Patents

Literature

57results about How to "Easy to transport over long distances" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

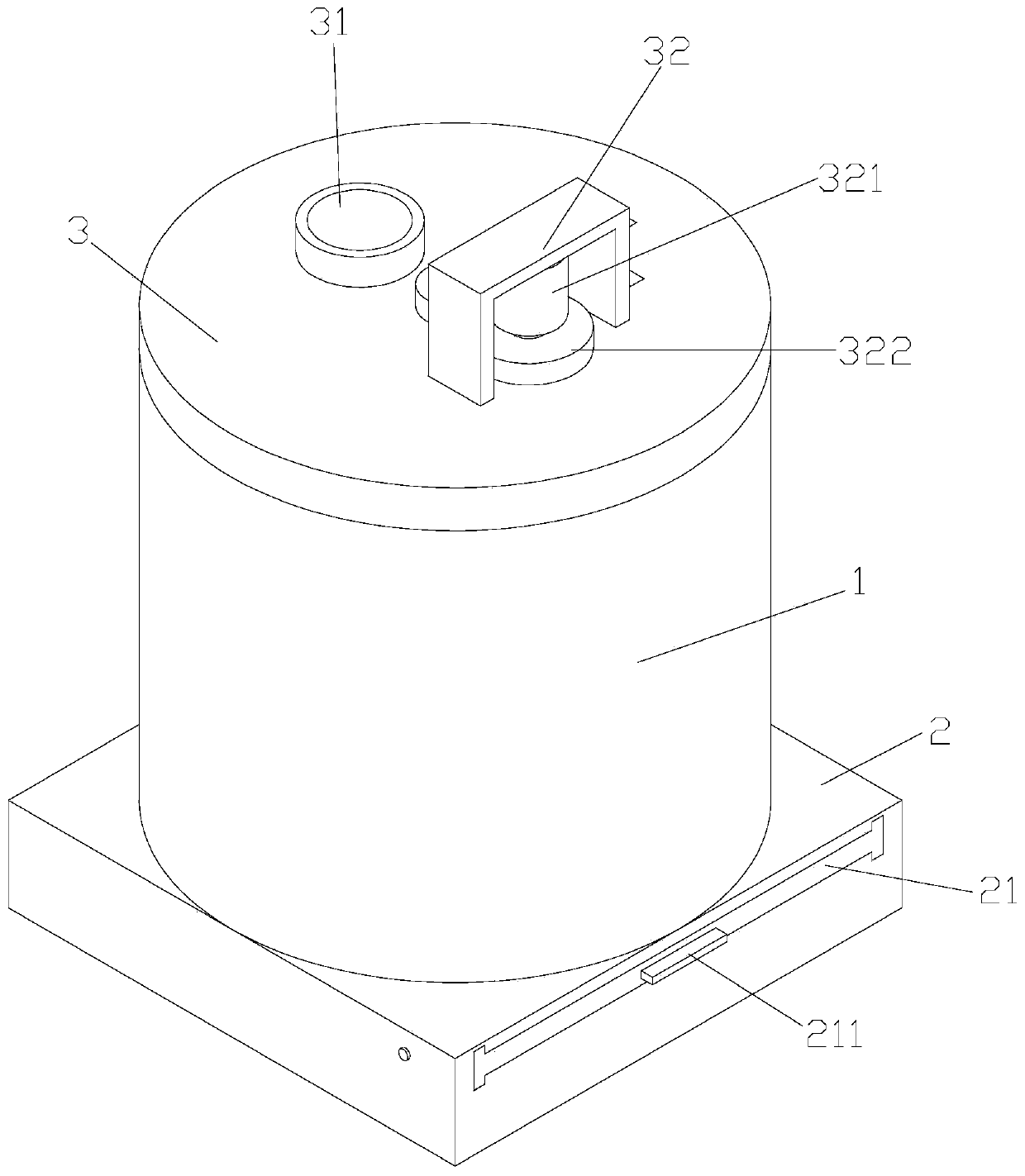

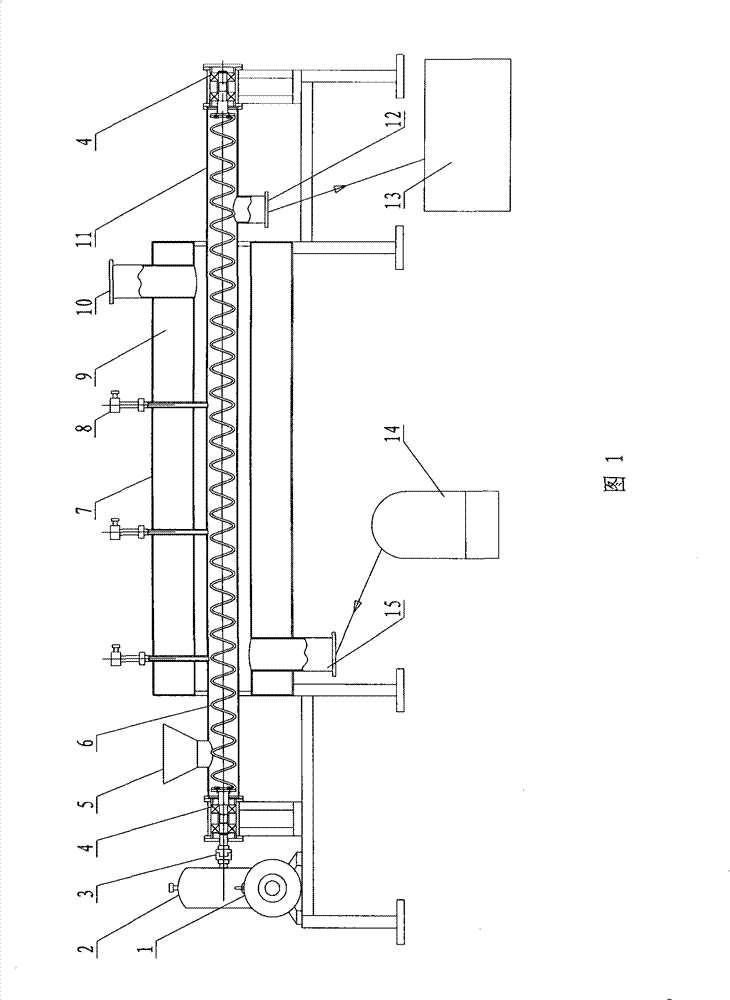

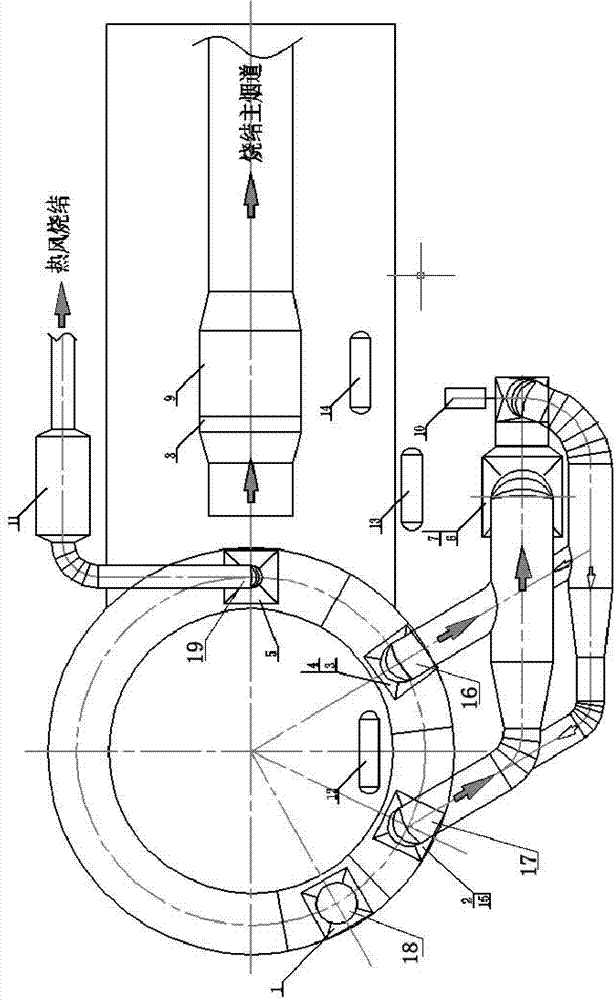

Biomass continuous pyrolysis charing apparatus with flexible spiral conveying apparatus

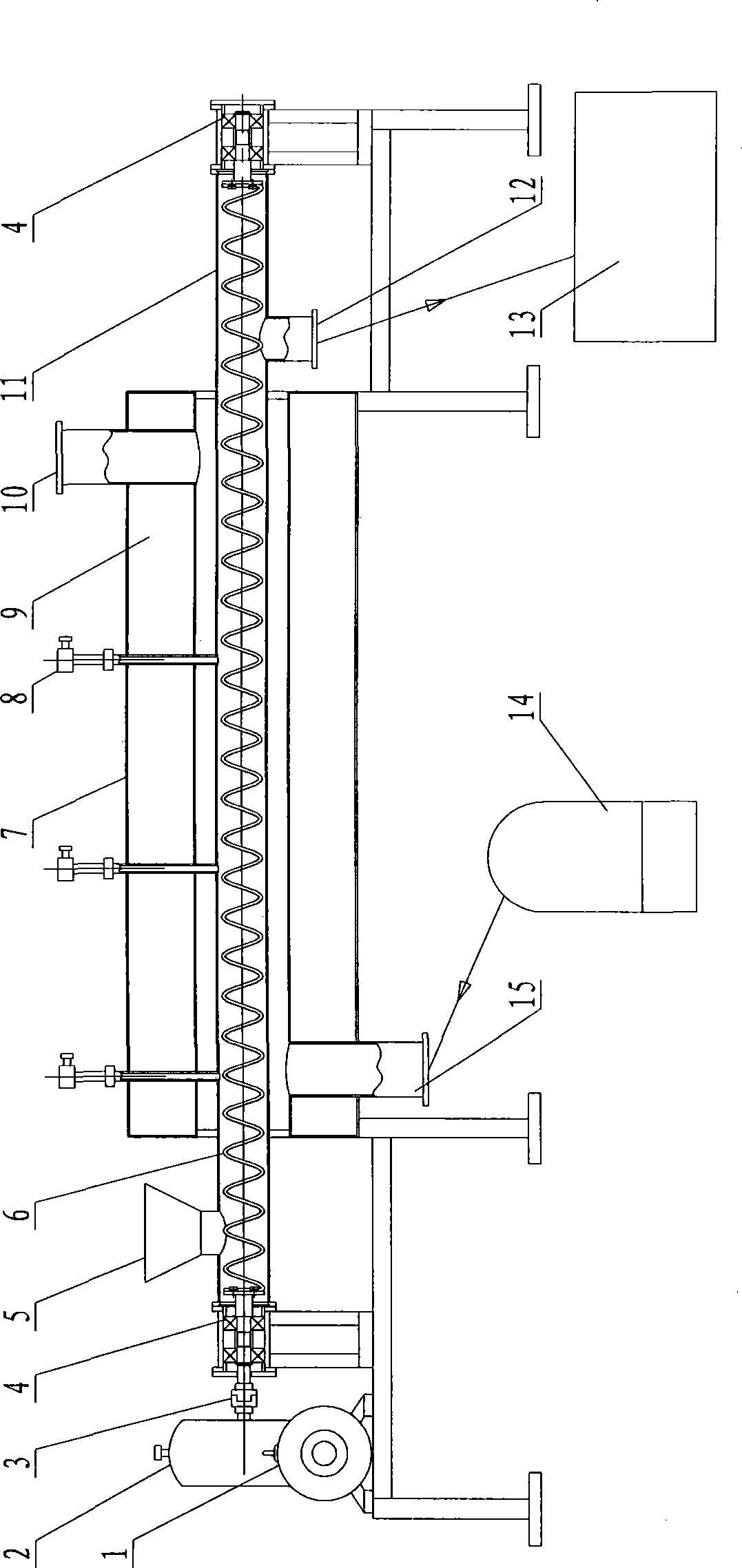

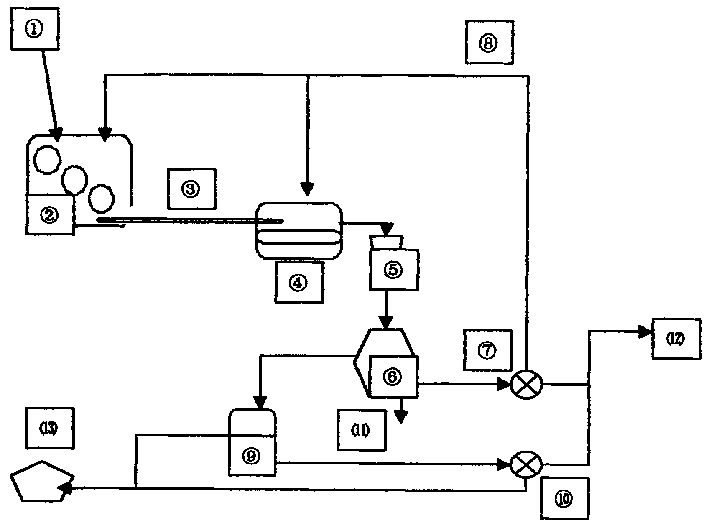

The invention discloses a biomass continuous pyrogenation carbonizing apparatus provided with a flexible screw conveying appliance, which comprises a motor (1), a coupling (3), bearings (4), a flexible screw spring (6), a pyrolysis tube (11), a feed inlet (5), a carbon discharging outlet (12) and a heating device; one end of the pyrolysis tube (11) is provided with the feed inlet (5) communicatedwith the inner cavity of the pyrolysis tube (11), and the other end is provided with the carbon discharging outlet (12) communicated with the inner cavity thereof; the inner cavity of the pyrolysis tube (11) is inserted with the flexible screw spring (6) along the axial direction; one end of the flexible screw spring (6) is connected with the output shaft of the motor (1) through the first bearing (4) and the coupling (3), and the other end is supported on the second bearing (4); and the outer side of the pyrolysis tube (11) is provided with the heating device for heating the pyrolysis tube (11). The biomass continuous pyrogenation carbonizing apparatus is easily suitable for long-distance convey and has simple structure.

Owner:SOUTH CHINA AGRI UNIV

Canned duck soup and bamboo shoot, and preparation method thereof

InactiveCN103431026AFull of nutritionFresh but not greasyFruit and vegetables preservationLyciumAmino acid

The invention discloses a preparation method of canned duck soup and bamboo shoot. Raw materials comprise 50 to 60 parts of bamboo shoot, 8 to 10 parts of duck skeleton, 4 to 8 parts of pernil, 1 to 2 parts of chive, 0.8 to 1.5 parts of hance brandisia herb, 1 to 1.6 parts of gynostemma pentaphylla, 0.6 to 1.4 parts of papaya Leaf, 1 to 2 parts of pseudo-ginseng, 0.7 to 1.2 parts of epimedium, 1 to 1.5 parts of ginkgo root, 1 to 2 parts of lucid ganoderma, 0.6 to 0.9 part of pseudo-ginseng leaf, 1 to 1.8 parts of wolfberry, and appropriate amounts of salt, yellow rice wine and chicken extract. The canned duck soup and bamboo shoot is rich in nutrients, can be preserved for a long term, and is convenient for long distance transportation; the taste is fresh but not greasy. Bamboo shoot is rich in protein, amino acid and fat; and is capable of clearing heat and reducing phlegm, tonifying qi and harmonizing stomach, and nourishing diaphragm and comforting stomach. A plurality of traditional Chinese medicine ingredients, such as hance brandisia herb, gynostemma pentaphylla, pseudo-ginseng and ginkgo root, capable of strengthening body and fortifying health, and maintaining beauty and keeping young are added into the soup, so that human body immunity is increased, and senescence is delayed.

