder resin contains a block polymer and a styrene-acrylic resin, the block polymer has a vinyl polymer segment and a polyester segment, the polyester segment has a branch structure and the block polymer has a melting point of 50° C. to 95° C.

Owner:CANON KK

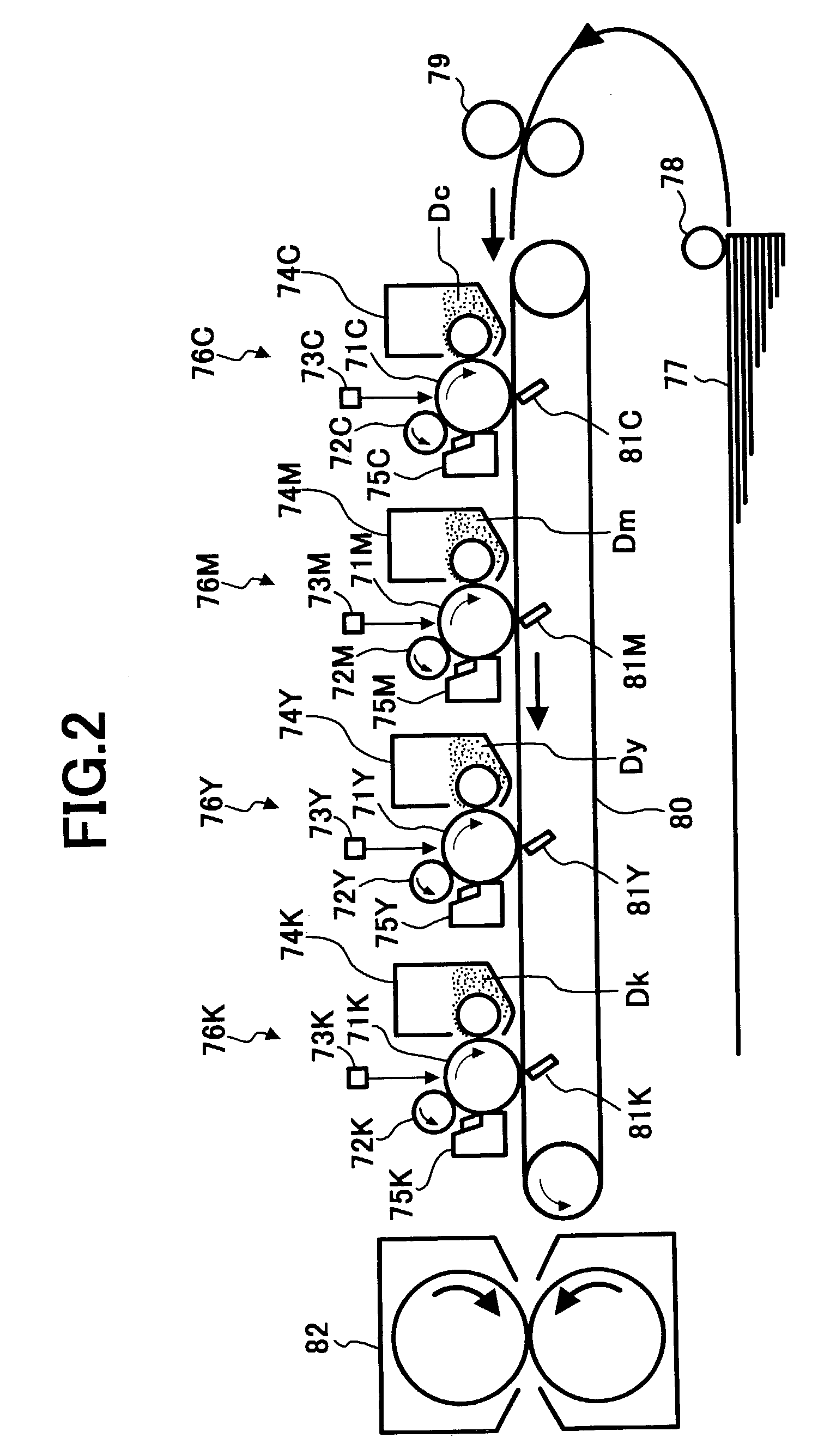

Color toner for developing electrostatic images, toner container containing the color toner, and image forming method and apparatus using the color toner

InactiveUS20050277046A1Low temperature fixabilityGood transferabilityDevelopersElectrographic processes using charge patternWaxImage formation

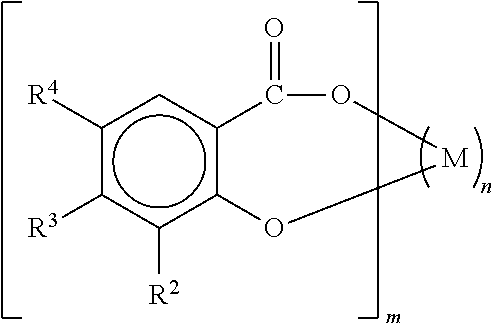

A color toner including toner particles including a colorant, a binder resin, and a wax; and an external additive including at least one of an inorganic particulate material and a particulate resin, wherein the binder resin includes a polyester resin (A) having a crystallinity and a formula (—O—CO—CR1═CR2—CO—O—(CH2)n—)m, wherein R1 and R2 independently represents a hydrocarbon, and n and m are repeating numbers; a resin (B); and a resin (C), wherein the resins (B) and (C) and the wax have an island-sea structure such that the resin (C) is present like islands in a sea of the resin (B) and the wax is substantially included in the resin (C). A toner container, an image forming method, an image forming apparatus and a process cartridge including the color toner are also provided.

Owner:SAWADA TOYOSHI +6

Toner and image forming method using the same

InactiveUS20060177756A1Excellent combination of low temperature fixabilityExcellent combination of heat-resistant propertyDevelopersPlasticizerImage formation

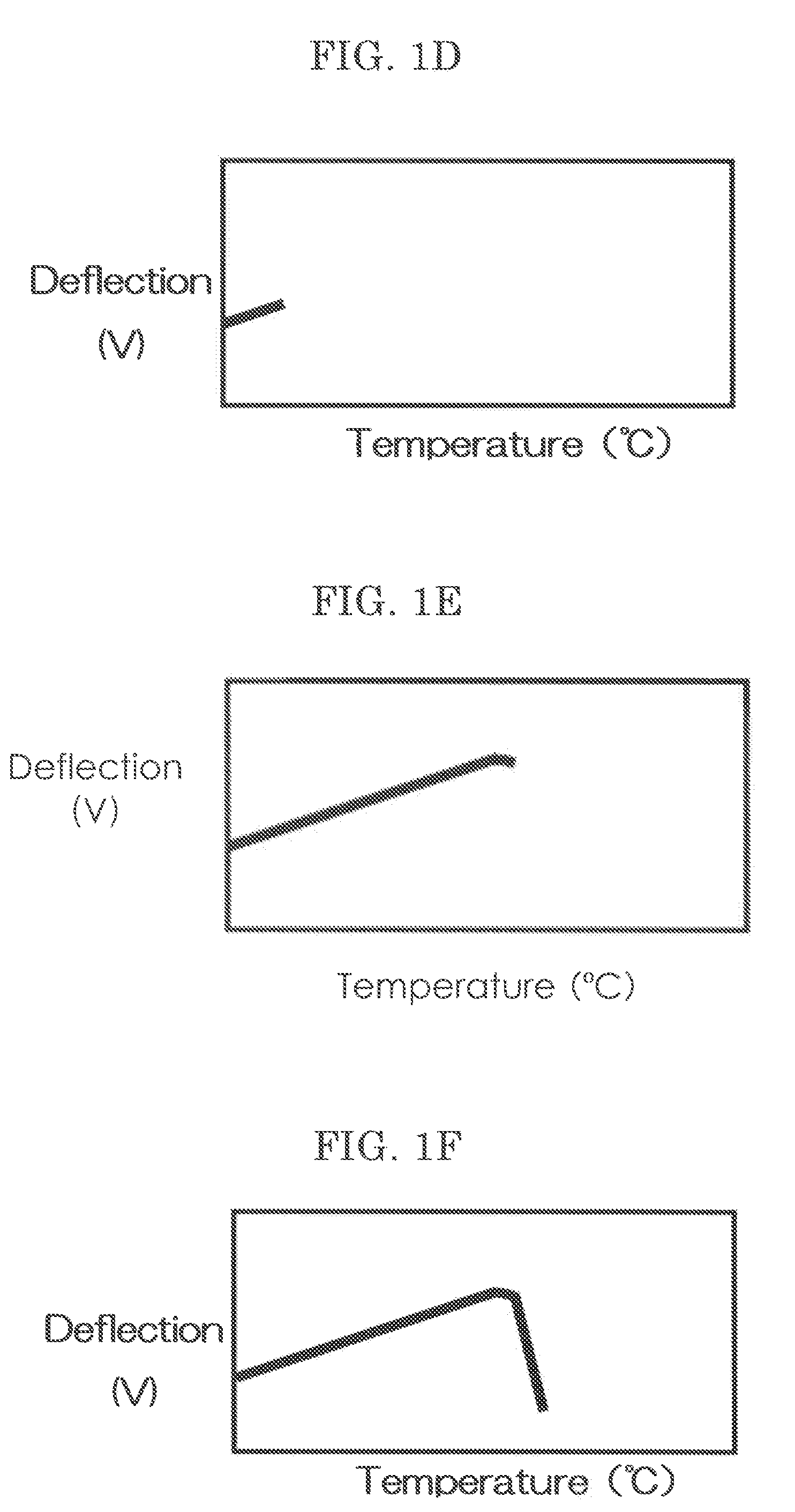

A toner formed of a toner composition containing a resin and a plasticizer, wherein the following relationships (1) and (2) are satisfied: Tg2r>Tg2t (1), and Tg1t−Tg2t>Tg1r−Tg2r (2), wherein Tg1r represents the peak of the resin for the first temperature rise and Tg2r represents the peak of the resin for the second temperature rise when a differential scanning calorimeter (DSC) measurement is performed for the resin, Tg1t represents the peak of the toner comprising the resin for the first temperature rise and Tg2t represents the peak of the toner comprising the resin for the second temperature rise when a differential scanning calorimeter (DSC) measurement is performed for the toner.

Owner:RICOH KK

Toner, method for manufacturing the toner, developer including the toner, toner container containing the toner, and image forming method, image forming apparatus and process cartridge using the toner

ActiveUS20070141506A1Conducive to preservationLow temperature fixabilityDevelopersParticulatesVitrification

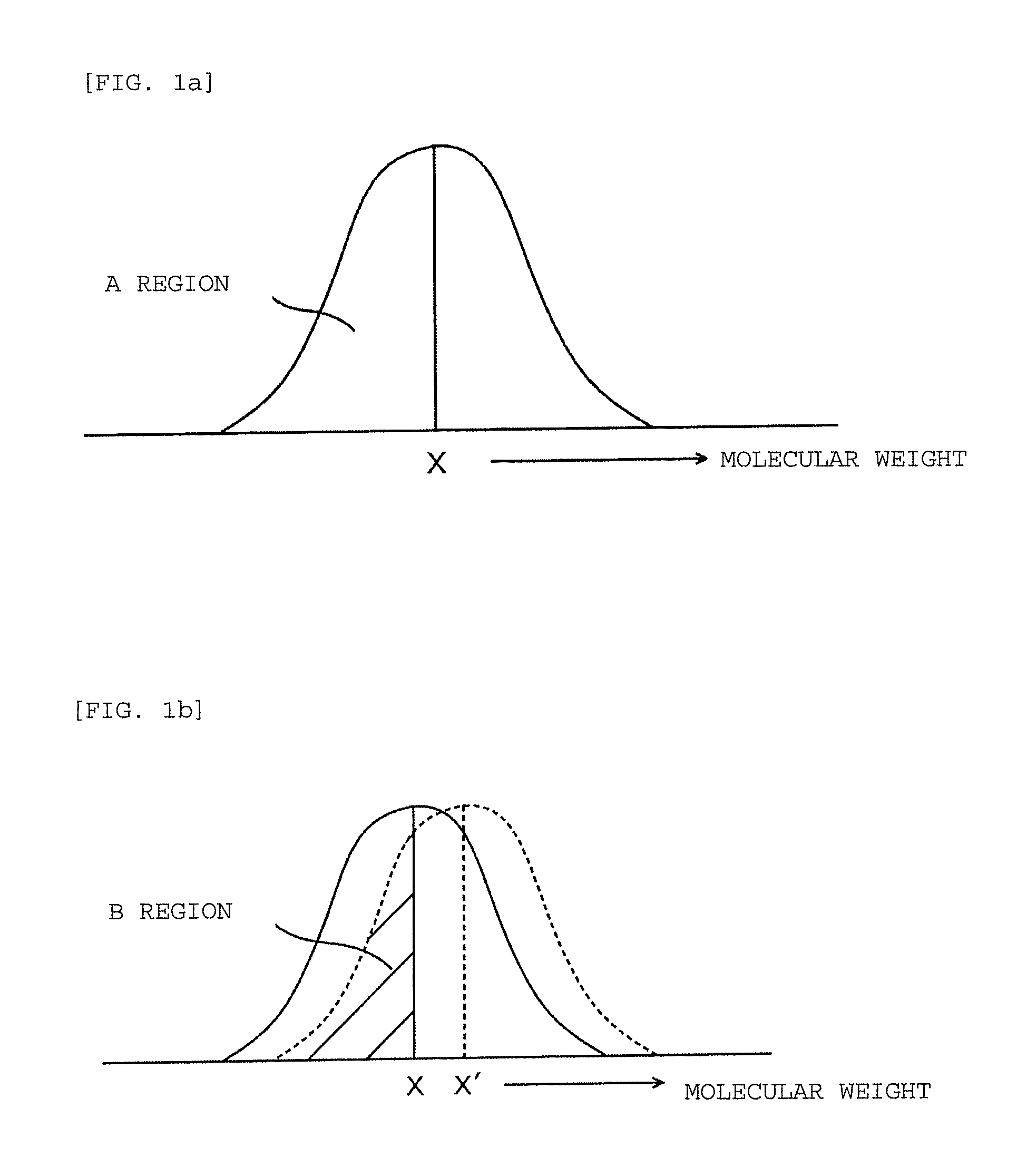

A toner including toner particles comprising a binder resin; and at least two kinds of particulate resins which are located on at least a surface of the toner particles, wherein the toner satisfies at least one of the following relationships (TgA−TgB)≧20° C., wherein TgA and TgB represent glass transition temperatures (Tg) of a particulate resin (A) having a highest Tg and a particulate resin (B) having a lowest Tg among the at least two kinds of particulate resins, respectively; and 100,000≦Mwc≦6,000,000 and 8,000≦Mwd≦800,000, wherein Mwc and Mwd represent weight average molecular weights (Mw) of a particulate resin (C) having a highest Mw and a particulate resin (D) having a lowest Mw among the at least two kinds of particulate resins, respectively, wherein Mwc>Mwd.

Owner:RICOH KK

Toner and two-component developer

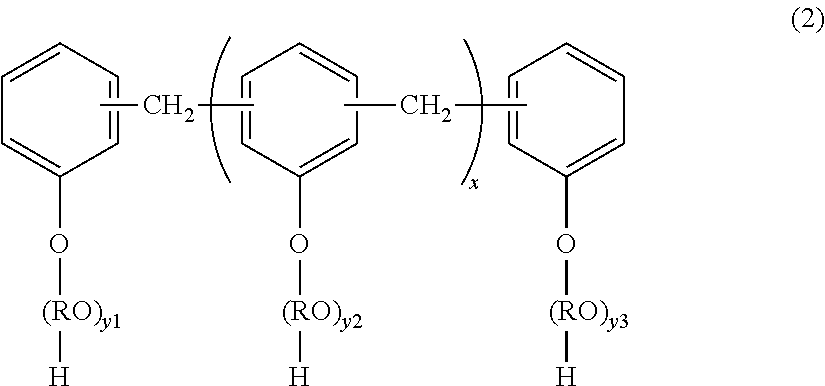

Provided is a toner obtained by melting and kneading a binder resin containing a polyester resin A and a polyester resin B, a colorant, and a wax, in which in the resin A, the content of a polyhydric alcohol unit derived from an aromatic diol, the content of a polyhydric alcohol unit derived from an oxyalkylene ether of a novolac type phenol resin, and the content of a polyvalent carboxylic acid unit derived from an aliphatic dicarboxylic acid, which contains a straight-chain hydrocarbon having 4 or more to 16 or less carbon atoms as a main chain and has carboxyl groups at both of its terminals, fall within specific ranges, and in the resin B, the content of a polyhydric alcohol unit derived from an aromatic diol and the content of a polyvalent carboxylic acid unit derived from an aromatic dicarboxylic acid or a derivative thereof fall within specific ranges.

