Method for continuously producing (methyl) hydroxyethyl acrylate and (methyl) diester acrylate and sulfoacid resin catalyst

A technology of sulfonic acid resin and acrylate, which is applied in chemical instruments and methods, preparation of ester groups and hydroxyl groups, catalysts for physical/chemical processes, etc. It can solve the problems of affecting downstream use and high product color number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

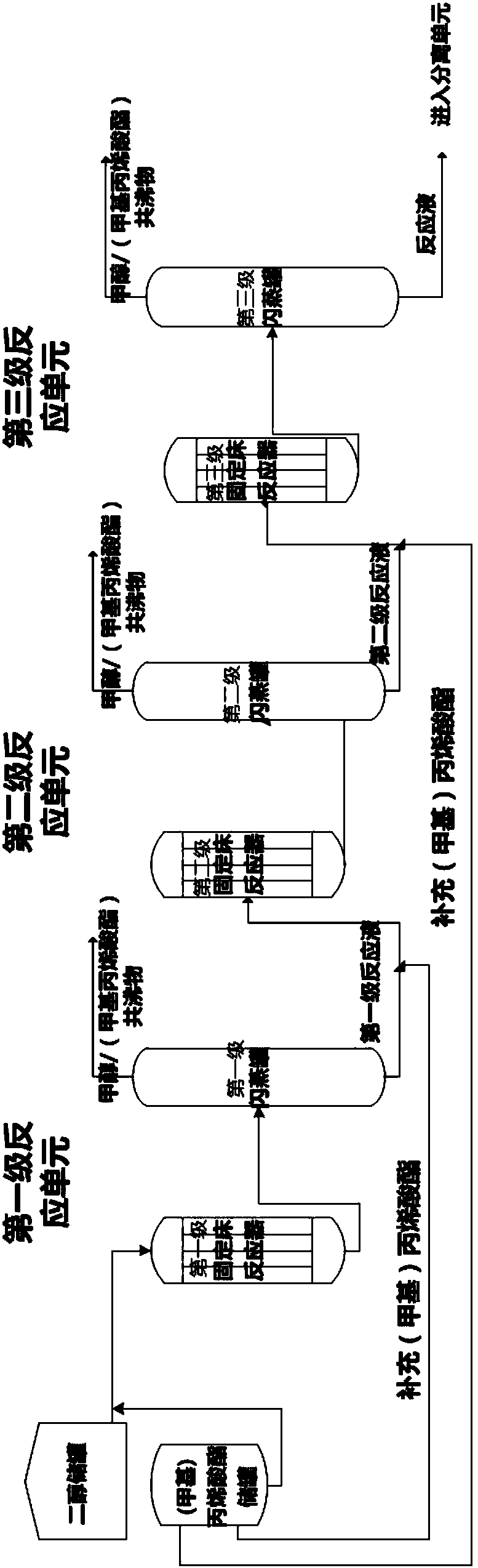

Method used

Image

Examples

preparation example 1

[0091] (a) Combine styrene, vinyltris-(trifluoro)methoxysilane, cyclohexyl (meth)acrylate, 1,6-hexanediol diacrylate, n-undecane and azobisisobutyl Nitrile, the molar ratio is 0.5: 1.5: 1: 0.2: 0.6: 0.014 for feeding, using suspension polymerization, reacting at 70° C. for 5 hours to prepare low surface energy polymer microspheres;

[0092] (b) Swell the prepared polymer microspheres in methanol for 4 hours, and then add sulfuric acid. The molar ratio of polymer microspheres to sulfuric acid is 1:2, and the reaction is sulfonated at 50°C for 8 hours, filtered and washed with water. Obtain 1# sulfonic acid resin catalyst.

[0093] Using GB-T1720-79(89) paint film adhesion measurement method and sessile drop method contact angle measurement method to detect the obtained sulfonic acid resin catalyst, the adhesion reached level 2 and the contact angle reached 103°.

preparation example 2

[0095] (a) Combine styrene, vinyl tris(2,2,2-trifluoro)ethoxysilane, isobornyl (meth)acrylate, 1,4-propylene glycol diacrylate, n-eicosane and peroxide Benzoyl, the molar ratio is 0.7:2.5:1:0.35:0.9:0.016 for feeding, using suspension polymerization, reacting at 95℃ for 3h to prepare low surface energy polymer microspheres;

[0096] (b) Swell the prepared polymer microspheres in n-hexane for 4 hours, and then add sulfur trioxide. The molar ratio of polymer microspheres to sulfur trioxide is 1:3. The sulfonation reaction is carried out at 80°C for 6 hours, and then filtered After washing with water, 2# sulfonic acid resin catalyst can be obtained.

[0097] Using GB-T1720-79(89) paint film adhesion measurement method and sessile drop method contact angle measurement method to detect the obtained sulfonic acid resin catalyst, the adhesion reached level 2 and the contact angle reached 110°.

preparation example 3

[0099] (a) Styrene, 1,4-propanediol diacrylate, n-eicosane and benzoyl peroxide were charged with a molar ratio of 0.7:0.35:0.9:0.016, and the suspension polymerization was used at 95℃. React for 3 hours to prepare low surface energy polymer microspheres;

[0100] (b) Swell the prepared polymer microspheres in n-hexane for 4 hours, and then add sulfur trioxide. The molar ratio of polymer microspheres to sulfur trioxide is 1:3. The sulfonation reaction is carried out at 80°C for 6 hours, and then filtered After washing with water, 3# sulfonic acid resin catalyst can be obtained.

[0101] Using GB-T1720-79(89) paint film adhesion measurement method and sessile drop method contact angle measurement method to detect the obtained sulfonic acid resin catalyst, the adhesion reached level 4 and the contact angle reached 82°.

[0102] From the performance test results of the sulfonic acid resin catalysts obtained in the above three preparation examples, it can be seen that the sulfonic acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com