Owner:柳培健

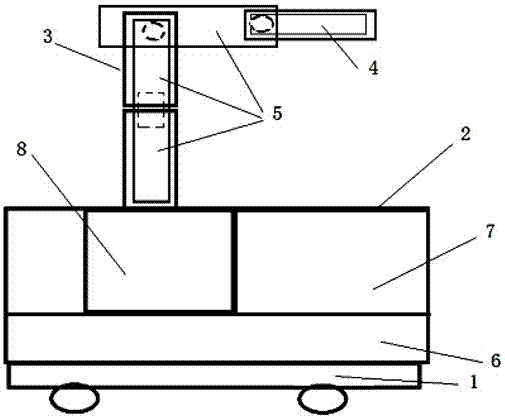

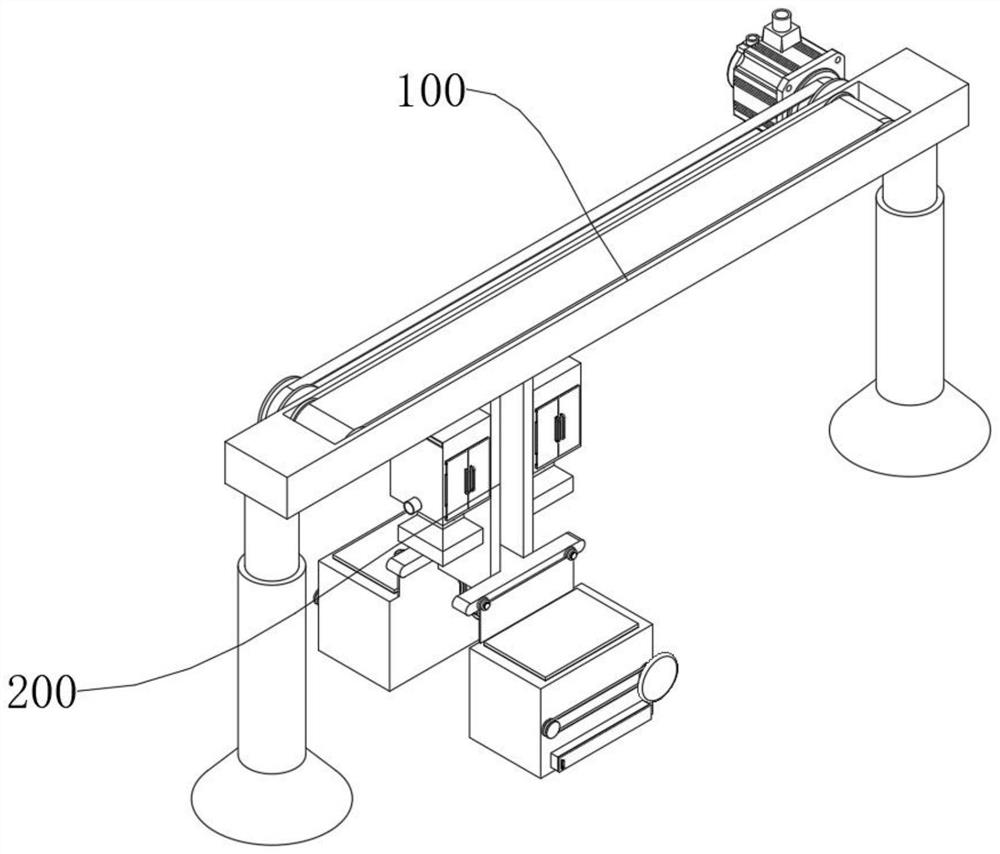

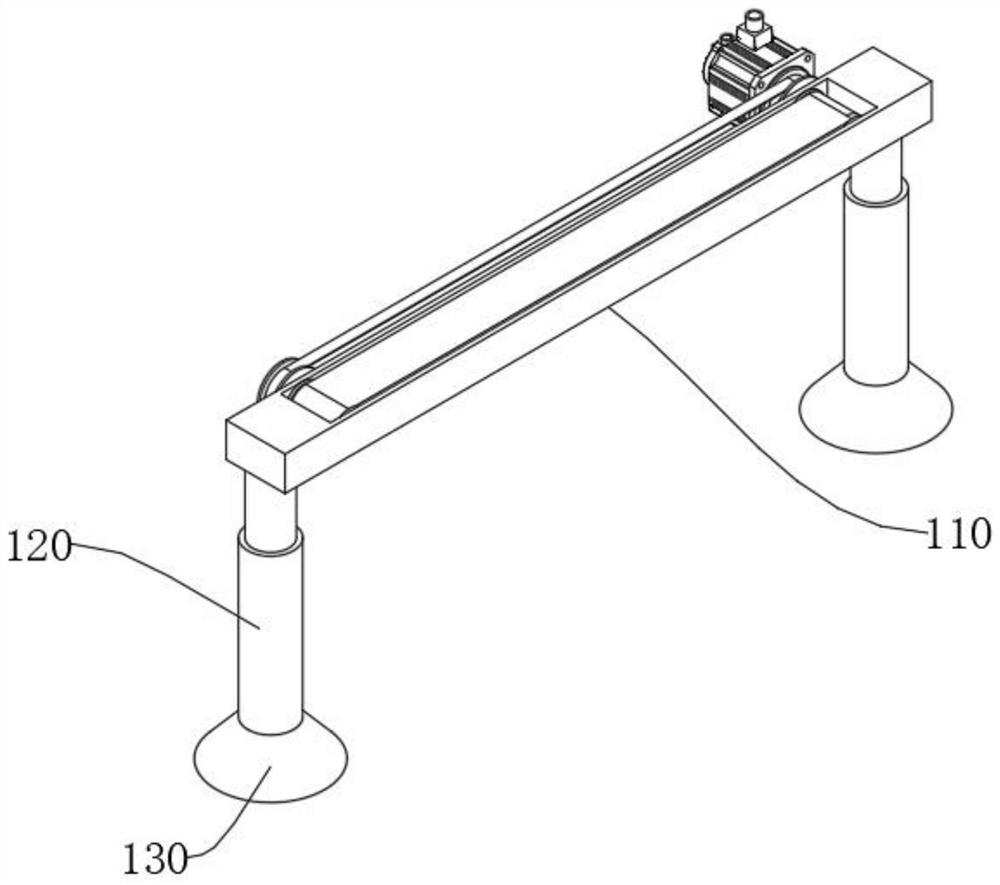

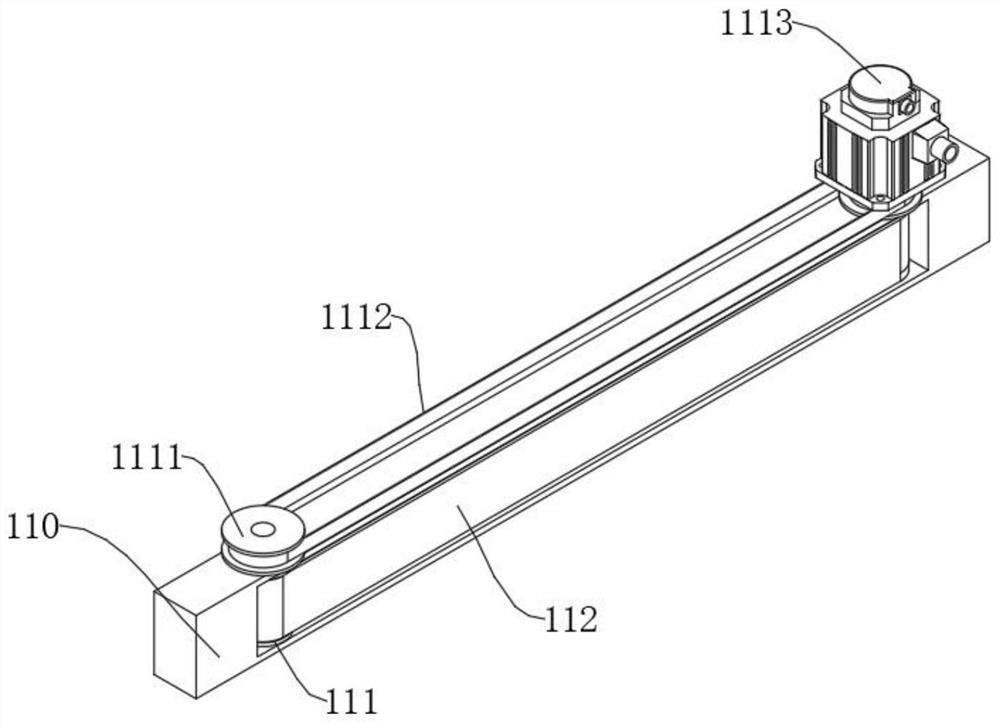

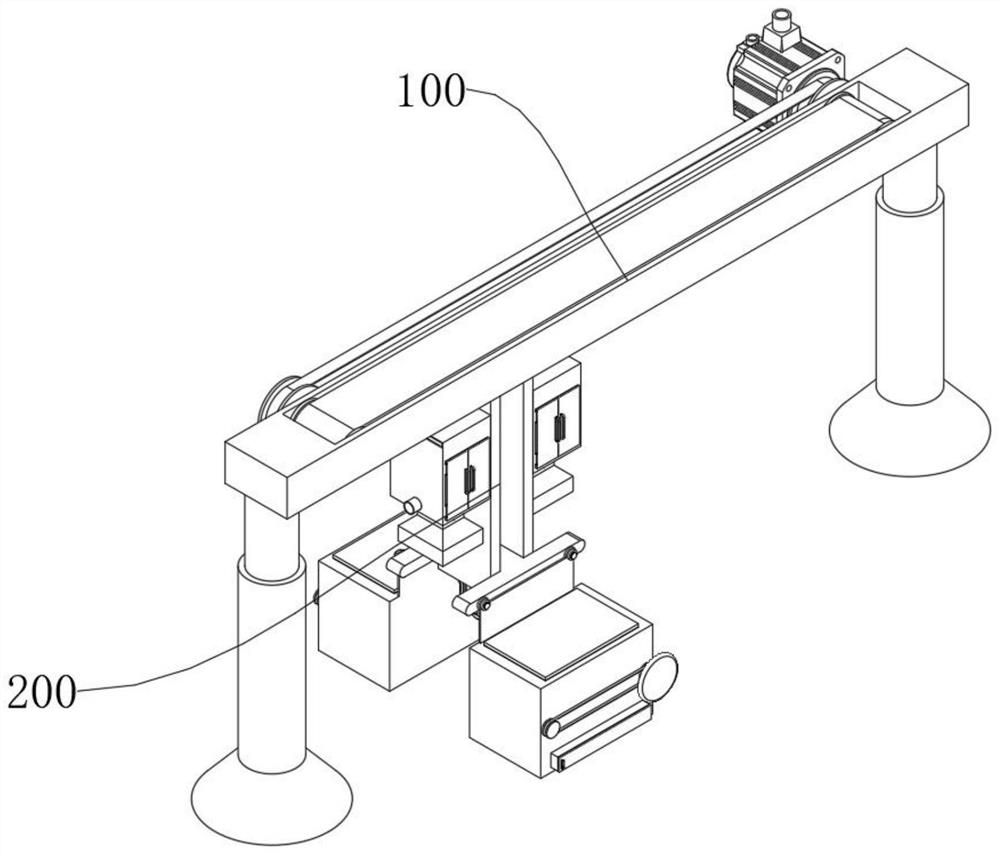

Mechanical arm convenient to move

InactiveCN107225598AEasy to transport over long distancesAvoid damageArmsElectric machineryEngineering

Owner:ANHUI ZHILIANG INVESTMENT GRP

Seedling growing method for Blumea balsamifera seeds

The invention discloses a seedling growing method for Blumea balsamifera seeds. The method includes that mature seed artificial culture technologies such as artificial beekeeping fertilization and seed water tank nutrition liquid culture are used for improving seed fertility and facilitating seed collection; effective and repeatedly-practiced sowing technologies such as a seedbed processing method, a substrate formula, sowing seasons and a seeding method are summarized, and seed emergence rate is improved to 10%-30%; and nutrition bag seedlings with equal culture quality are taken to a mountain to plant stocks, and pest control measures for different nursery stages, nursery temperature and humidity management key points and the like are systematically summarized. By means of the method, millions of nutrition bag seedlings with good quality and low price are cultured successfully, and the problem that a local government is prevented from developing a Blumea balsamfera industry due to lack of seedlings is solved.

Owner:GUIZHOU YIHE BIOTECH

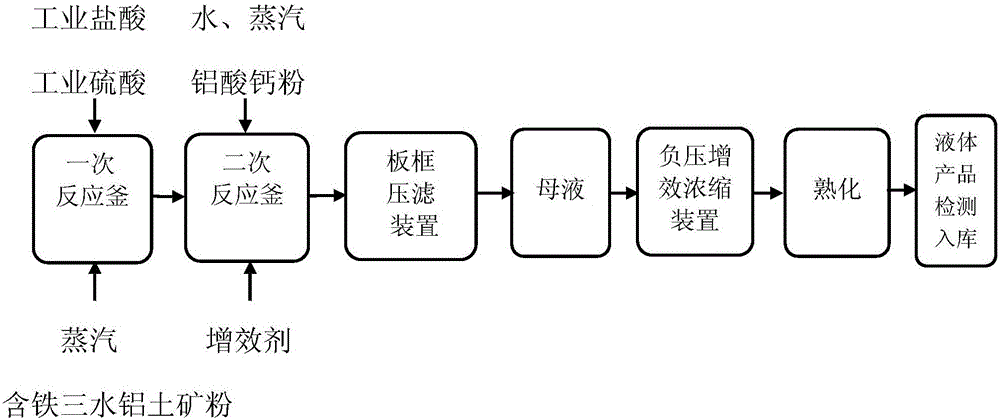

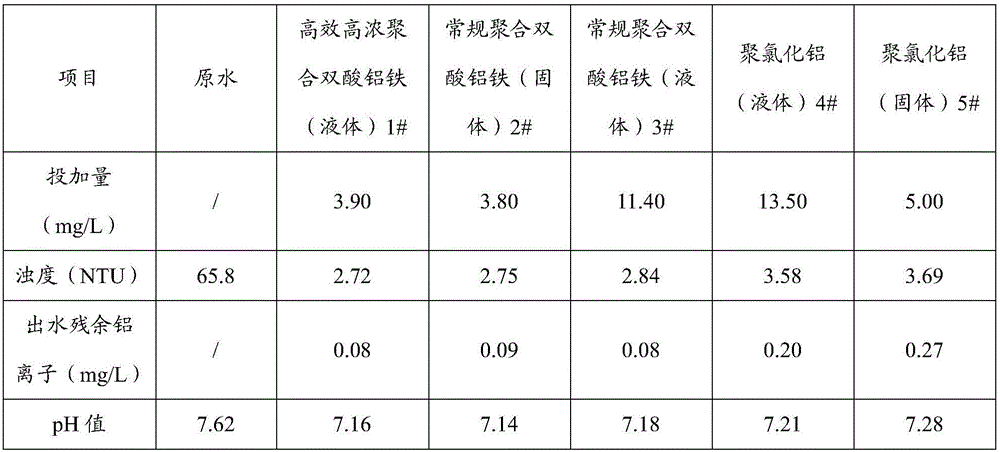

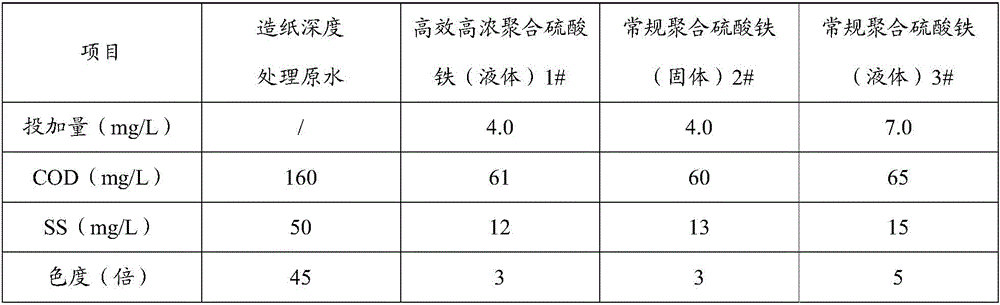

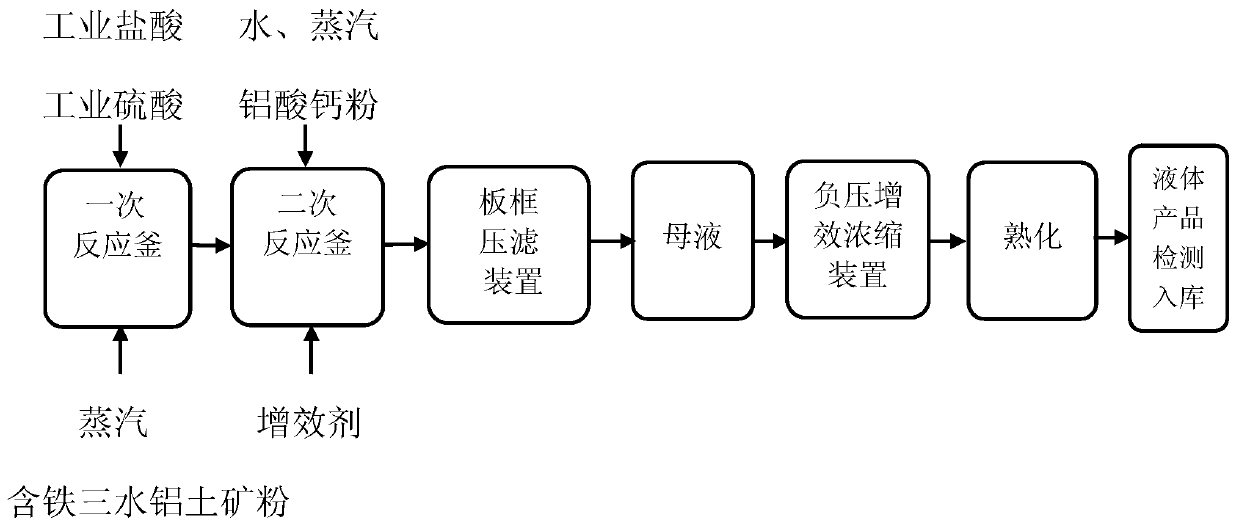

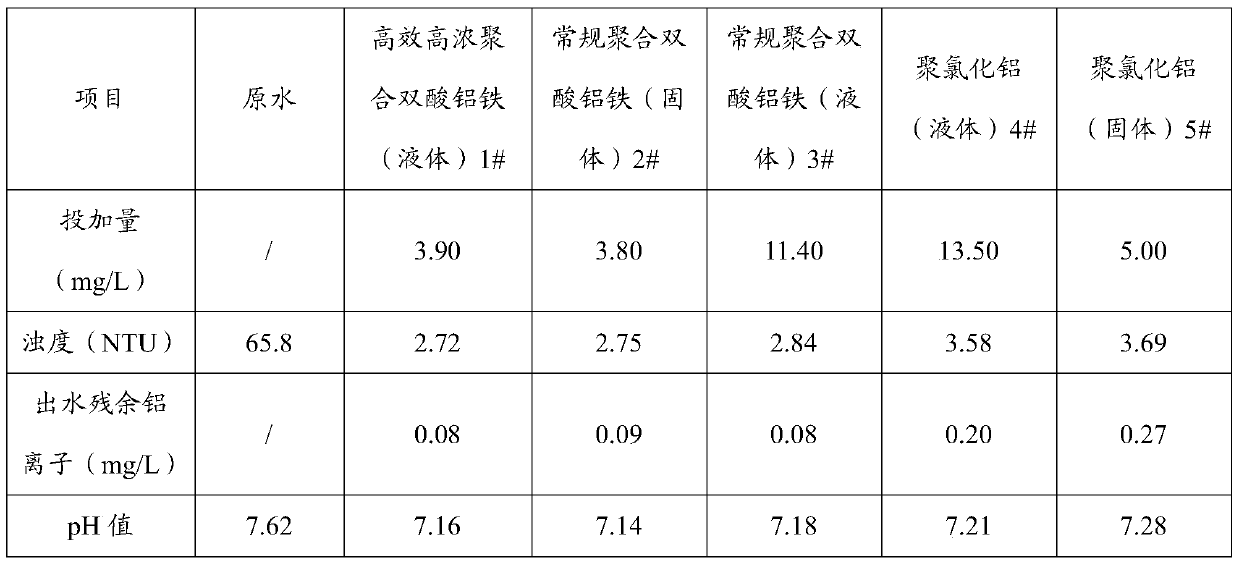

Production process of high-efficiency and high-concentration polyaluminum ferric chloride sulfate

ActiveCN106565003AGuaranteed purityExclude the influence of aggregation effectIron compoundsWater/sewage treatment by flocculation/precipitationHigh concentrationProcess equipment

The invention discloses a production process of high-efficiency and high-concentration polyaluminum ferric chloride sulfate. The production process comprises the following steps: under a condition ofnot adding a large amount of technological equipment and other raw materials, extracting aluminum and ferric ions from ferric trihydrate alumina mineral powder by a sulfuric acid and hydrochloric aciddi-acid dissolving mode, performing polymerization reaction with calcium aluminate powder, and generating the high-efficiency and high-concentration liquid polymerized di-acid ferro-aluminum througha negative pressure synergic concentration process to replace a conventional solid product. The process is simple, practical and easy to operate; the water purification effect of the prepared high-efficiency and high-concentration liquid polymerized di-acid ferro-aluminum and the water purification effect of the conventional solid product is about 1 to 1; and the equipment investment is low, the cost performance of the raw materials is high, the production cost is greatly reduced, and the production process is suitable for industrial production.