Owner:CANON KK

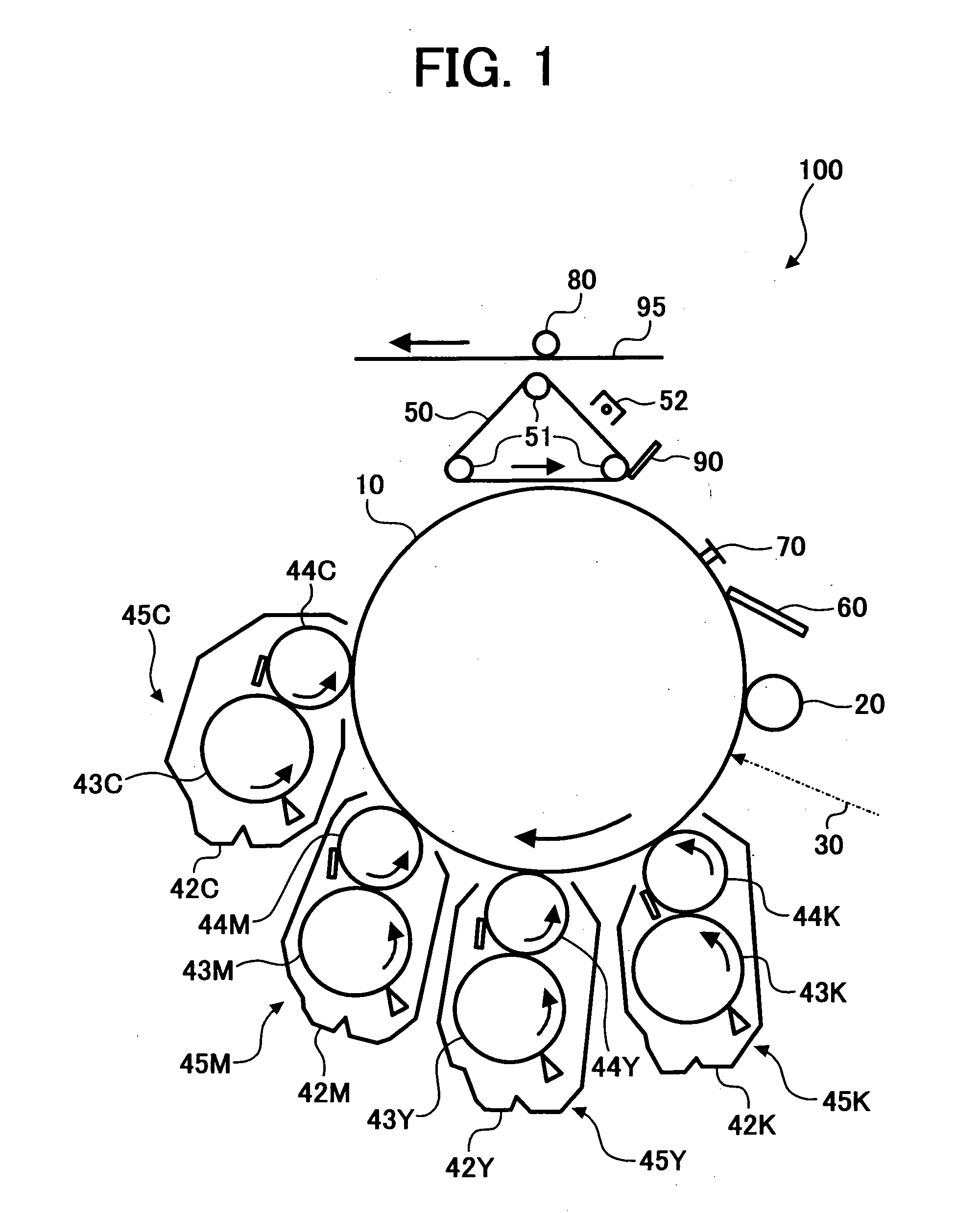

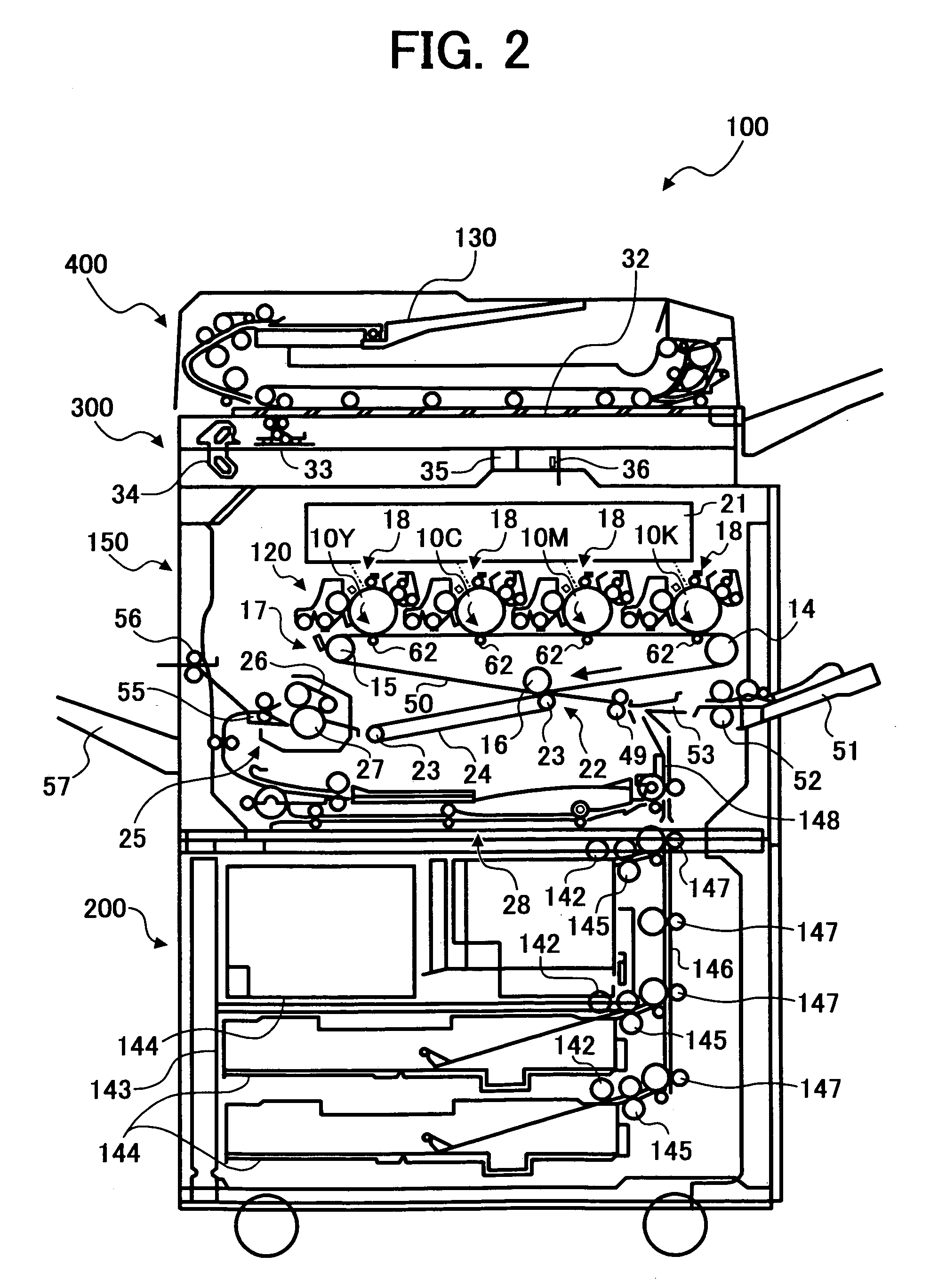

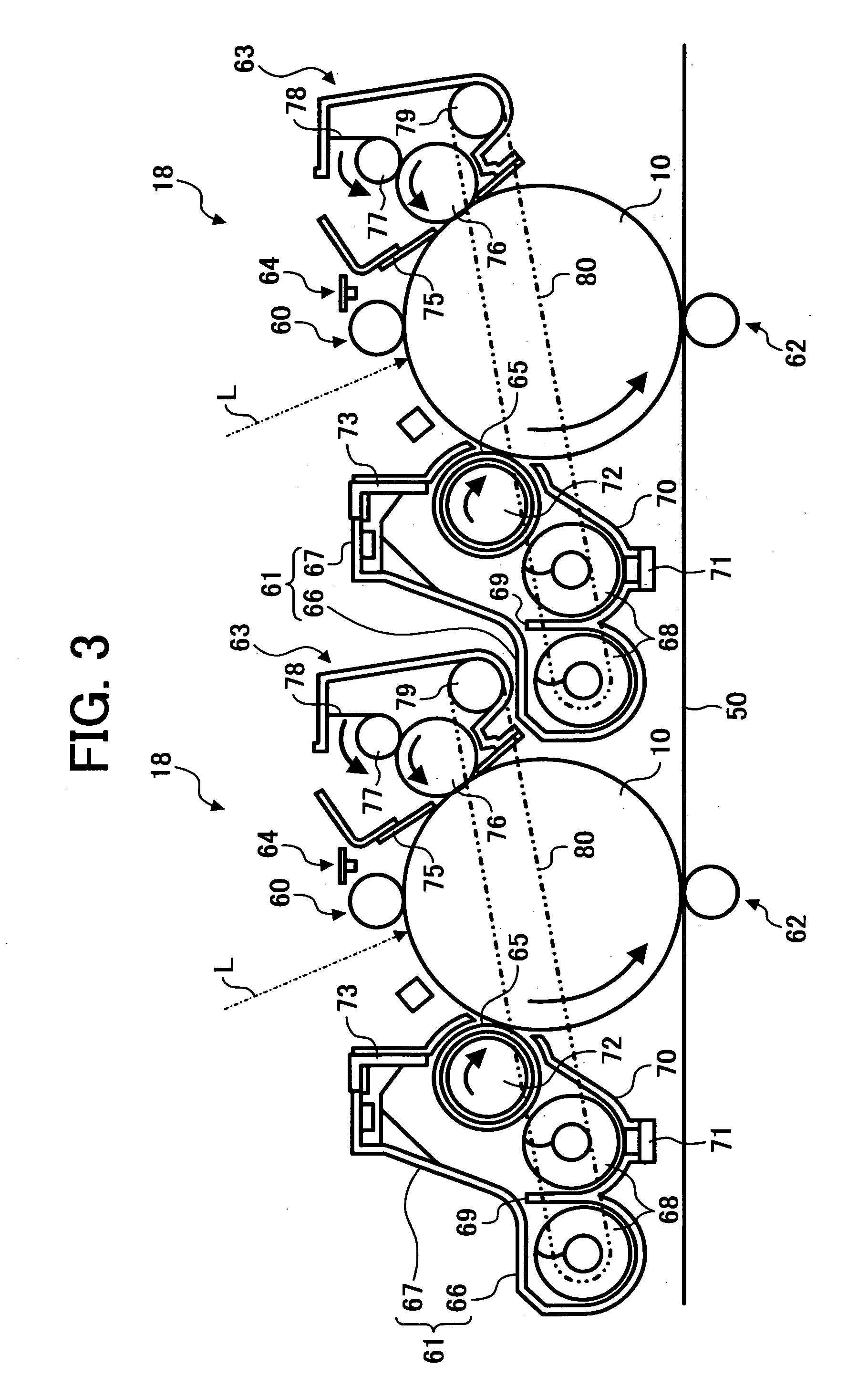

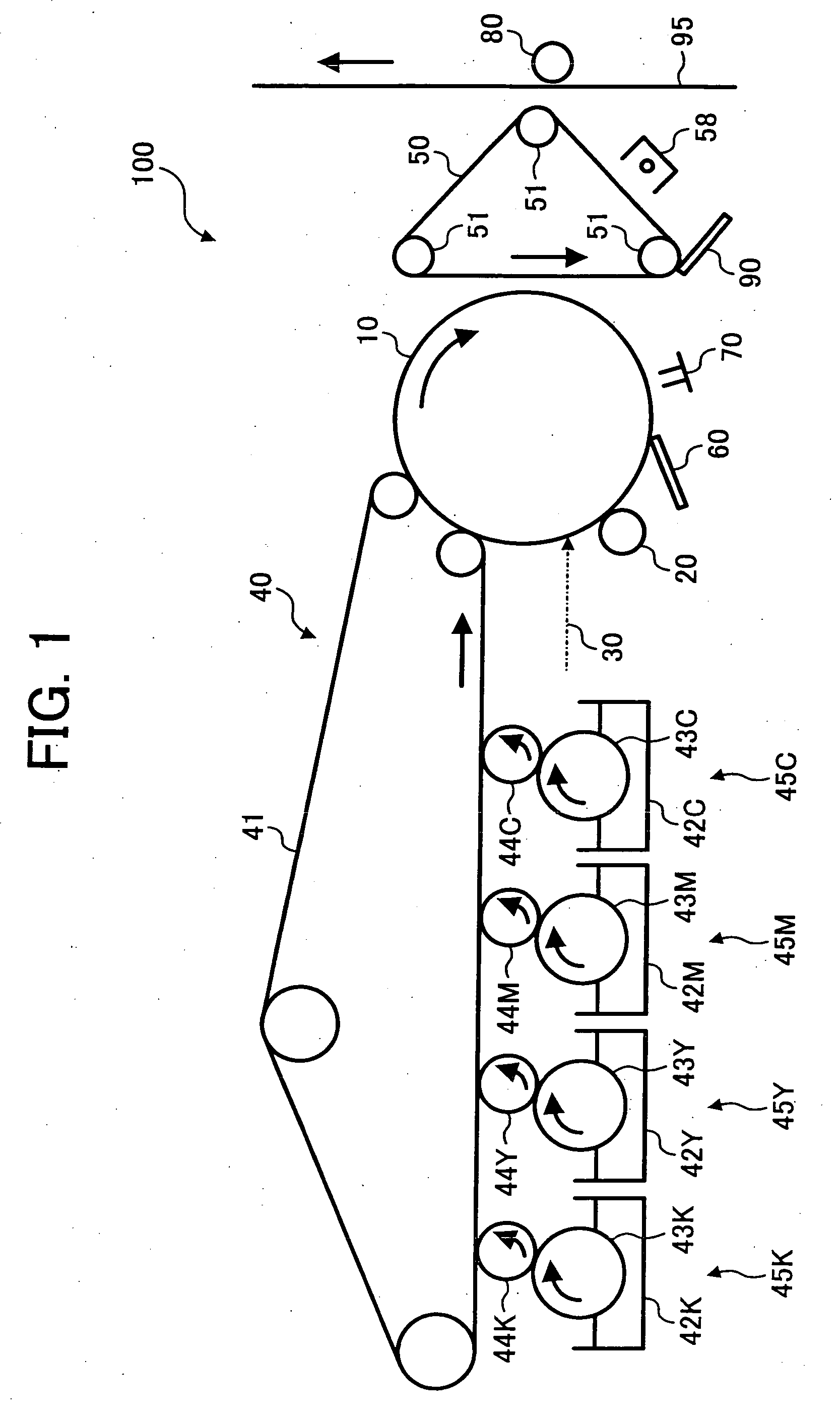

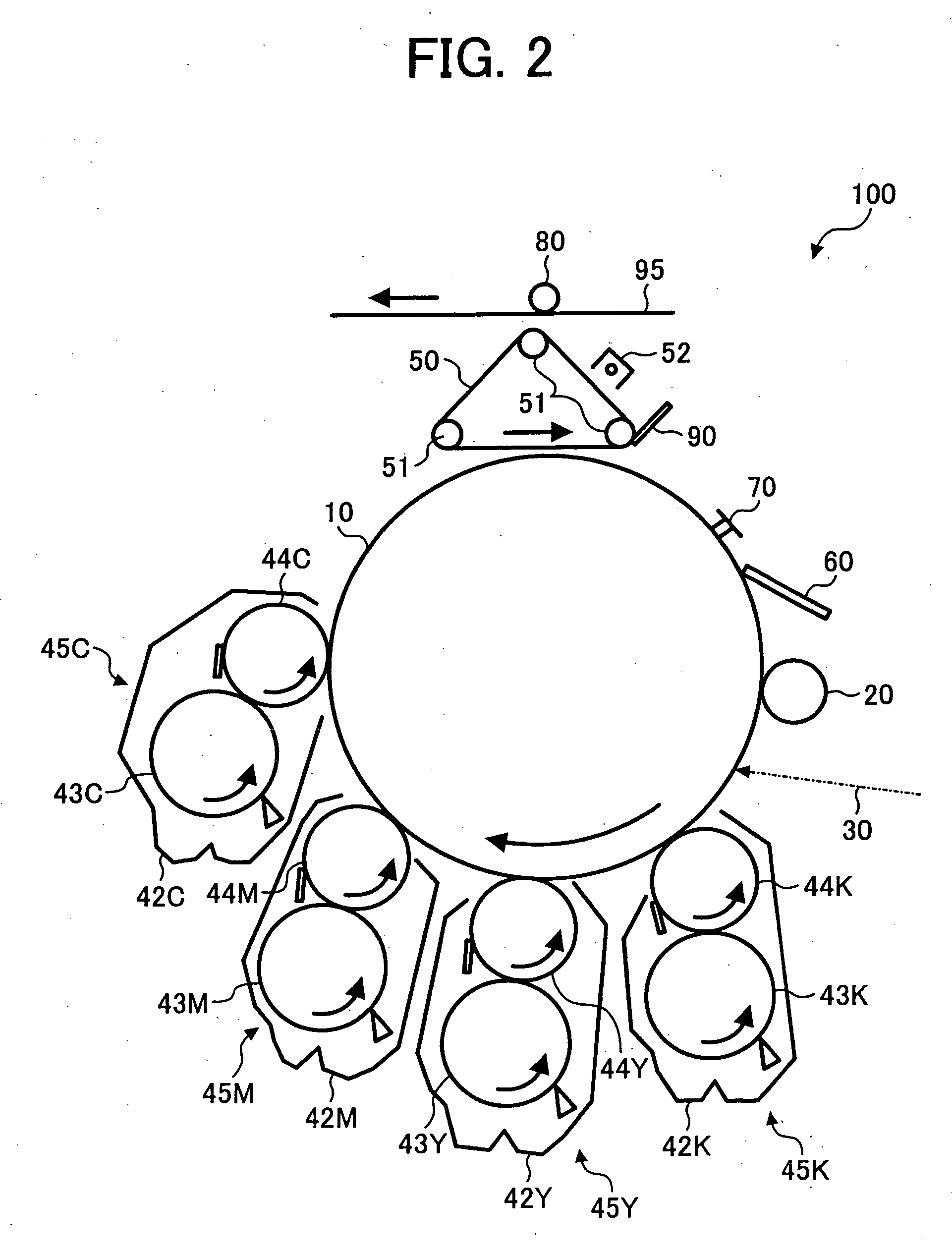

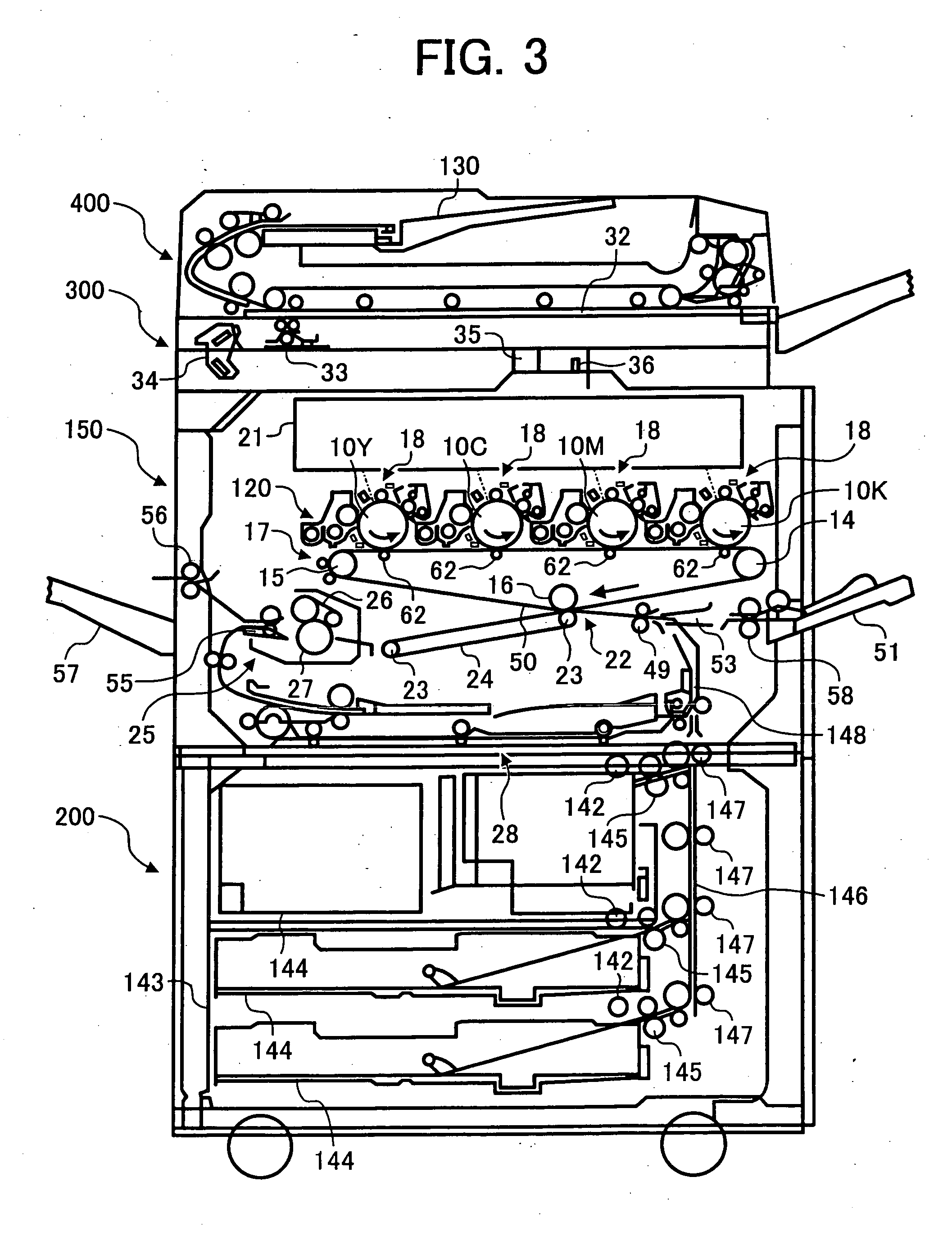

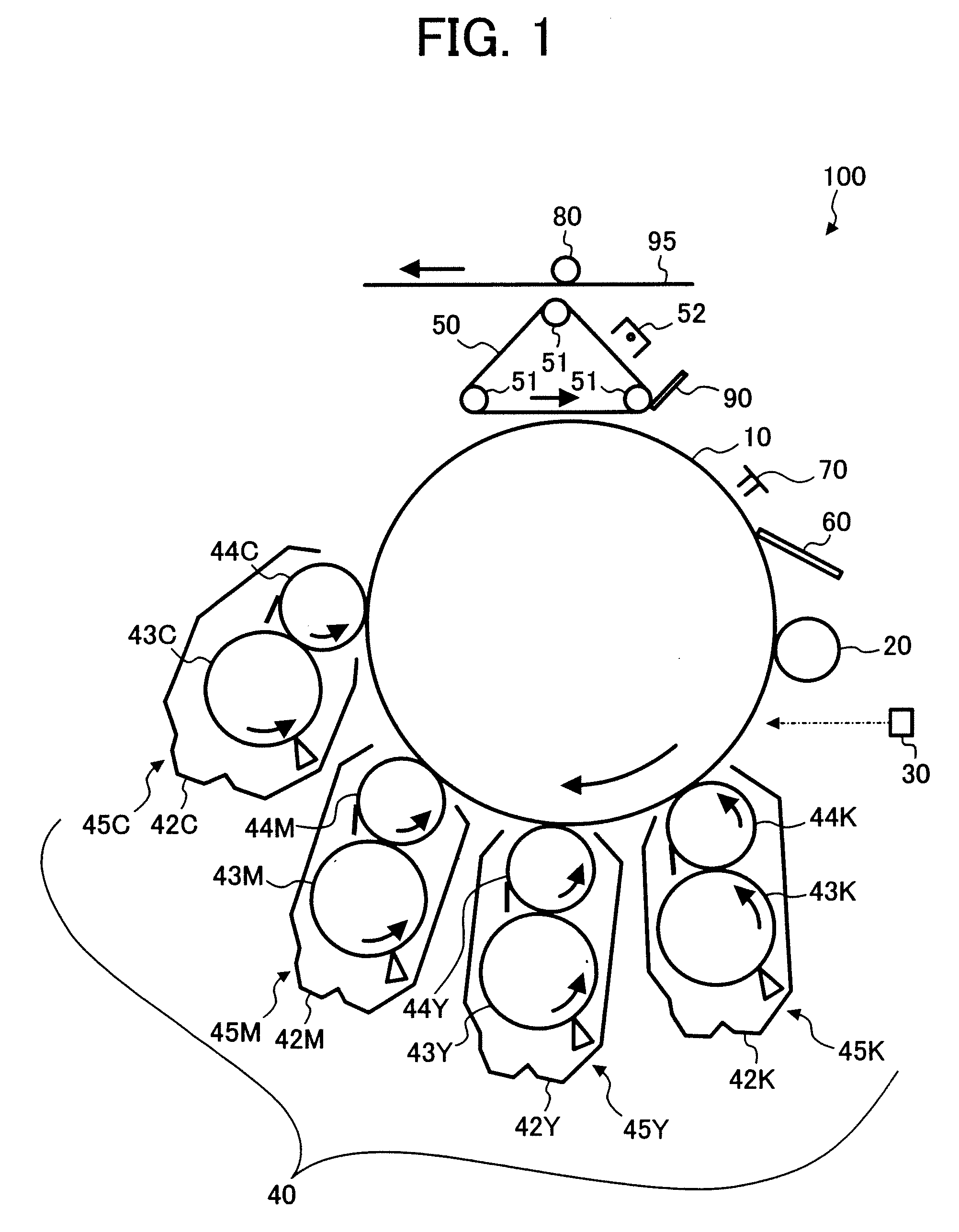

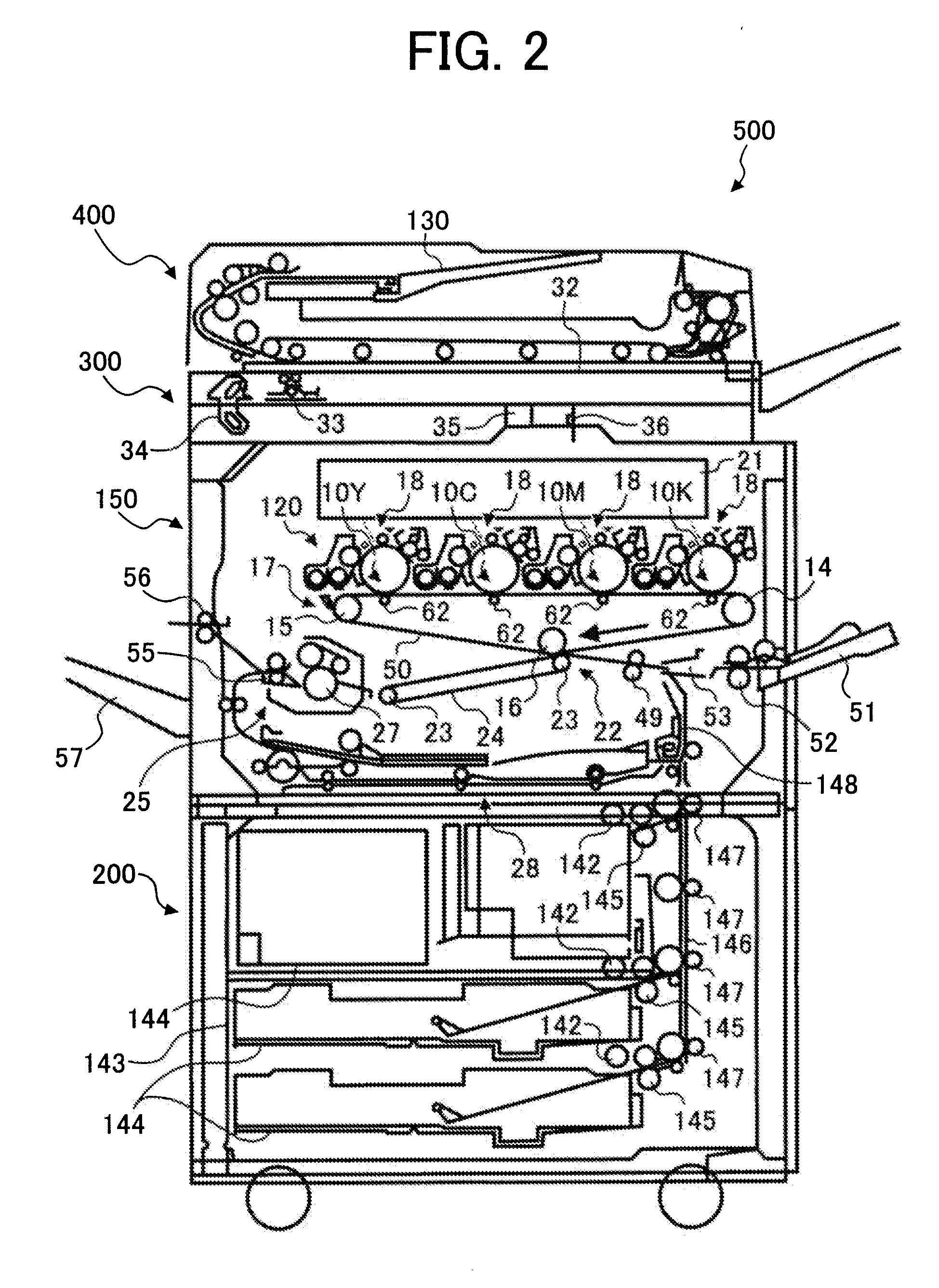

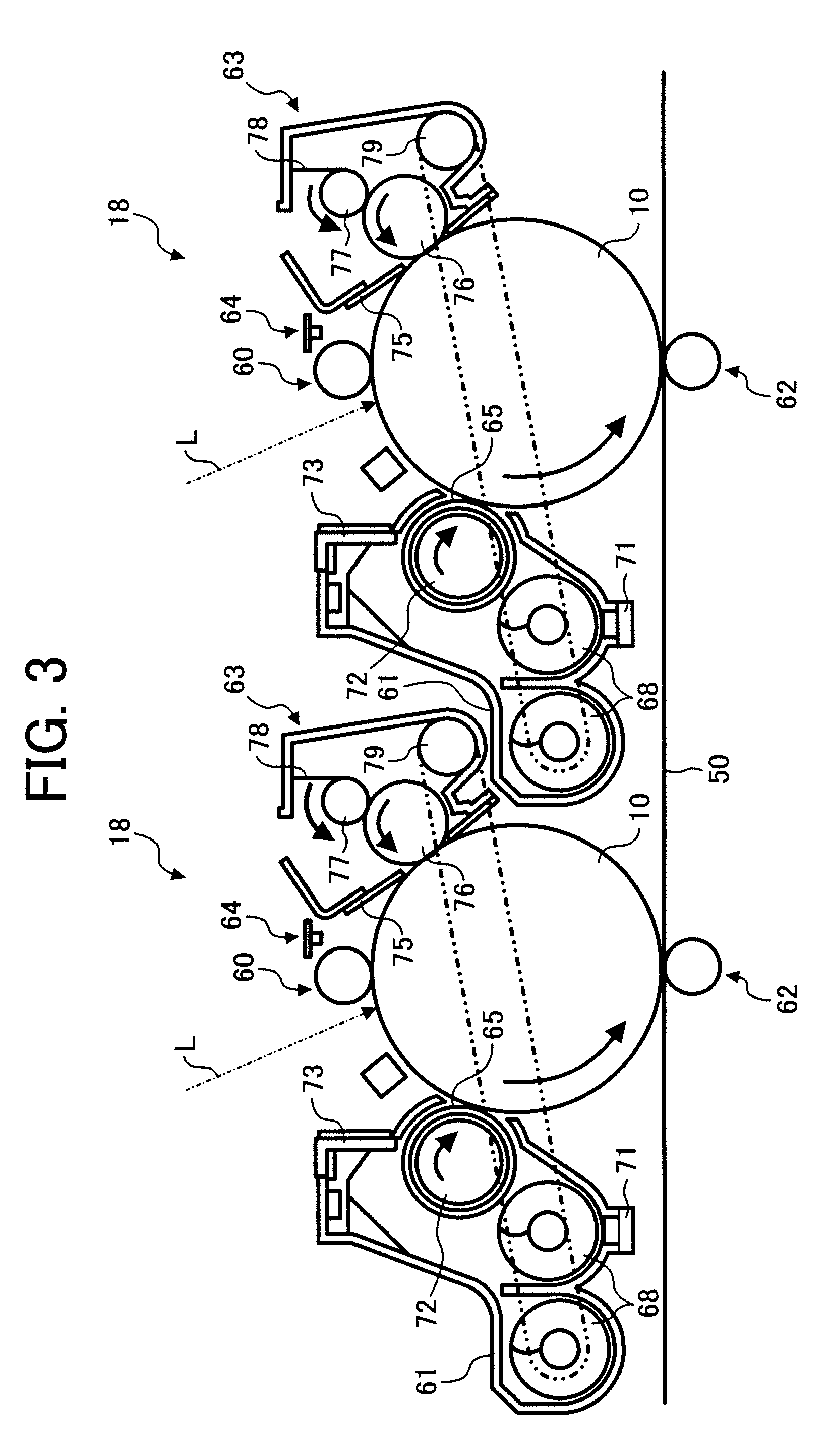