Owner:蓝保(厦门)水处理科技有限公司

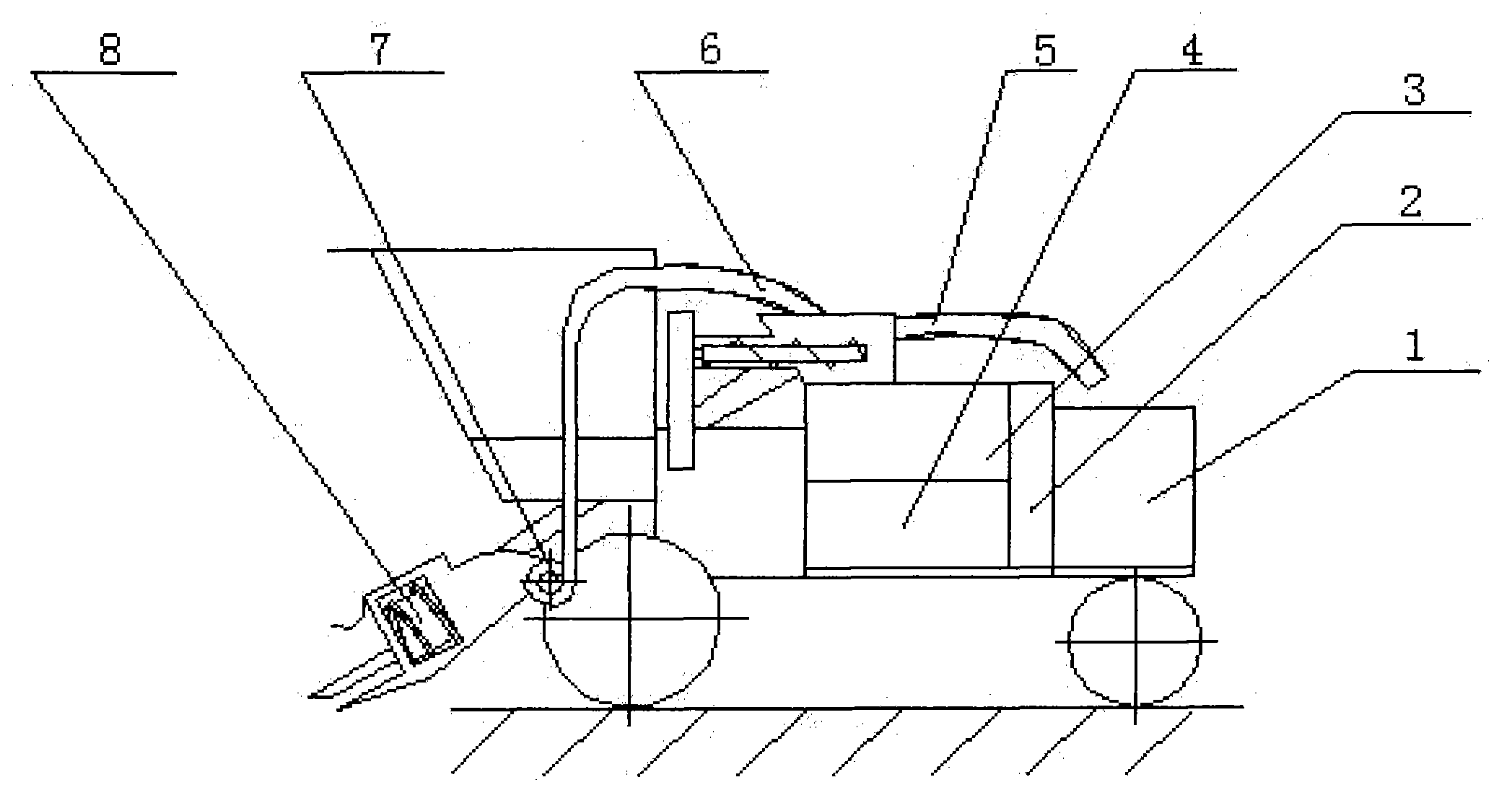

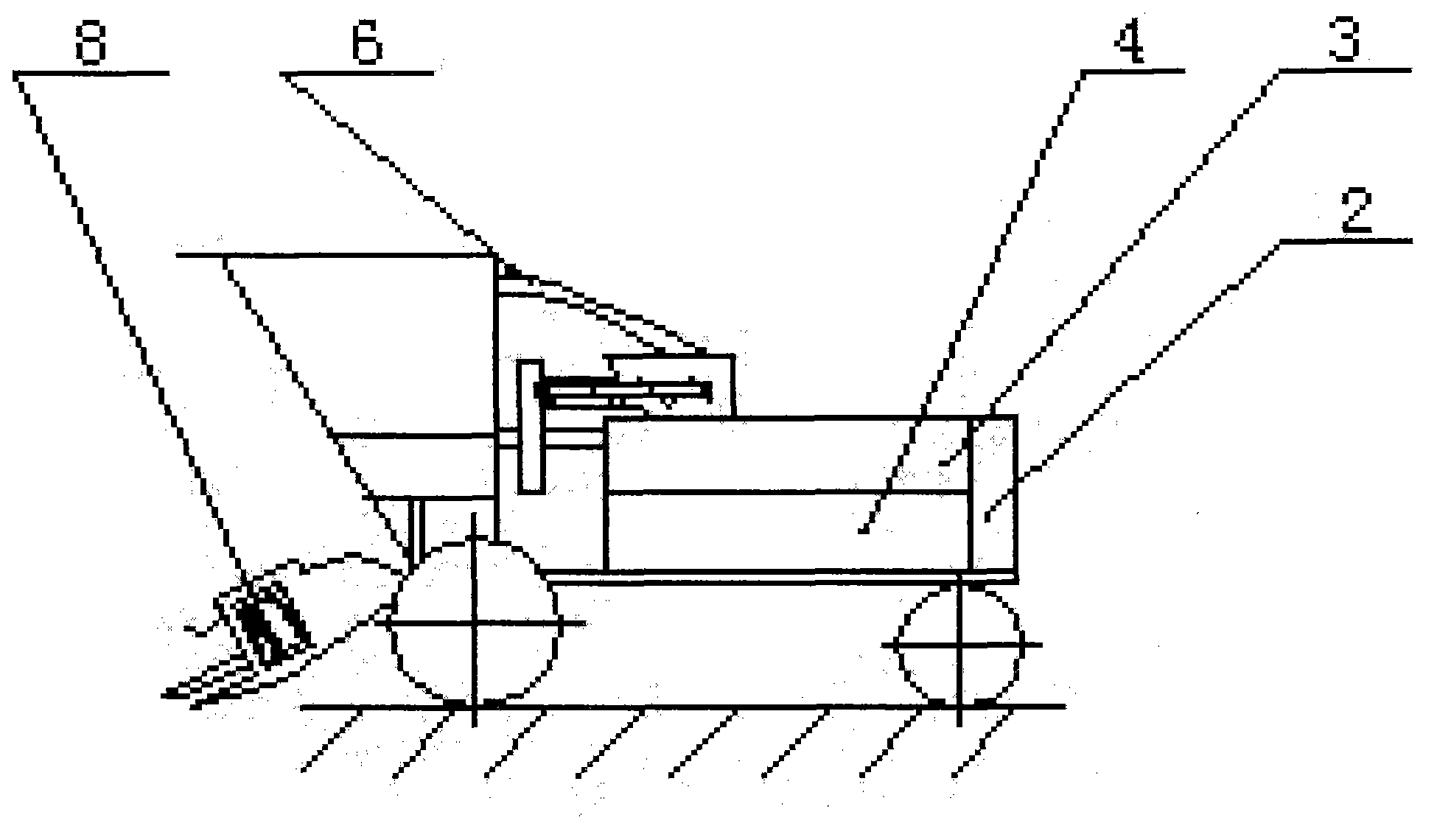

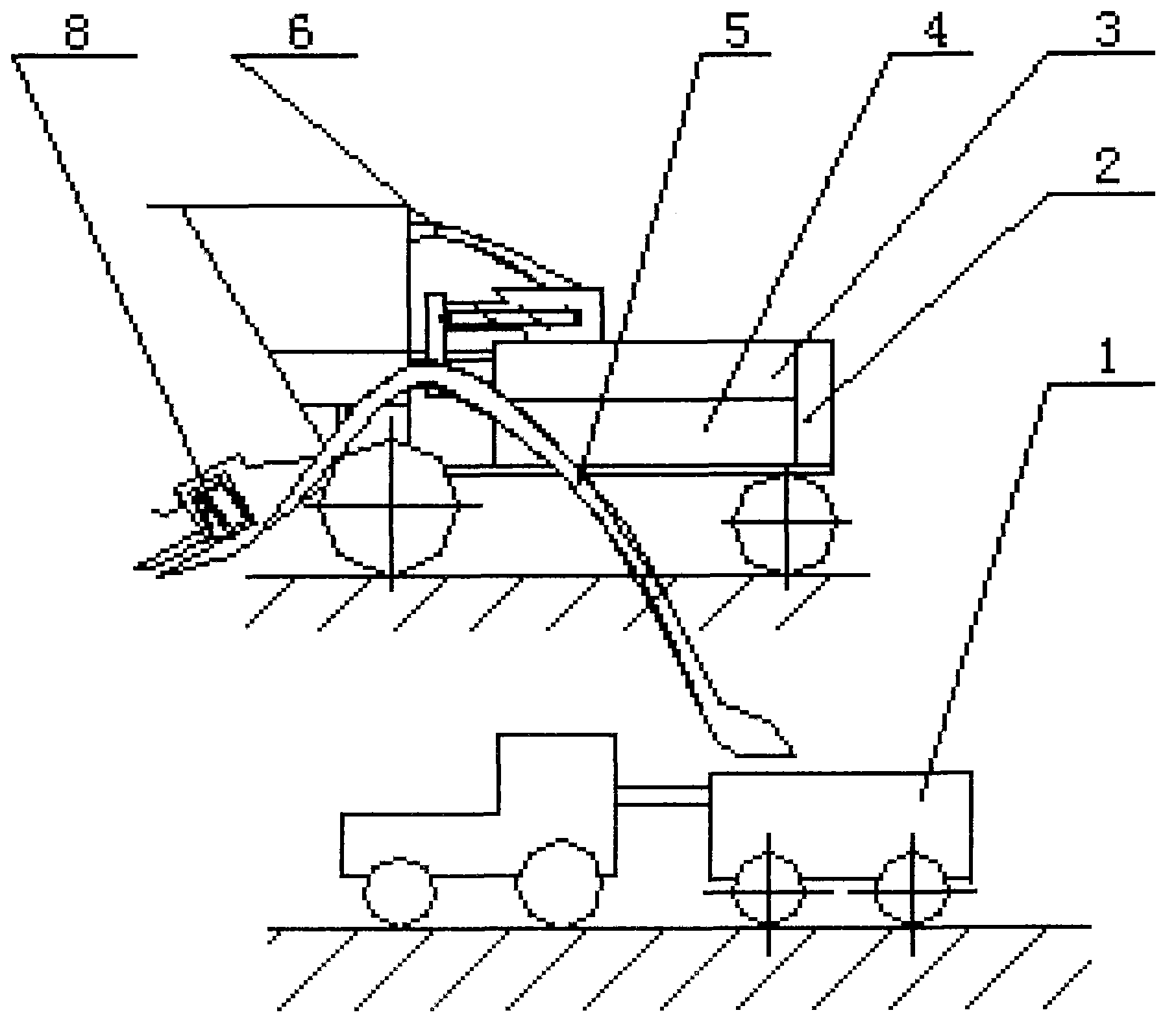

Self-propelled combine corn harvester for harvesting spike or seed, collecting straws and juicing

The invention relates to a self-propelled combine corn harvester for harvesting spike or seed, collecting straws and juicing, belongs to the field of agricultural machinery, and achieves large-scale harvesting of useful substance of complete stools of ripe corn to automatically obtain three products, namely corn, straw juice and straw residue separately. The self-propelled combine corn harvester includes four types, namely two types of integral combine harvesters and two types of split combine harvesters. The self-propelled combine corn harvester mainly used for acquiring fleeting syrup in fresh corn straws, and accordingly recycling, efficient and comprehensive utilization of complete corn stools is achieved, high-quality and cheap raw materials are provided for industrial syrup, feed, fuel and the like, optimal replacement (industrial syrup) of petroleum is provided, and a brand new approach for reducing corn saccharification consumption is provided.

Owner:徐道清

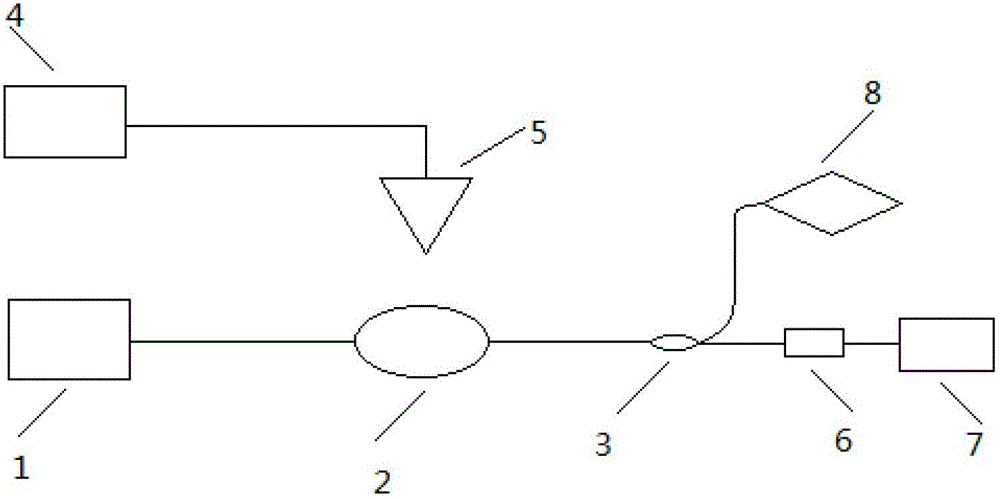

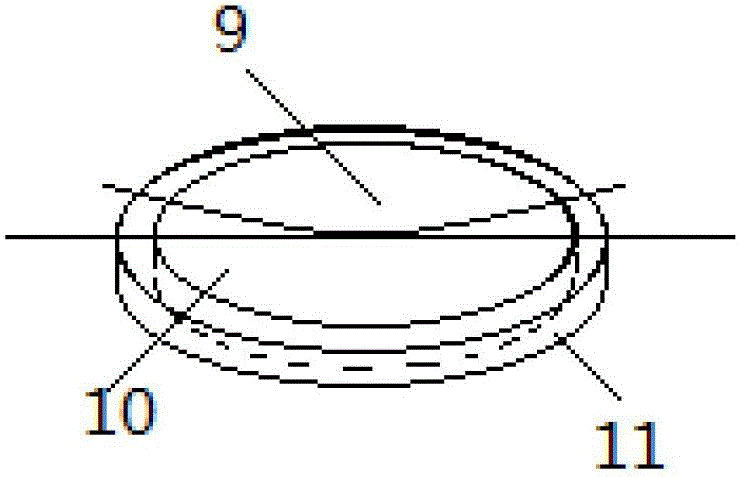

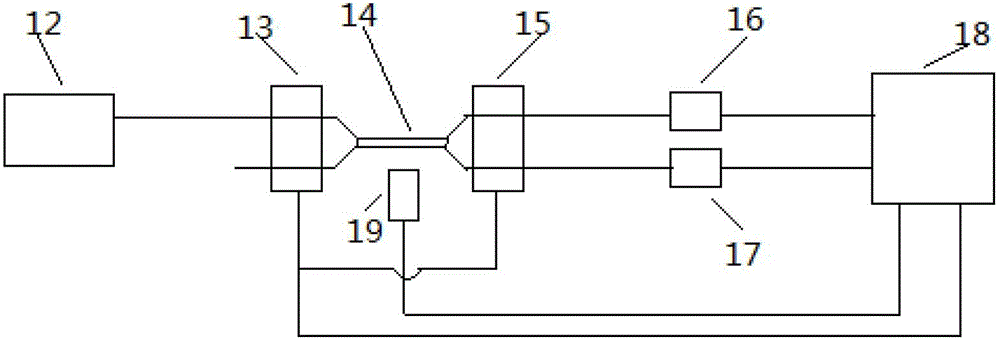

Acoustic frequency detector and acoustic frequency detecting system with multi-mode coupler

ActiveCN102879082AImprove anti-interference abilityEasy to transport over long distancesSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansCapacitanceFrequency spectrum

The invention relates to an acoustic frequency detector and an acoustic frequency detecting system with a multi-mode coupler. The acoustic frequency detector comprises a multi-mode optical fiber coupler, an aluminum film and a metal block, the diameter of the circular aluminum film ranges from 30mm to 40mm, the thickness of the circular aluminum film ranges from 2.5 micrometers to 3.5 micrometers, the periphery of the circular aluminum film is flatly adhered on the metal block, two ends of the multi-mode optical fiber coupler are fixed, a middle coupling region of the multi-mode optical fiber coupler naturally droops to be in contact with the aluminum film, and the length of the middle coupling region ranges from 5mm to 10mm. The acoustic frequency detecting system with the multi-mode coupler comprises the acoustic frequency detector, an acoustic frequency signal generator, a loudspeaker, a wide-spectrum light source, a 1X2 optical fiber coupler, a high-speed photovoltaic conversion module and a frequency spectrum analyzer. Compared with the traditional acoustic frequency detector and the traditional acoustic frequency detecting system which are implemented in a capacitance detecting method, the acoustic frequency detector and the acoustic frequency detecting system have the advantages of high interference resistance and easiness in long-distance transmission owing to an optical fiber acoustic sensing mode.

Owner:HUAZHONG UNIV OF SCI & TECH

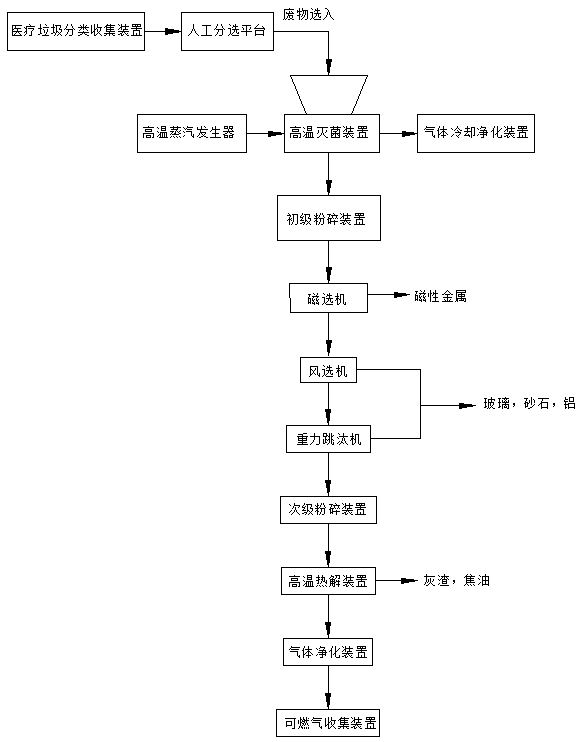

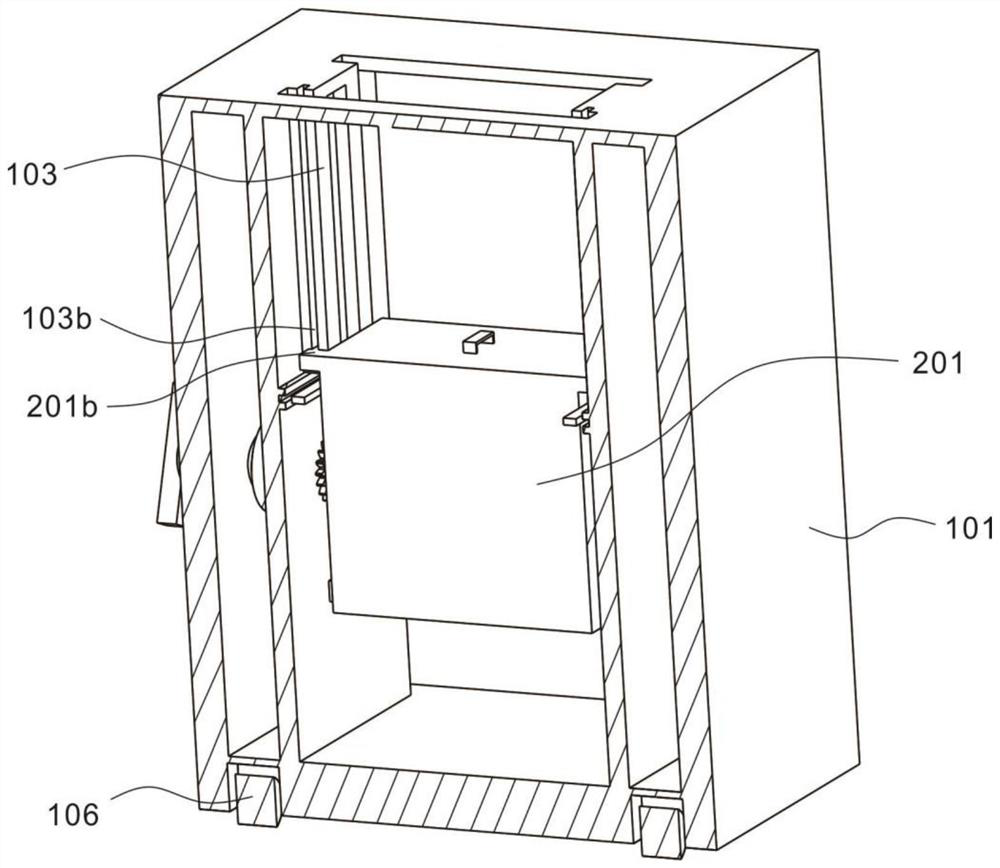

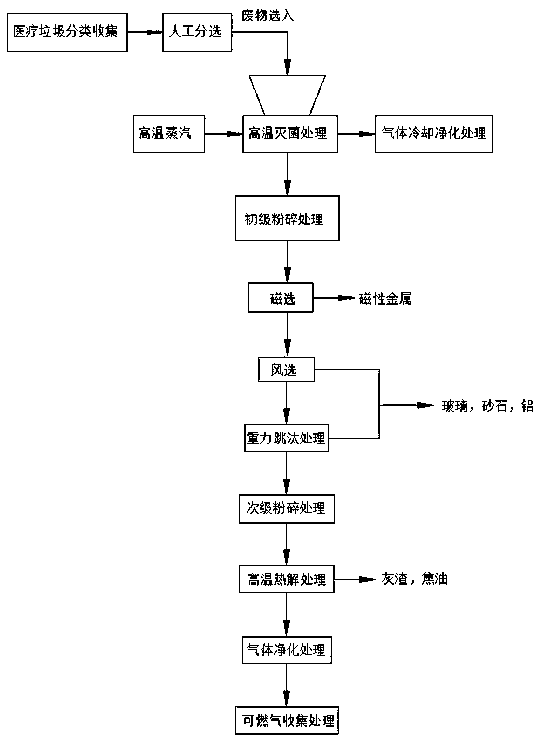

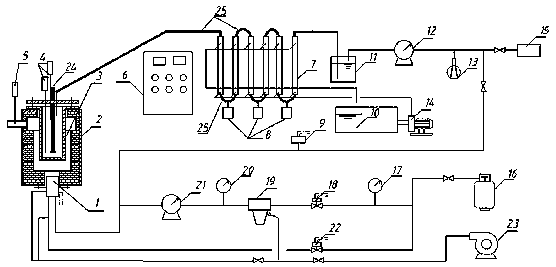

Medical waste classifying and high-temperature pyrolysis treatment system

InactiveCN109737418AAchieve recyclingReduce wasteMedical waste disposalMagnetic separationHigh energyPollution

The invention discloses a medical waste classifying and high-temperature pyrolysis treatment system. The medical waste classifying and high-temperature pyrolysis treatment system comprises a classified collecting device, a manual sorting platform, a high-temperature sterilizing device, a primary smashing device, a sorting device, a secondary smashing device and a high-temperature pyrolysis treatment device, wherein medical waste raw materials mainly treated by the system are preliminarily selected through the classified collecting device and the manual sorting platform; and then the medical waste is classified through a magnetic separator, a wind separator and a gravity washbox, the separated magnetic metal, aluminum, glass, gravel and the like can be treated by a recycle department, recycling of useful materials in the medical waste is realized, and the separated waste with high content of other organic matters is converted into an available energy form through the high-temperature pyrolysis treatment. According to the medical waste classifying and high-temperature pyrolysis treatment system, the reduction of wasting of resources is facilitated, and the system has the characteristics of a high reducing quantity degree, low secondary pollution and high energy recovery.

Owner:DONGGUAN UNIV OF TECH

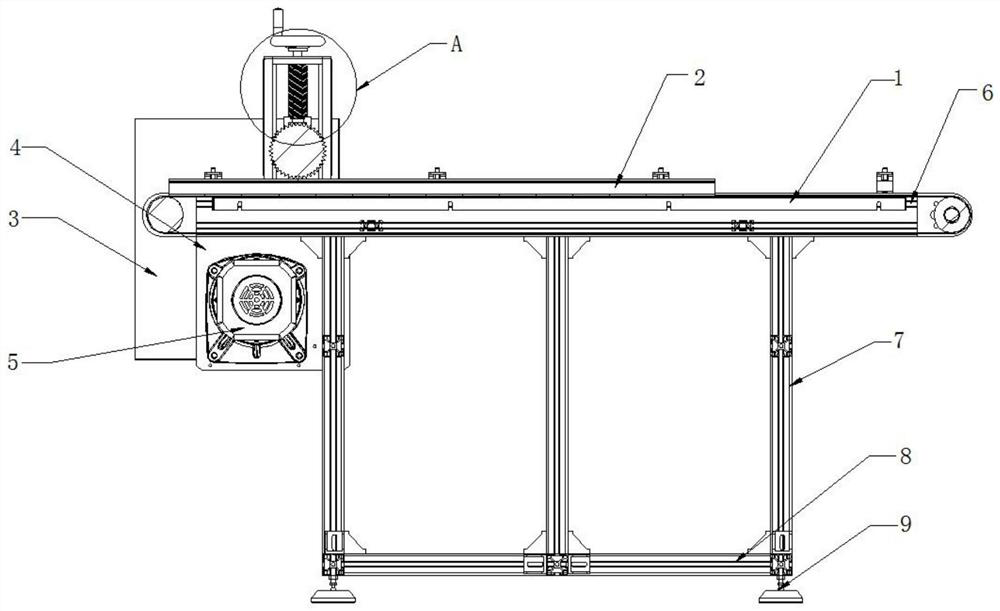

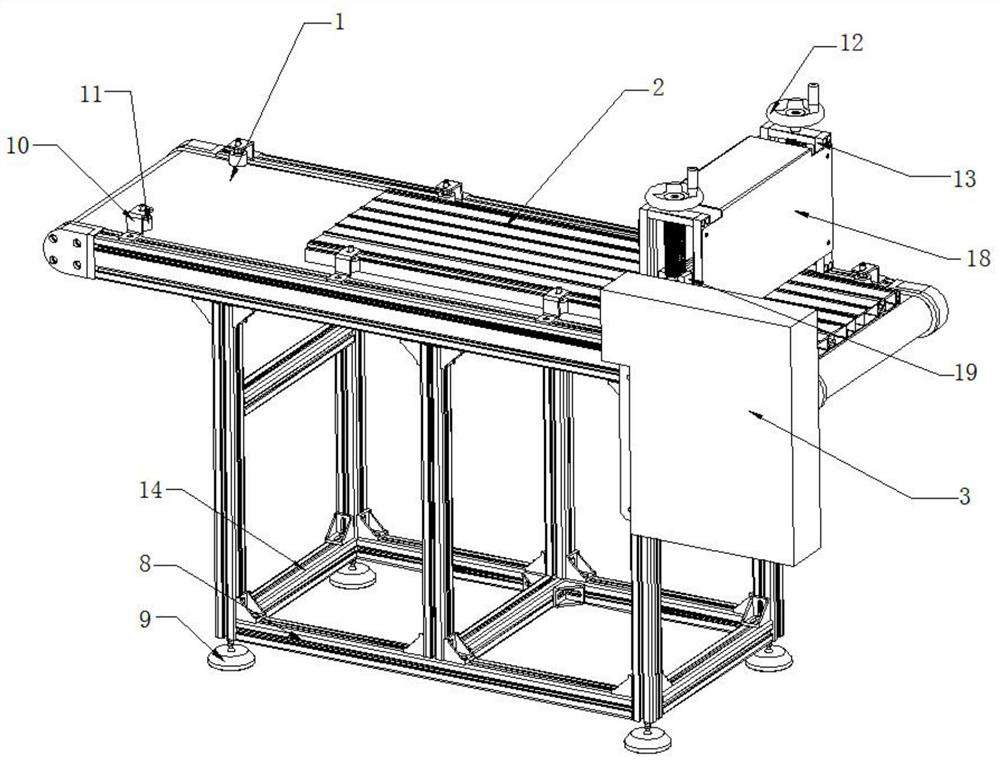

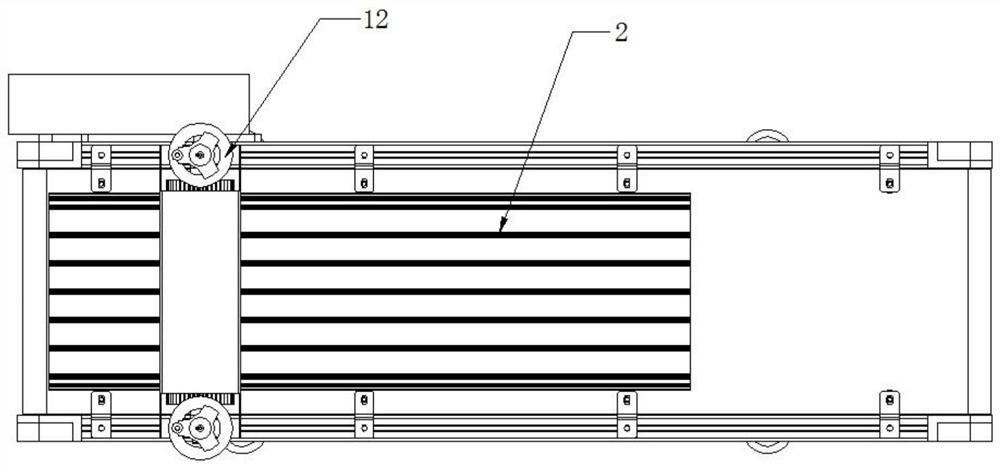

Cloth bag dust removal type powdery magnesium sulfate long-distance conveying device

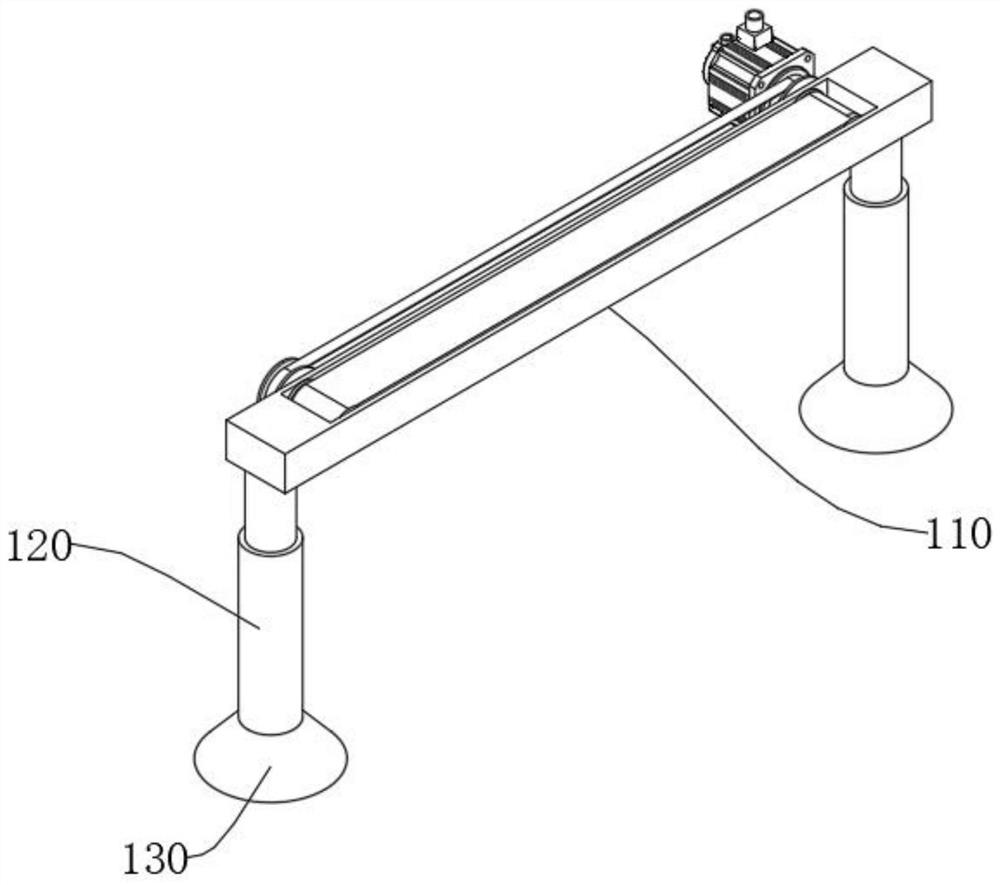

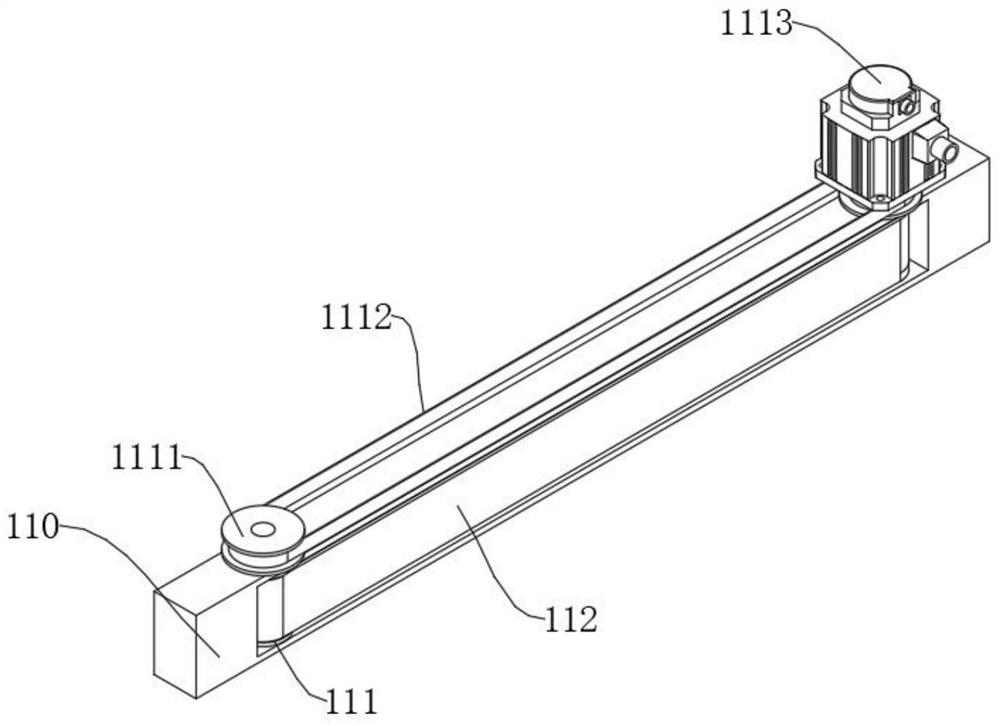

ActiveCN112027722AEasy to transport over long distancesEasy to operateConveyorsSupporting framesElectric machineryDust control

The invention relates to the technical field of magnesium sulfate, in particular to a cloth bag dust removal type powdery magnesium sulfate long-distance conveying device. The conveying device comprises a conveying frame and a conveying mechanism on the conveying frame. The conveying frame at least comprises a fixing frame and electric telescoping legs. Two belt rollers are arranged in the fixingframe in a rotating manner. Conveying belt trays are arranged on the end portions of the belt rollers. A conveying belt is arranged between the two conveying belt trays. The end portion of one conveying belt tray is connected with an output shaft of a conveying motor. A conveyer belt is arranged between the outer walls of the two belt rollers. The end portions of piston rods of the two electric telescoping legs are fixedly arranged on the bottoms, close to the two ends, of the fixing frame correspondingly. The conveying mechanism at least comprises a moving frame. The top of the moving frame is fixedly arranged on the outer wall of the conveyer belt. A groove is formed in the surface of the moving frame. A screw rod is arranged in the groove in a rotating manner. According to the conveyingdevice, powdery magnesium sulfate can be conveyed in a long distance, contamination to the belt trays is avoided, and cloth bag dust removing can be carried out for air.