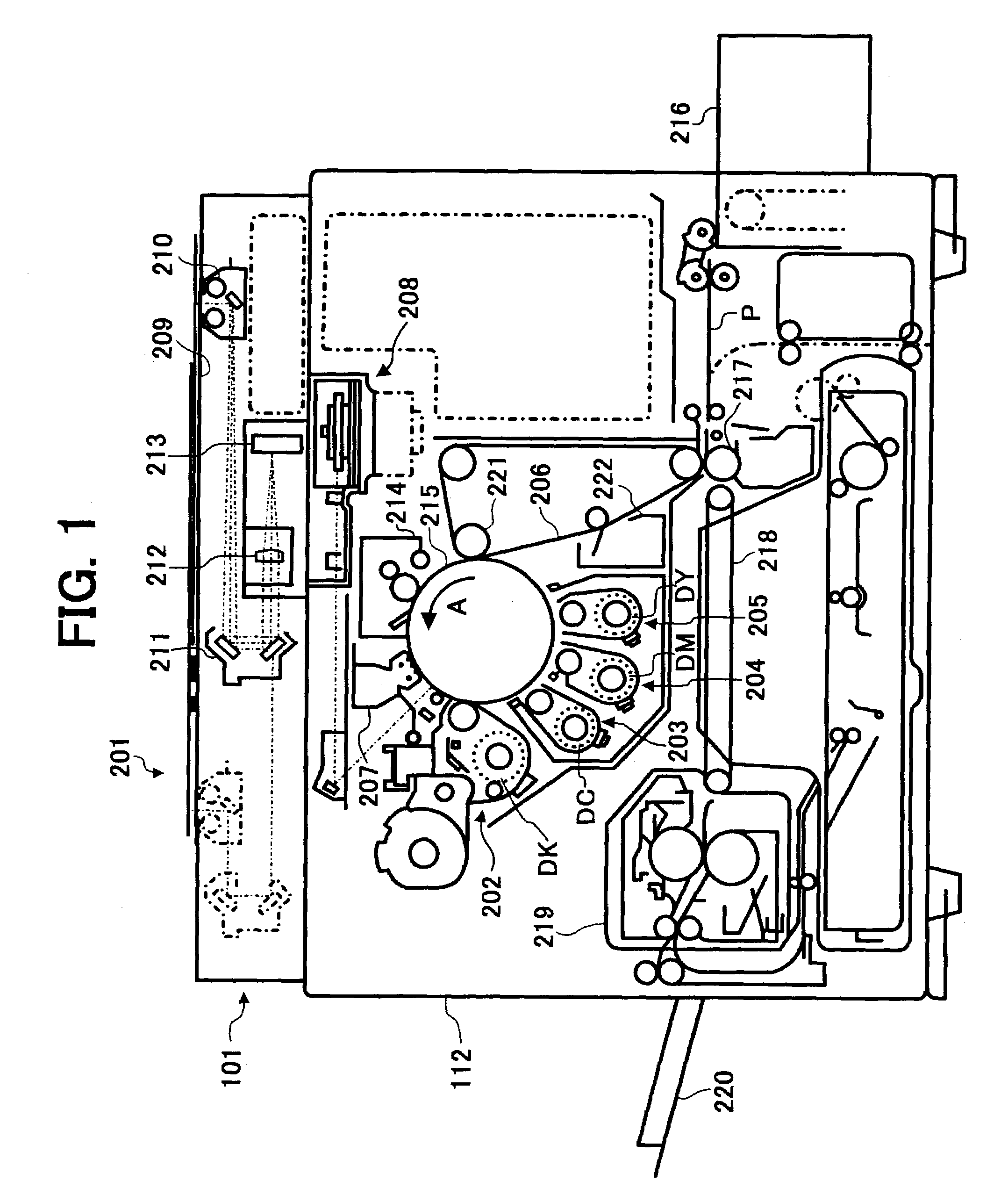

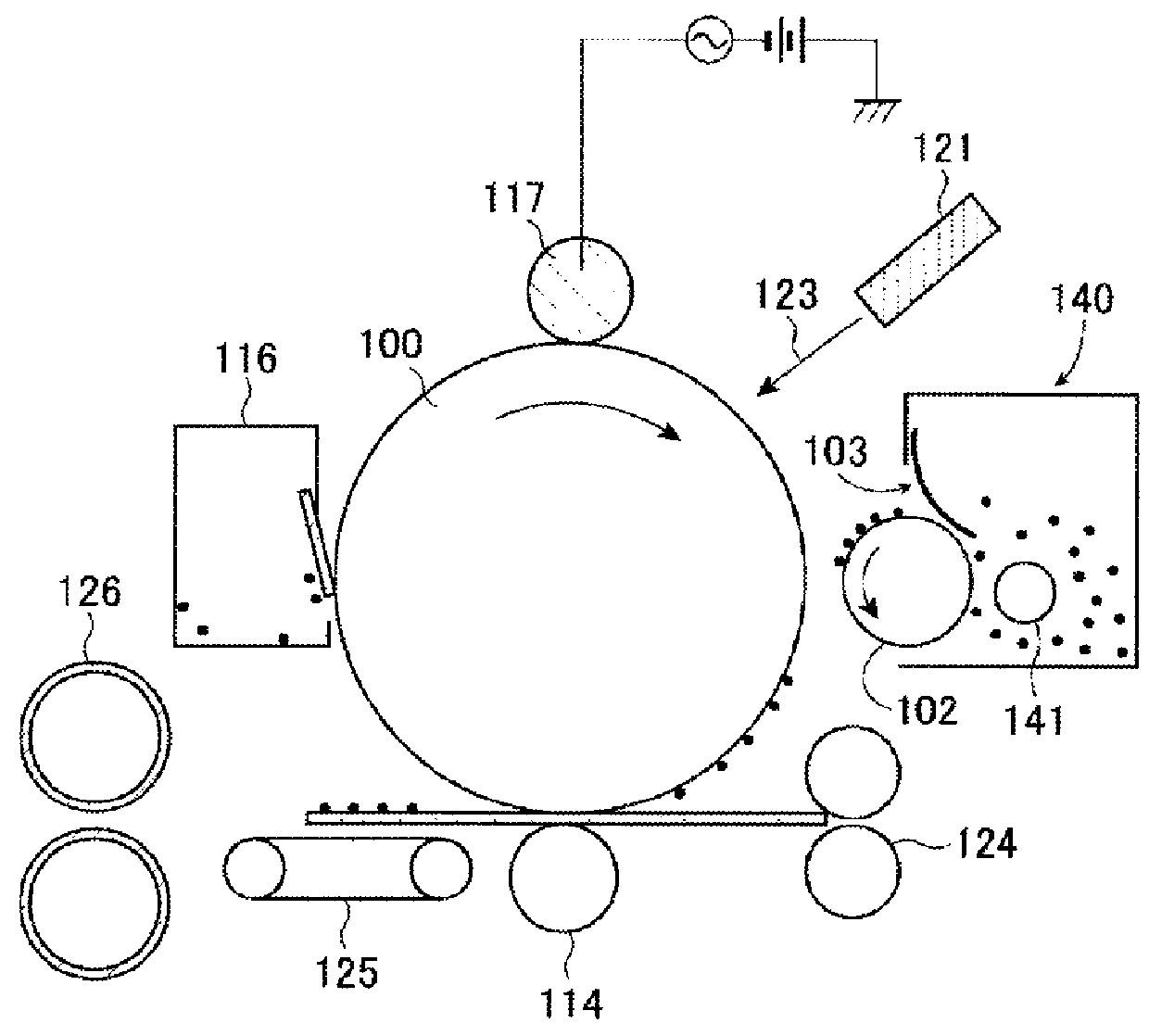

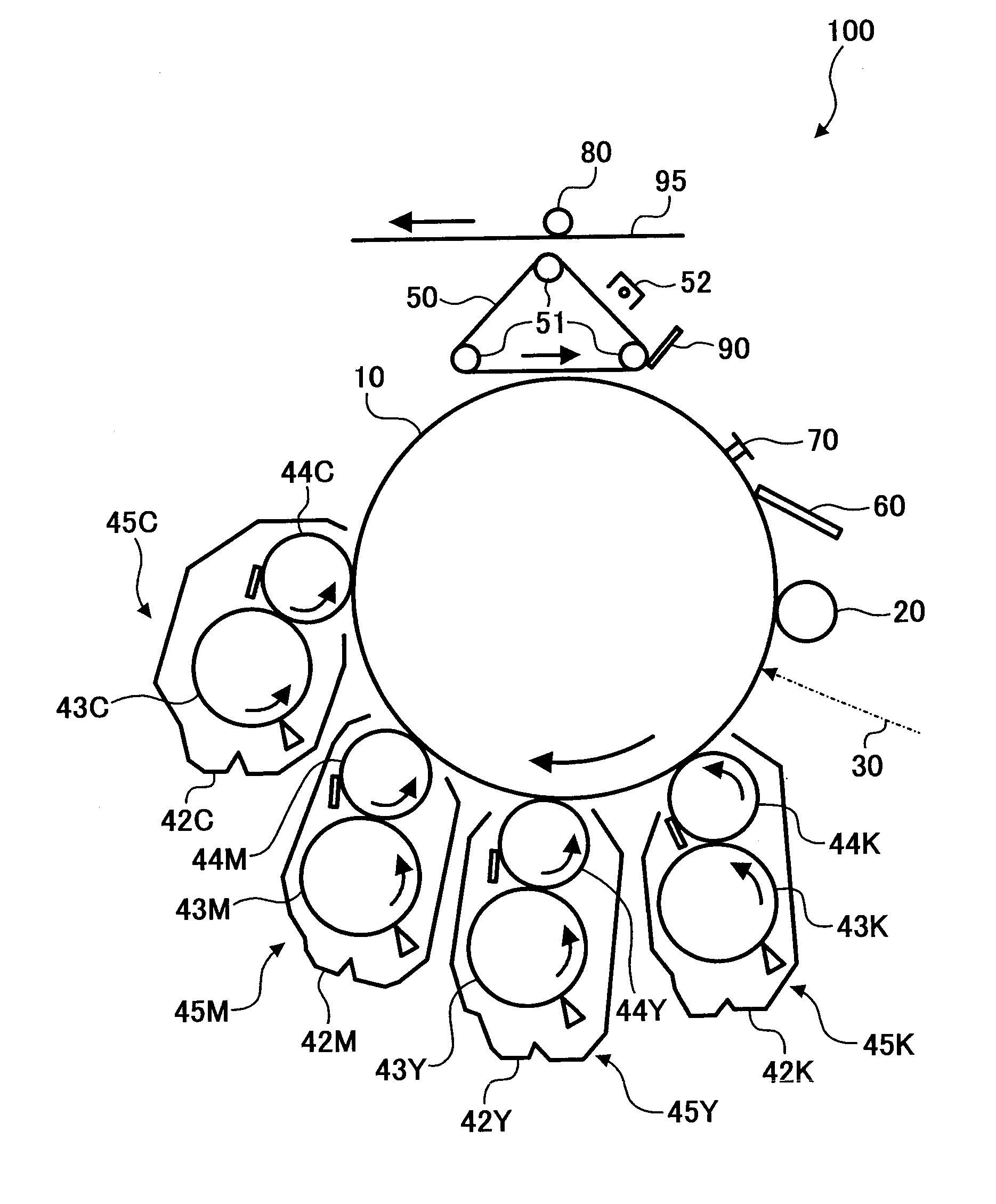

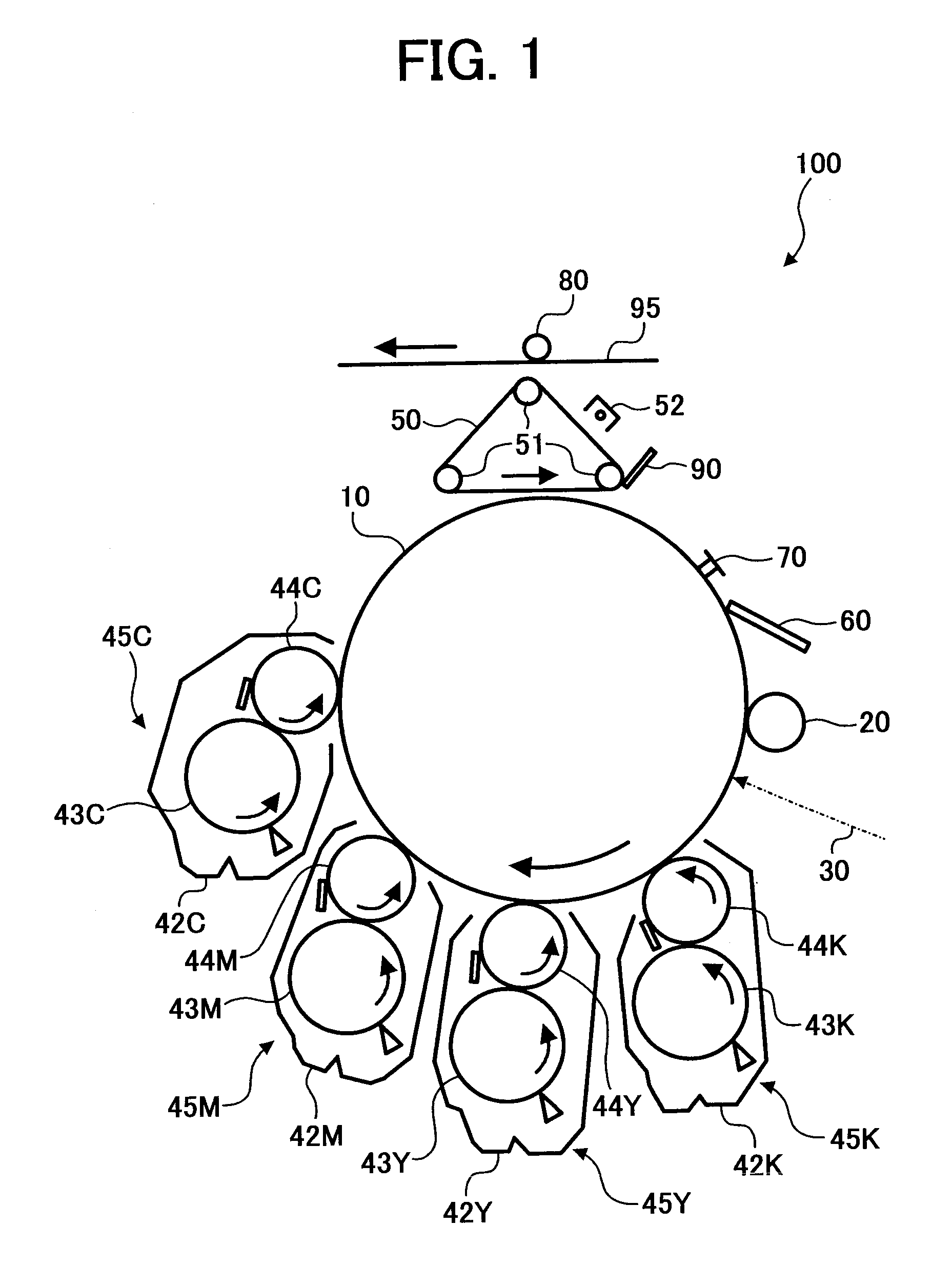

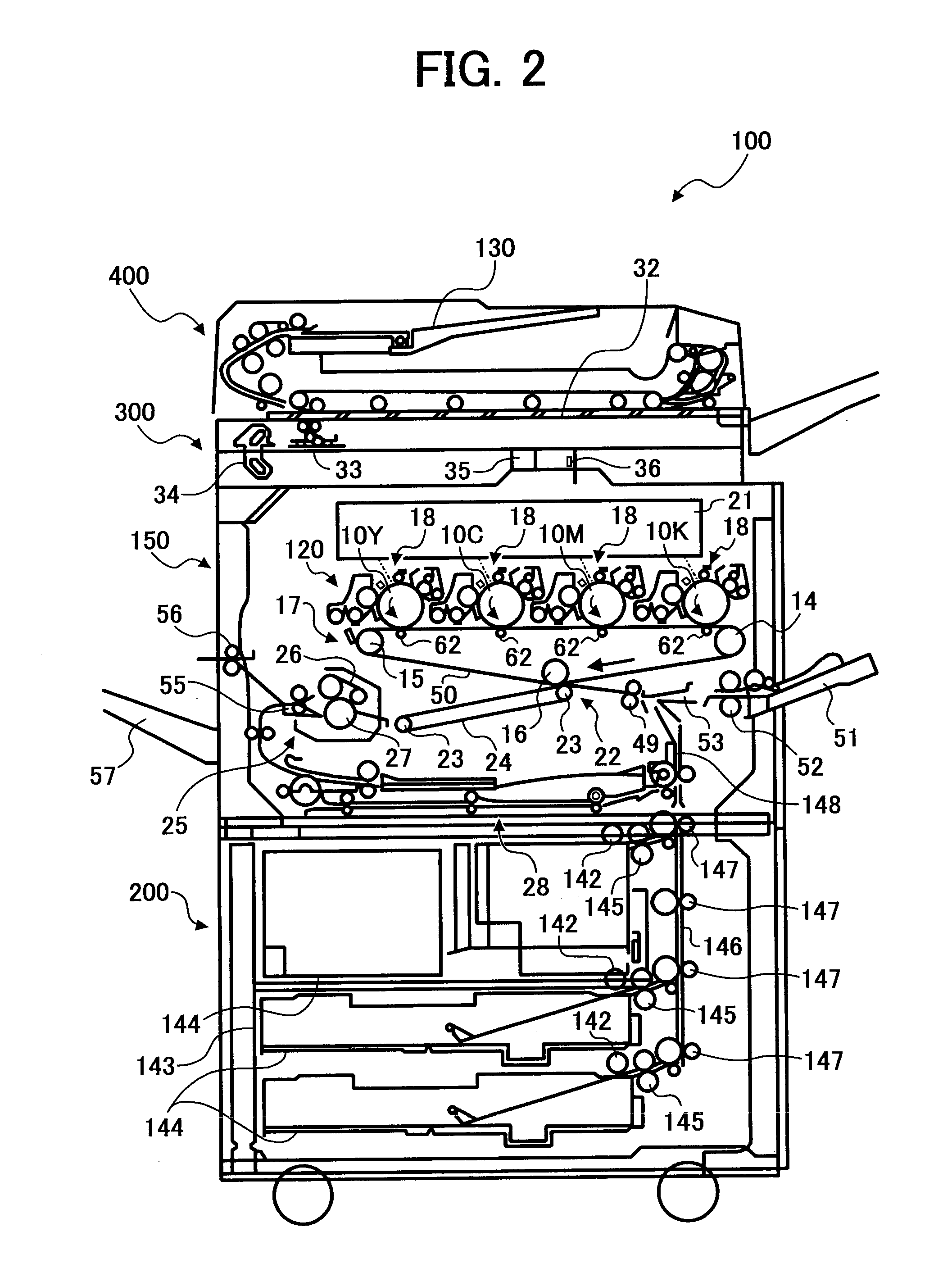

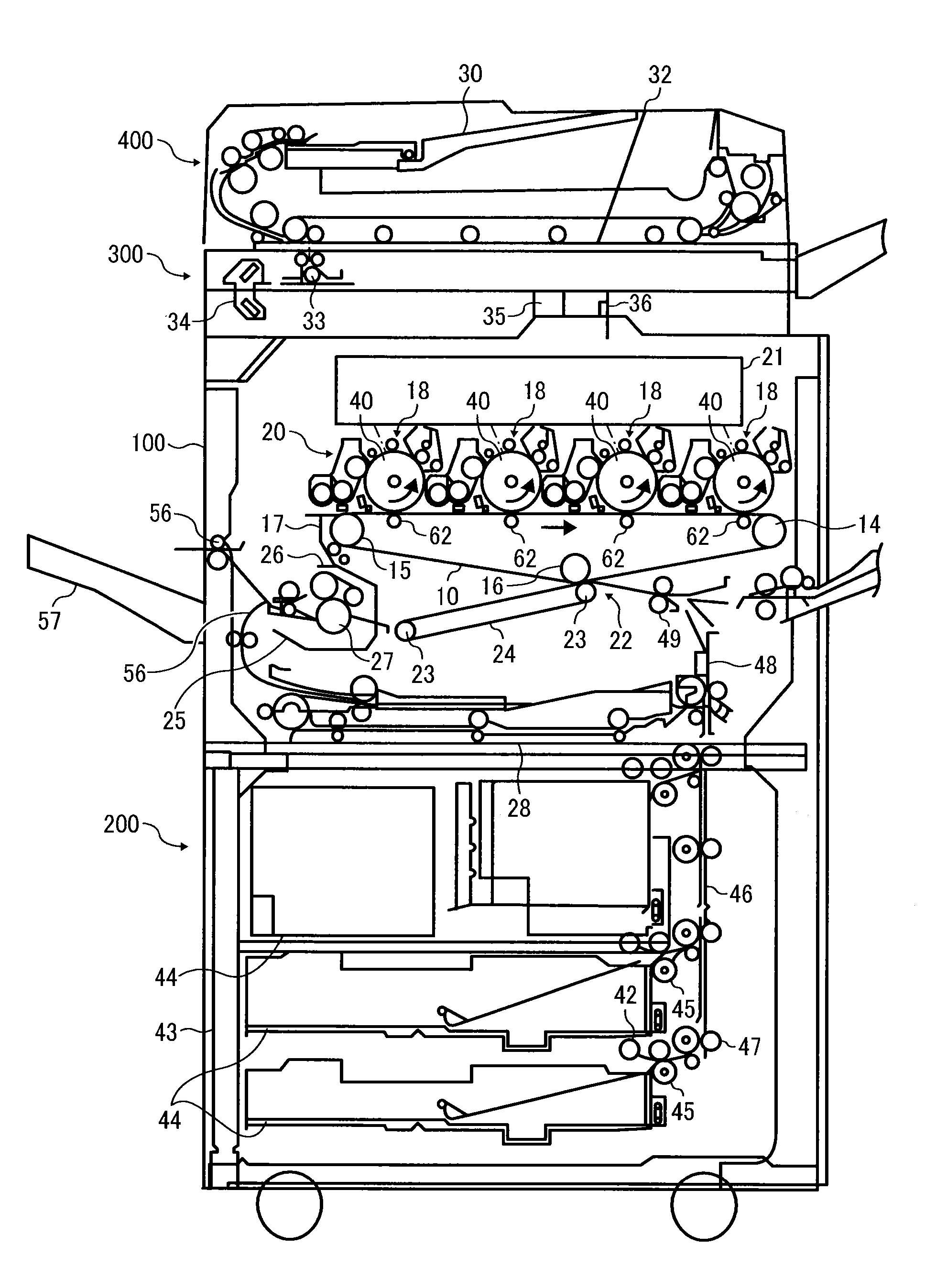

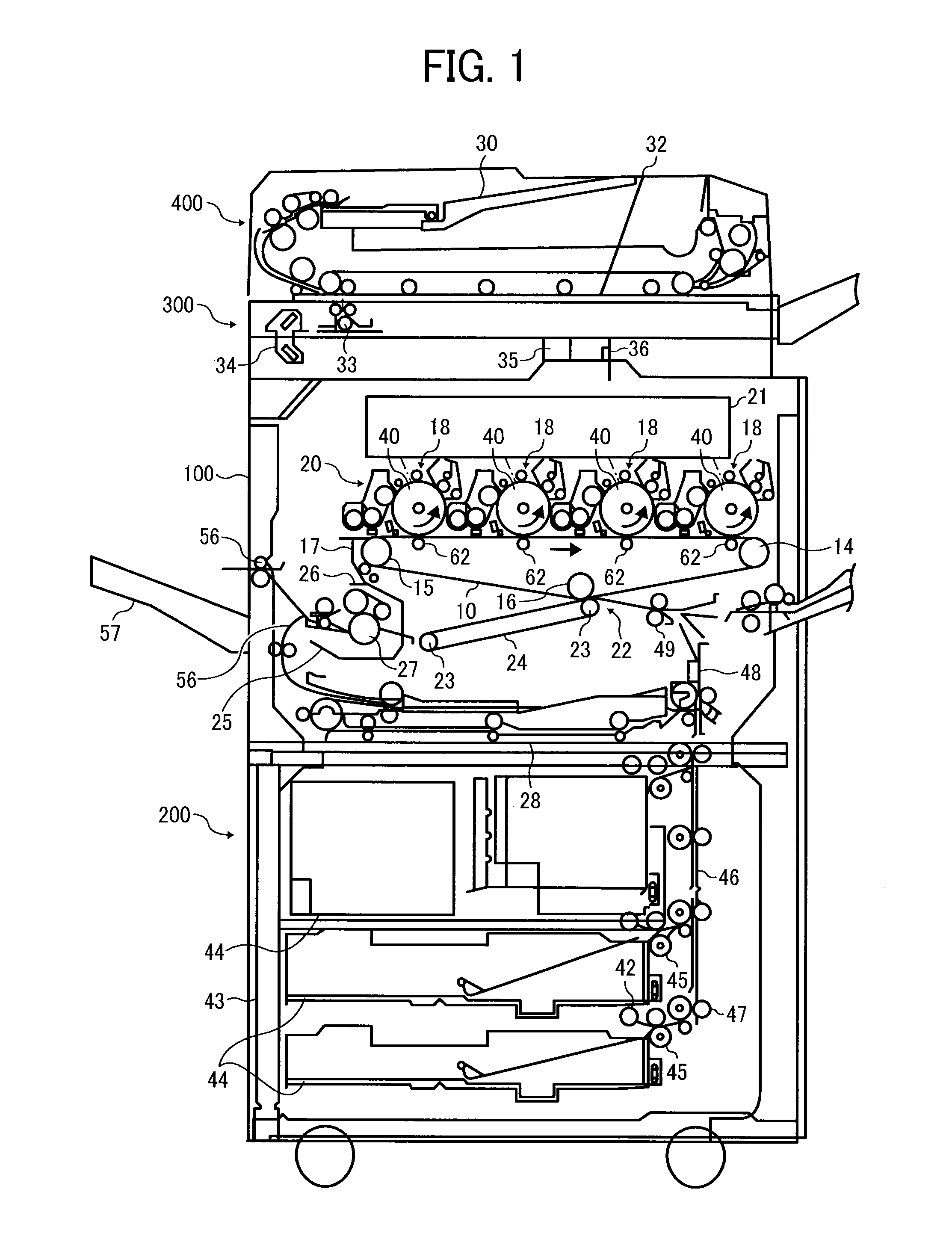

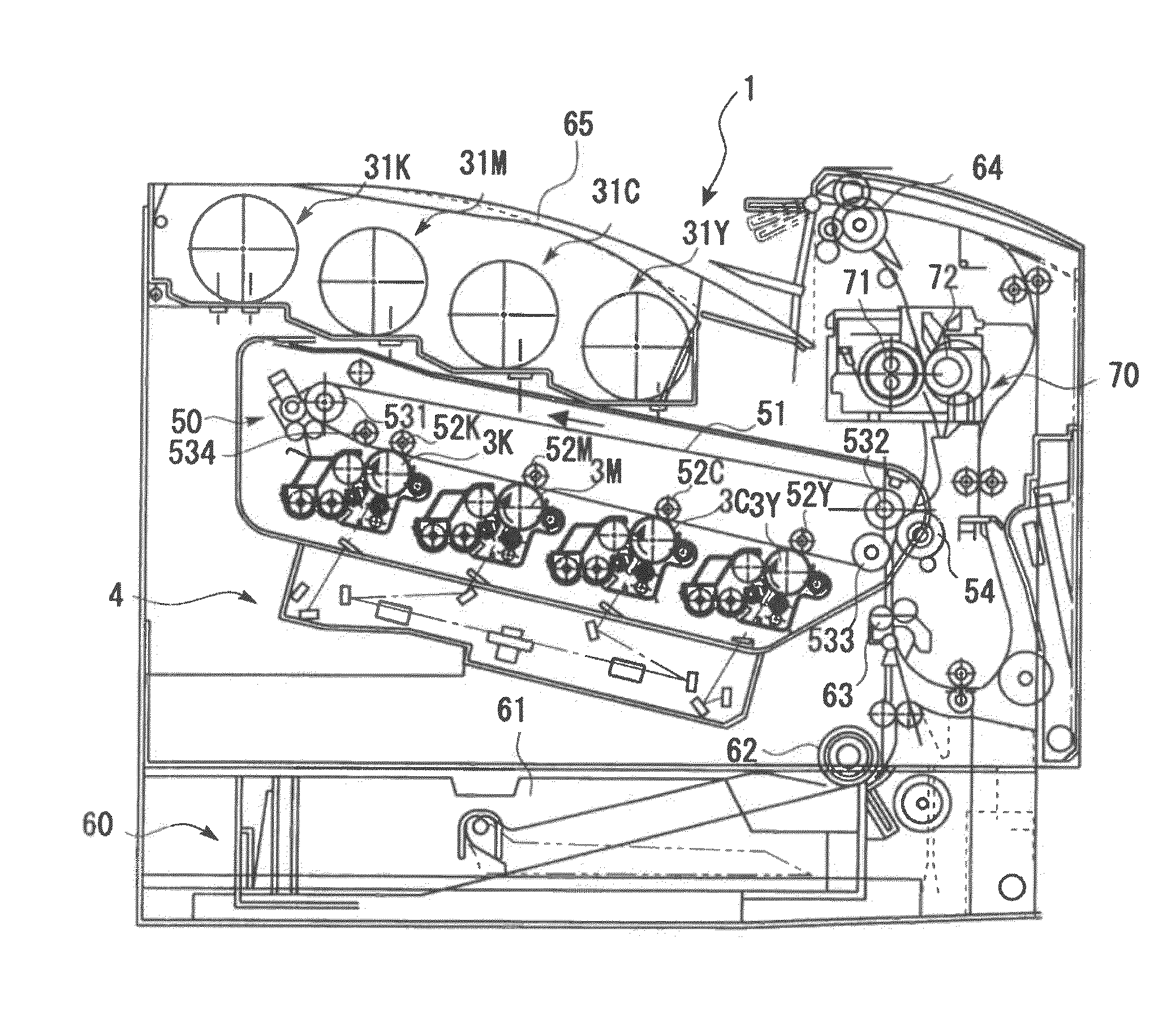

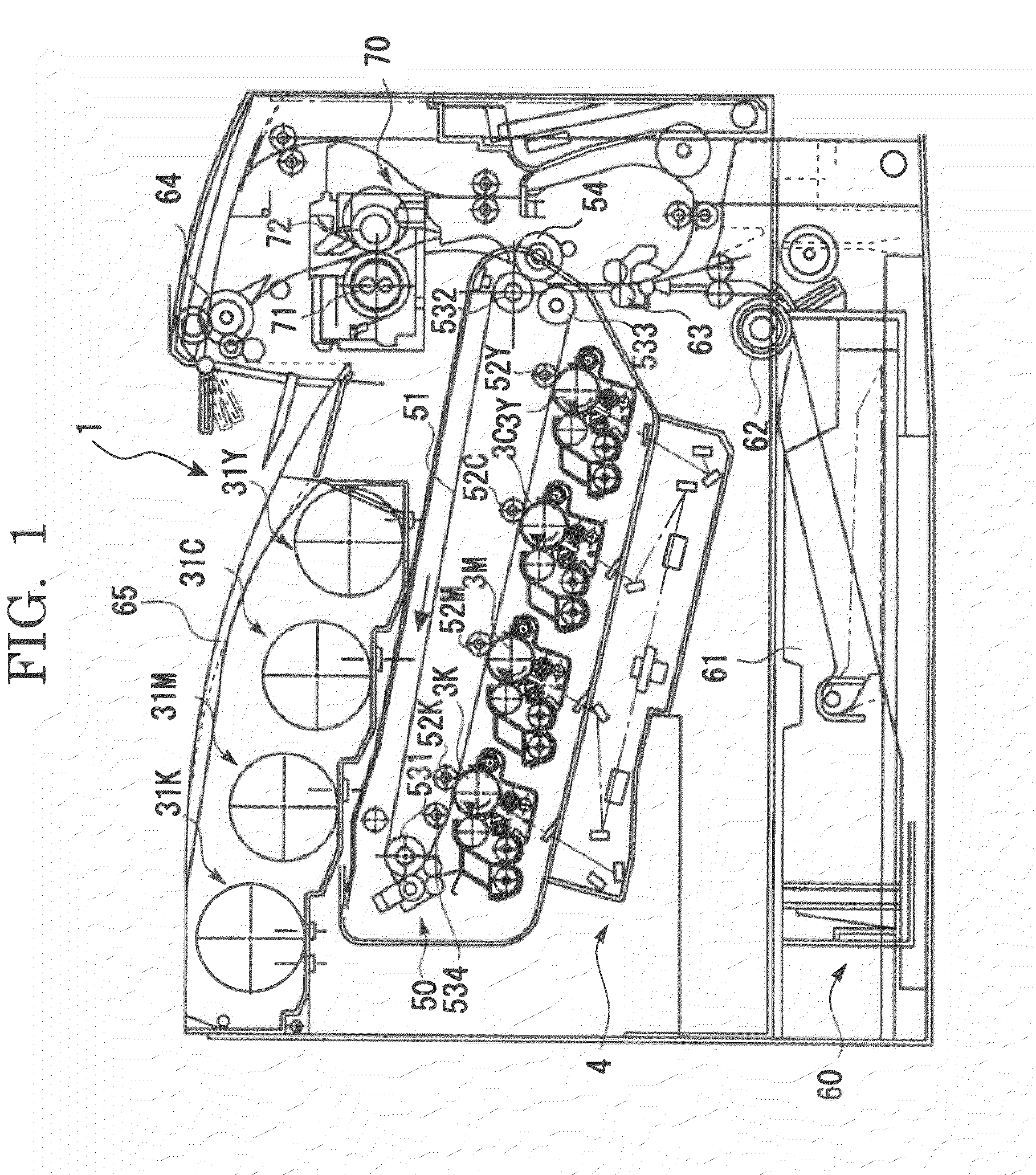