Owner:湖南谊诚科技有限公司

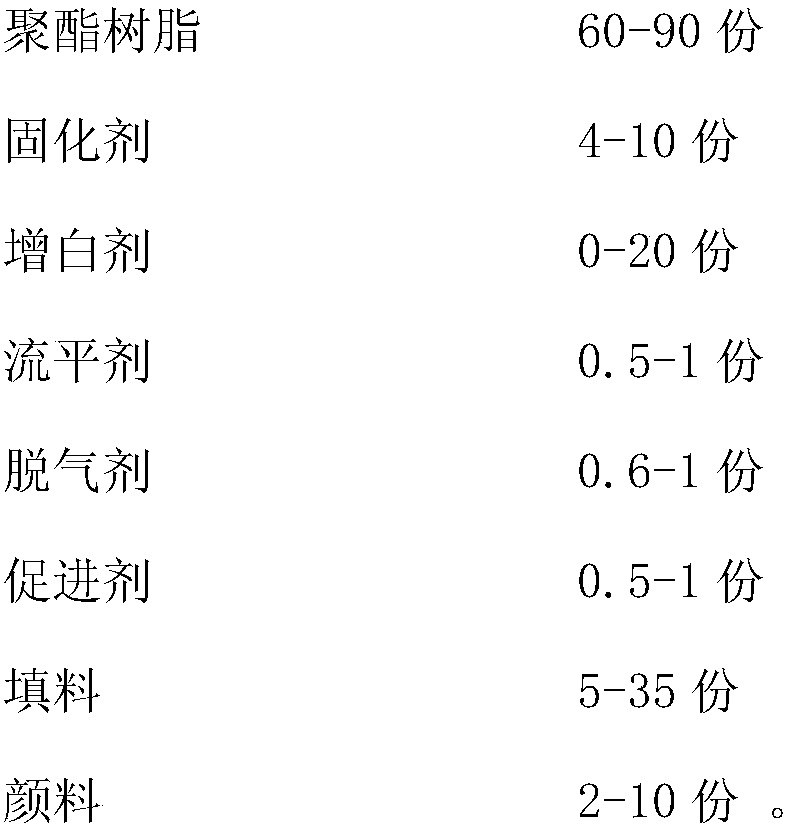

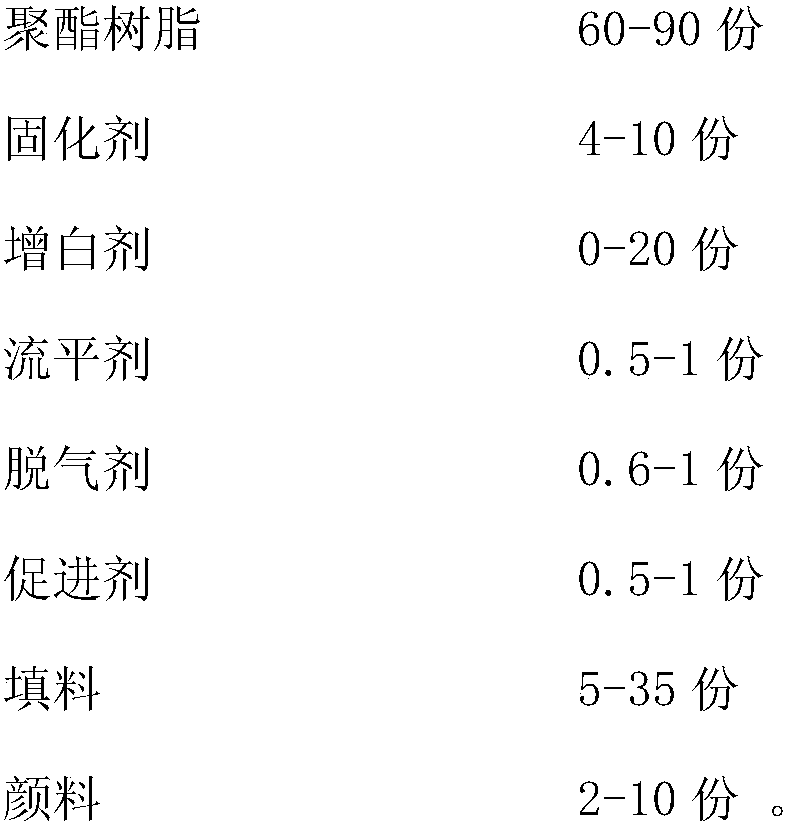

Touch powdery coating and preparation method thereof

InactiveCN109535918ALow costEasy to transport over long distancesPolyurea/polyurethane coatingsPowdery paintsWhitening AgentsPolyester resin

The invention relates to a touch powdery coating and a preparation method thereof, relates to a powdery coating, and in particular, relates to the touch powdery coating and the preparation method thereof. The invention provides the touch powdery coating with low cost, easy long-distance transportation, simple operation, time saving, high efficiency, high utilization rate and no organic matter volatilization VOC, and a preparation method thereof. The touch powdery coating includes the following components in parts by weight: 60-90 parts of polyester resin, 4-10 parts of a curing agent, 0-20 parts of a whitening agent, 0.5-1 part of a leveling agent, 0.6-1 part of a degassing agent, 0.5-1 part of an accelerator, 5-35 parts of a filler, and 2-10 parts of a pigment. The special production technology is not needed to adopt, and the product can be prepared only from multiple raw materials through a conventional production and manufacturing processes. Because the finished product is powder, the finished product is easy to pack and transport for a long distance, and is long in storage time.

Owner:YANGZHOU JINCHEN CHEM

Method for preparing Hmong's local flavor pickled-soup beef offal hotpot seasoning

ActiveCN102894334AEasy to transport over long distancesFood preservationFood preparationMonosodium glutamateFlavor

Owner:贵州省黄平县乐源旅游特色食品厂

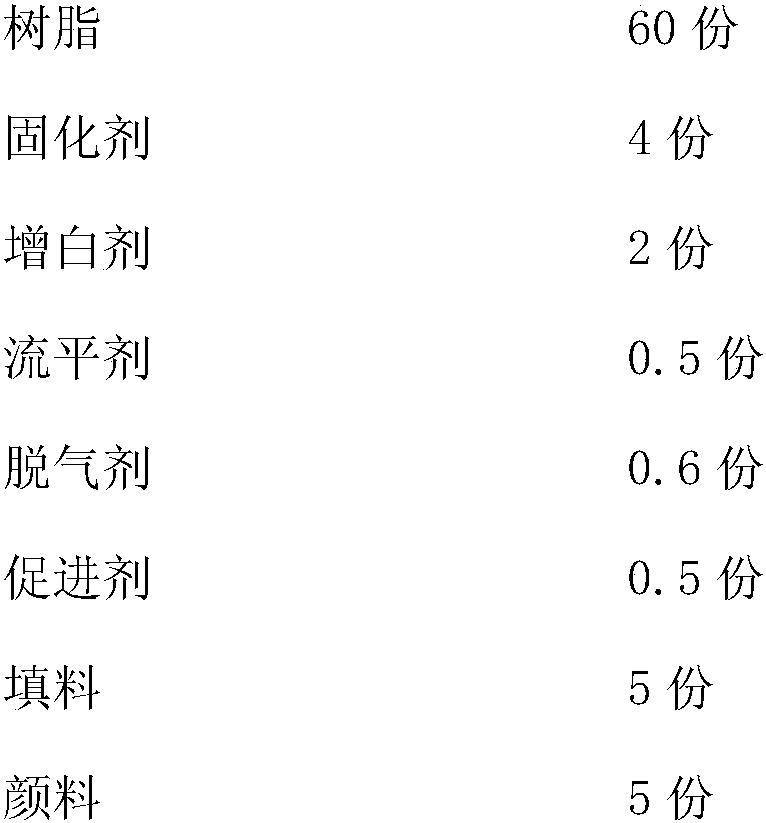

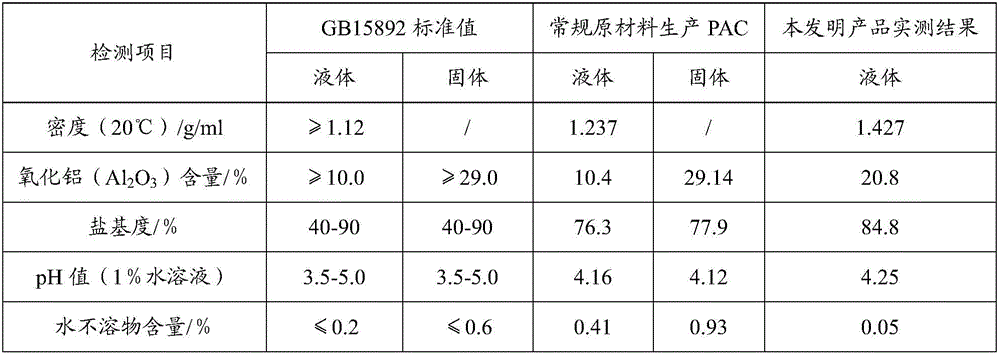

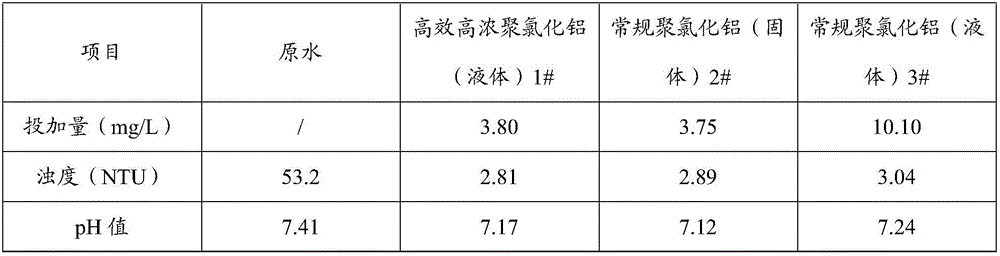

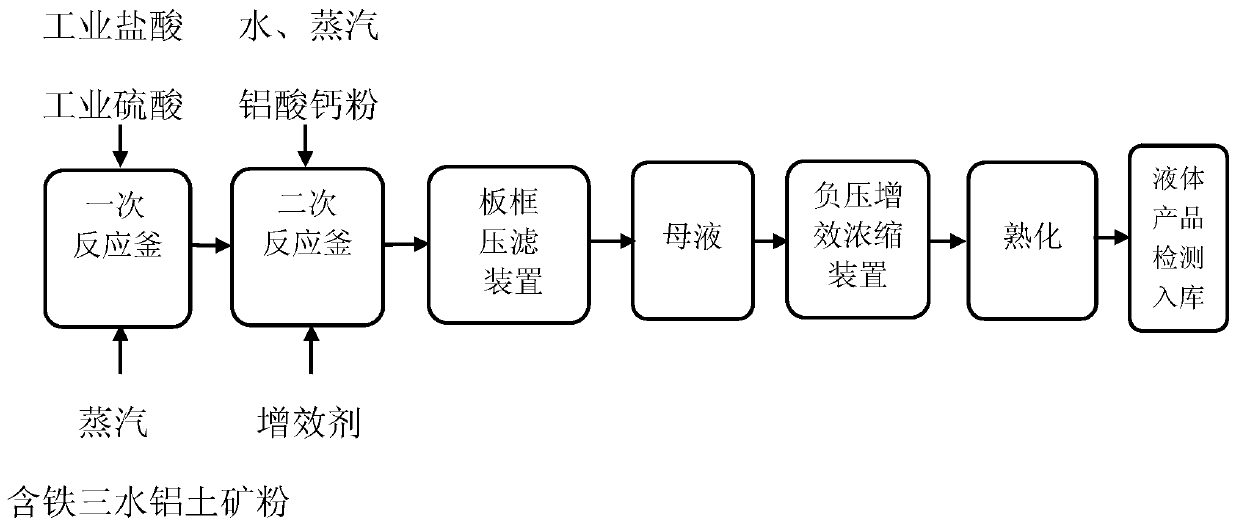

Production technology of high-efficiency and high-concentration polyaluminum chloride

The invention discloses a production technology of high-efficiency and high-concentration polyaluminum chloride. Under the condition that lots of process devices and other raw materials are not added, treated aluminum-containing waste residues are neutralized by adopting an aluminum ingot and aluminum tape surface pickling waste liquid to serve as raw materials, and then the high-efficiency and high-concentration liquid polyaluminum chloride is produced through a negative-pressure synergistic concentration technology to replace a conventional solid product. The technology is simple and easy to operate, low in production input and suitable for industrial production; the water purification ratio of the prepared high-efficiency and high-concentration liquid polyaluminum chloride to the conventional solid product is about 1:1; and meanwhile, the production cost of the polyaluminum chloride is greatly reduced by using the aluminum-containing waste residues, wastes are changed into treasures, and the production technology meets the environmental protection concepts of energy conservation and emission reduction and circulation economy.

Owner:蓝保(厦门)水处理科技有限公司

Seedling growing method for hybrid ramie seeds through plug shallow earthing

InactiveCN110547149AQuality improvementReduce the impactCultivating equipmentsPlant cultivationTerrainSoil quality

The invention discloses a seedling growing method for hybrid ramie seeds through plug shallow earthing. Land parcels which have a flat terrain and loose soil are selected as seedbed land, diseases andpests, grass seeds and the like in soil are killed by means of high temperature, ultraviolet lamp irradiation and other methods, the soil quality is improved, the influence of the diseases and pestsand the grass seeds on the seeds is lowered, the labor force is reduced, and the cost is lowered; besides, seedling growing is achieved by means of plug shallow earthing, transplanting is facilitated,plugs can be directly transported to a field in which ramie is about to be planted, and long-distance transportation is facilitated; by directly taking seedlings with soil out of the plugs, the rootsystems and growing points of the seedlings are protected, the water retention rate is high, and the survival rate of the young seedlings is increased.

Owner:达州市农业科学研究院

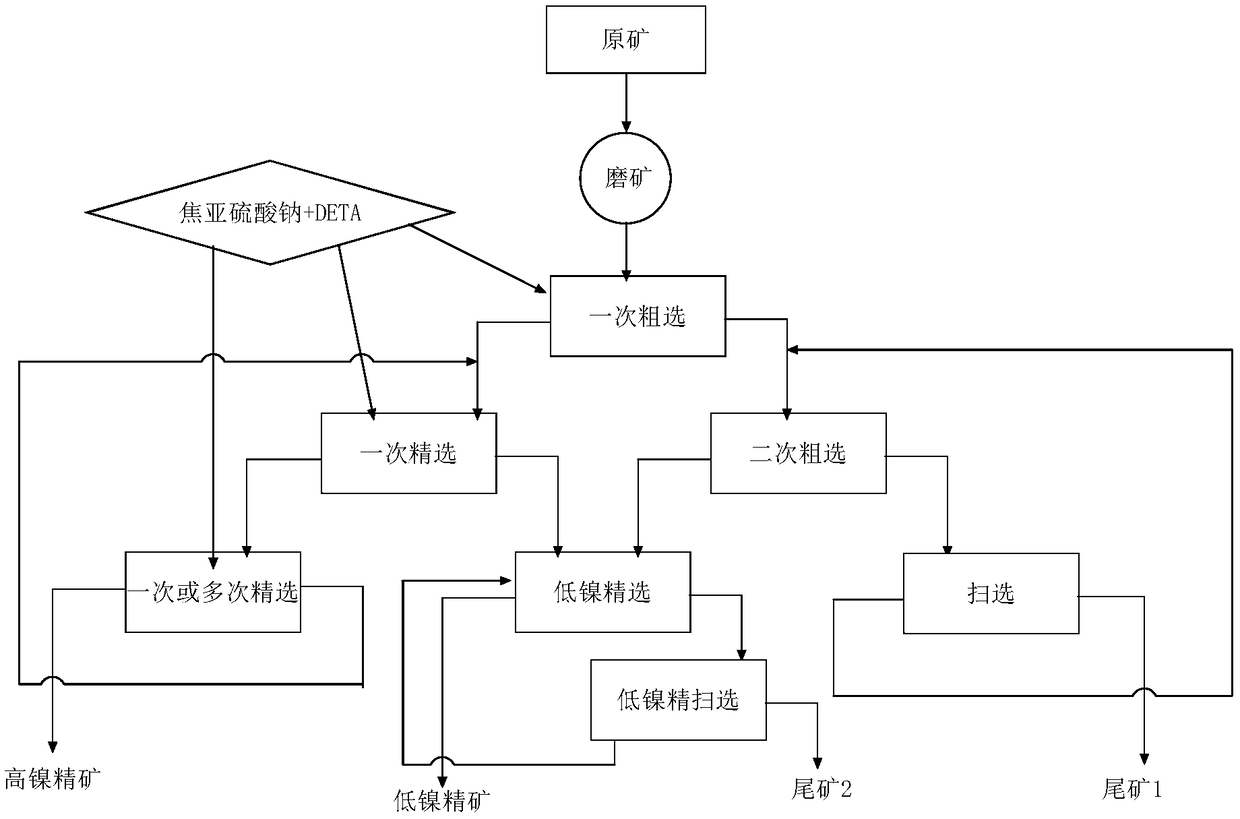

Beneficiation method for producing multi-product nickel concentrate

The invention discloses a beneficiation method for producing multi-product nickel concentrate. The beneficiation method comprises the following steps that primary selection is carried out on primary rough concentration concentrate so as to obtain primary fine concentrate and primary fine tailings; one-time or multiple selection is carried out on the primary fine concentrate until the high-nickel ore concentrate with the nickel grade of 10-22% is obtained; a magnetic pyrite activator, a collecting agent and a foaming agent are added into the primary roughing tailings to carry out secondary rough selection so as to obtain secondary rough concentrate and secondary rough tailings; and the primary fine tailings are combined with the secondary rough concentrate, at least one low-nickel concentration is carried out until the low-nickel ore concentrate with the nickel grade of greater than 5% is obtained. According to the beneficiation method, two types of nickel ore concentrate products can be obtained at the same time in the same beneficiation process, the requirement for producing high-grade nickel concentrate can be met, and the comprehensive recovery rate of nickel cannot be reduced.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

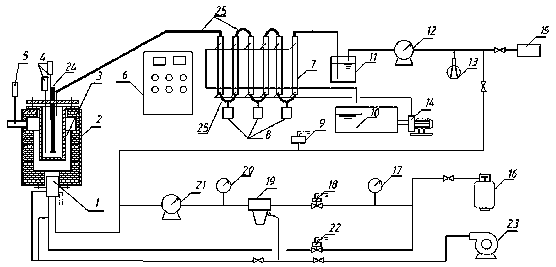

Solid waste material vertical solidifying and gasifying technique secondary power generation comprehensive utilization method

InactiveCN1199739CHigh resource utilization rateNo secondary pollutionSolid waste disposalIncinerator apparatusSlagWaste material

A comprehensive utilization method for secondary power generation by solid waste solidification and gasification process, comprising the following steps: 1) solid waste solidification: turning domestic waste into dense and hard solid waste rods; (2) waste gasification: solid waste rods Add anti-fire gasifier dry distillation to generate combustible gas; (3) Gasification power generation: supply the generated combustible gas to the internal combustion generator for power generation; (4) Secondary power generation: collect the waste heat of the internal combustion generator, and send it to the low-pressure boiler to generate steam, The generated steam is used to drive the low-pressure steam generator to generate electricity to achieve secondary power generation; (5) slag utilization; (6) waste heat utilization, using the waste heat of the low-pressure steam generator to break open the plastic bags of garbage and dry the garbage moisture. The present invention has the advantages of high recycling rate of domestic waste, no secondary pollution, less project investment, etc., solves the problem of waste leakage pollution, the odor problem caused by the centralized stacking of waste, and the problem of mass production of dioxin, and creates a new A precedent for secondary power generation from domestic waste.

Owner:张连发

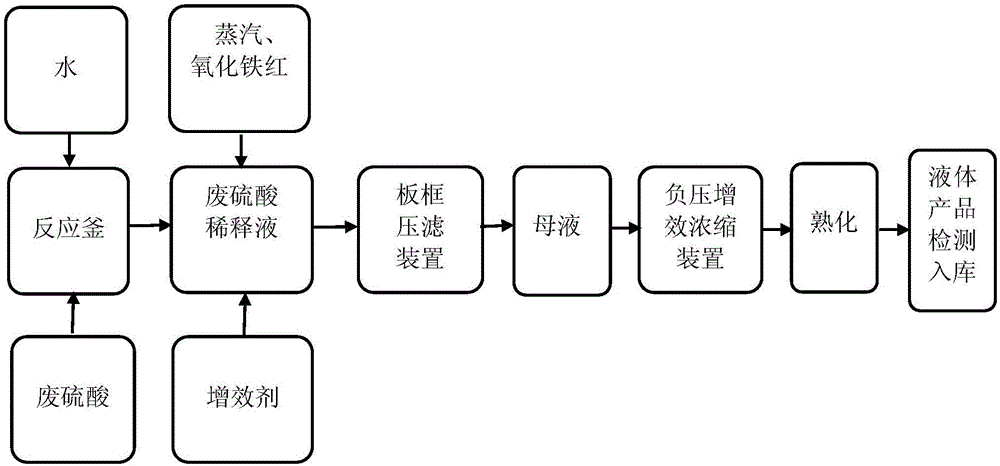

Production technology of high-efficiency high-concentration polymeric ferric sulfate

InactiveCN106587169AGuaranteed purityAvoid cloggingIron sulfatesWater/sewage treatment by flocculation/precipitationHigh concentrationEnvironmental resistance

The invention discloses a production technology of high-efficiency high-concentration polymeric ferric sulfate. Under the condition that a catalytic oxidation process is omitted and massive processing equipment does not need to be increased, a rolled steel pickling byproduct namely iron oxide red reacts with industrial waste sulphuric acid, and through a negative pressure synergy concentration technology, high-efficiency high-concentration liquid polymeric ferric sulfate is prepared, so that the purposes of resource utilization is achieved, and solid products are replaced. A preparation method of the high-efficiency high-concentration polymeric ferric sulfate is simple, practical and easy to operate; and ratio of the water purifying effect of the prepared high-efficiency high-concentration liquid polymeric ferric sulfate to the water purifying effect of the solid products is close to 1 to 1, the equipment investment is low, and the production technology is suitable for industrialized production. The byproduct namely the iron oxide red and the industrial waste sulphuric acid are used, so that other problems caused in a catalytic oxidation process can be solved, and the production cost is greatly reduced. According to the production technology disclosed by the invention, waste is turned into wealth, and one kind of waste is used for governing other kinds of waste, so that environmental-friendly ideas of saving energy, reducing emission, and recycling economy can be achieved.

Owner:蓝保(厦门)水处理科技有限公司

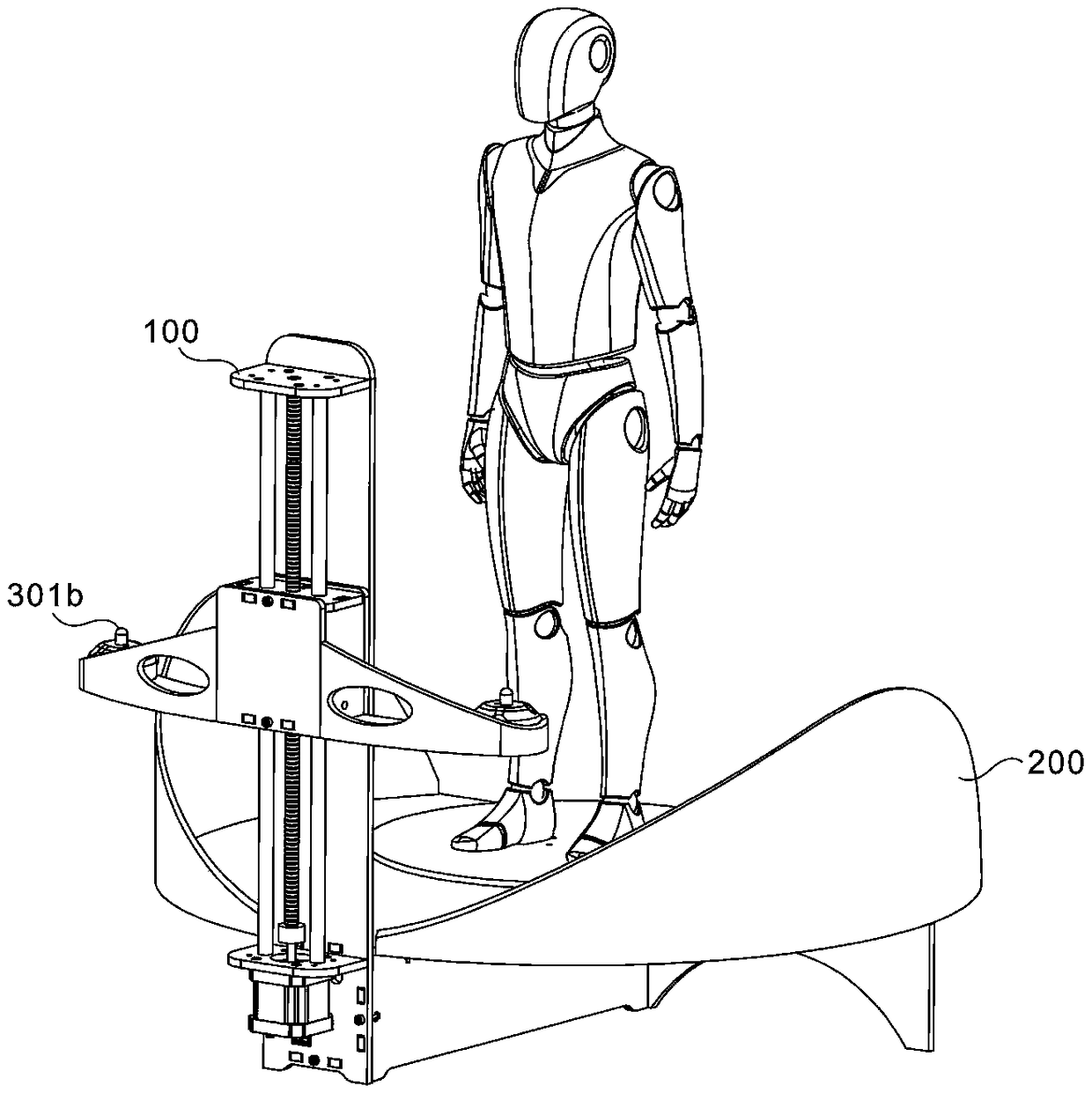

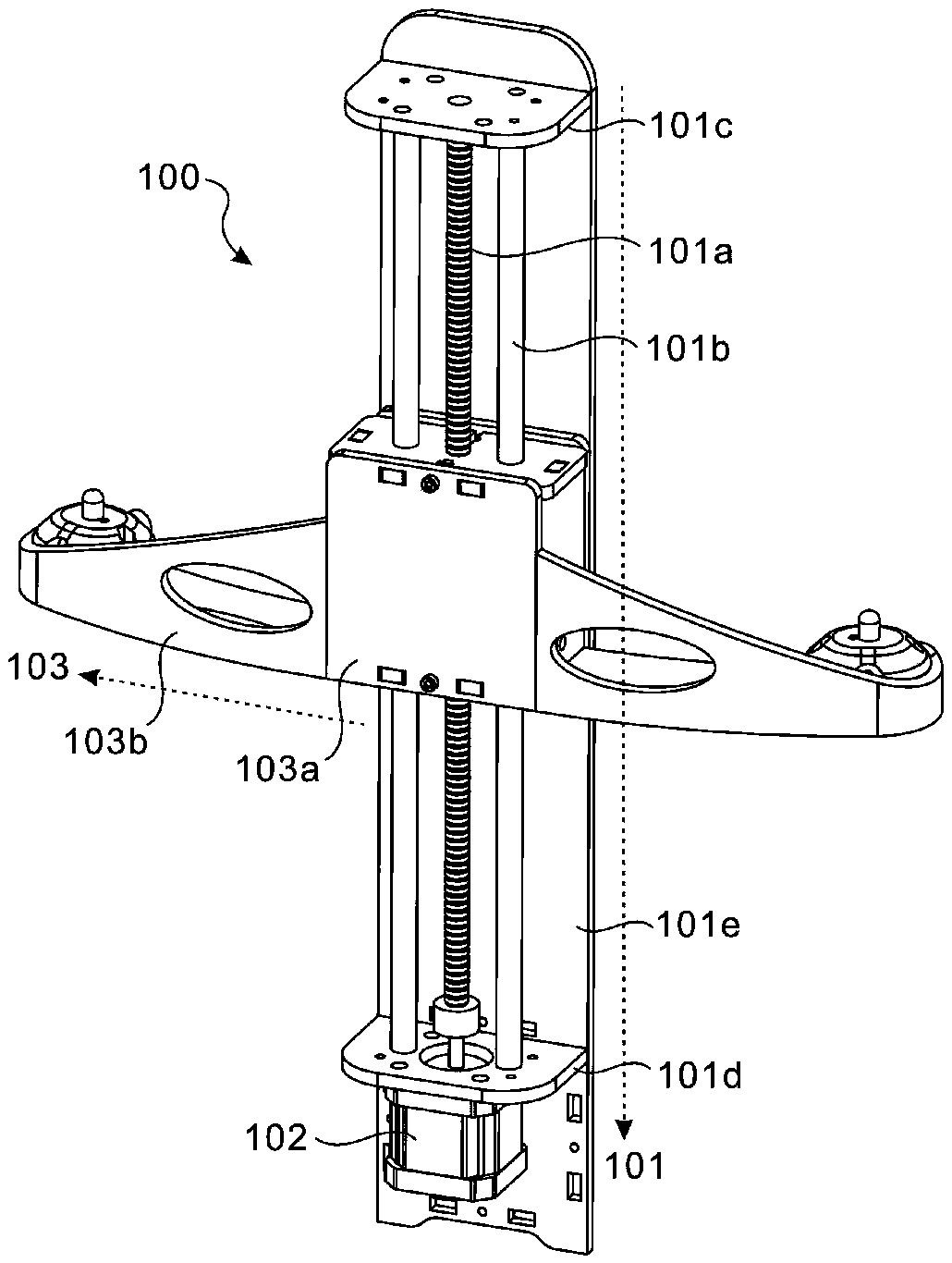

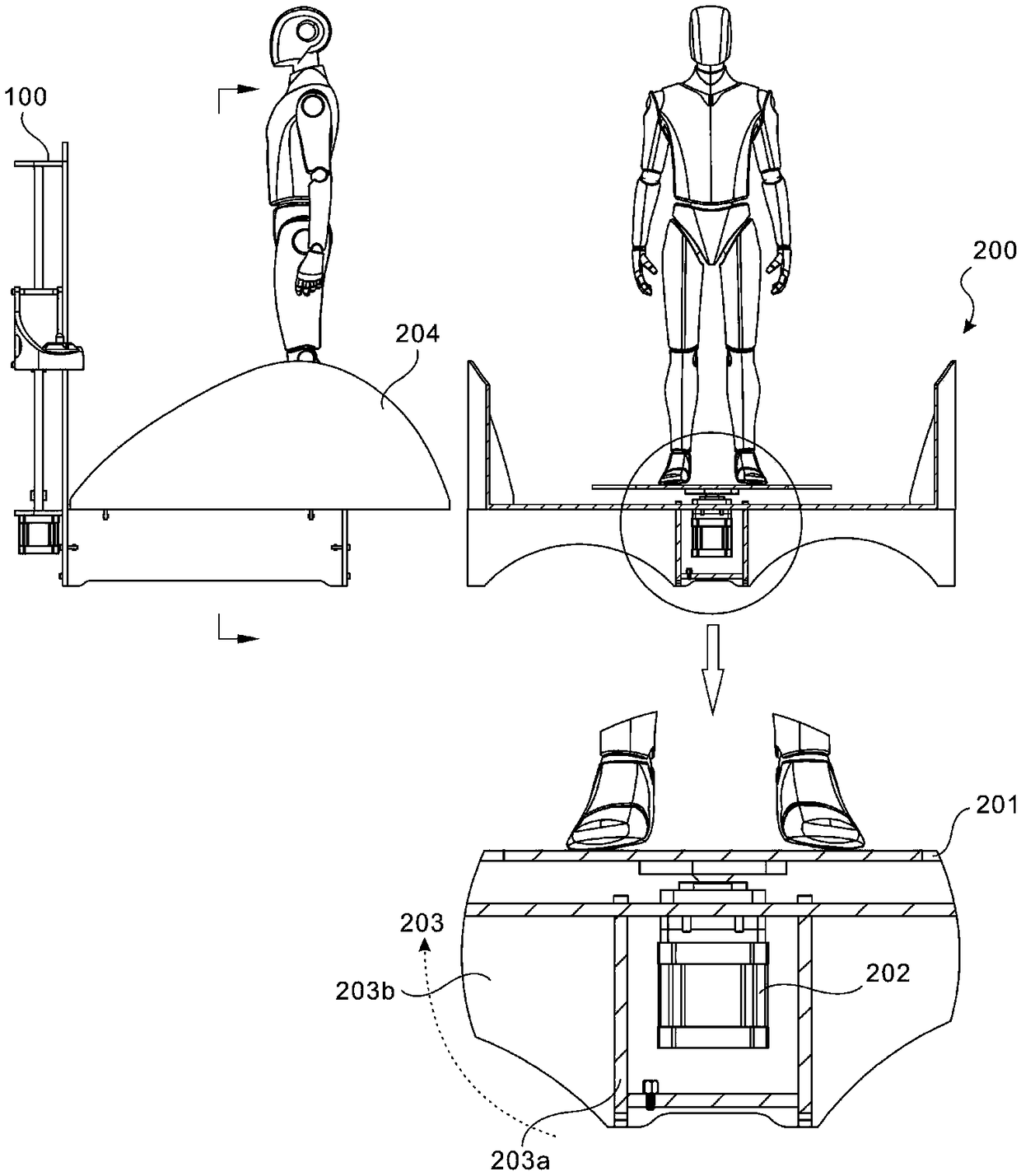

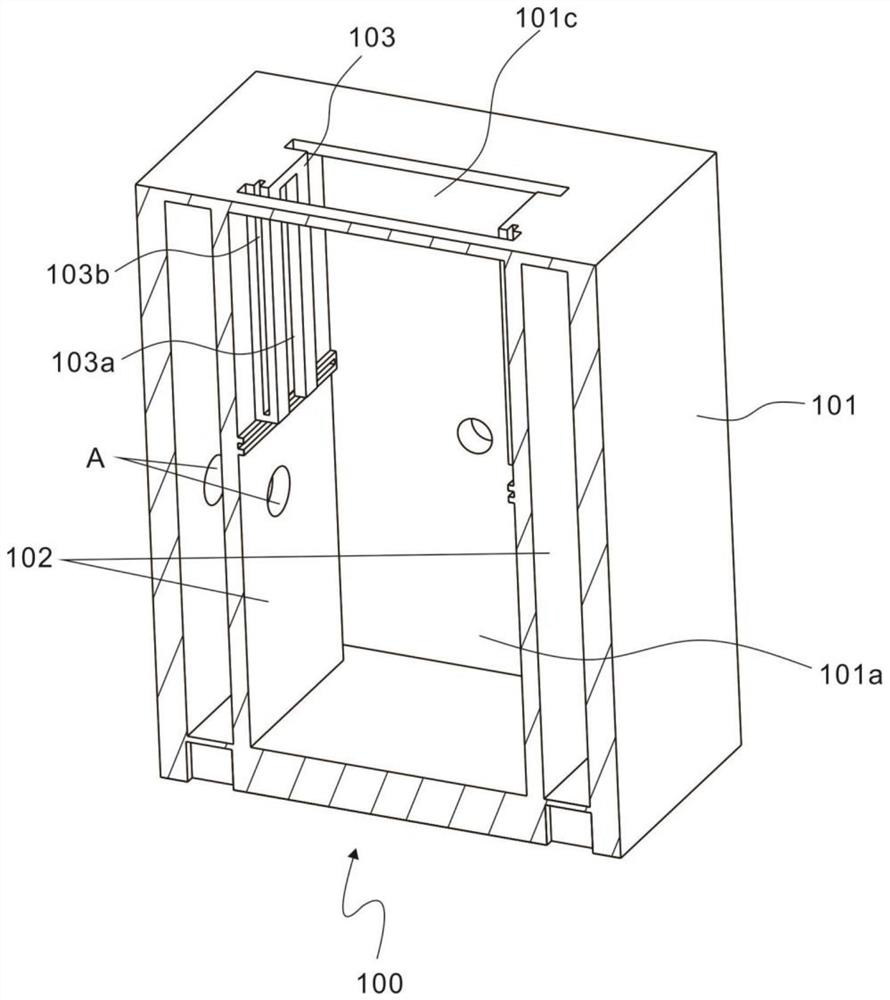

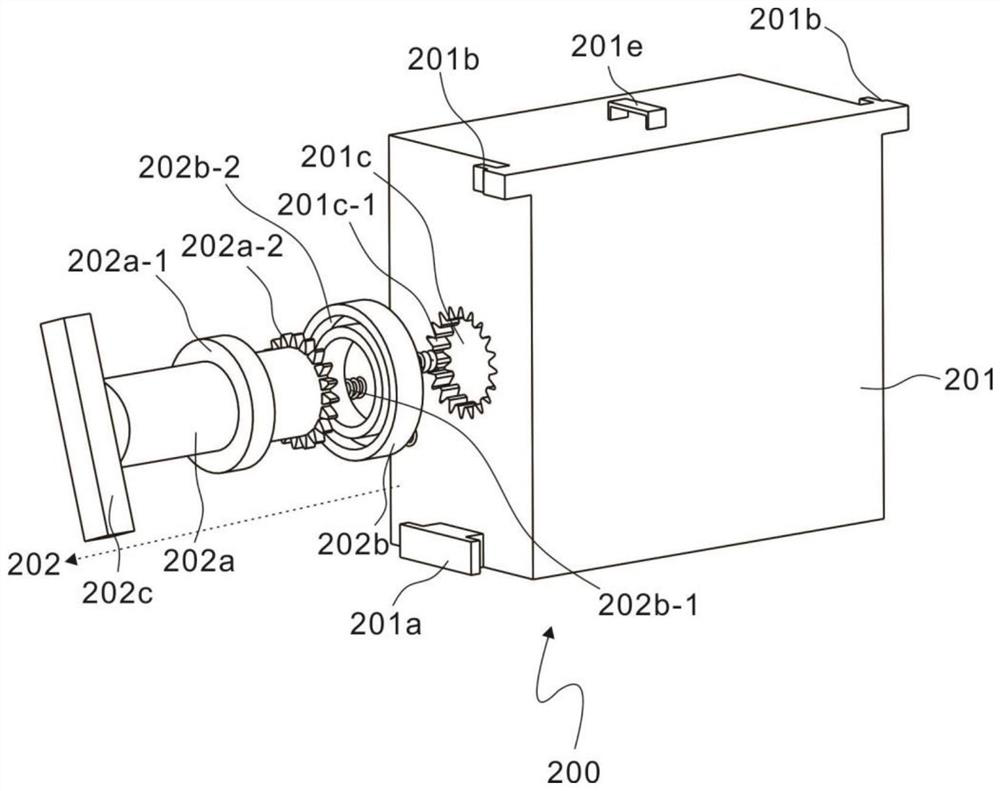

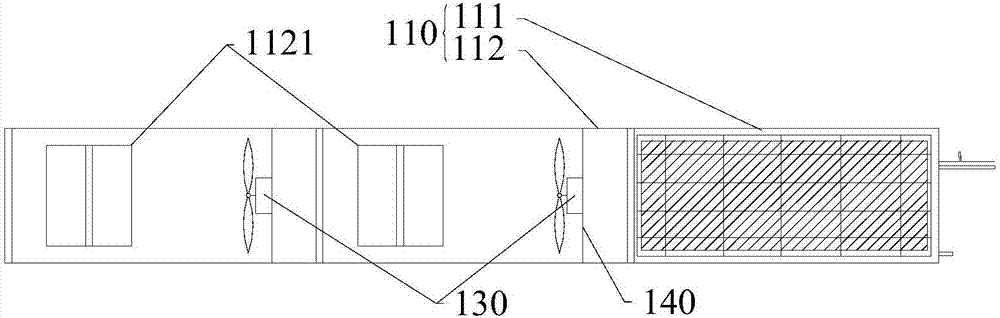

Compensated body scanner

InactiveCN109059801AQuick connectionSafe and reliable connectionUsing optical meansBody scannerMotor unit

The invention discloses a compensated body scanner, comprising a first movement unit, which includes a lifting assembly, a first power component and a first bracket component. The lifting assembly passes through the first bracket assembly; the end of the first lifting assembly is coupled to a first power assembly; and the first bracket assembly is fixed with a signal receiver; the second movementunit which includes a rotation assembly, a second power assembly and a second bracket assembly. The second power component is fixed to the second bracket assembly with a power output end facing upward, and the rotating component fixed to a power output end of the second power component; and a platform compensation unit. The compensatory body scanner of the present invention is a detachable and assembled structure, and the external wires of each functional unit are divided into two sections and connected by a wiring mechanism, so that the two sections can be simultaneously disassembled and assembled following each functional unit.