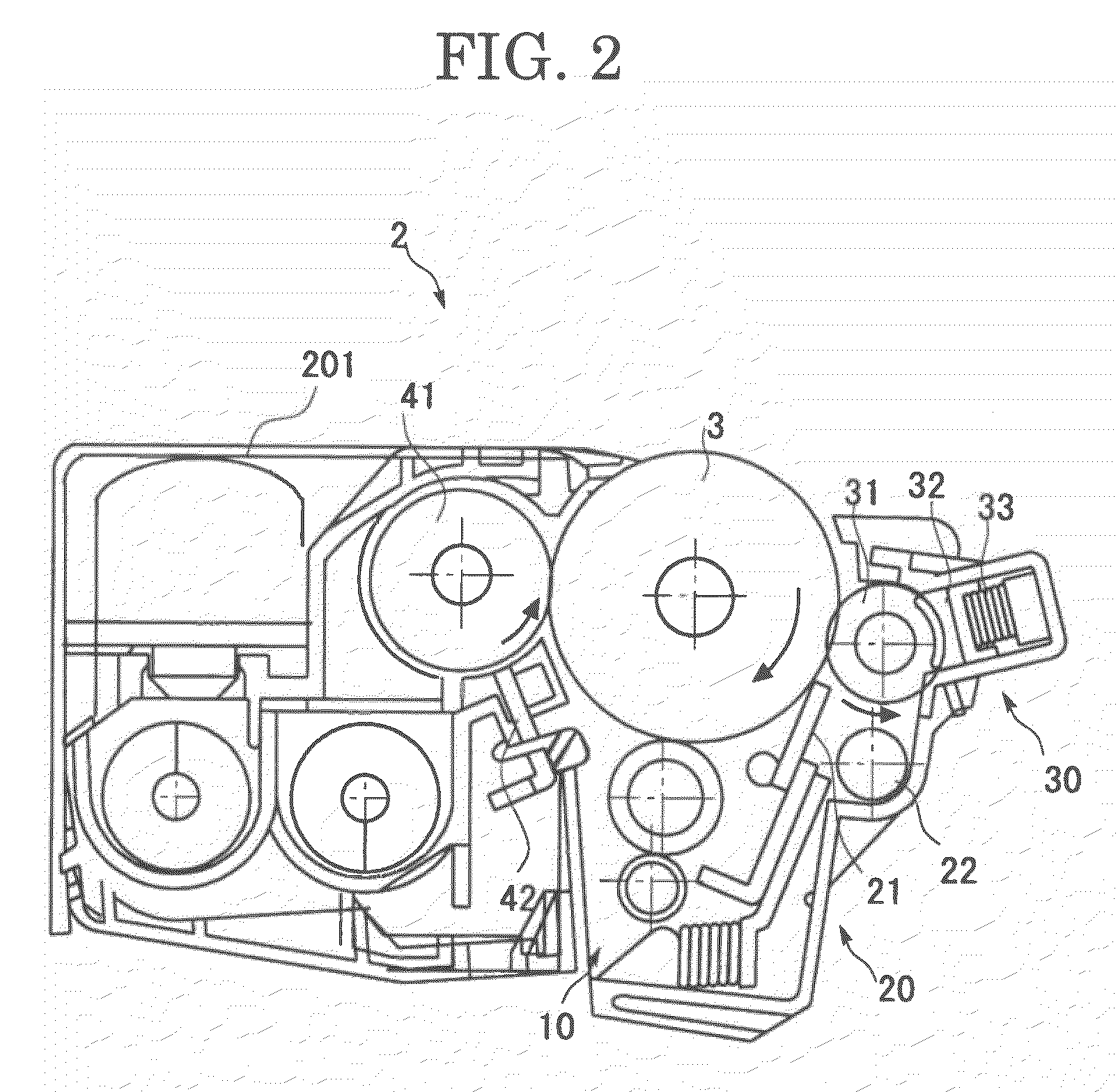

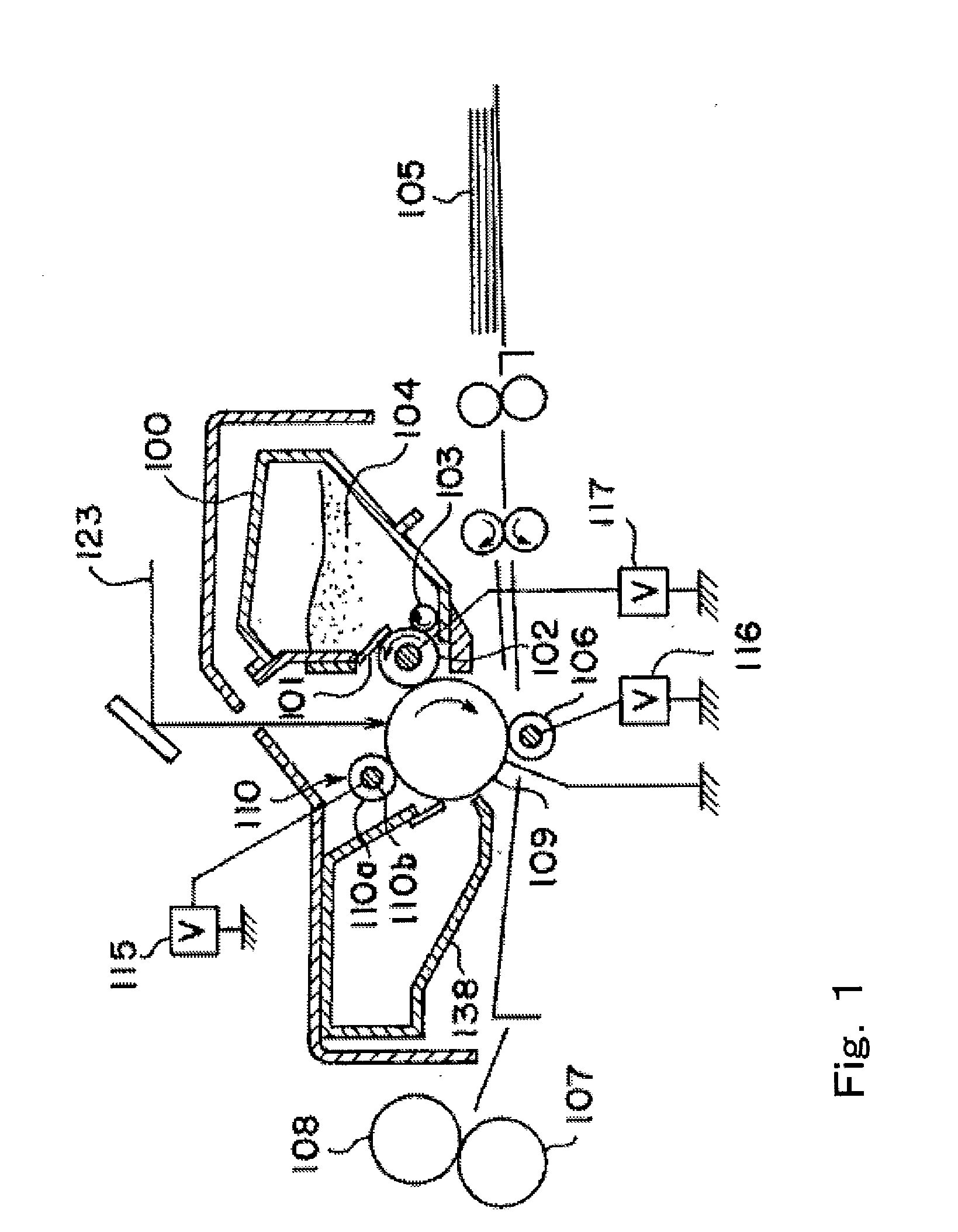

Image forming apparatus, and toner and developer used therein

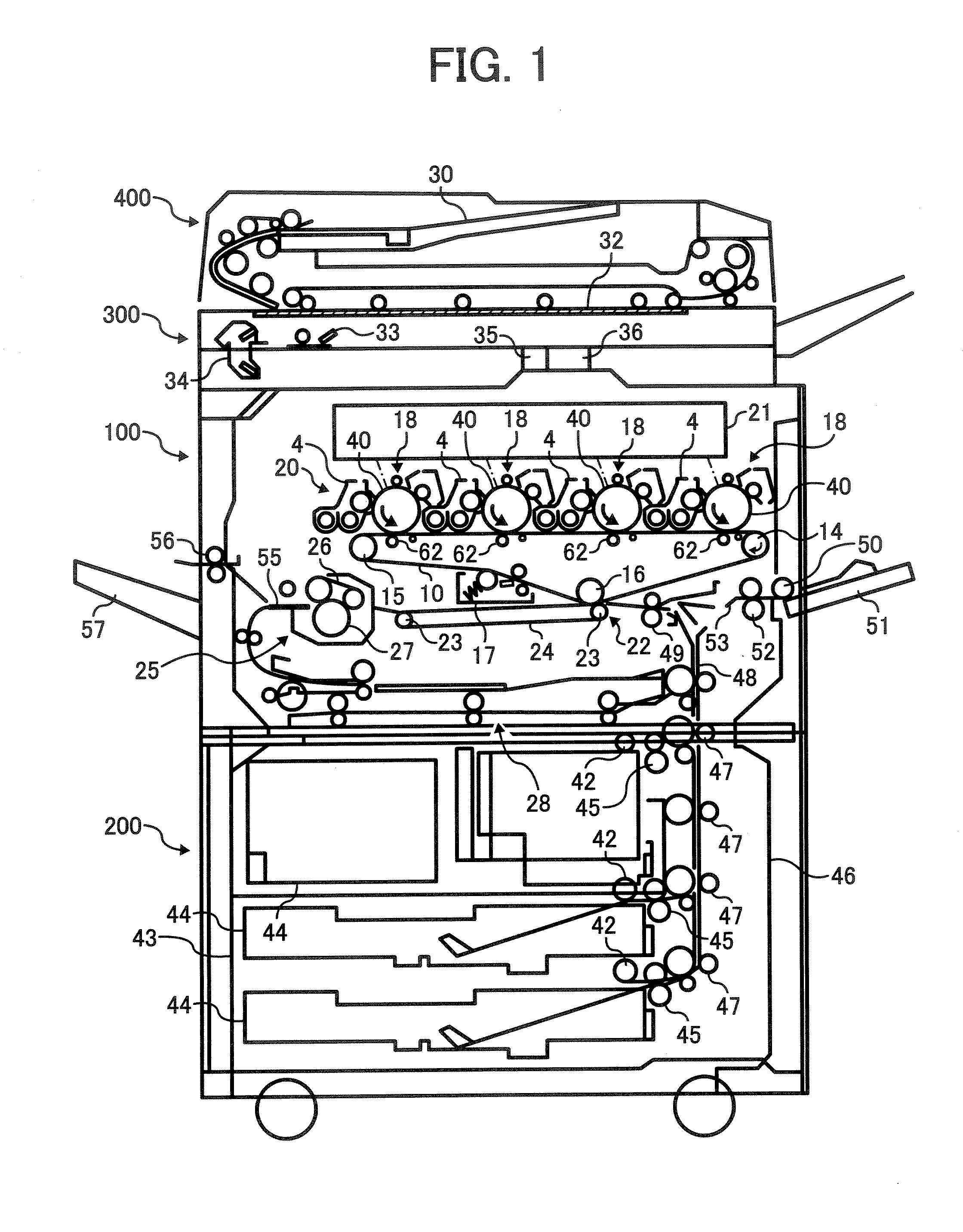

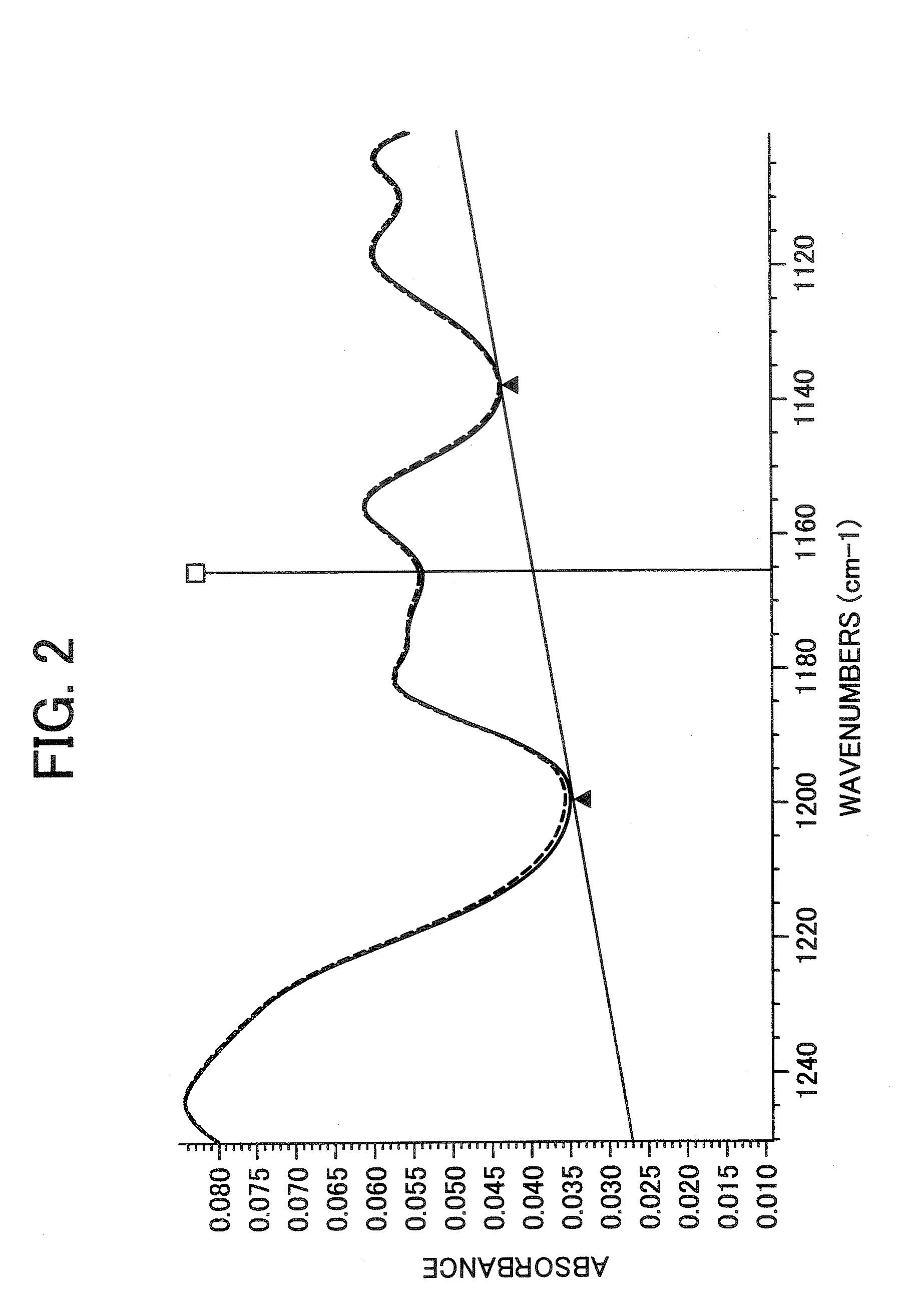

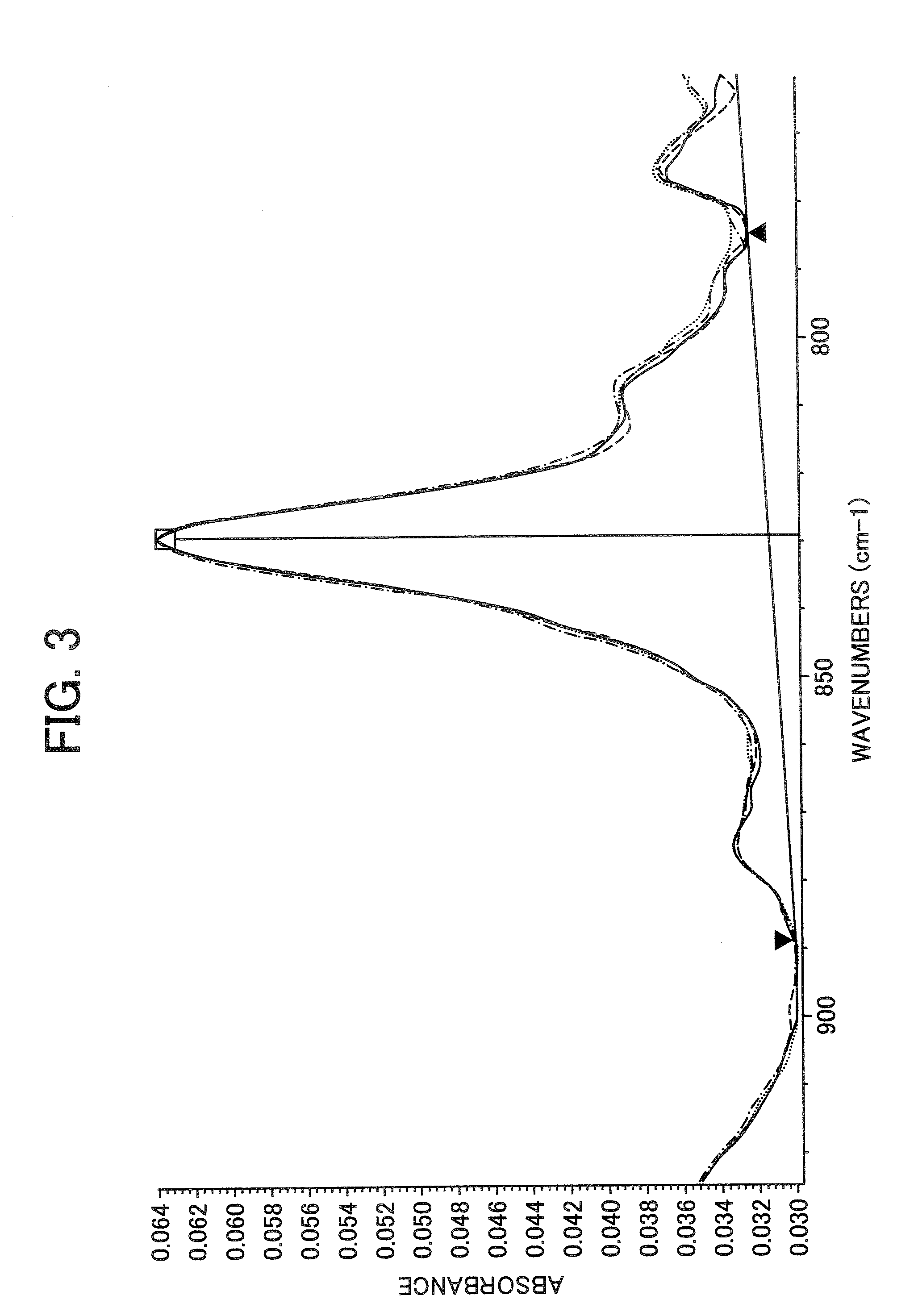

InactiveUS20070184377A1Low-temperature fixabilityElectrographic process apparatusDevelopersEngineeringColoring agents