Owner:JIANGNAN UNIV

Industrial part equipment transportation robot

ActiveCN112645015ANot easy to loseSo as not to damagePackaging vehiclesContainers for machinesControl engineeringMaterial resources

The invention discloses an industrial part equipment transportation robot. The industrial part equipment transportation robot comprises a moving module and a storage module, the moving module comprises a storage box, grid baffles and sliding strips, a cavity is formed in the storage box, the grid baffles are vertically and symmetrically arranged in the cavity, and the grid baffles are connected to the top of the cavity from the bottom of the cavity; the sliding strips are vertically arranged on the grid baffles and are oppositely arranged; and the storage module comprises a part frame and a rotating part, the part frame is arranged between the grid baffles of the interior of the cavity, the two sides of the part frame are movably connected with the sliding strips, and the rotating part is arranged at one side of the storage box and connected with the part frame. The industrial part equipment transportation robot is used for part conveying in industrial production, parts can be stored in a classified and orderly manner confusion is avoided, manual carrying is not needed, manpower and material resources are saved, and long-distance conveying is facilitated; and meanwhile, cost is saved, operation is easy, and the parts are not prone to being lost.

Owner:合肥龙智机电科技有限公司

Method of medical waste sorting and high-temperature pyrolysis treatment

InactiveCN109737419AAchieve recyclingReduce wasteMedical waste disposalSpecial form destructive distillationHigh energyMedical waste

The invention discloses a method of medical waste sorting and recycling and high-temperature pyrolysis treatment. The method of the medical waste sorting and recycling and high-temperature pyrolysis treatment comprises the steps that sorting and collecting medical waste are carried out, waste raw materials without special treatment requirements are sorted out through a manual sorting mode; then the waste raw materials are subjected to high temperature sterilization treatment through a high temperature sterilization device, and the selected waste is further sorted through magnetic separation, air classification and gravity jigging; and separated magnetic metals, aluminum, glass, sand and stone and the like can be treated by recycling departments to realize recycling of useful substances inthe medical waste, separated waste with high content of other organics can be converted into an available energy form through the high-temperature pyrolysis treatment, and the waste of resources is facilitated to be reduced; and the method of the medical waste sorting and recycling and the high-temperature pyrolysis treatment has the characteristics of high reduction degree, low secondary pollution and high energy recovery rate.

Owner:DONGGUAN UNIV OF TECH

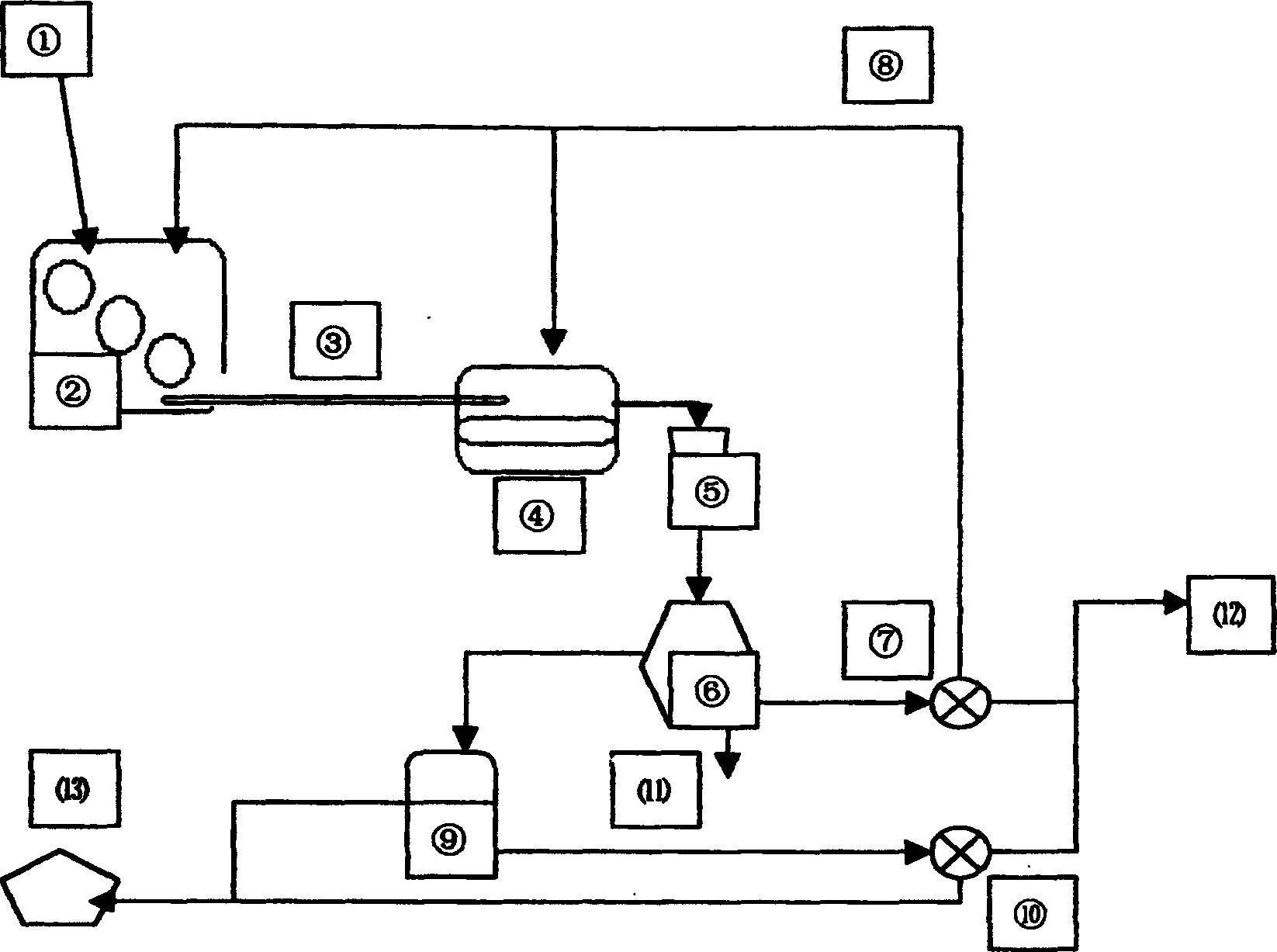

Production process of polymerized diacid ferro-aluminum for water treatment

ActiveCN111514840AImprove solubilityReduce the difficulty of cleaningIron compoundsChemical/physical/physico-chemical stationary reactorsPhosphatePhosphoric acid

The invention discloses a production process of polymerized diacid ferro-aluminum for water treatment. The preparation method comprises the following steps: a, under stirring, reducing a proper amountof water, 127-168 parts of hydrochloric acid with the total acidity of 30-32% and 8-14 parts of sulfuric acid with the total acidity of 97-99% into a reaction tank for mixing; adding 35-58 parts of iron-containing bauxite trihydrate powder with the aluminum oxide content of 40-45% and the iron oxide content of 20-25% into the mixture at normal pressure and normal temperature, and stirring the mixture to be dissolved; continuously raising the temperature until the temperature of the reaction system is controlled at 105-125 DEG C, and reacting for 3.5-5.0 hours under normal pressure; b, supplementing a proper amount of water into the feed liquid obtained in the step a while stirring; adding 46-63 parts of calcium aluminate powder, raising the temperature of the feed liquid by utilizing reaction self-heating in the adding process, adjusting the density of the feed liquid to be greater than or equal to 1.25 g / ml by using water after adding is finished, then adding 4-7 parts of a synergisttrisodium phosphate, raising the temperature until the temperature of a reaction system is controlled to be 100-115 DEG C, and reacting for 3-4 hours under normal pressure; and c, discharging the feed liquid obtained in the step b to obtain mother liquor.

Owner:绍兴上虞联谊化工有限公司

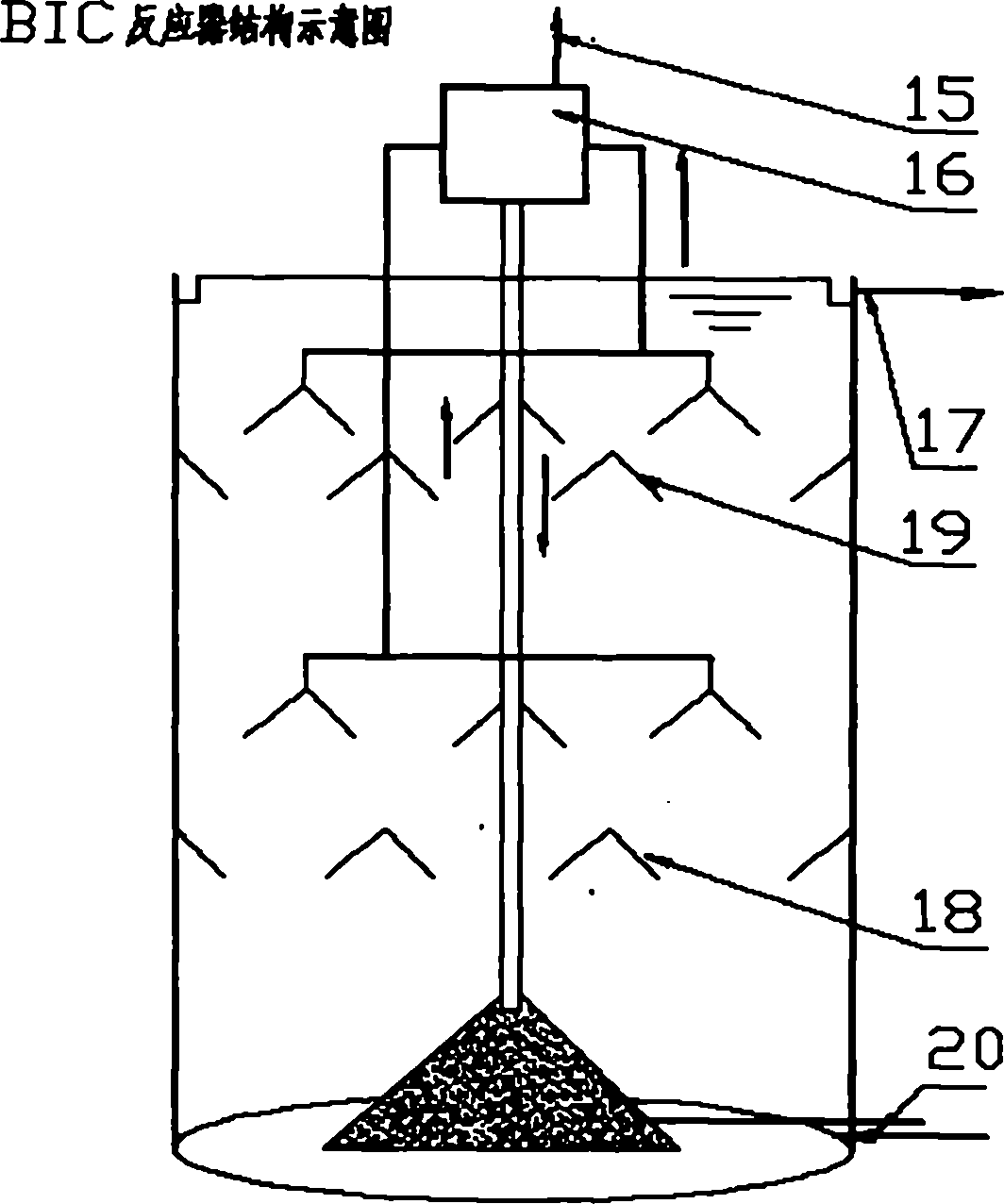

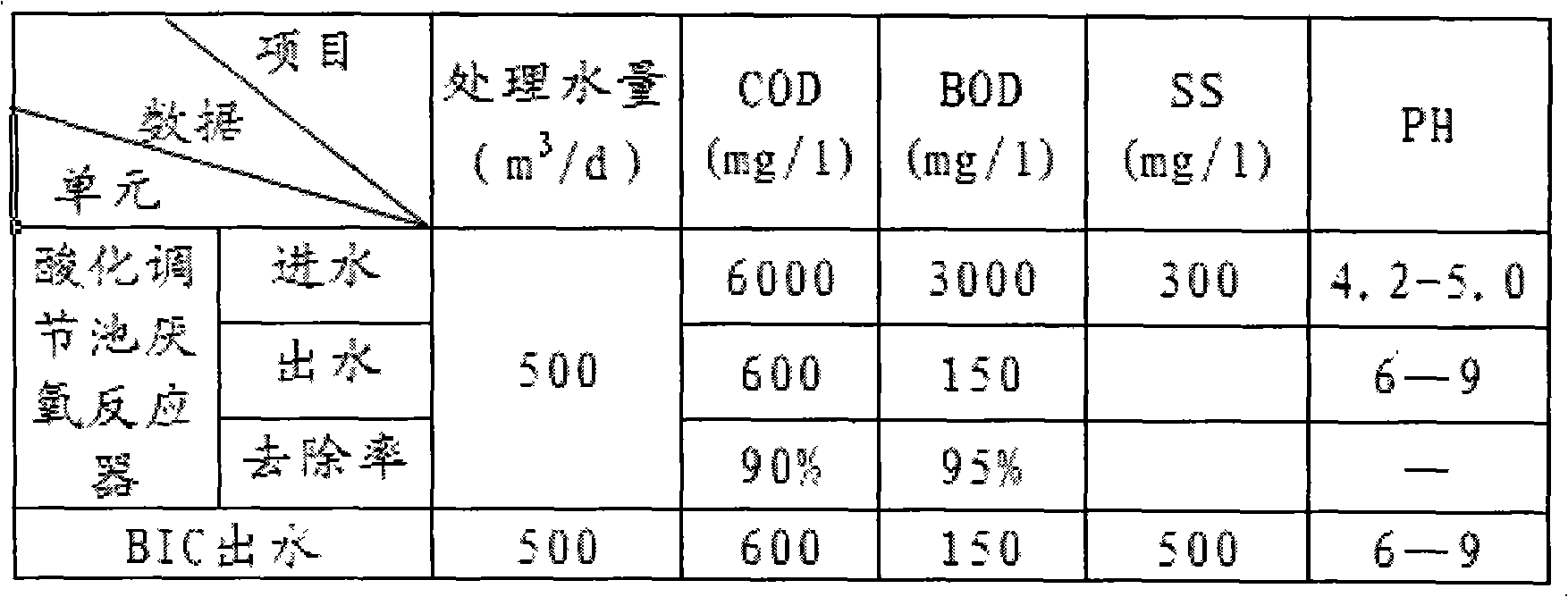

Treatment system for bean vermicelli production wastewater

InactiveCN103508621APromote energy saving and emission reductionGuaranteed effectMultistage water/sewage treatmentWaste water treatment from food industryHigh concentrationChemical oxygen demand

The invention relates to a treatment system for bean vermicelli production wastewater, and belongs to the technical field of sewage treatment. The treatment system comprises a water inlet and a water outlet, wherein a first settling pond, an acidification adjustment pond, a lifting water pump, an anaerobic reactor, a second settling pond and an aerobic treatment pond are sequentially communicated between the water inlet and the water outlet through a pipeline; the first settling pond is used for the early-stage settling treatment of wastewater, the acidification adjustment pond is used for adjusting the water quality and quantity of high-concentration wastewater, and the anaerobic reactor is used for carrying out anaerobic fermentation, producing biogas and purifying the wastewater; the second settling pond is also provided with a branch loop reflowing to the anaerobic reactor, and the acidification adjustment pond also comprises a water quantity adjusting pond. According to the invention, a large amount of waste pollutants can be converted into a green energy namely biogas, thereby achieving a great promoting effect on the energy conservation and emissions reduction and benefit increasing of enterprises; through an anaerobic reaction, the removal rate of COD (chemical oxygen demand) is 90%, thereby ensuring the effect of wastewater treatment and up-to-standard release.