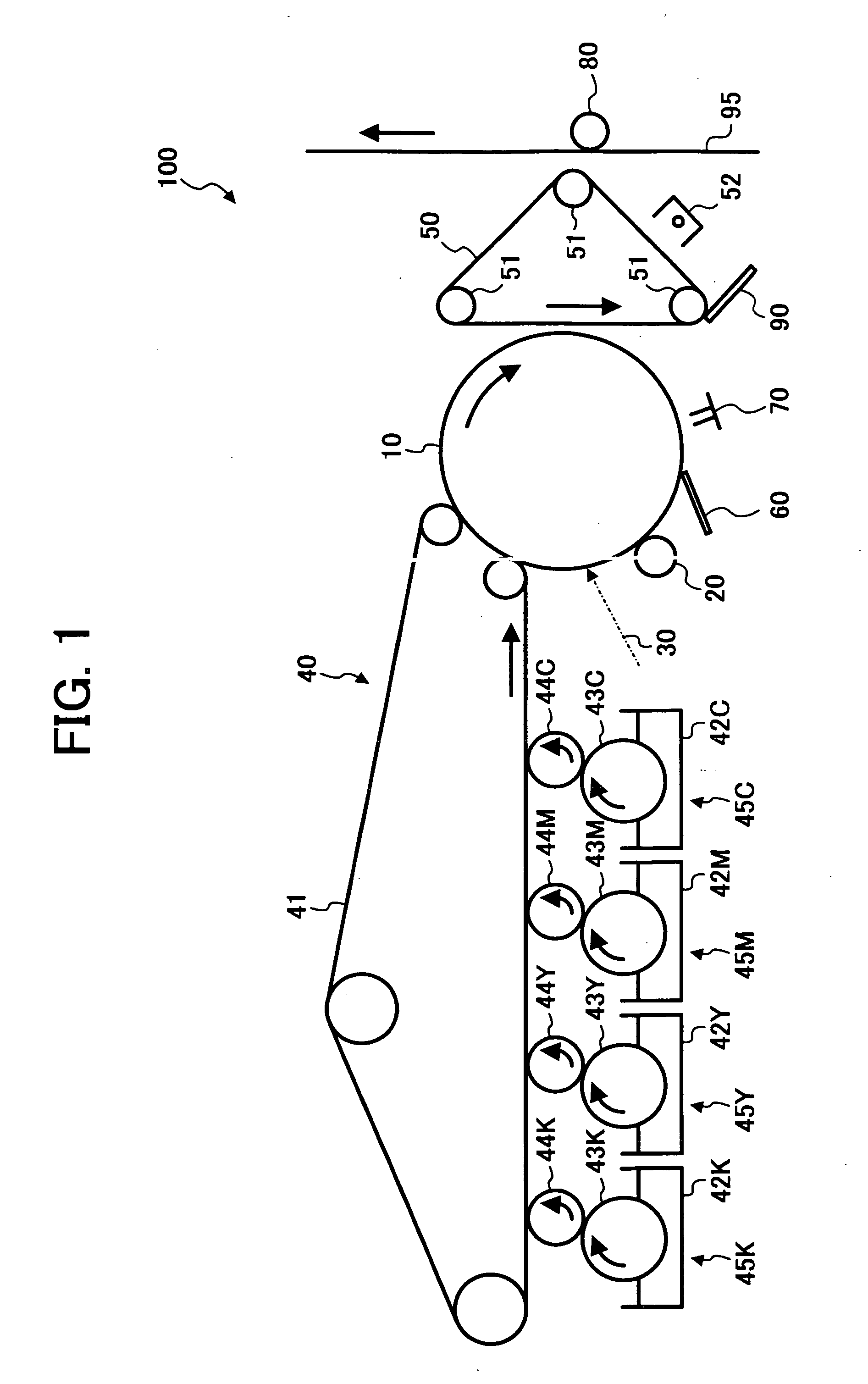

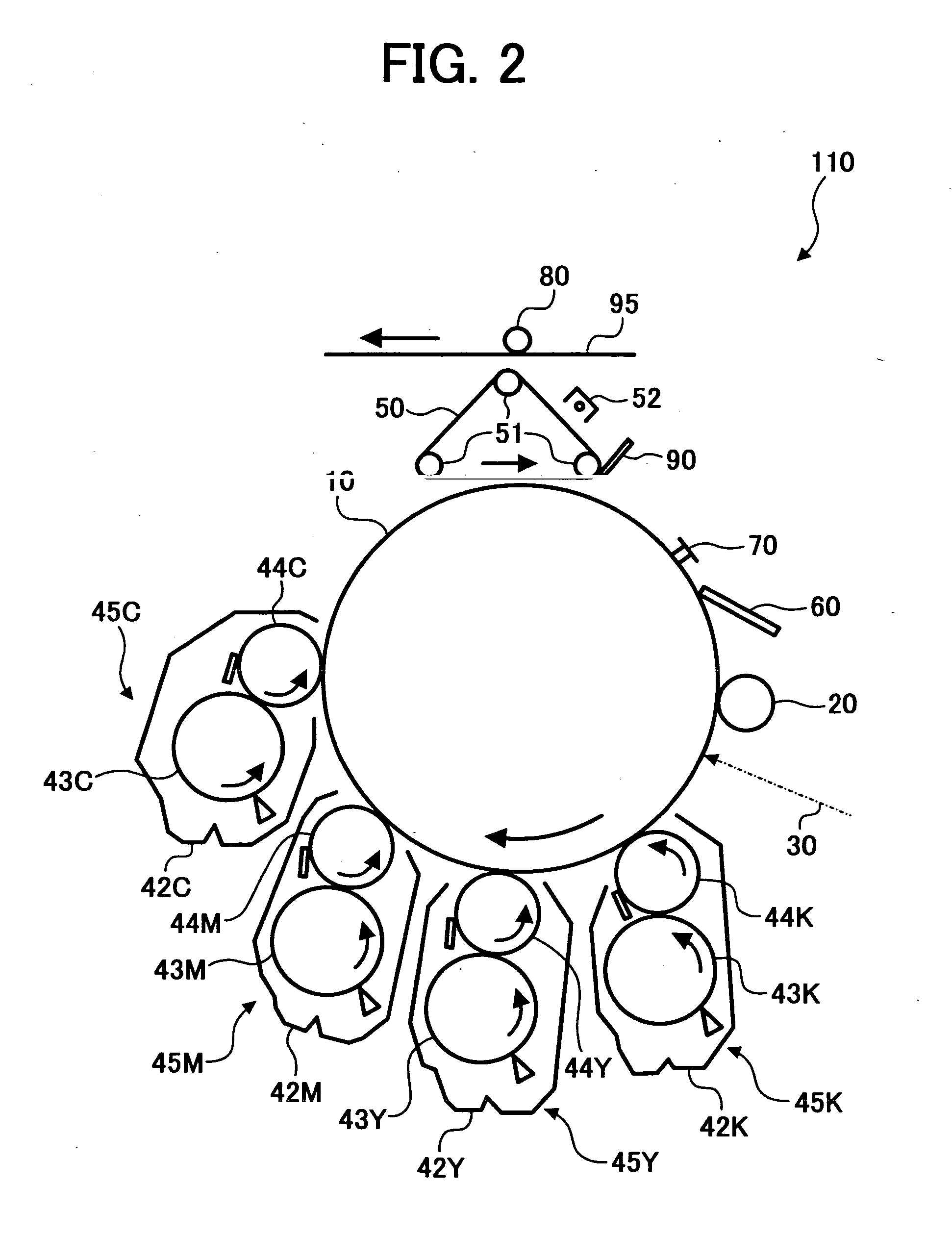

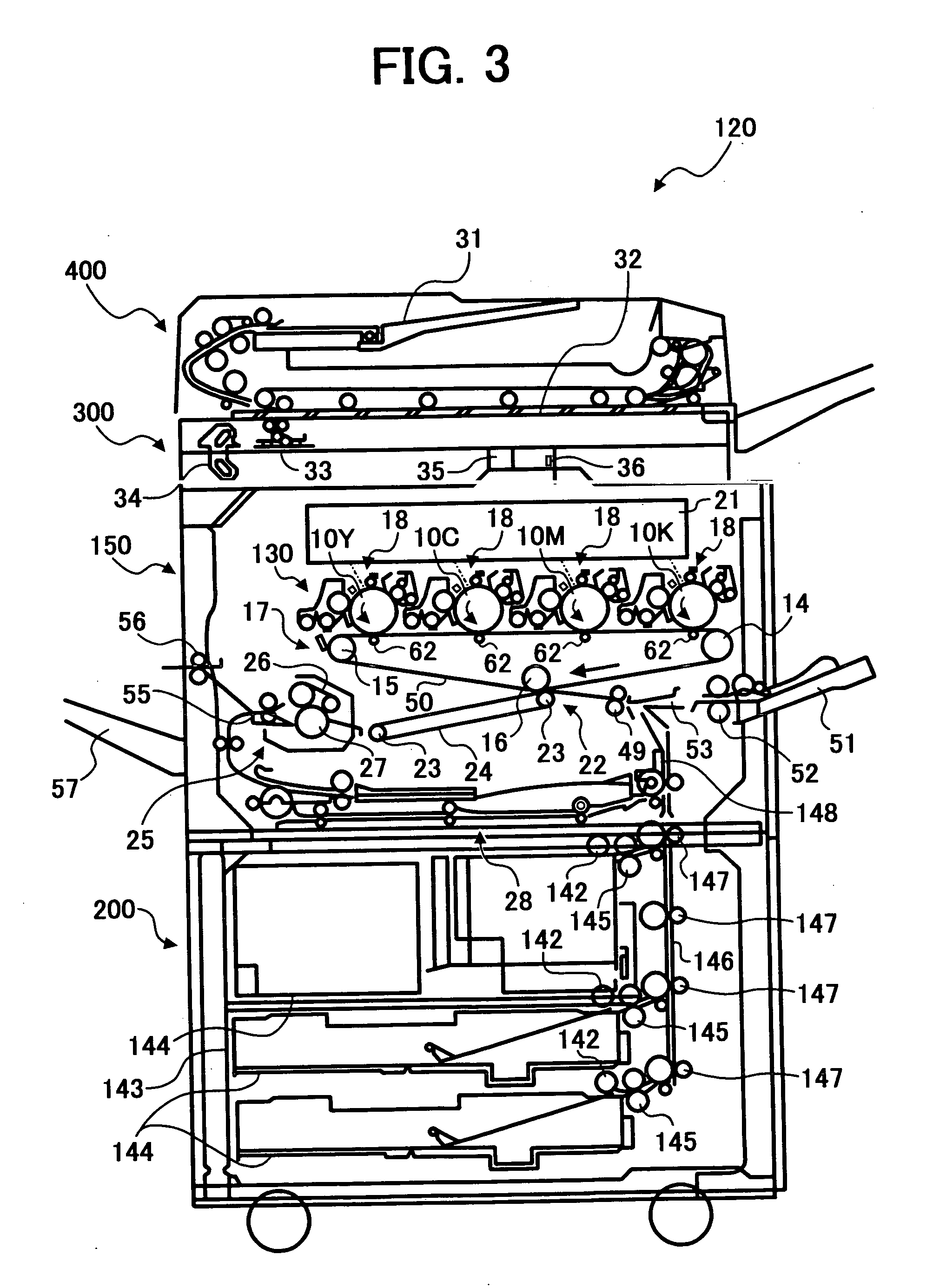

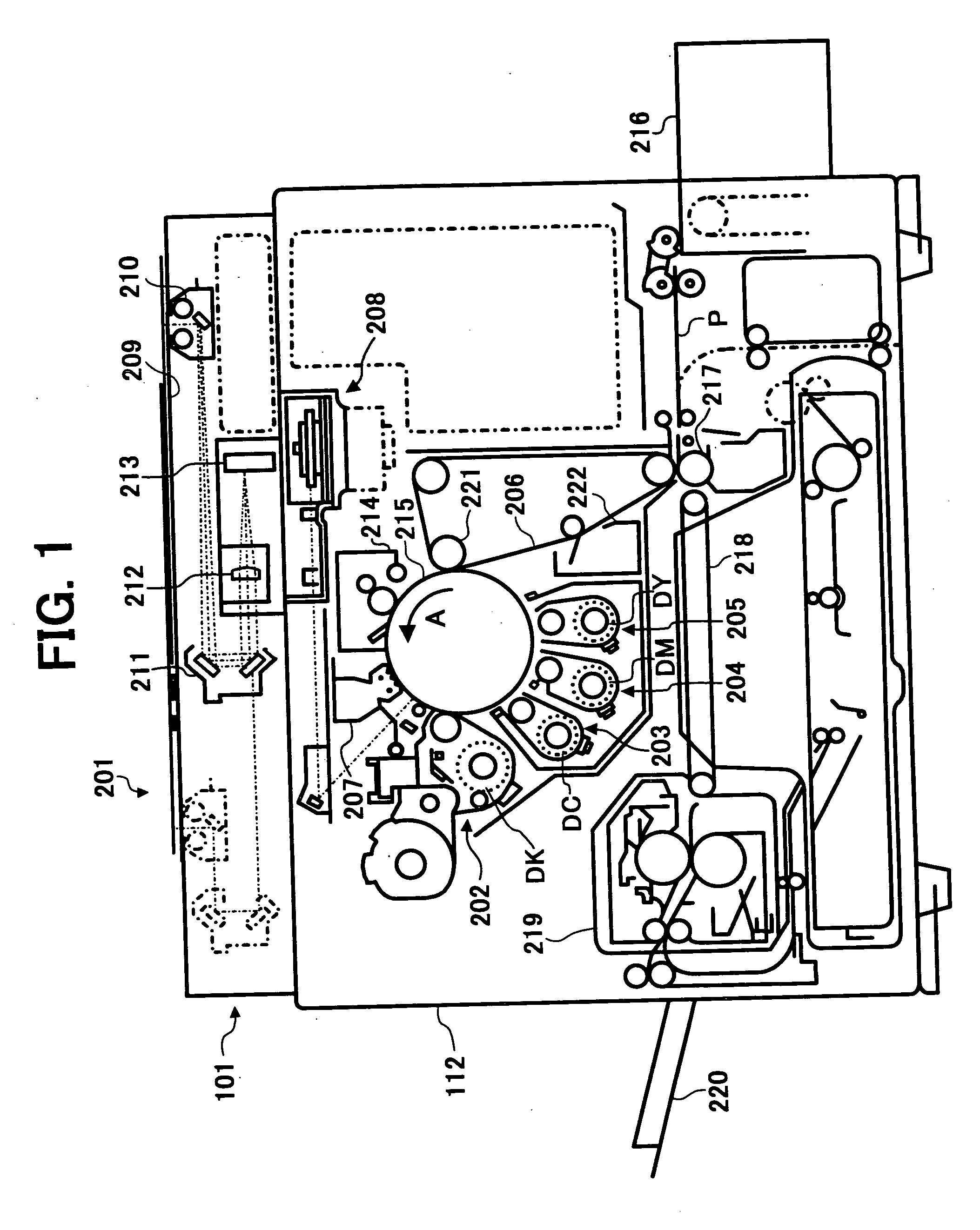

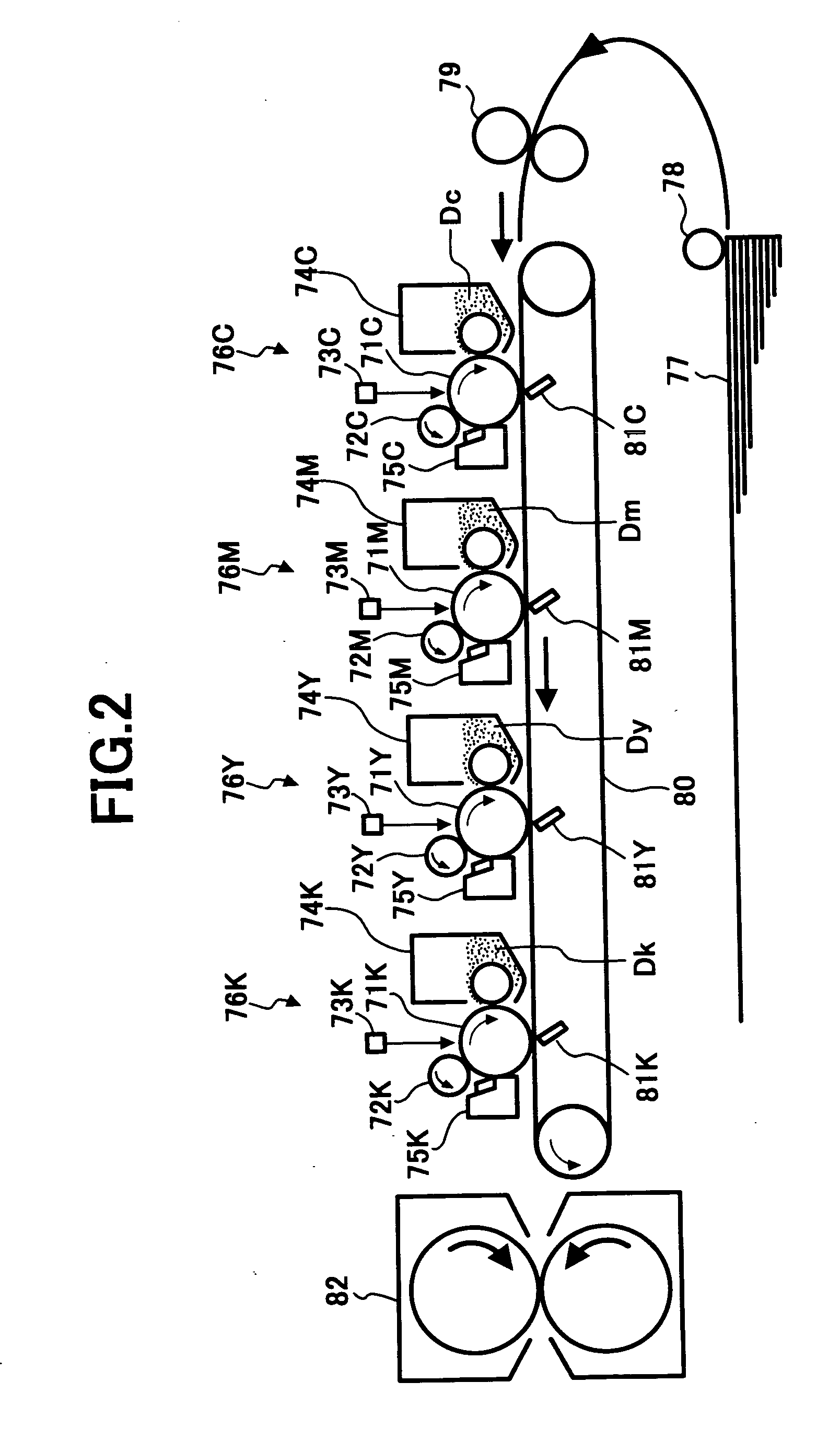

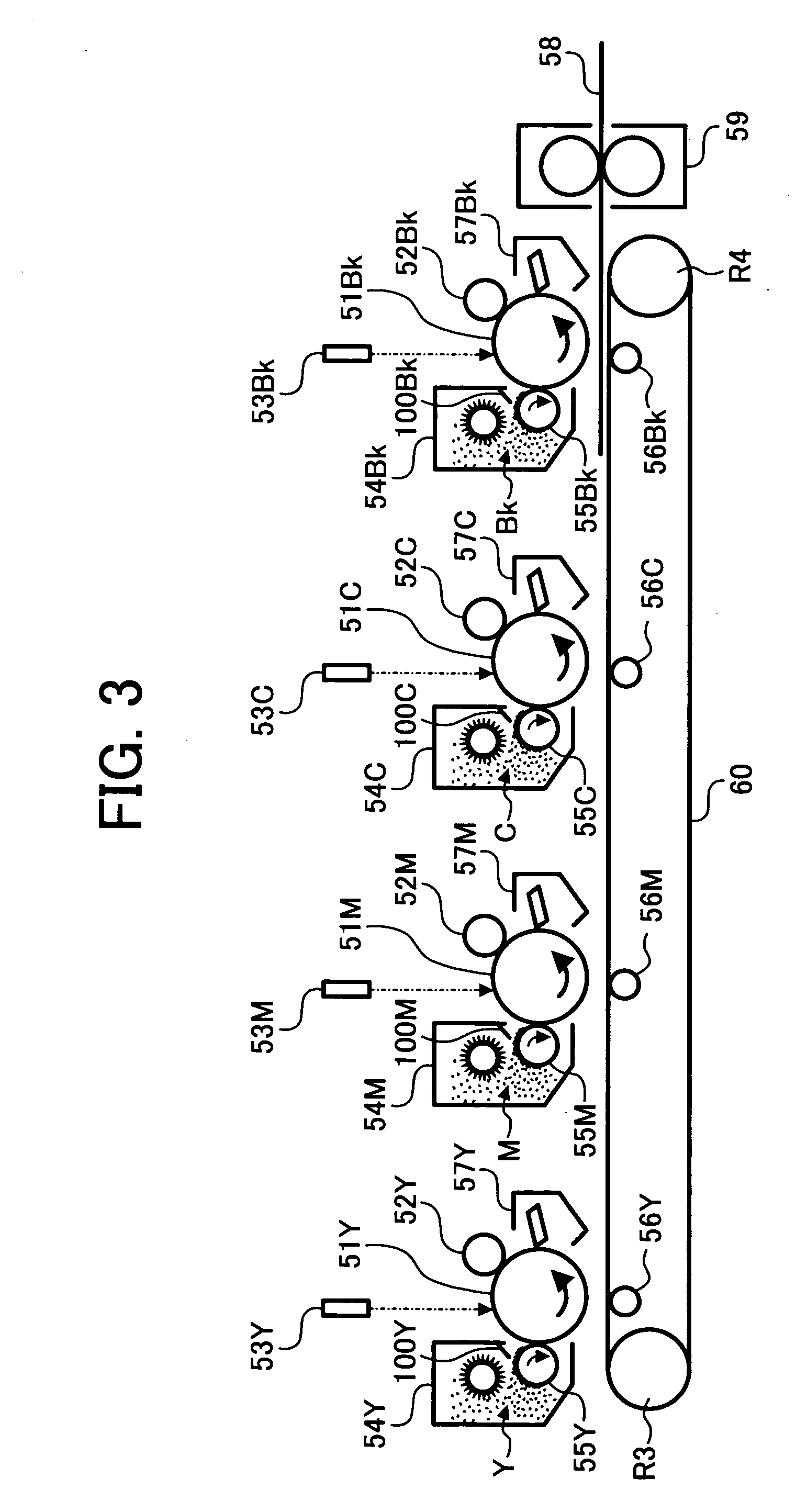

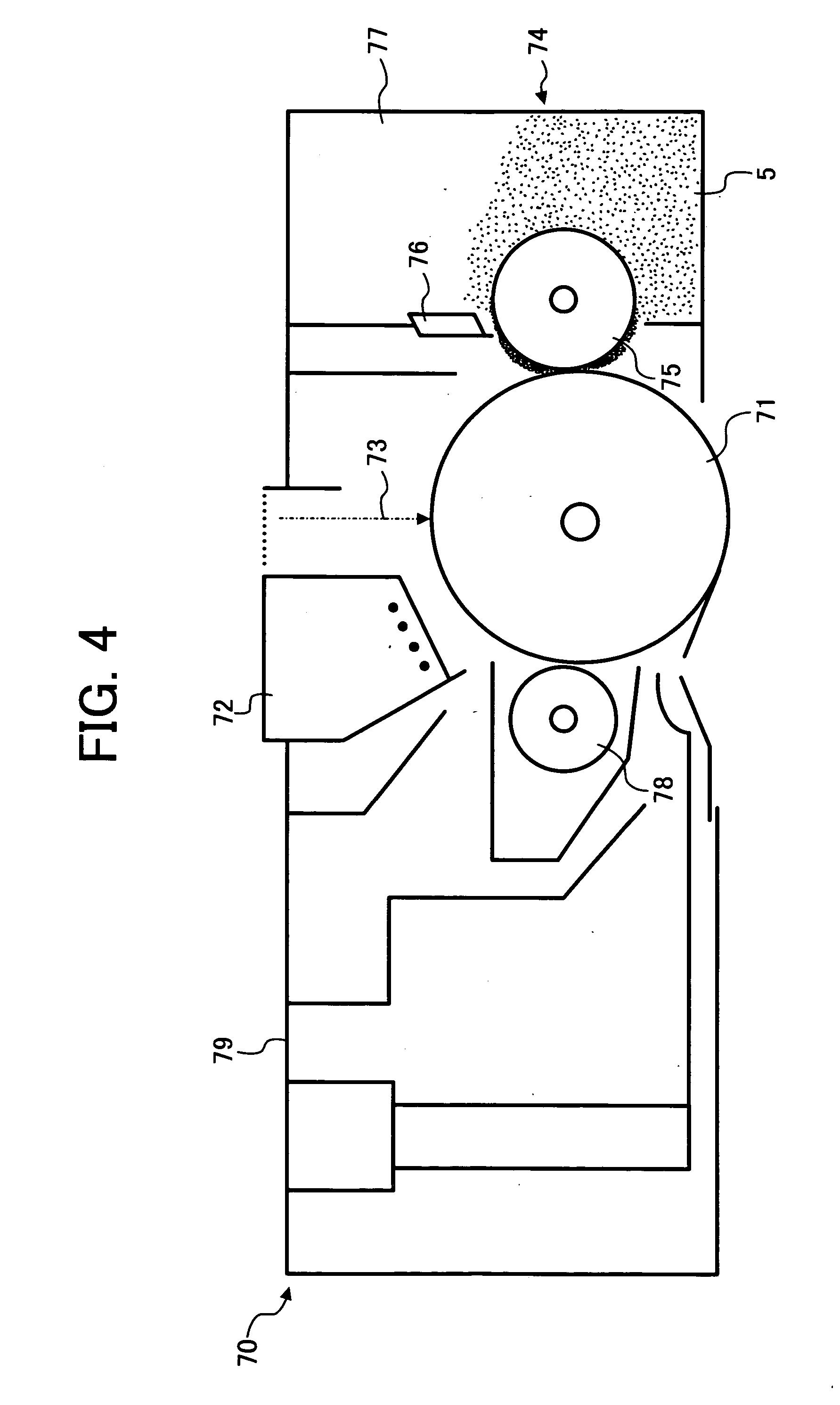

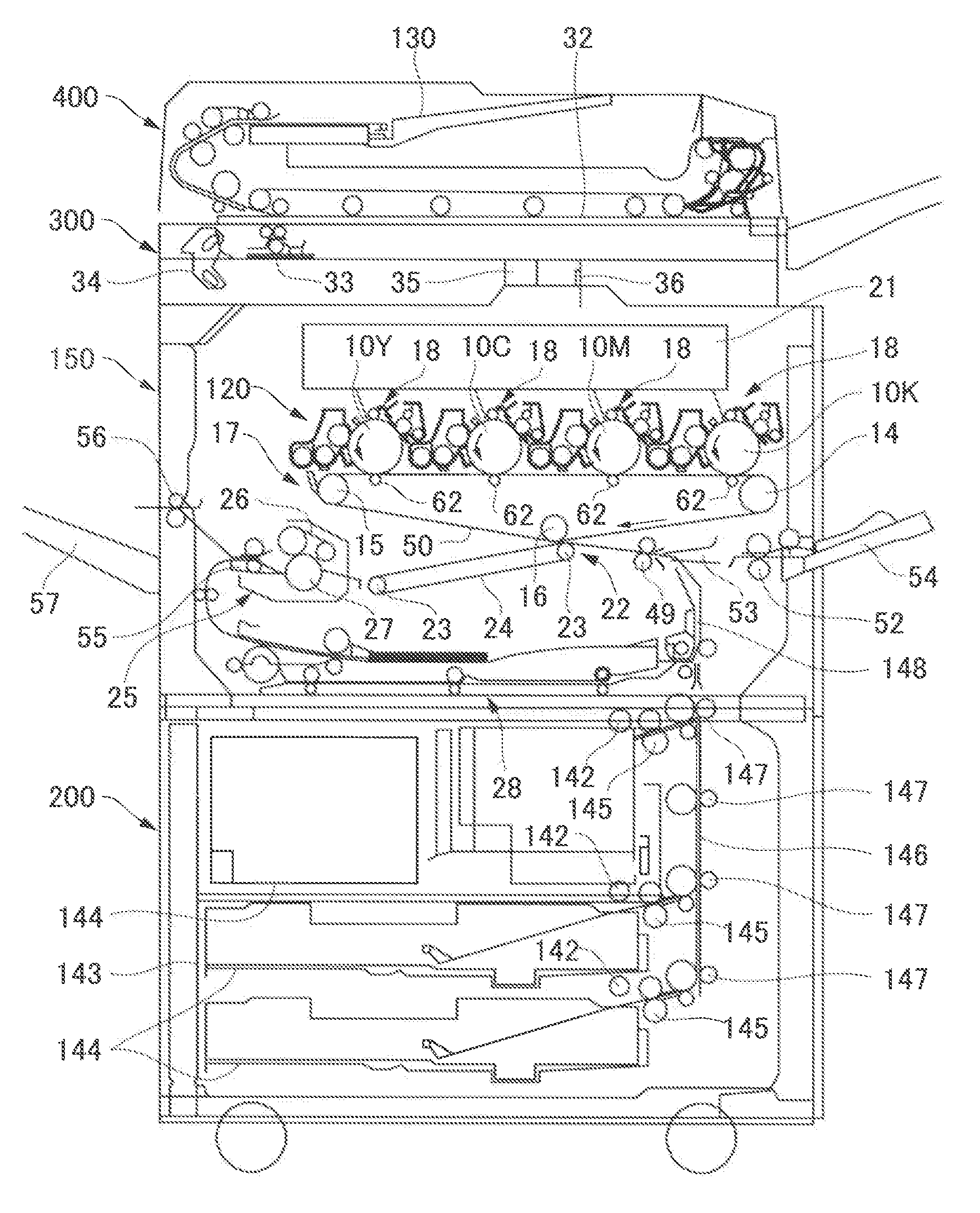

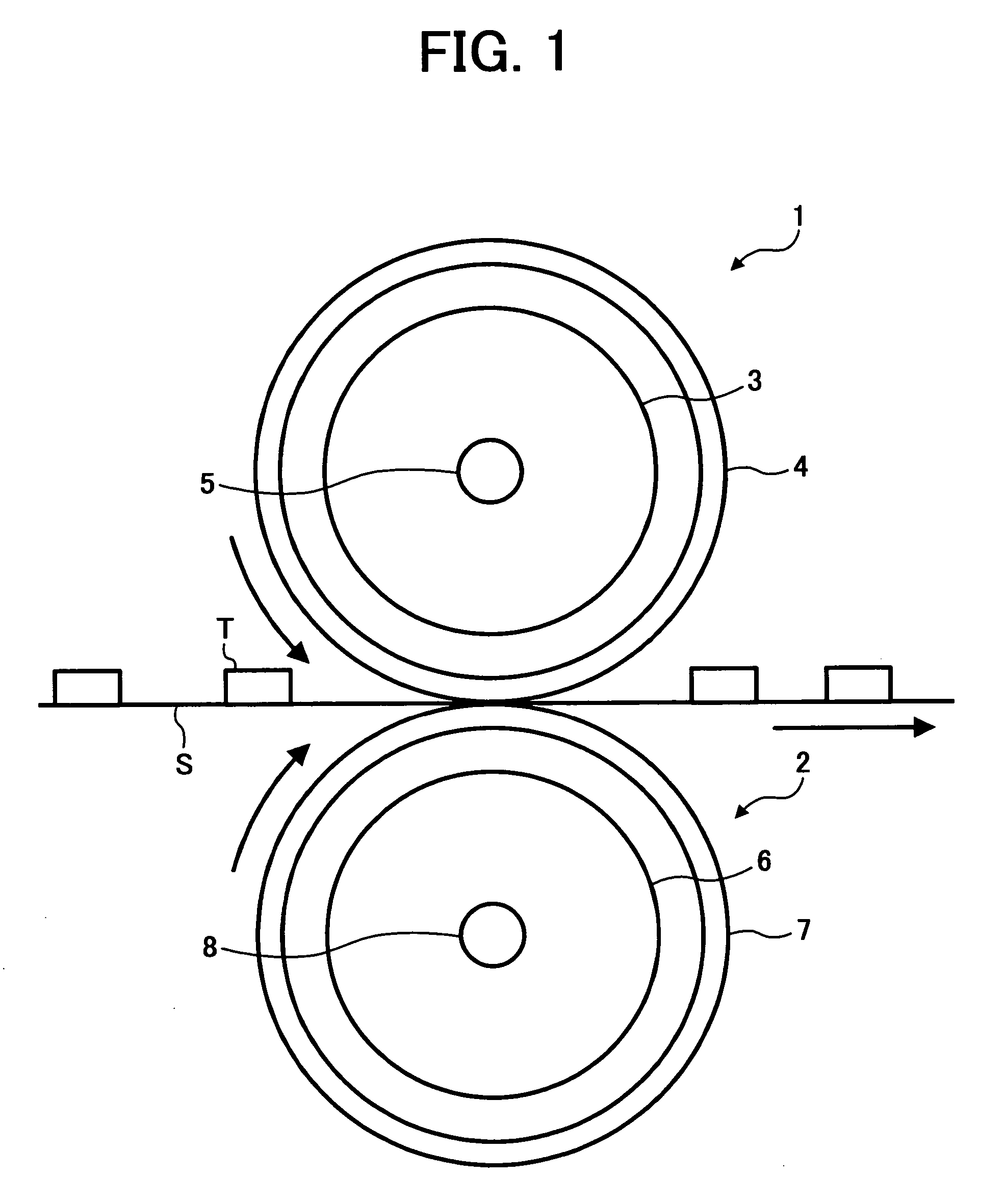

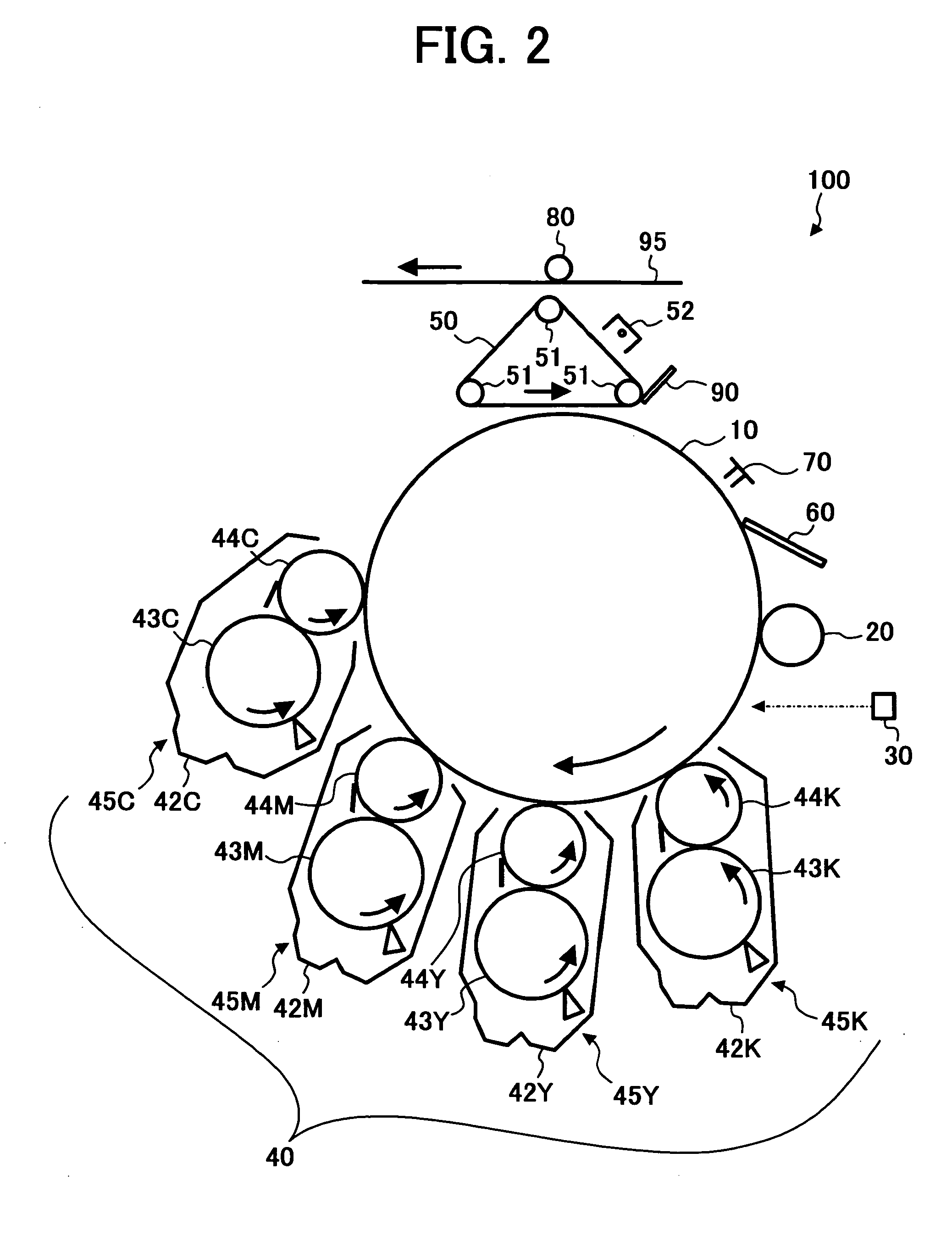

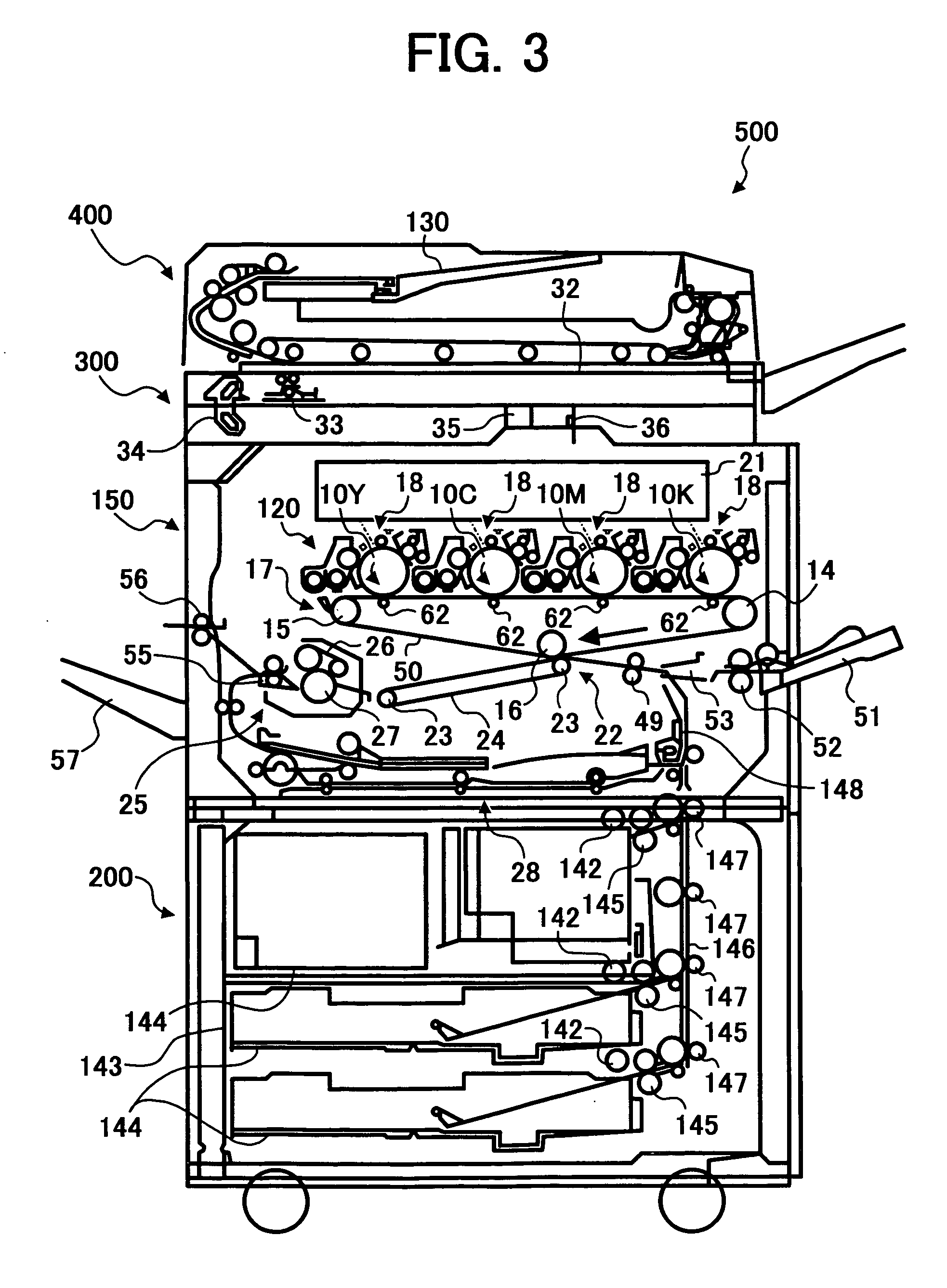

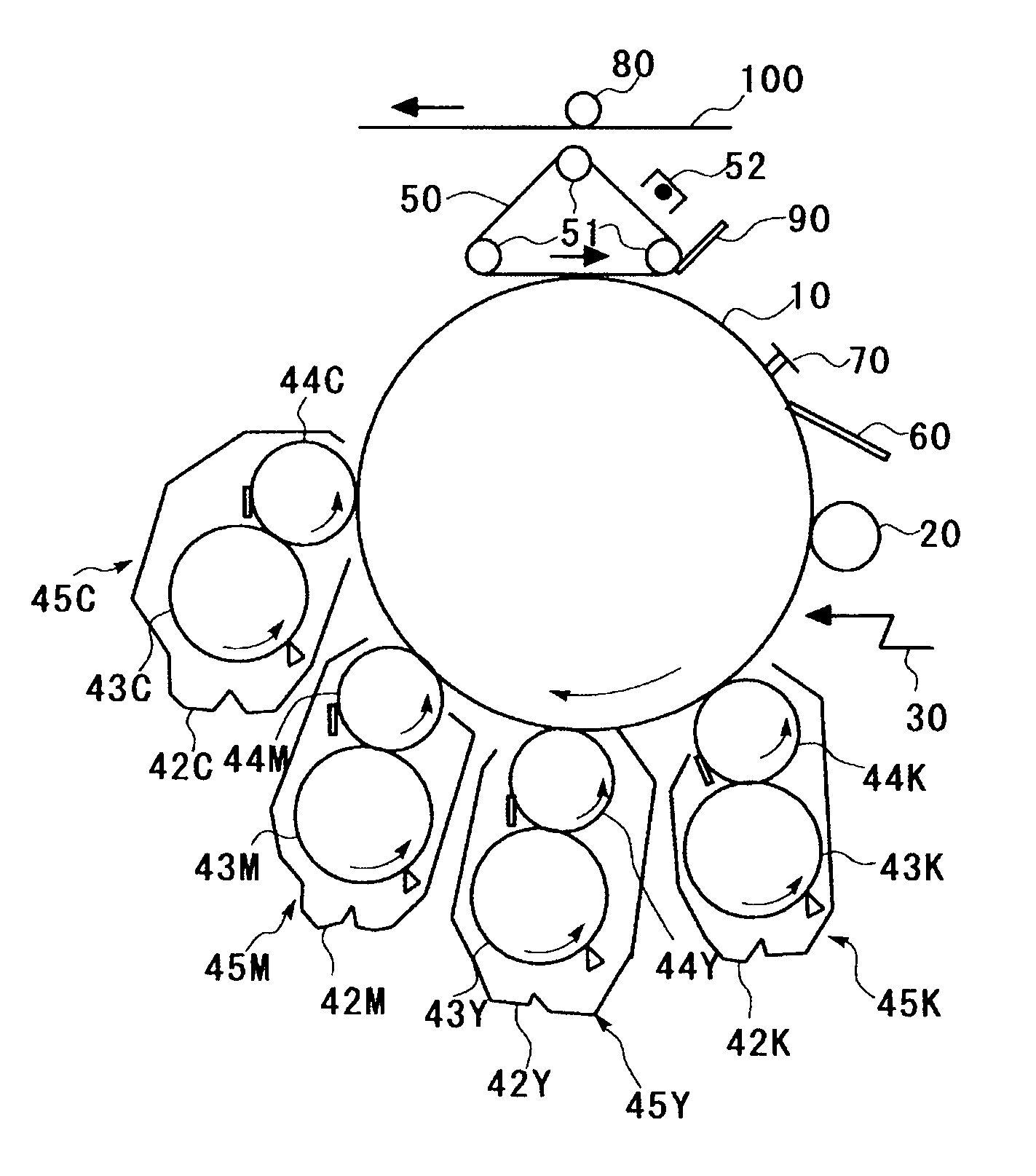

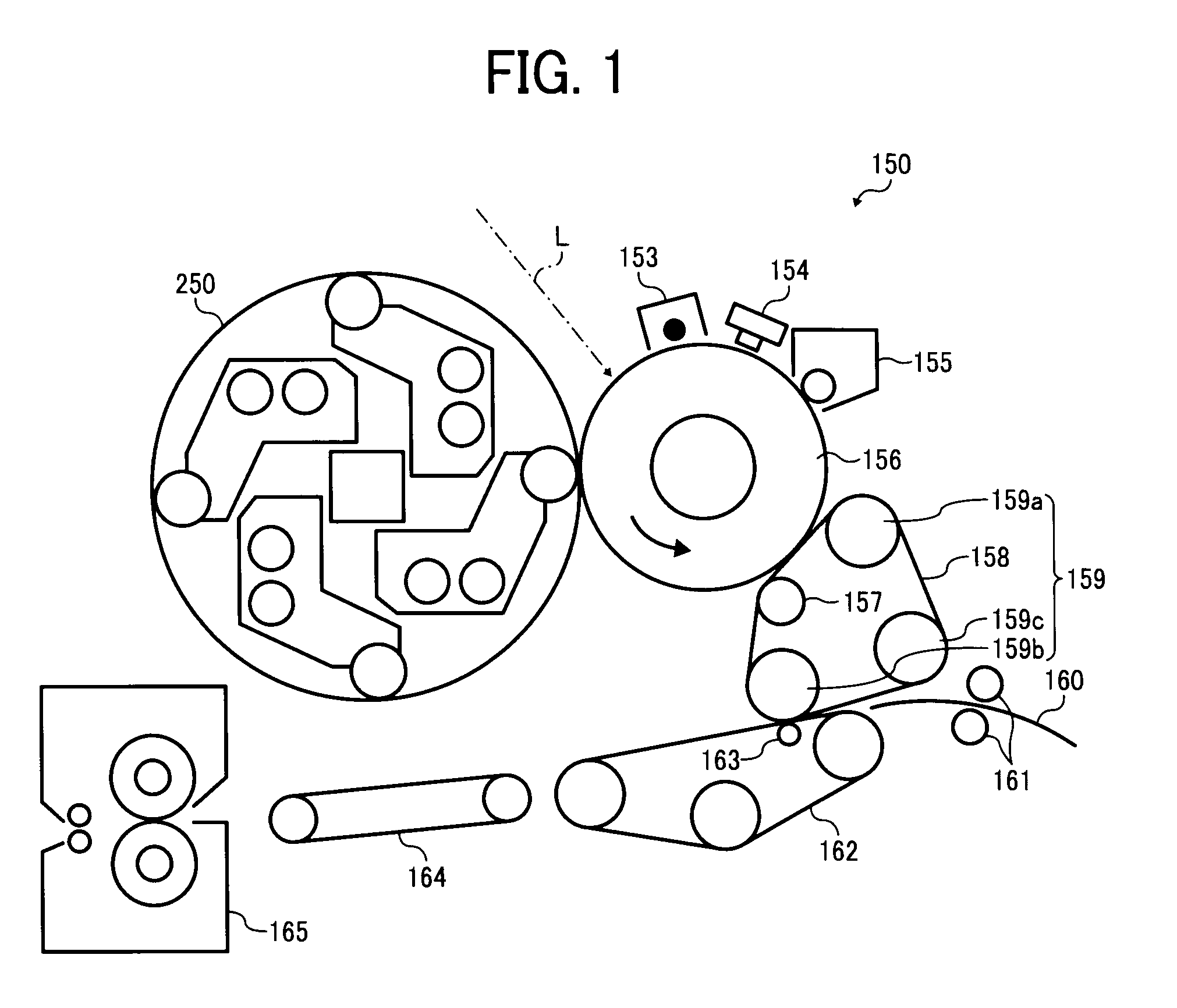

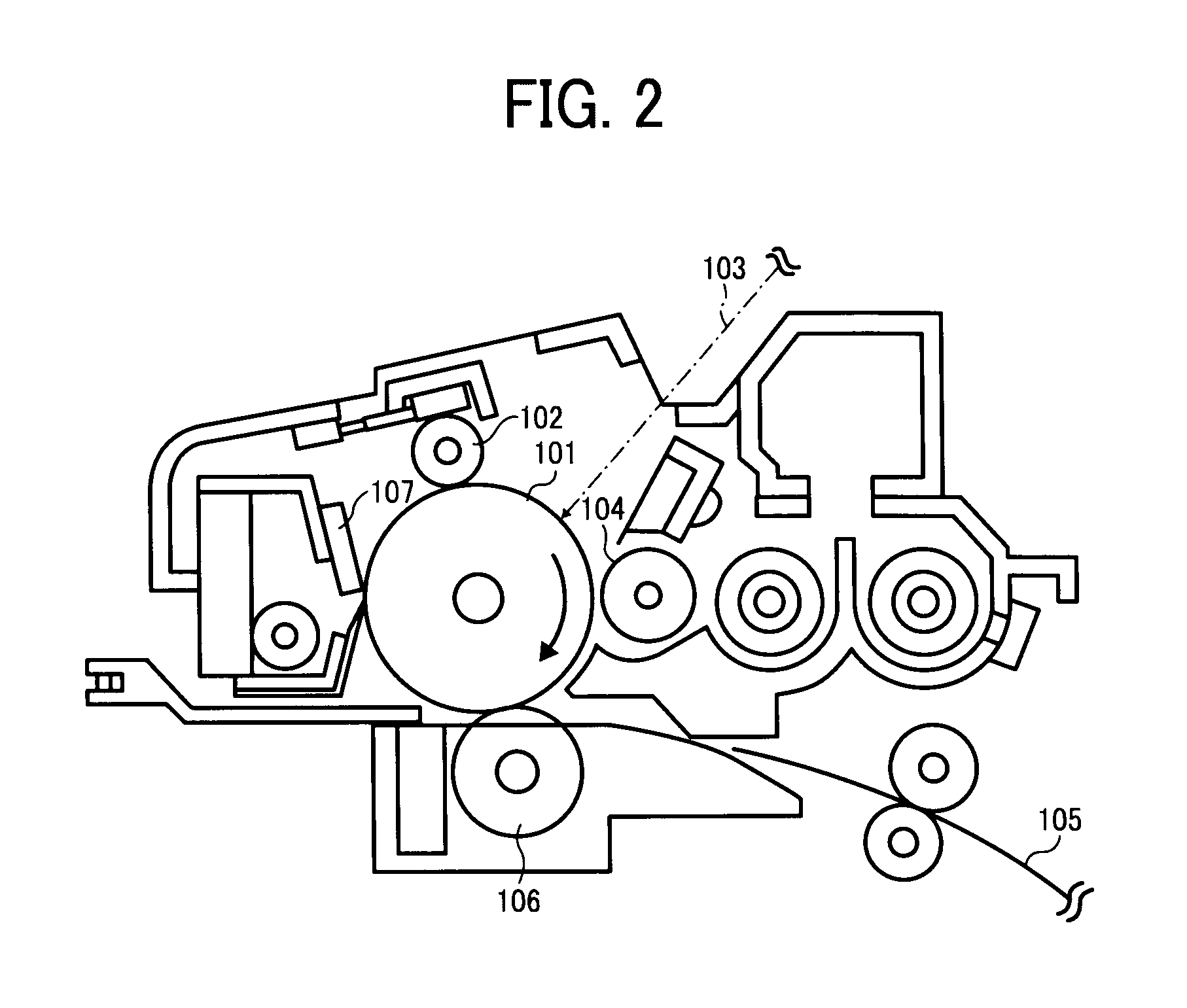

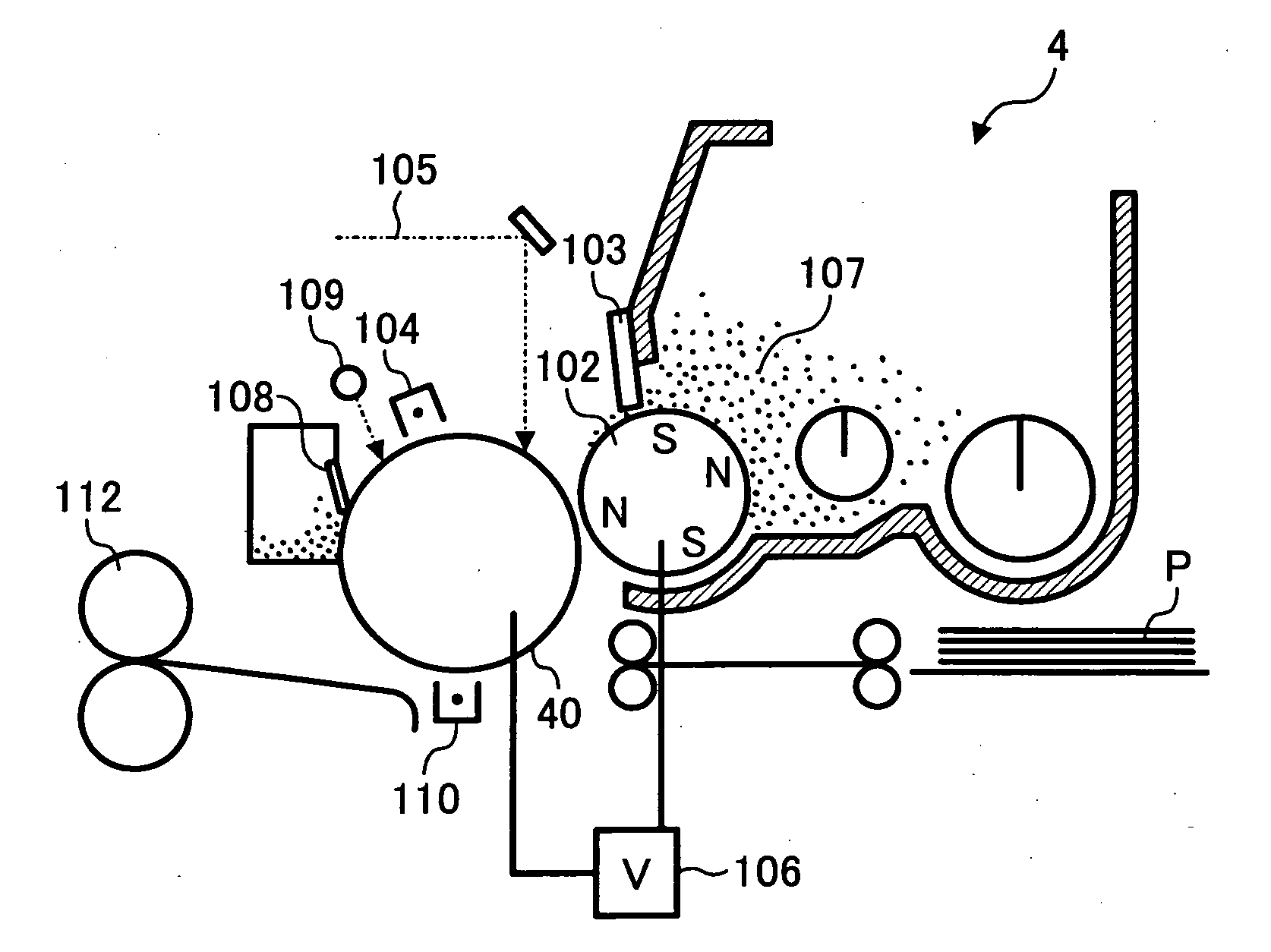

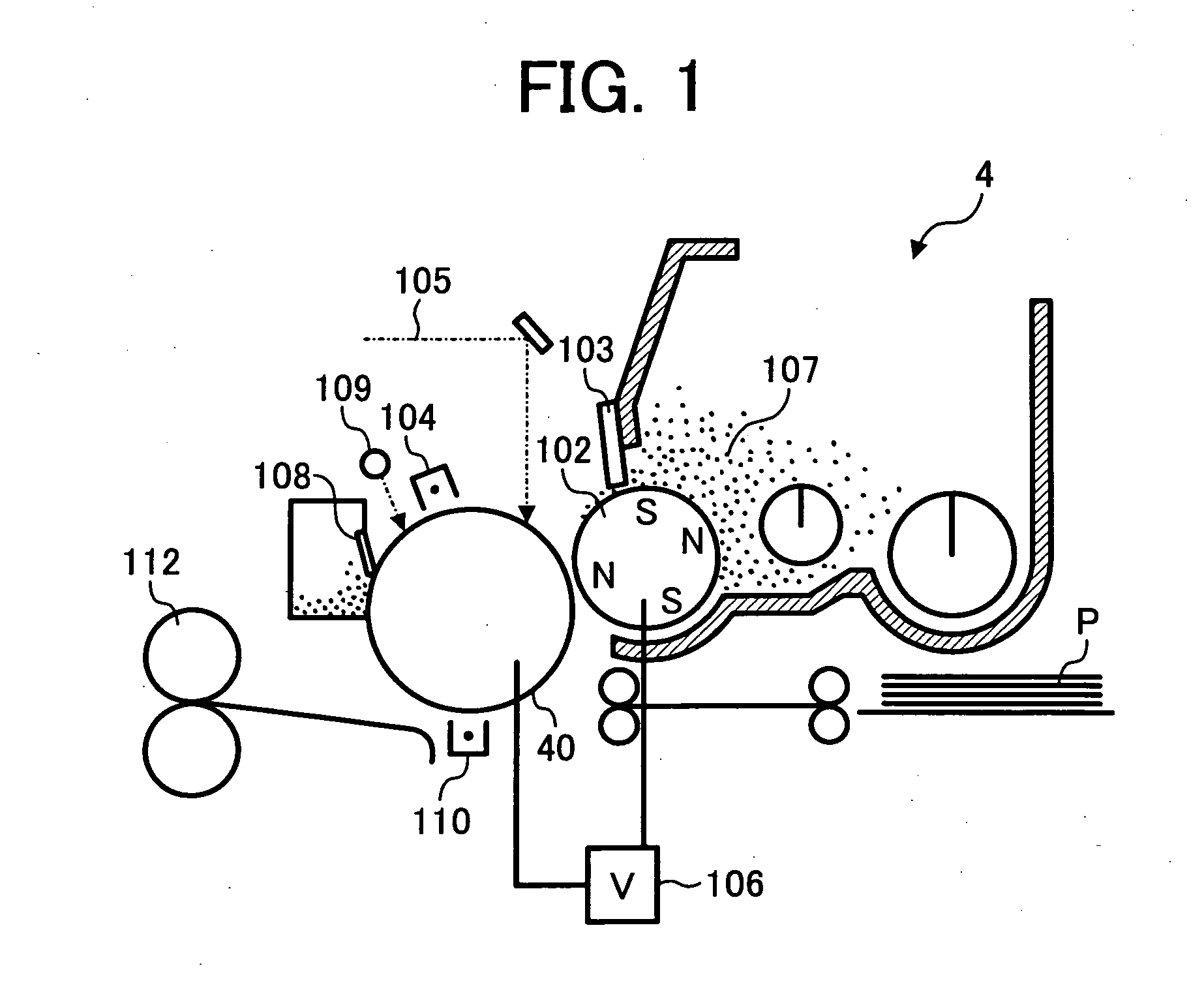

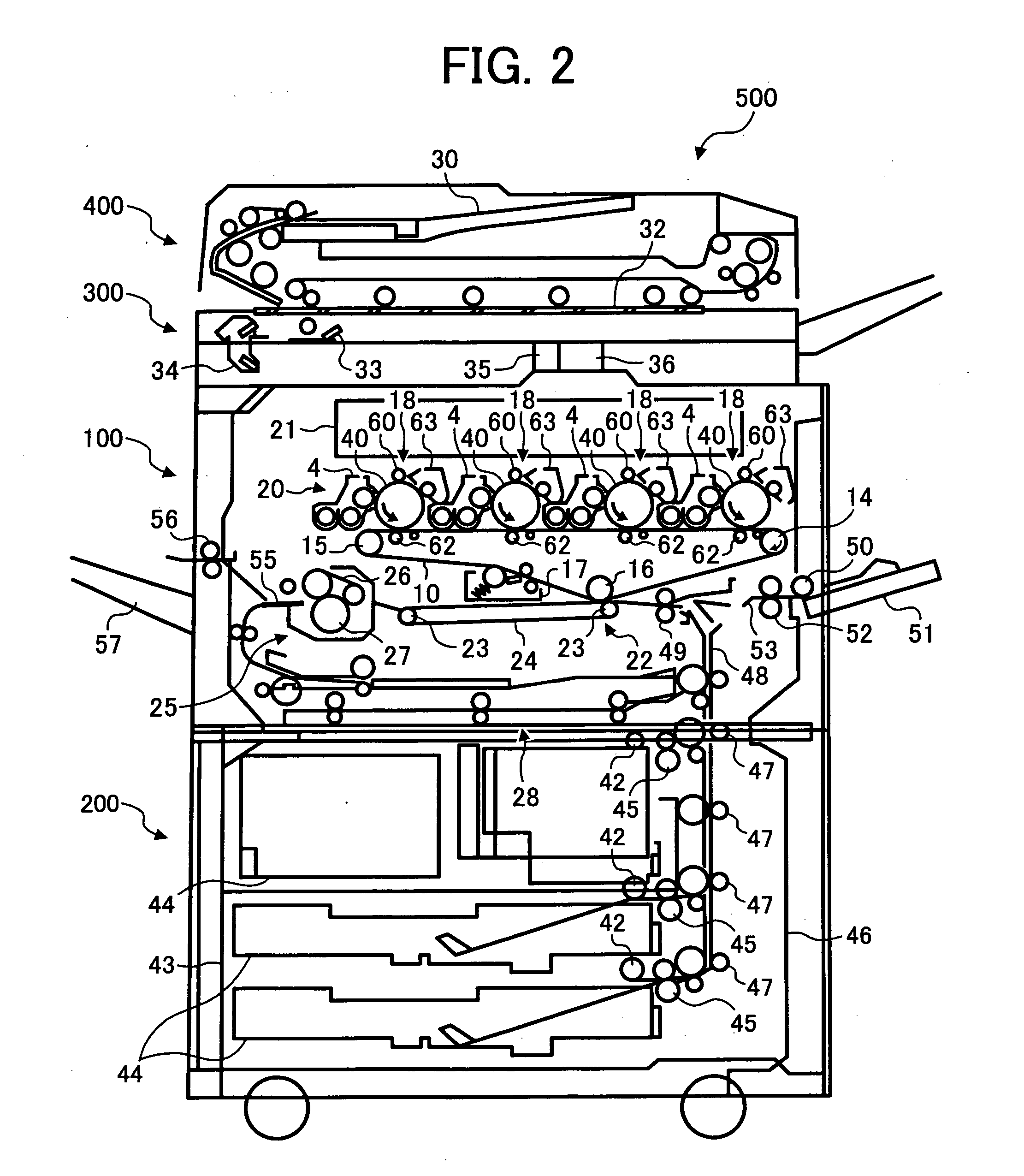

An image forming apparatus producing images at a speed of from 500 to 1,700 mm / sec, including an image bearer; a charger; an irradiator; an image developer developing an electrostatic latent image with a developer including a toner including a binder resin and a colorant; a transferer; a cleaner; and a fixer, wherein the binder resin includes a crystalline polyester resin and an amorphous resin, wherein a peak ratio (W / R) of a specific peak height (W) of the crystalline polyester resin to a specific peak height (R) of the amorphous resin is from 0.050 to 0.555, and a toner transfer rate T (%) determined by the following formula (1) is from 75 to 100%:T(%)=(V−A)×100 / V (1)wherein V represents a toner volume (mg / cm2) of the toner image on the image bearer; and A represents a toner volume (mg / cm2) thereof remaining on the image bearer after transfer.

Owner:RICOH KK

Color toner for developing electrostatic images, toner container containing the color toner, and image forming method and apparatus using the color toner

InactiveUS7052815B2Low temperature fixabilityGood transferabilityDevelopersElectrographic processes using charge patternWaxImage formation

A color toner including toner particles including a colorant, a binder resin, and a wax; and an external additive including at least one of an inorganic particulate material and a particulate resin, wherein the binder resin includes a polyester resin (A) having a crystallinity and a formula (—O—CO—CR1=CR2-CO—O—(CH2)n—)m, wherein R1 and R2 independently represents a hydrocarbon, and n and m are repeating numbers; a resin (B); and a resin (C), wherein the resins (B) and (C) and the wax have an island-sea structure such that the resin (C) is present like islands in a sea of the resin (B) and the wax is substantially included in the resin (C). A toner container, an image forming method, an image forming apparatus and a process cartridge including the color toner are also provided.

Owner:RICOH KK

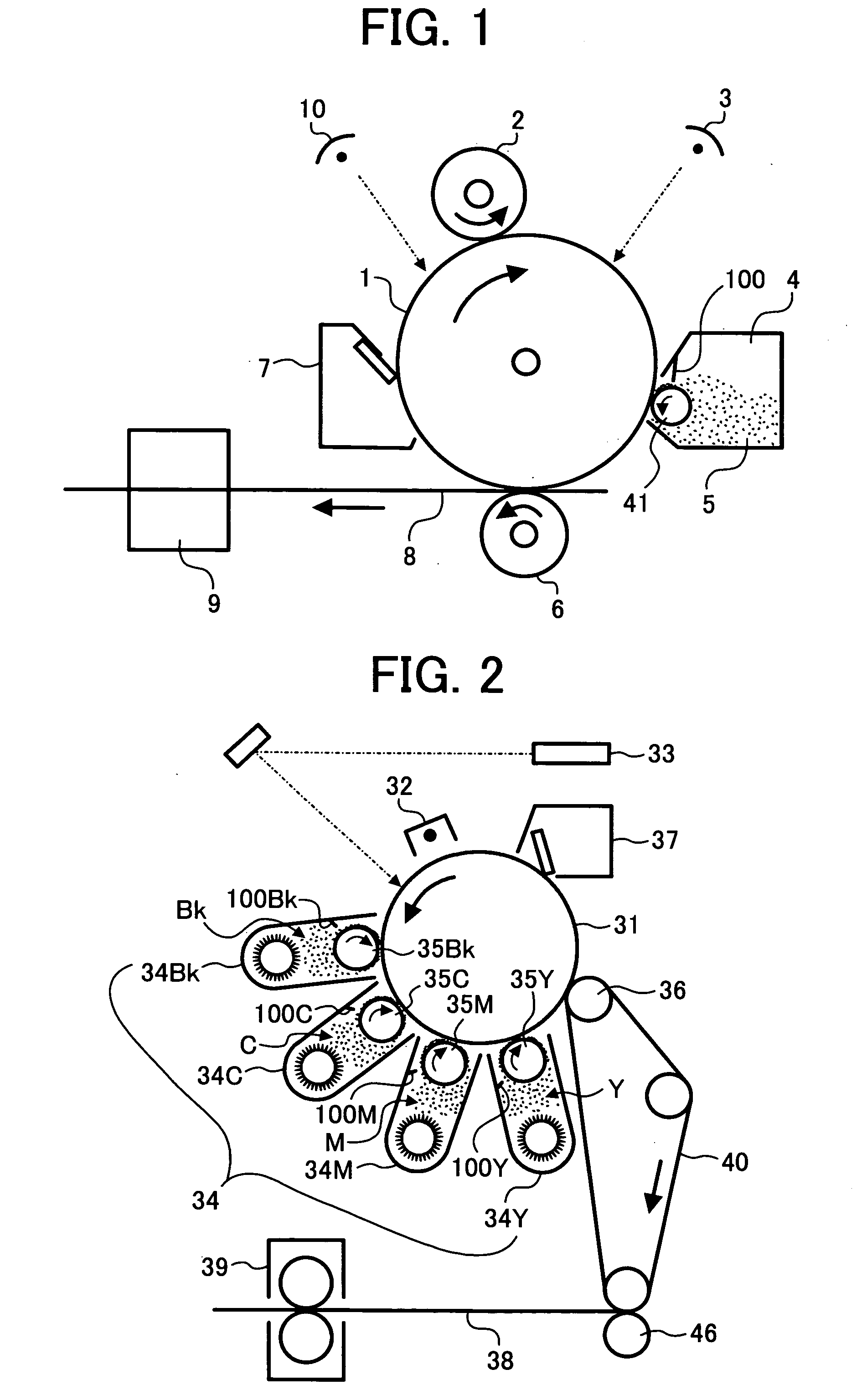

Dry toner, toner kit, and image forming apparatus and process cartridge using the dry toner

ActiveUS20050064310A1Low temperature fixabilityImage producedElectrographic process apparatusDevelopersDiketoneLatent image

A toner for forming a full color image, which includes a colorant and a binder resin including a polyester resin which is prepared by a polycondensation ester reaction in the presence of a titanium-containing catalyst selected from the group consisting of halogenated titanium, titanium diketone enolates, titanium carboxylates, titanyl carboxylates, and salts of titanyl carboxylates. A toner kit including a yellow toner, a magenta toner, a cyan toner and a black toner, wherein each of the toners is the toner mentioned above. An image forming apparatus including an image bearing member; a charger; a light irradiator; a developing device configured to develop an electrostatic latent image with a developer including the toner mentioned above; a transfer device; and a fixing device.

Owner:RICOH KK

Toner, developer, and image forming method

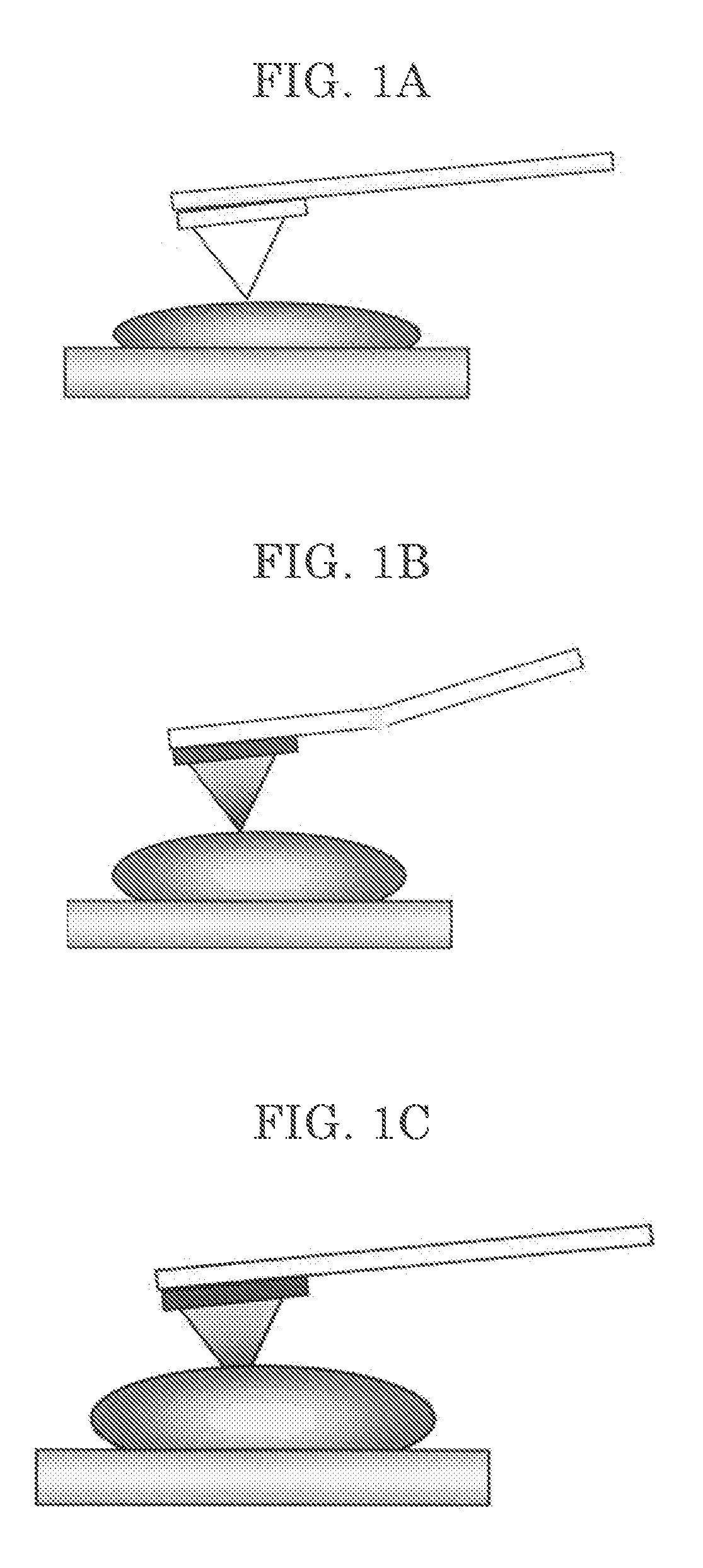

ActiveUS20090220883A1Improve responseImprove stabilityElectrographic process apparatusDevelopersEngineeringCore shell

A toner containing at least a binder resin and a colorant, wherein the toner has a core-shell structure composed of a core, and a shell having a thickness of 0.01 μm to 2 μm on a surface of the core, and wherein the toner satisfies the following relation:1.1≦ST / CT≦2.0where ST is a softening temperature of the shell, and CT is a softening temperature of the core, both measured by a SPM probe with an integrated heater.