Owner:YANTAI DESHENGDA LONGKOU VERMICELLI

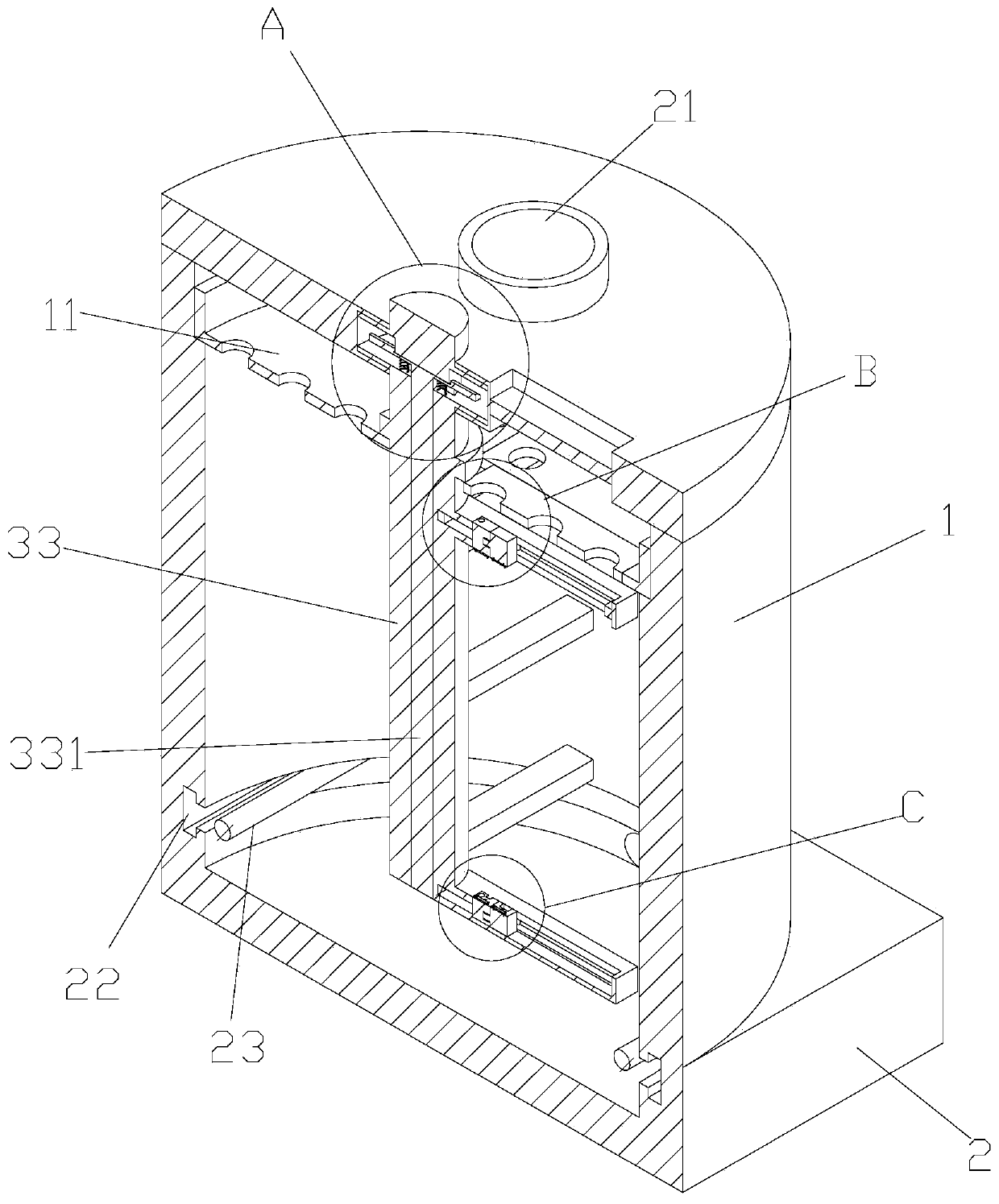

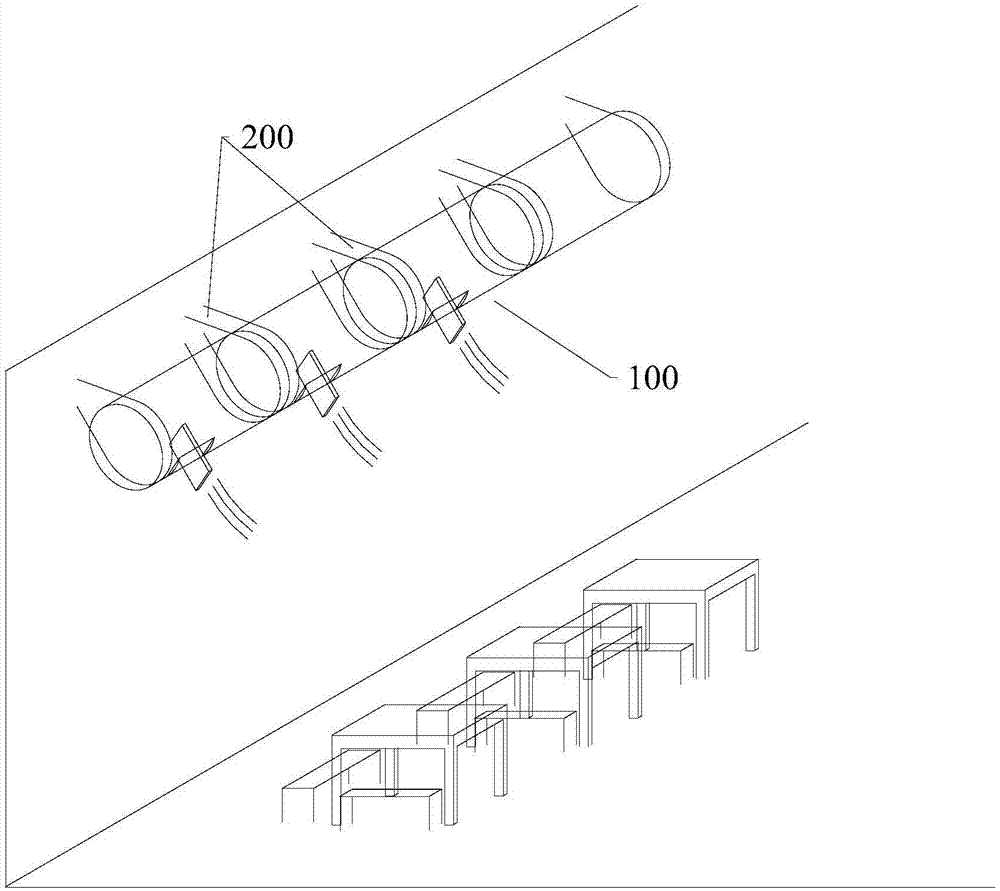

Biomass continuous pyrolysis charing apparatus with flexible spiral conveying apparatus

The invention discloses a biomass continuous pyrogenation carbonizing apparatus provided with a flexible screw conveying appliance, which comprises a motor (1), a coupling (3), bearings (4), a flexible screw spring (6), a pyrolysis tube (11), a feed inlet (5), a carbon discharging outlet (12) and a heating device; one end of the pyrolysis tube (11) is provided with the feed inlet (5) communicated with the inner cavity of the pyrolysis tube (11), and the other end is provided with the carbon discharging outlet (12) communicated with the inner cavity thereof; the inner cavity of the pyrolysis tube (11) is inserted with the flexible screw spring (6) along the axial direction; one end of the flexible screw spring (6) is connected with the output shaft of the motor (1) through the first bearing (4) and the coupling (3), and the other end is supported on the second bearing (4); and the outer side of the pyrolysis tube (11) is provided with the heating device for heating the pyrolysis tube (11). The biomass continuous pyrogenation carbonizing apparatus is easily suitable for long-distance convey and has simple structure.

Owner:SOUTH CHINA AGRI UNIV

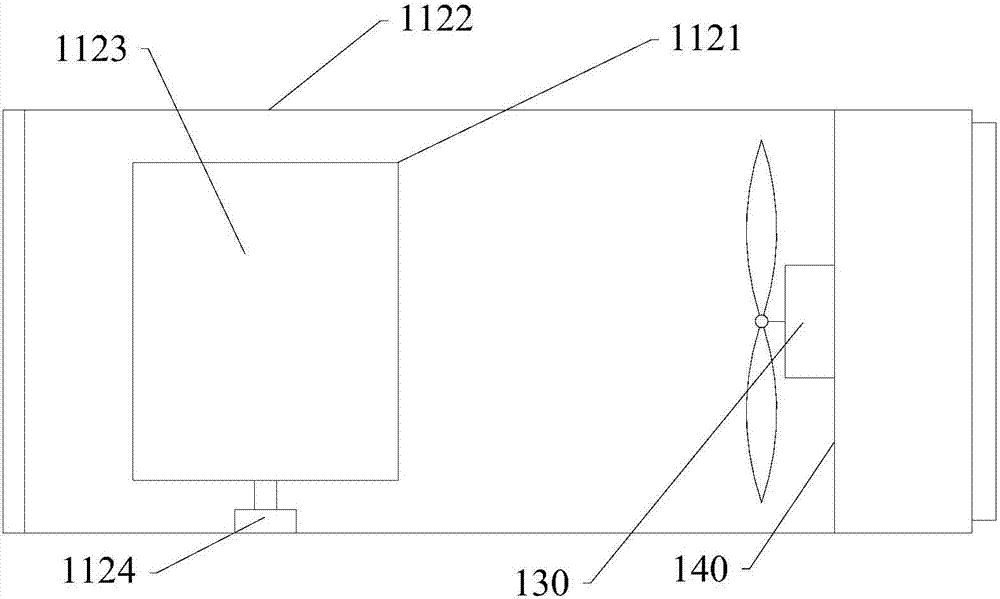

Indoor heat exchanging device and air conditioner

PendingCN107504665AEasy to transport over long distancesImprove adaptabilityDucting arrangementsCondensate preventionProcess engineeringMechanical engineering

The invention relates to an indoor heat exchanging device and further relates to an air conditioner comprising the indoor heat exchanging device. The indoor heat exchanging device comprises a circulating pipeline, a heat exchanger and a fan; the circulating pipeline comprises a heat exchanging pipeline and an air supply pipeline; the air supply pipeline and the heat exchanging pipeline are detachably connected; the air supply pipeline communicates with the heat exchanging pipeline; an air outlet is formed in the air supply pipeline; the heat exchanger is arranged in the heat exchanging pipeline; the fan is arranged in the air supply pipeline; and when the fan rotates, in the air supply pipeline, air can be delivered in the direction of the air outlet. According to the indoor heat exchanging device and the air conditioner, the heat exchanger and the fan are combined and mounted in the circulating pipeline, the air after heat exchanging is delivered for a long distance, the cost is low, realization is easy, the overall length of the circulating pipeline can be selected according to the actual working conditions, and the adaptability of the circulating pipeline for the environment is improved.

Owner:GREE ELECTRIC APPLIANCES INC

A production process of high-efficiency and high-concentration polymerized aluminum iron bis-acid

ActiveCN106565003BLow costKeep healthyIron compoundsWater/sewage treatment by flocculation/precipitationSulfateChloride

The invention discloses a production process of high-efficiency and high-concentration polyaluminum ferric chloride sulfate. The production process comprises the following steps: under a condition ofnot adding a large amount of technological equipment and other raw materials, extracting aluminum and ferric ions from ferric trihydrate alumina mineral powder by a sulfuric acid and hydrochloric aciddi-acid dissolving mode, performing polymerization reaction with calcium aluminate powder, and generating the high-efficiency and high-concentration liquid polymerized di-acid ferro-aluminum througha negative pressure synergic concentration process to replace a conventional solid product. The process is simple, practical and easy to operate; the water purification effect of the prepared high-efficiency and high-concentration liquid polymerized di-acid ferro-aluminum and the water purification effect of the conventional solid product is about 1 to 1; and the equipment investment is low, the cost performance of the raw materials is high, the production cost is greatly reduced, and the production process is suitable for industrial production.

Owner:蓝保(厦门)水处理科技有限公司

A long-distance conveying device for bag-type dust-removing powdered magnesium sulfate

ActiveCN112027722BEasy to transport over long distancesEasy to operateConveyorsSupporting framesElectric machineryDust control

The invention relates to the technical field of magnesium sulfate, in particular to a bag dust removal type powdered magnesium sulfate long-distance conveying device. It includes a conveying frame and a conveying mechanism on the conveying frame. The conveying frame at least includes: a fixed frame, two belt rollers are arranged for rotation inside the fixed frame, a conveying belt pulley is arranged at the end of the belt roller, and a conveyor belt is arranged between the two conveying belt pulleys. Conveyor belt, the end of one of the conveyor belt discs is connected with the output shaft of the conveyor motor, the conveyor belt is arranged between the outer walls of the two belt rollers, the electric telescopic legs, and the ends of the piston rods of the two electric telescopic legs are respectively fixed on the fixed frame near the two sides. At the bottom of the end, the conveying mechanism at least includes: a mobile frame, the top of which is fixedly arranged on the outer wall of the conveyor belt. Disk, and can carry out bag dust removal to the air.

Owner:湖南谊诚科技有限公司

A kind of tobacco potted planting method and its application

ActiveCN109220681BSimple and fast operationLow cultivation labor intensityTobacco cultivationReceptacle cultivationNicotiana tabacumGreenhouse

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

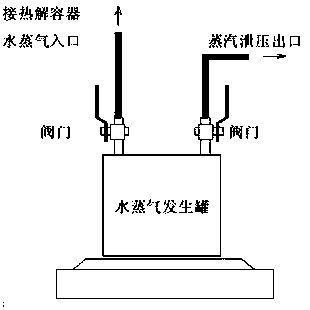

A comprehensive utilization process and device for sintering waste heat

ActiveCN103438723BRealize gradient scientific utilizationExtensive secondary use valueEnergy industryIncreasing energy efficiencyEngineeringDeaerator

The invention relates to an integrated utilization technology and device of sintering waste heat. The hot smoke of a cooling machine section 1 passes through a medium-pressure superheater and a medium-pressure evaporator I; the hot smoke of section 2 passes through a medium-pressure evaporator II and a medium-pressure preheater; the smoke of the section 1 and the section 2 is collected through pipelines and passes through a vertical type low-pressure superheater and a low-pressure evaporator, and then is sent back to ring cold section 1 and section 2 to continuously cool and sinter mineral aggregates; the feedwater passes through a feedwater preheater, then enters into a deoxygenization water tank after being deoxygenized by a thermal deaerator; the water is naturally circulated between the low-pressure evaporator and a low-pressure boiler barrel, heat exchange is realized, and the generated saturated steam passes through the low-pressure superheater for external supply. The technology provided by the invention has the advantages that after adopting the waste heat integrated utilization scheme, gradient scientific utilization of waste heat resource of the existing sintering circuit is realized, matched waste heat utilization equipment is arranged at each waste heat resource point so as to achieve maximization of waste heat utilization, and meanwhile, the produced superheated steam has a wide secondary utilization value, thus being convenient forfacilitating the long-distance conveying of the steam.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

Manual knurling conveying line

PendingCN113682072AImprove the versatility of useEasy to transportEmbossing decorationsElectric machineryEngineering

The invention discloses a manual knurling conveying line and relates to the technical field of knurling. The manual knurling conveying line comprises a conveying line and a placing frame, wherein a profile body is arranged on the outer surface of the conveying line; limiting idle wheels are mounted at two ends of the exterior of the profile body; a mounting plate is arranged on the exterior of each limiting idle wheel; a conveying chain is installed in the conveying line; a motor is arranged at one end of the exterior of the conveying chain; the placing frame is located outside the motor; a connecting frame is mounted on the exterior of the placing frame; supporting columns are arranged on the the exterior of the bottom of the conveying line; and a transverse plate is mounted at one end of the exterior of the bottom of each supporting column. According to the manual knurling conveying line, when the profile body is subjected to knurling treatment, hand wheels can be manually rotated according to the thickness of the profile body; a screw can synchronously rotate through rotation of the hand wheel; the height of a knurling shaft can be synchronously adjusted through anticlockwise or clockwise rotation of the screw; and the profiles with different thicknesses can be conveniently used.

Owner:湖南朗乐科技股份有限公司

Seedling growing method for Blumea balsamifera seeds

The invention discloses a seedling growing method for Blumea balsamifera seeds. The method includes that mature seed artificial culture technologies such as artificial beekeeping fertilization and seed water tank nutrition liquid culture are used for improving seed fertility and facilitating seed collection; effective and repeatedly-practiced sowing technologies such as a seedbed processing method, a substrate formula, sowing seasons and a seeding method are summarized, and seed emergence rate is improved to 10%-30%; and nutrition bag seedlings with equal culture quality are taken to a mountain to plant stocks, and pest control measures for different nursery stages, nursery temperature and humidity management key points and the like are systematically summarized. By means of the method, millions of nutrition bag seedlings with good quality and low price are cultured successfully, and the problem that a local government is prevented from developing a Blumea balsamfera industry due to lack of seedlings is solved.

Owner:GUIZHOU YIHE BIOTECH

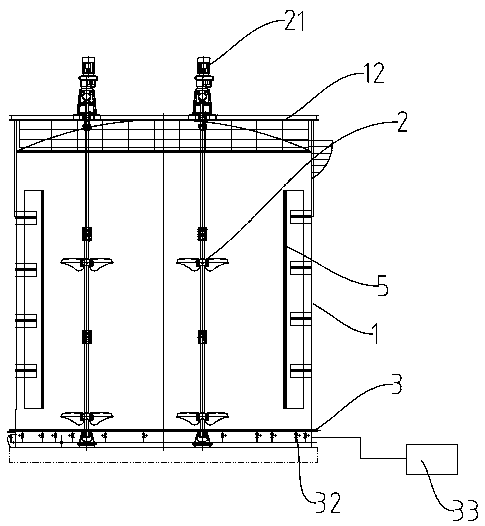

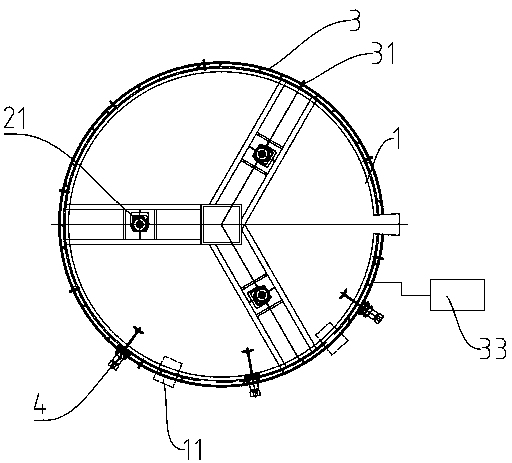

Coal-water slurry storage tank anti-sedimentation device

ActiveCN105936390BPrevent precipitationImprove liquidityLarge containersMixer accessoriesAgricultural engineeringSlurry

The invention discloses an anti-sedimentation device for a coal-water slurry storage tank, which is characterized in that it comprises a tank body, several vertical agitators, purging devices, side agitators and spoilers, and the tank body is provided with a tank cover and A number of slurry outlets, vertical agitators are evenly distributed in the tank along the center of the tank, the vertical agitator is fixed between the bottom wall of the tank and the tank cover, and the purger includes a side wall arranged outside the bottom of the tank The main pipe, several branch pipes, several valves and air compressors, each branch is provided with a separate valve, the main pipe is connected to the air compressor, and the air compressor blows compressed air into the tank through the main pipe and branch pipes. The present invention fundamentally solves the anti-sedimentation problem of the coal-water slurry storage tank, enables the coal-water slurry to have the fluidity like water for long-distance transportation, has better anti-sedimentation effect than other forms, and can effectively solve the problem of storage tank operation safety Hidden dangers, reducing the pressure on corporate logistics cleanup.

Owner:JIANGSU QIULIN HEAVY IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com