Owner:RICOH KK

Toner containing unsaturated polyester in binder resin, method for preparing the toner, and developer including the toner

A toner including a binder resin comprising a polyester resin in an amount of from 50 to 100% by weight, wherein the polyester resin includes an unsaturated polyester resin which is preferably a crystalline polyester resin; a colorant; and a fatty acid metal salt which is preferably microencapsulated. A method for preparing a toner including forming particles of a toner composition including at least a binder resin including a polyester resin in an amount of from 50 to 100% by weight and a colorant, in an aqueous medium to prepare a dispersion of a particulate material, wherein the polyester resin includes an unsaturated polyester resin; drying the particulate material; and mixing a fatty acid metal salt with the particulate material to subject double bonds of the unsaturated polyester resin to oxidation polymerization.

Owner:RICOH KK

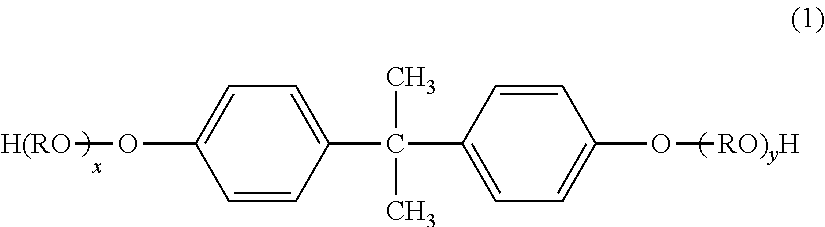

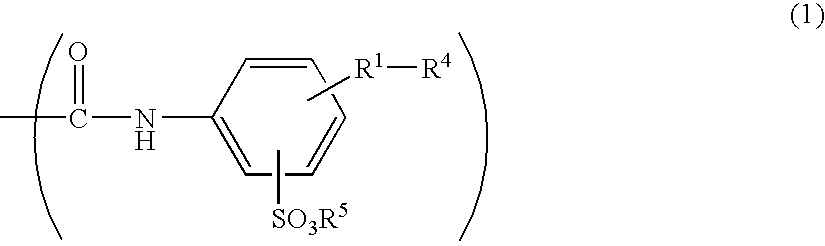

Toner for developing electrostatic image, fixing method for fixing image formed of the toner, and image forming method and process cartridge using the toner

ActiveUS20050250037A1Improve bindingLittle background foulingElectrographic process apparatusDevelopersPolyesterImage formation

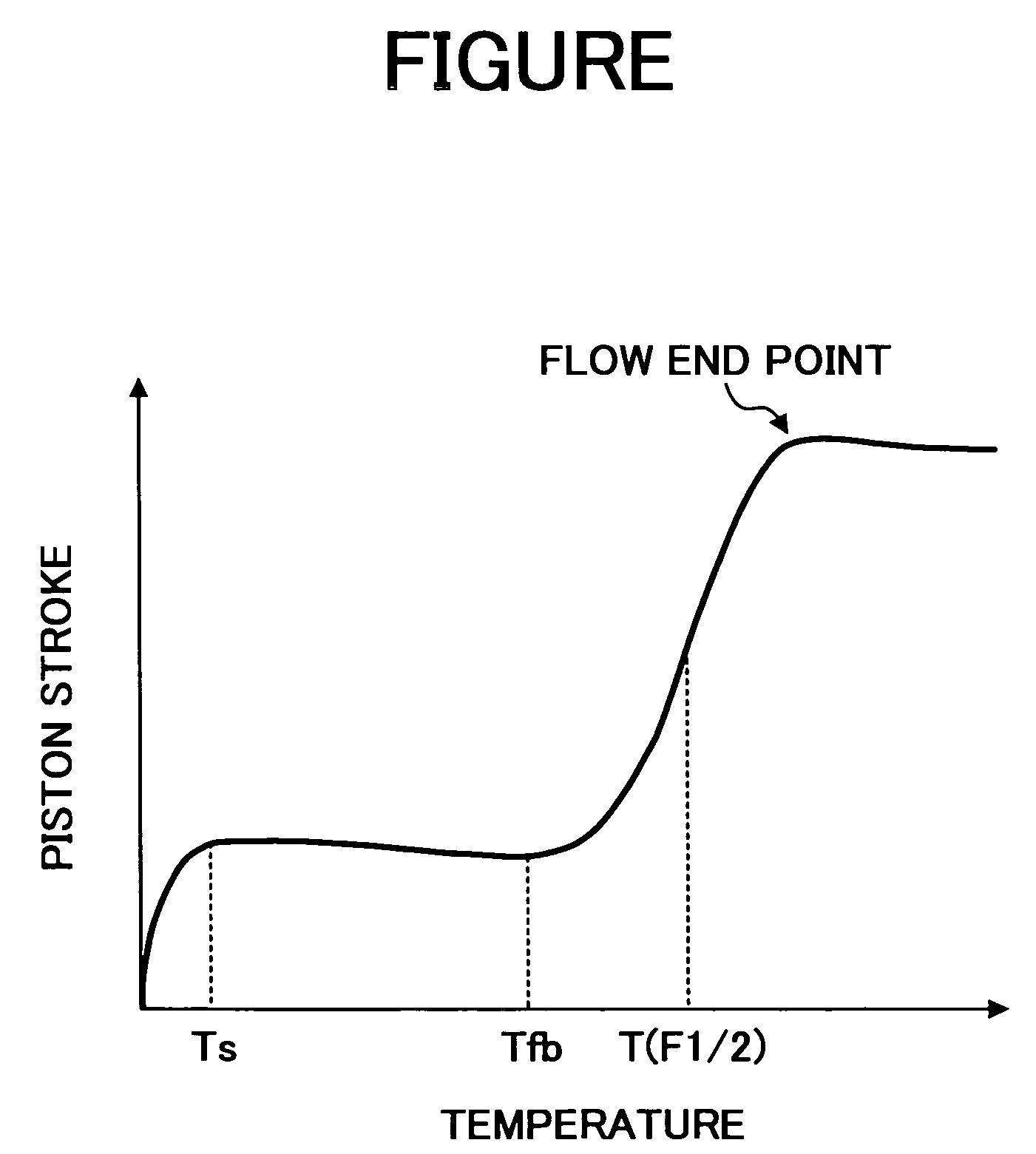

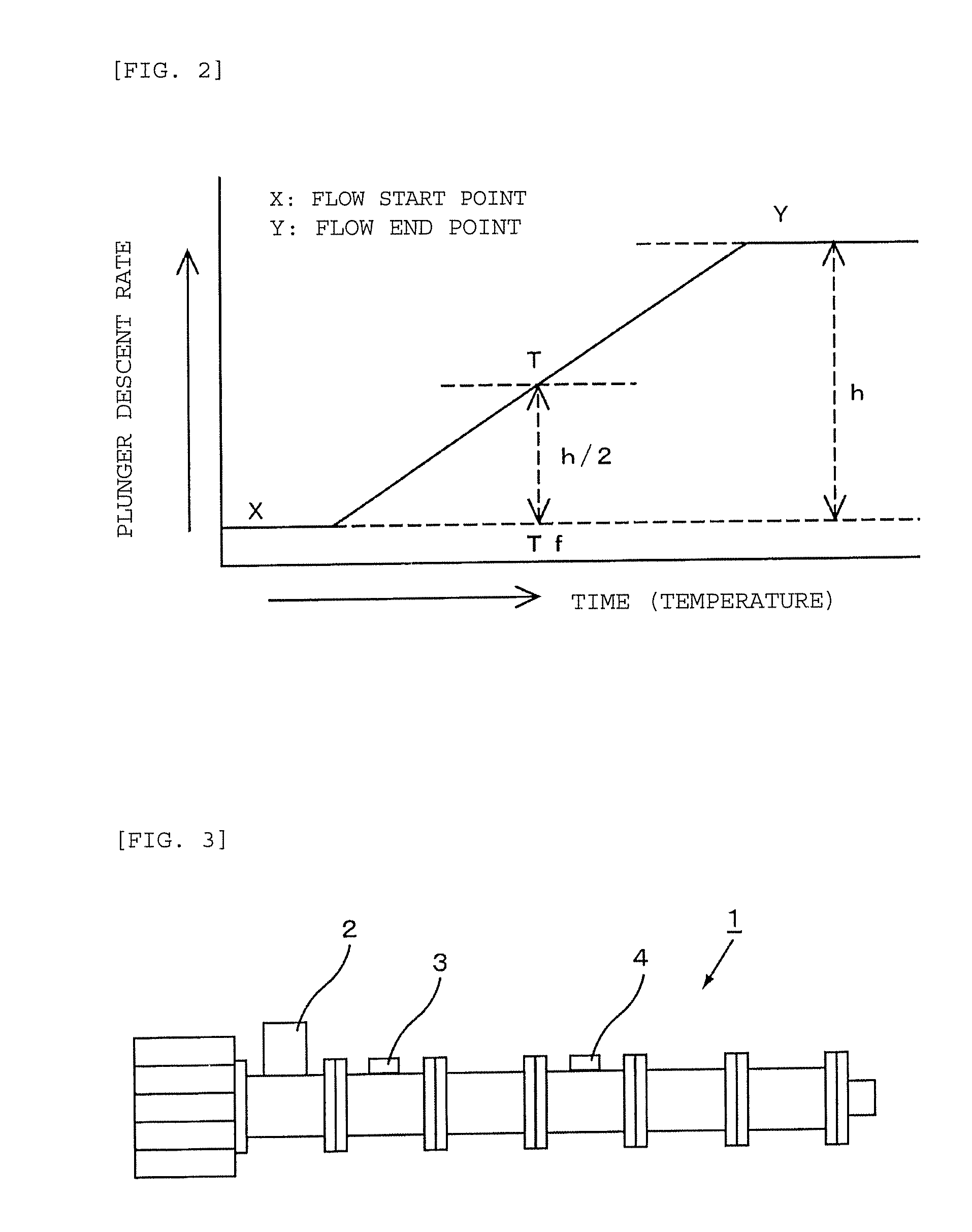

A toner including toner particles including a colorant; a binder resin; and a release agent, wherein the binder resin includes a polyester resin (A) having a crystallinity and a specific formula (1), wherein a molar ratio of the ester bond of the crystalline polyester resin to total ester bonds included in the binder resin is not less than 0.60, and wherein the toner has a weight average particle diameter of from 3.0 to 9.0 μm, and includes toner particles having a particle diameter not greater than 5 μm in an amount of from 60 to 90% by quantity. A fixing method in which a toner image of the toner is fixed with a fixing device including a fixing roller having a thickness not greater than 1.0 mm and a pressure roller, wherein the fixing pressure is not greater than 1.5×105 Pa. An image forming method and a process cartridge using the toner are also provided.

Owner:RICOH KK

Electrostatic image developing toner, toner kit and image forming apparatus

ActiveUS20090123186A1Excellent blocking resistanceLow temperature fixabilityDevelopersElectrographic process apparatusHydrogen atomEther

A toner is provided that comprises a colorant and a binder resin, wherein the binder resin comprises a polyester resin that is prepared by a polycondensation reaction in the presence of at least a titanium-containing catalyst expressed by General Formula (II) or (II), the toner has a volume average particle diameter of 2.0 μm to 10.0 μm and a ratio Dv / Dn within a range of 1.00 to 1.40, in which Dv represents a volume average particle diameter and Dn represents a number average particle diameter,Ti(—X)m(-OH)n General Formula (I)O═Ti(—X)p(-OR)q General Formula (II)in General Formulas (I) and (II), X represents a residue of a mono-alkanolamine of 2 to 12 carbon atoms or a polyalkanolamine from which a hydrogen atom of one hydroxyl group is removed; other hydroxyl group(s) and still other hydroxyl group(s), within the polyalkanolamine molecule that has a directly bonding Ti atom, may polycondense to form a ring structure; other hydroxyl group(s) and still other hydroxyl group(s) may polycondense intermolecularly to form a repeating structure; and the polymerization degree is 2 to 5 in a case of forming the repeating structure; R represents one of a hydrogen atom and alkyl groups of 1 to 8 carbon atoms that may have 1 to 3 ether bonds; “m” is an integer of 1 to 4; “n” is an integer of 0 to 3; the sum of “m” and “n” is 4; “p” is an integer of 1 or 2; “q” is an integer of 0 or 1; the sum of “p” and “q” is 2; and in a case that “m” and “p” is 2 or more, the respective Xs may be identical or different each other.

Owner:RICOH KK

Toner

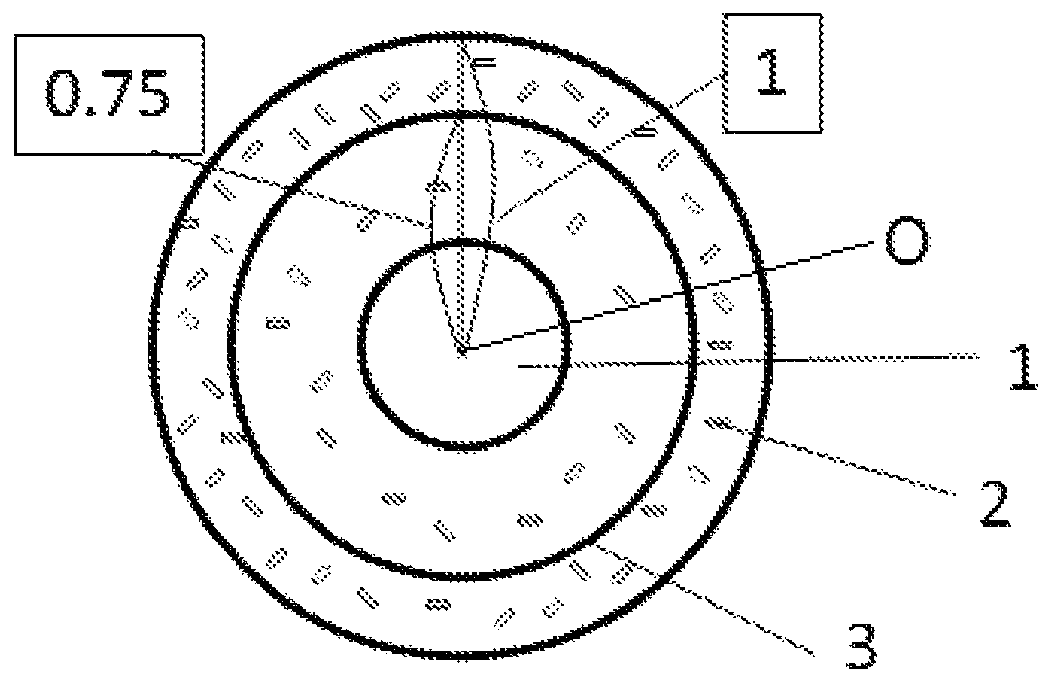

ActiveUS9964874B2Low-temperature fixabilityIncrease resistanceDevelopersPolyesterElectron microscope

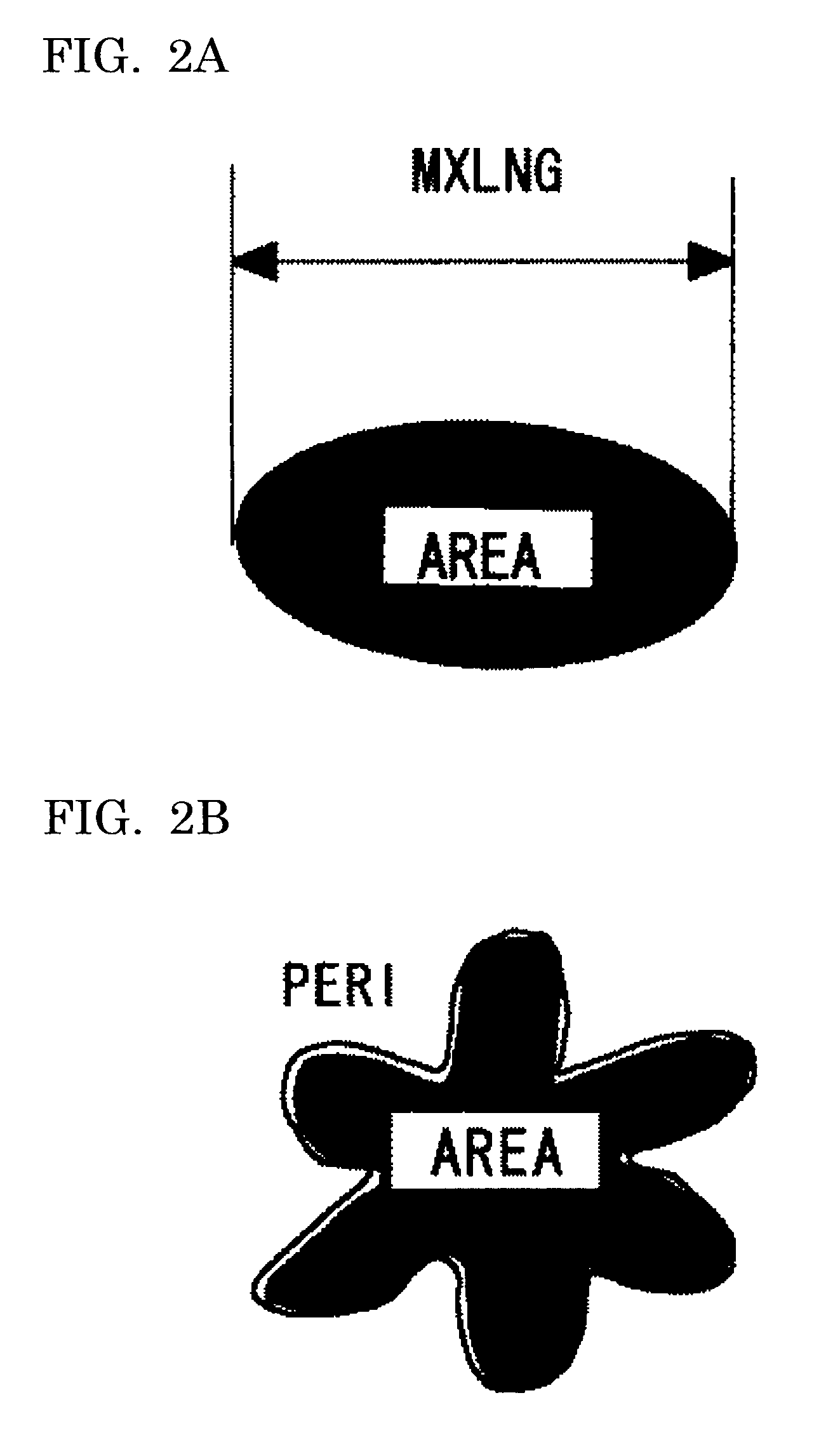

Provided is a toner including a binder resin, a colorant, a crystalline polyester, and a release agent, wherein a cross-sectional image of the toner is observed using a scanning transmission electron microscope, domains of the crystalline polyester are present in the cross-sectional image of the toner, the domains have a number-average major diameter of at least 50 nm and not more than 300 nm, the number of the domains is at least 8 and not more than 500, and the domains are present at least 60 number % and not more than 100 number % from an outline of the cross-sectional image to 25% of the distance between the outline and the centroid of the cross-sectional image.

Owner:CANON KK

Resin composition for toner and method for preparing resin composition for toner

The present invention aims to provide a resin composition for toners which enables to obtain a toner having excellent low temperature fixability and high temperature offset resistance, and a toner. The resin composition for toners is obtained by reacting a mixture of a branched polyester (A) having a number average molecular weight of 2,000 to 7,000 and a hydroxyl value of 20 to 80, and a low molecular weight linear polyester (B) having a number average molecular weight of 2,000 to 5,000 and a hydroxyl number of 20 to 55, with an isocyanate compound containing two or more isocyanate groups in one molecule, which comprises a crosslinked structure of said branched polyester (A), a structure in which said branched polyester (A) and said low molecular weight linear polyester (B) are bonded by said isocyanate compound, and an unreacted portion of said low molecular weight linear polyester (B).

Owner:MITSUI CHEM INC

Toner, and image forming apparatus and process cartridge using the same

InactiveUS20080233511A1Improve charging effectStably forming quality images for a long timeElectrographic process apparatusDevelopersCompound aPolymer science

A toner including particles including a toner composition including a binder resin and a coloring material, wherein the toner composition includes a laminate compound A in which a cation between layers is modified by an organic cation, and a laminate compound B in which an anion between layers is modified by an organic anion, the laminate compound A is of negative charging property upon particulation of the laminate compound A by dispersion or internal addition in the binder resin and the laminate compound B is of positive charging property upon particulation of the laminate compound B by dispersion or internal addition in the binder resin, and the toner is of a positive charging property.

Owner:RICOH KK

Toner, developer including the toner, and developing device and image forming apparatus using the toner

InactiveUS20050208403A1Easy to optimizeLow temperature fixabilityDevelopersElectrographic processes using charge patternParticulatesImage formation

A toner including toner particles including a binder resin containing at least one polyester resin comprising an inorganic tin (II) compound and an external additive including a particulate inorganic material having a volume average particle diameter greater than 70 nm and less than 300 nm. The binder resin preferably includes a polyester resin having a weight average molecular weight of from 5,000 to 50,000 and another resin having a weight average molecular weight of from 200,000 to 400,000. A developer including the toner; and a developing device, an image forming apparatus and a process cartridge, which form toner images using the toner are also provided.

Owner:RICOH KK

Toner and image forming method using the toner

ActiveUS20100129748A1Increase resistanceLow-temperature fixabilityDevelopersElectrographic processes using charge patternVitrificationImage formation

A toner satisfying at least one of the following relationships:10° C.<(T1−T2)<60° C. and 0<Q2 / Q1<2 / 3wherein T1 represents a glass transition temperature of the toner and Q1 represents an endothermic quantity at a melting point thereof before melting when heated from −20° C. to 150° C. at a heating speed of 10° C. / min, and T2 represents a glass transition temperature thereof and Q2 represents a an endothermic quantity at a melting point thereof after melting after heated from −20° C. to 150° C. at a heating speed of 10° C. / min, cooled to −20° C. at a cooling speed of 10° C. / min and heated again at a heating speed of 10° C. / min.

Owner:RICOH KK

Toner, development agent, image forming apparatus, and image forming method

InactiveUS20140080050A1Toner accumulatingLow viscosityElectrographic process apparatusDevelopersPulse nuclear magnetic resonanceImage formation

Toner contains a binder resin, wherein the binder resin contains a block copolymer A containing a crystalline segment X and a non-crystalline segment Y, wherein the toner has a thermo-mechanical analysis (TMA) compressive deformation amount (TMA %) of 10% or less at 50° C. and a relative humidity of 90%, wherein the toner has a spin-spin relaxation time (t130) of 10 ms or greater at 130° C. as measured by pulse nuclear magnetic resonance (NMR), wherein the toner has a spin-spin relaxation time (t′70) of 1 ms or less at 70° C. as measured by pulse NMR when descending from 130° C. to 70° C.

Owner:RICOH KK

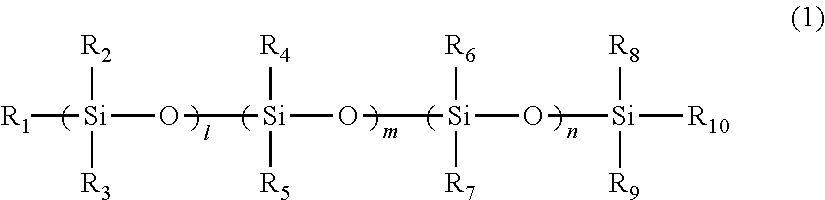

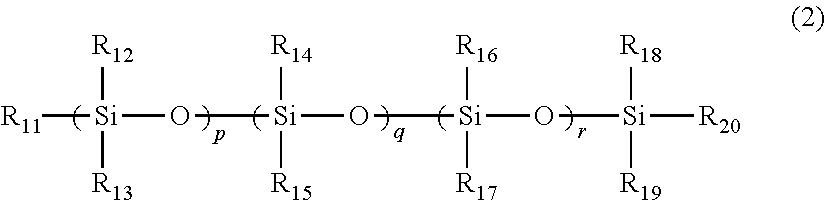

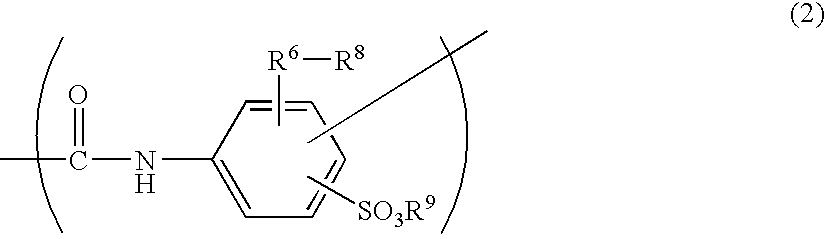

Toner and method for producing toner

A toner including: a binder resin containing an ethylene-vinyl acetate copolymer; a polysiloxane derivative A represented by structural formula 1; and a polysiloxane derivative B represented by structural formula 2:(in structural formula 1, R1 to R10 each independently represent a methyl group or a phenyl group, and l, m and n each independently represent an integer of at least 1)(in structural formula 2, at least one of R11 to R20 is an organic group having a C4-30 alkyl group, a C4-30 alkoxy group, an acrylic group, an amino group, a methacrylic group or a carboxyl group, the remaining groups among R11 to R20 each independently represent a methyl group or a phenyl group, and p, q and r each independently represent an integer of at least 1).

Owner:CANON KK

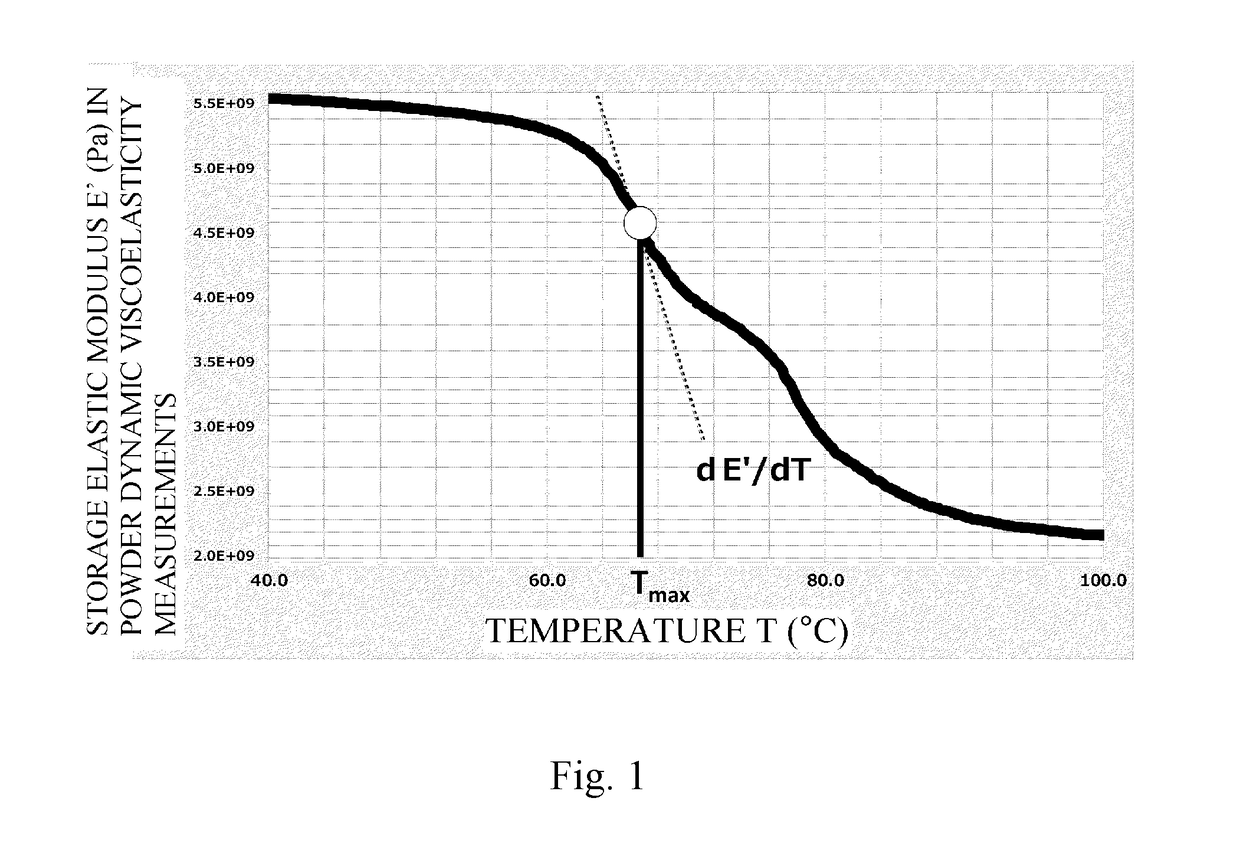

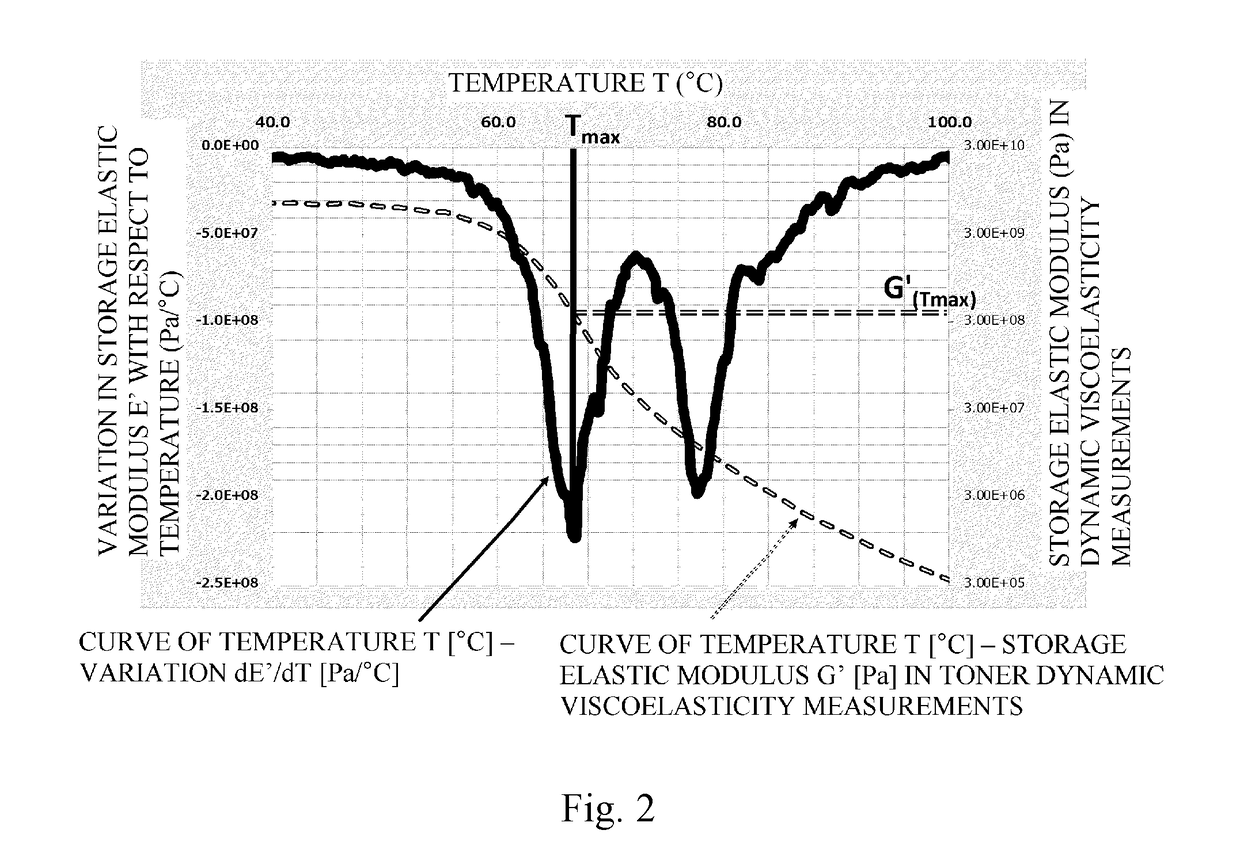

Toner, and external additive for toner

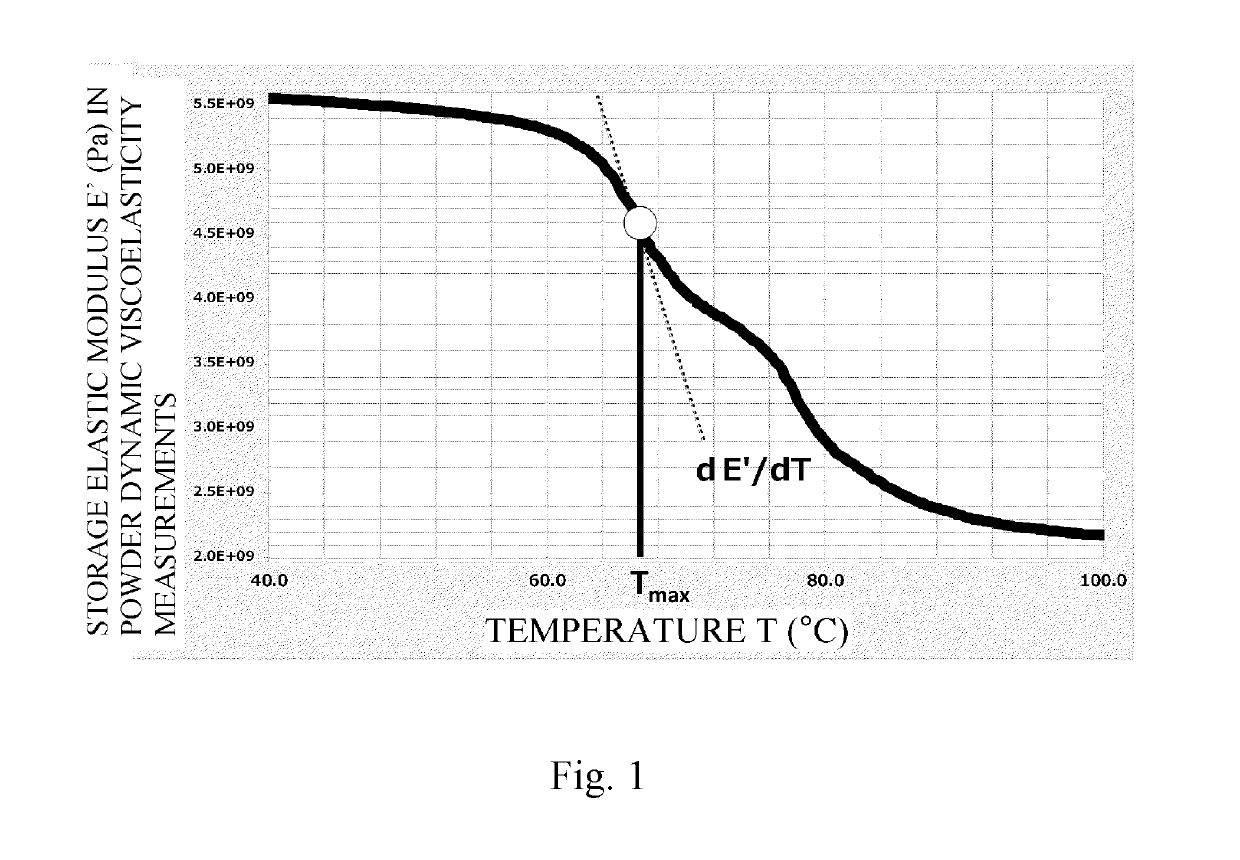

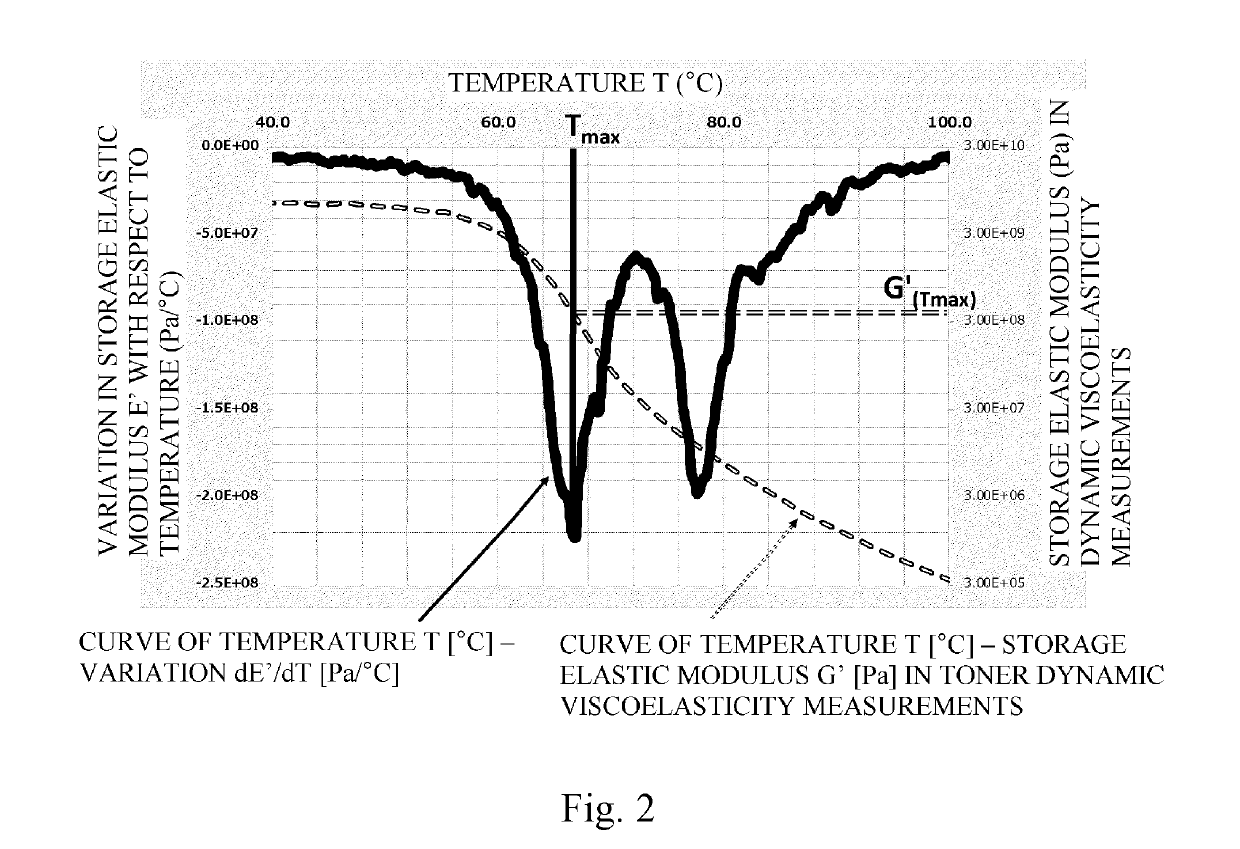

A toner comprising: a toner particle containing a binder resin and a colorant; and an external additive, wherein the external additive is a composite particle having an organic substance and an organosilicon polymer coating layer on the surface of the organic substance, and when a curve for the variation (dE′ / dT) in the storage elastic modulus E′ of the toner with respect to temperature T [° C.] is obtained on the basis of a curve of the temperature T—the storage elastic modulus E′ [Pa] of the toner, as determined by powder dynamic viscoelasticity measurements of the toner, the relative minimum value on the lowest temperature side between the onset temperature and 90° C. is −1.35×108 or less.

Owner:CANON KK

Toner, and external additive for toner

ActiveUS10241430B2Low temperature fixabilityLower performance requirementsDevelopersDynamic viscoelasticityPolymer coatings

Owner:CANON KK

Toner and method for producing the same

ActiveUS20110164901A1Achieving fixabilityGood fixabilityElectrographic process apparatusDevelopersPolyesterChemistry

A toner containing core particles each containing at least a resin A having a polyester skeleton and a colorant; and vinyl resin fine particles each of which encapsulates a resin B having at least a polyester skeleton and an endothermic peak measured by differential scanning calorimeter (DSC) at 40° C. to 110° C., wherein the vinyl resin fine particles are attached onto each of the core particles.

Owner:RICOH KK

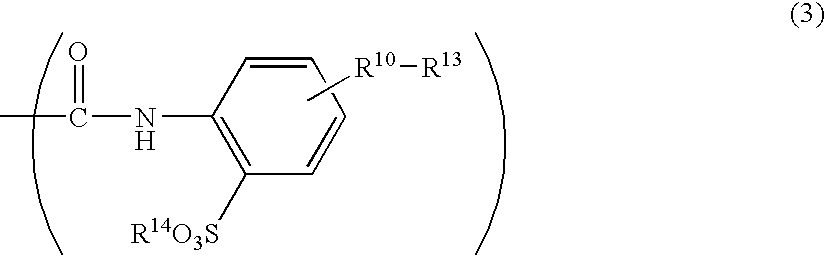

Resin for toner and toner

InactiveUS20070275317A1Good fixabilityGood charging propertyOrganic chemistryDevelopersPolyesterPolyol

A resin for toner containing a resin component having both a polyester unit produced by polycondensation of a polyhydric alcohol component and a polycarboxylic acid component, and an aryl group having a sulfonic ester group as a substituent; and a toner that contains the resin for toner.

Owner:CANON KK

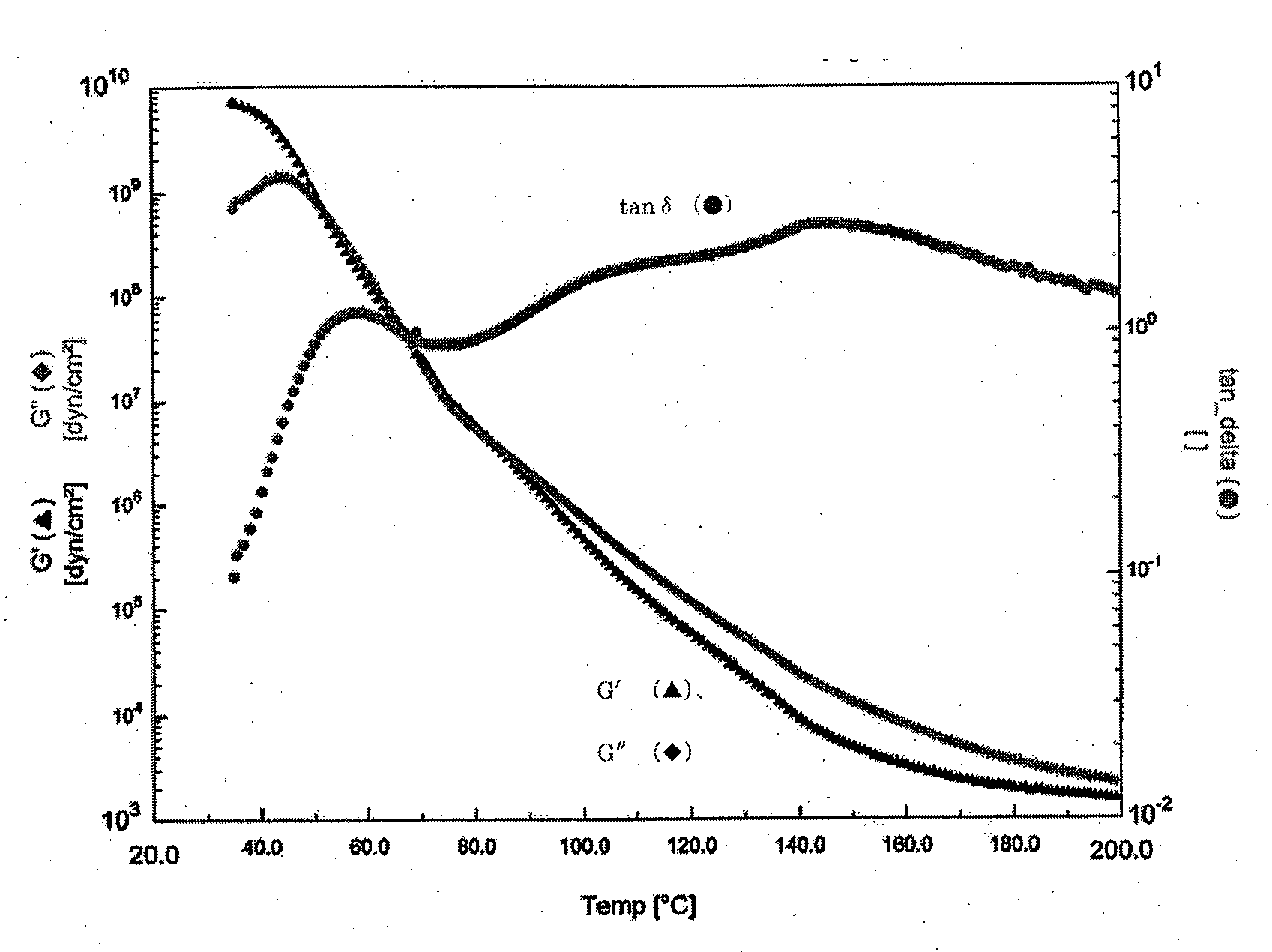

Non-magnetic toner

ActiveUS20090186290A1Excellent in transfer performanceLow-temperature fixabilityDevelopersWaxElastic modulus

Provided is anon-magnetic toner including toner particles each containing at least a binder resin, a colorant, and a wax component, and an inorganic fine powder, in which: (1) when a temperature in a temperature range of 50 to 80° C. at which a loss tangent (tan δ) shows a maximum is represented by T1, a storage elastic modulus of the toner at the temperature T1 (G′(T1)) satisfies a relationship of 5.00×107≦G′(T1)≦1.00×109 (dN / m2); (2) a continuous temperature range with a width of 15° C. or more in which the loss tangent (tan δ) is 0.80 to 2.00 is present in the temperature range of 50 to 80° C.; and (3) the loss tangent (tan δ) is 1.00 or more in a temperature range of 120 to 160° C.

Owner:CANON KK

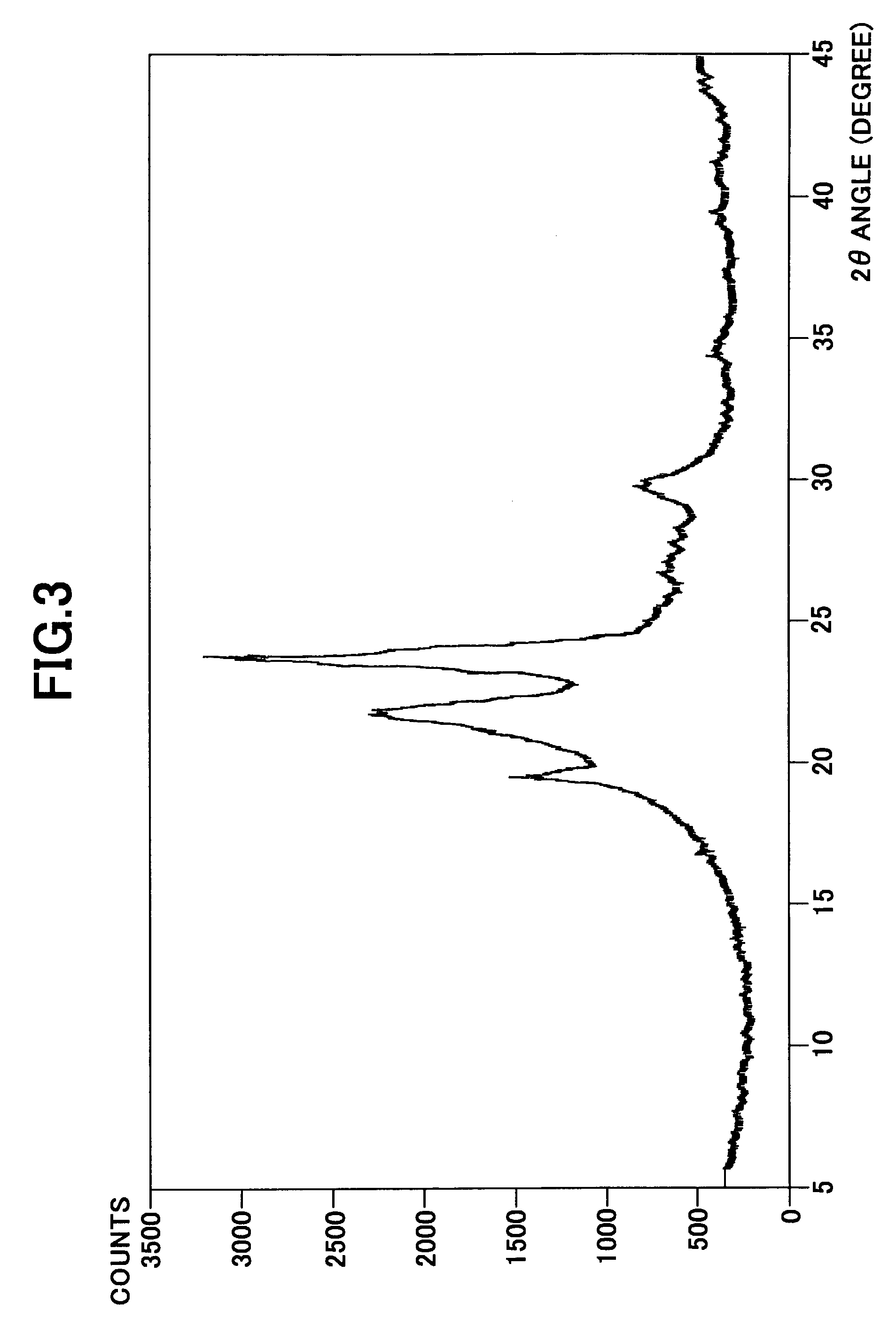

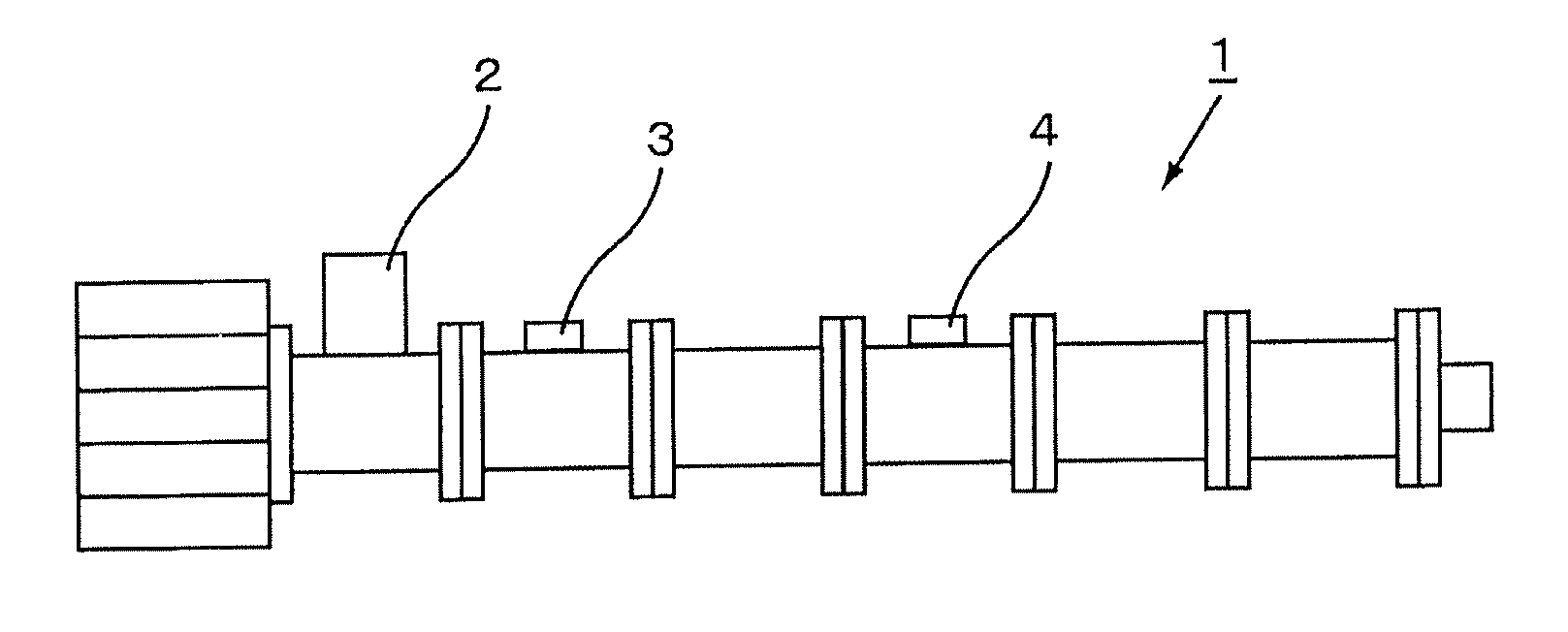

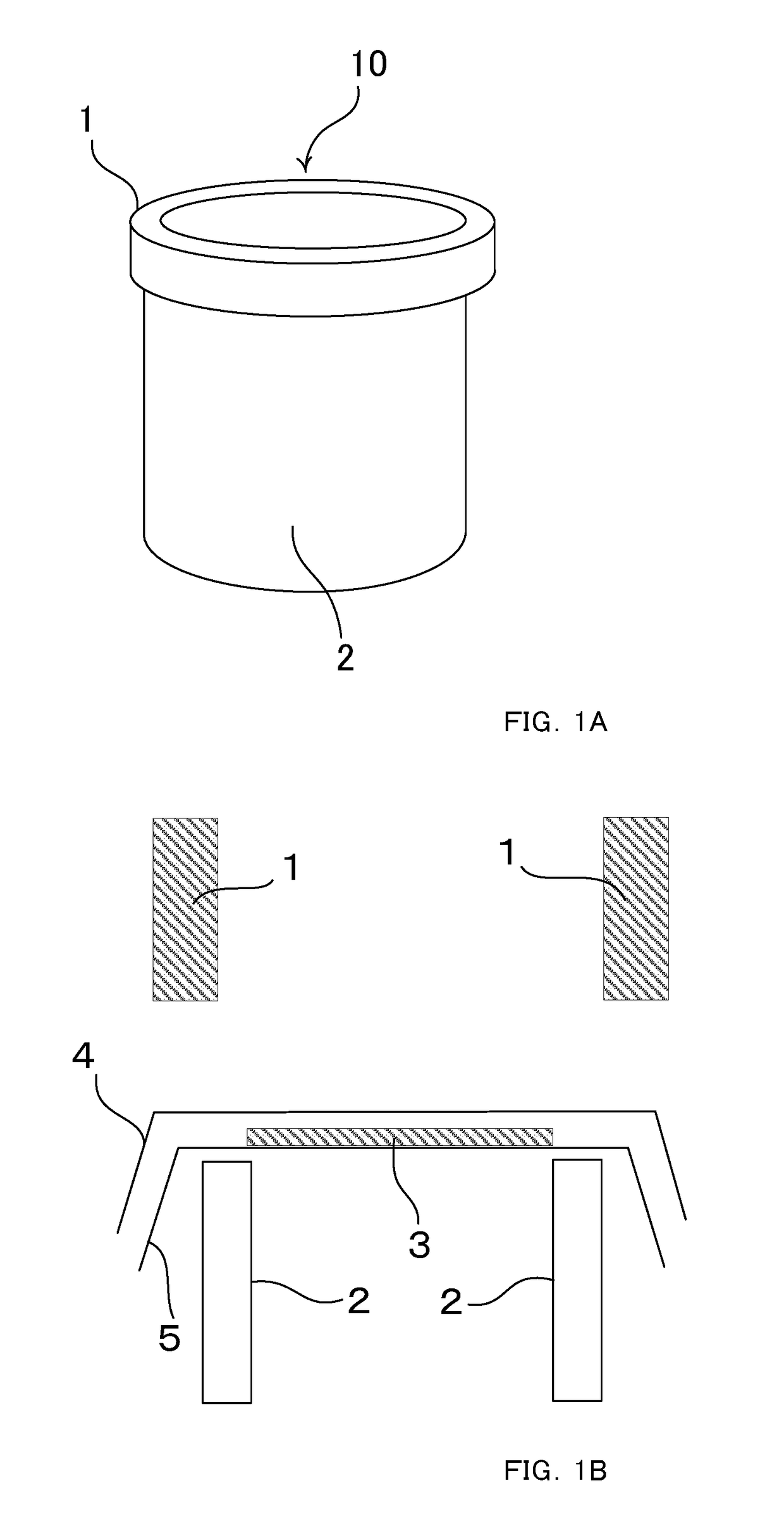

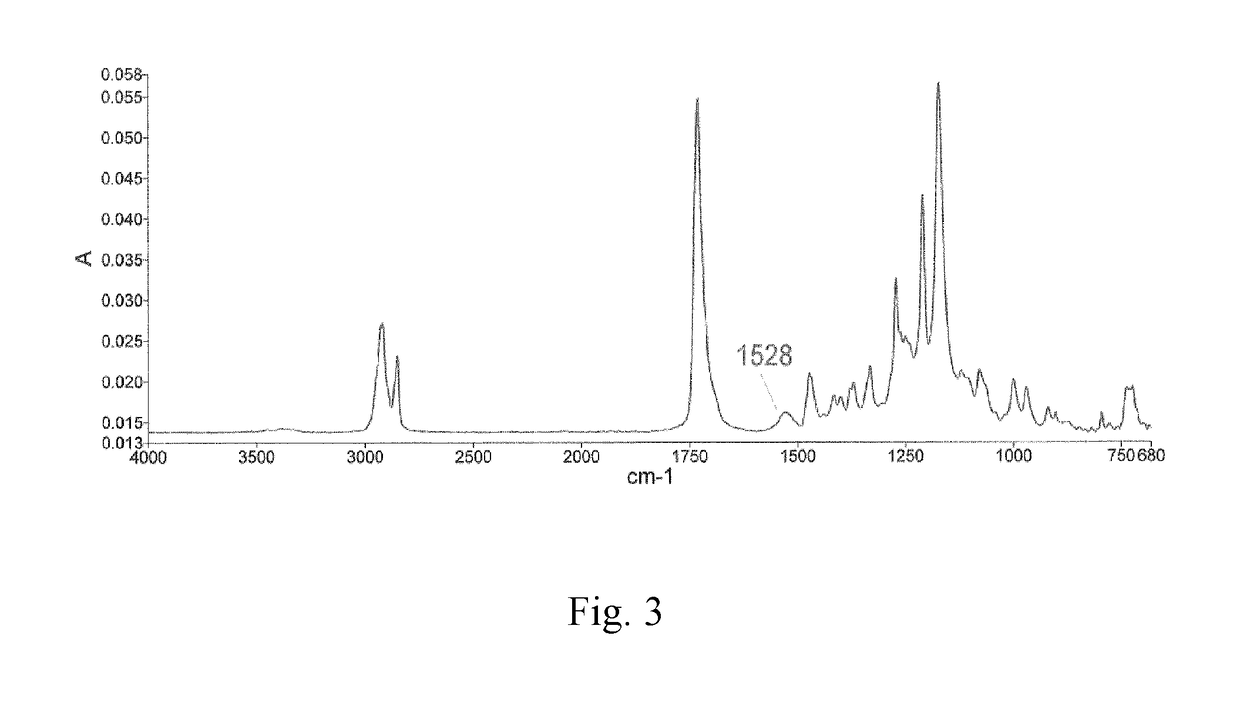

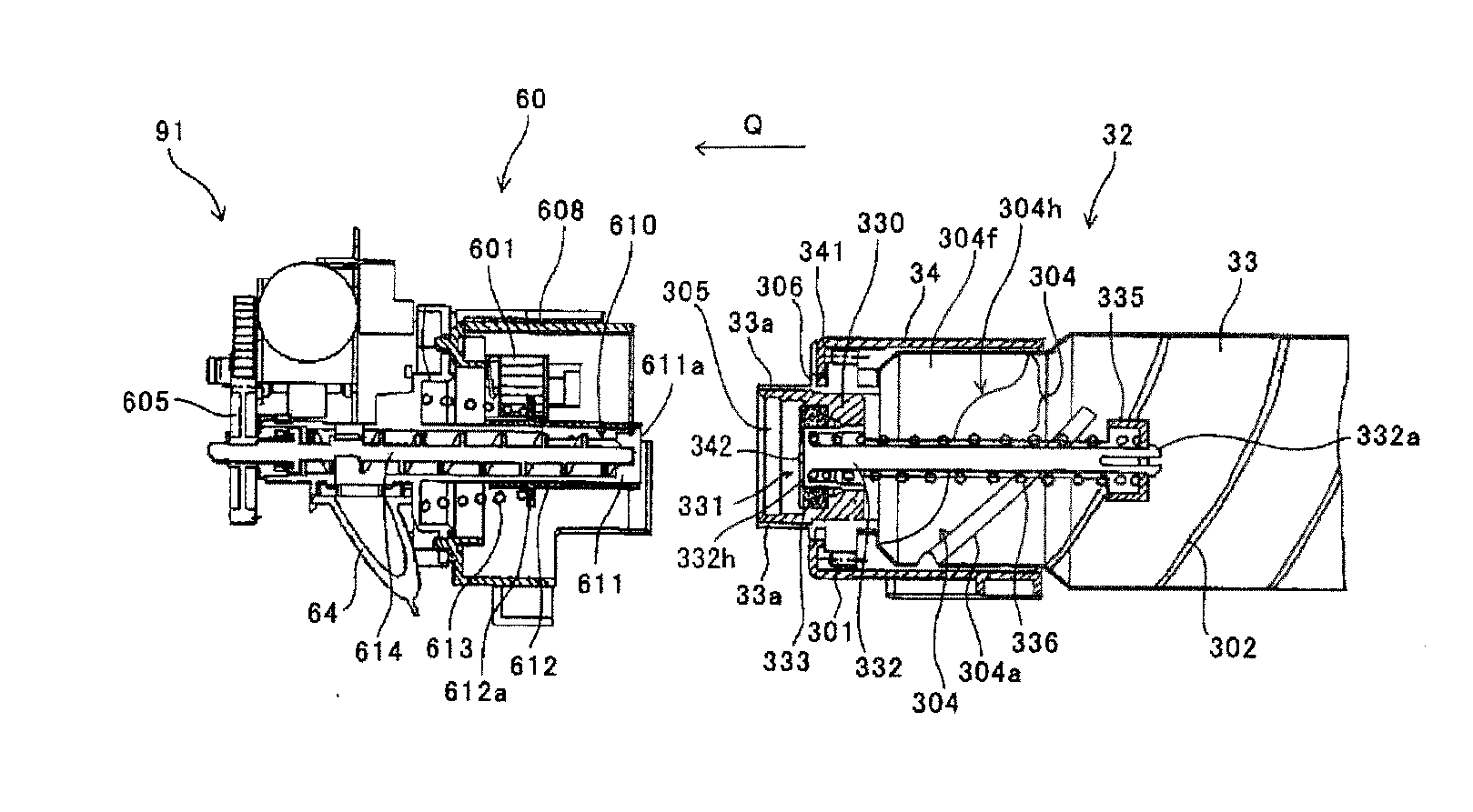

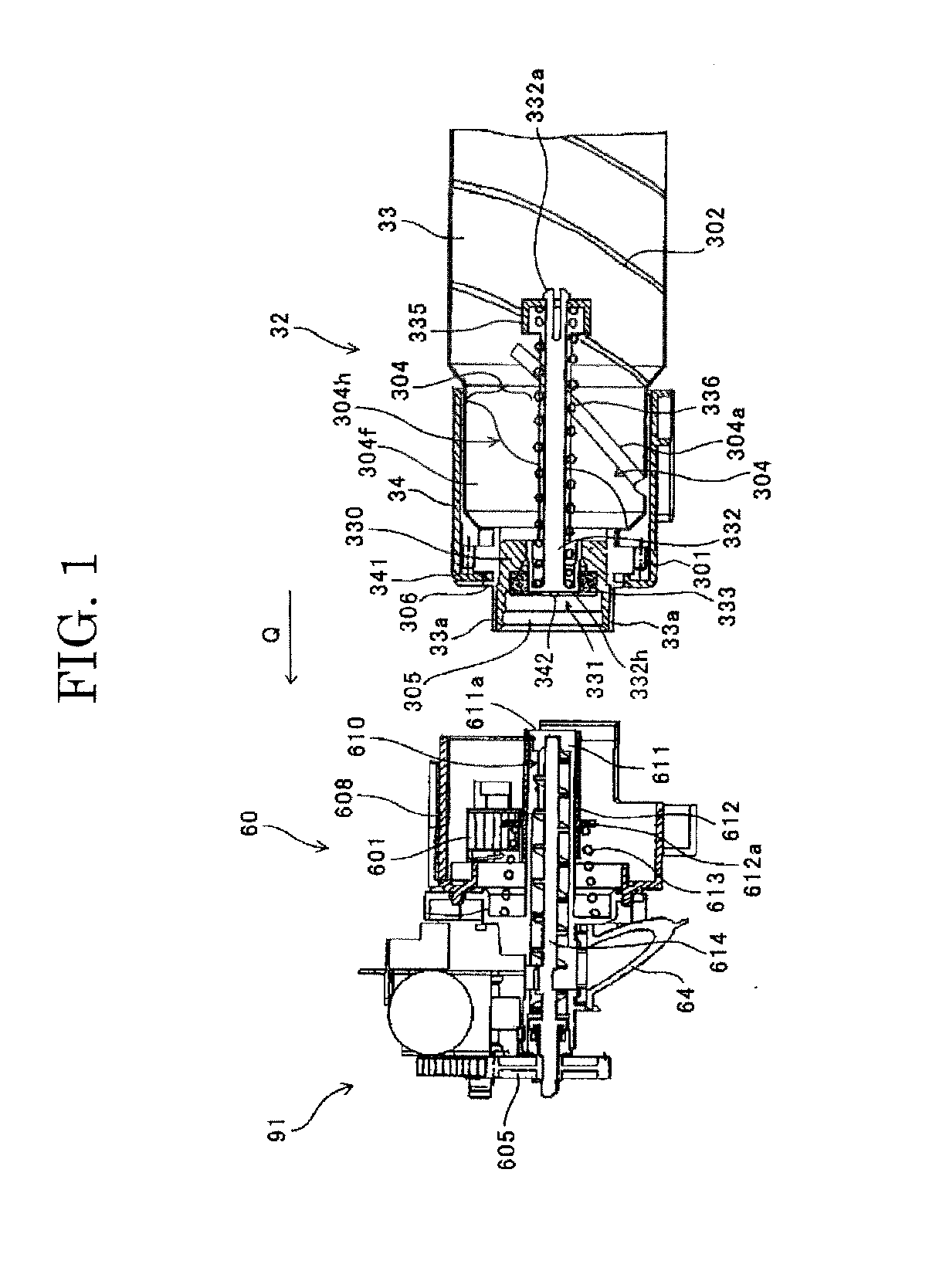

Toner housing container and image forming apparatus

ActiveUS20140348550A1Avoid it happening againLow temperature fixabilityElectrographic process apparatusDevelopersPolyester resinEngineering

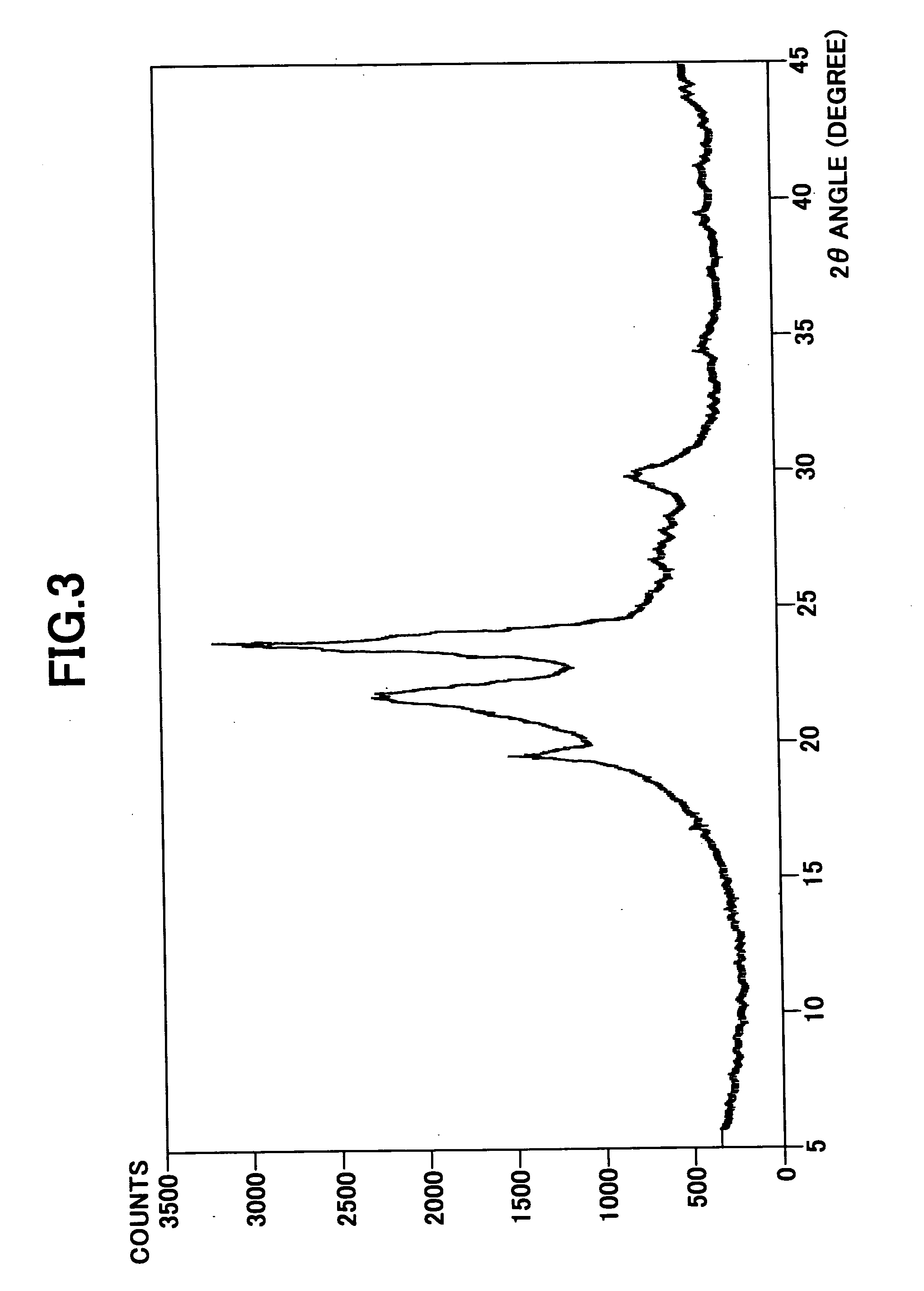

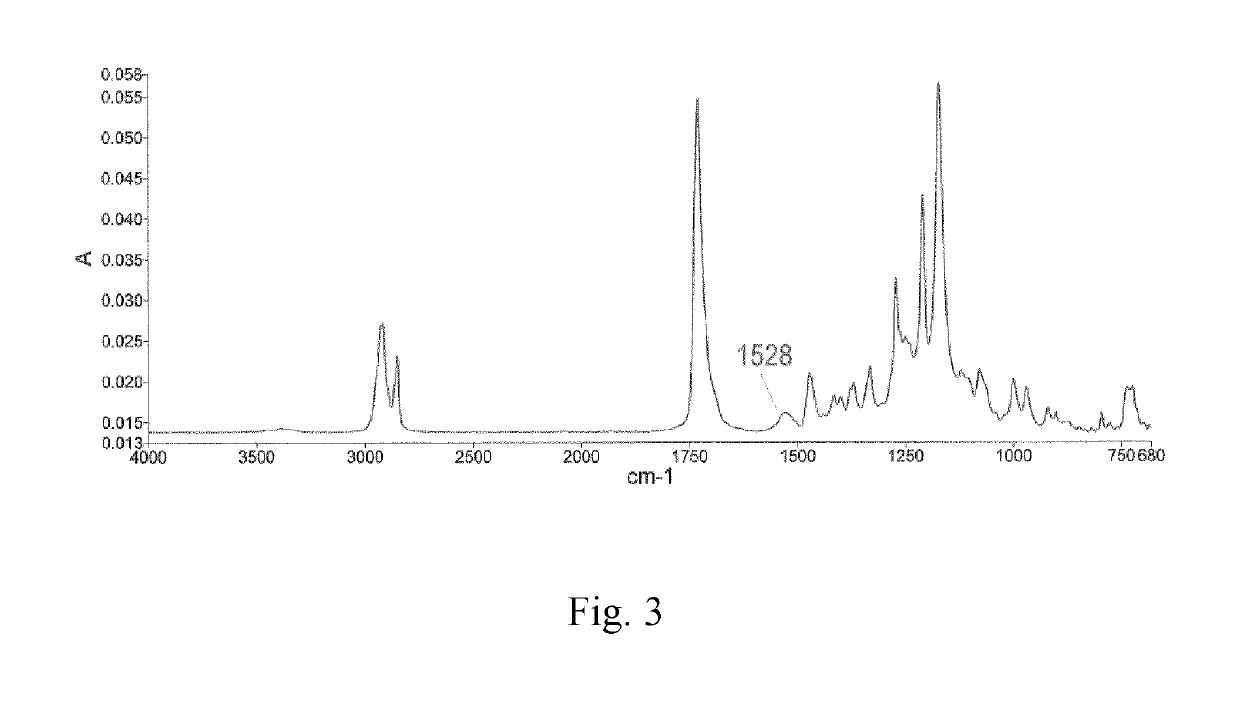

Toner housing container includes: container body housing a toner; conveying portion conveying the toner from longer direction one end of container body to its other end at which container opening portion is provided; pipe receiving port receiving a conveying pipe fixed to toner conveying device; and uplifting portion moving the toner toward toner receiving port of conveying pipe. Toner has molecular weight distribution having a peak in a range of 103 to 104, and has C / R of from 0.03 to 0.55 between peak height C attributed to crystalline polyester resin and R attributed to non-crystalline resin when measured by FT-IR after stored at 45° C. for 12 hours. Container body includes protruding portion protruding from container body interior side toward the one end. Uplifting portion includes uplifting wall surface extending from container body internal wall surface toward protruding portion. Protruding portion is present between uplifting wall surface and toner receiving port.

Owner:RICOH KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com