A comprehensive utilization process and device for sintering waste heat

A waste heat and process technology, applied in the field of comprehensive utilization process and device of waste heat in sintering plants of existing iron and steel enterprises, can solve the problems of not fully reflecting the value of waste heat of sintering flue gas, insufficient utilization of waste heat, secondary waste of energy, etc. Secondary utilization value, the effect of facilitating long-distance transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

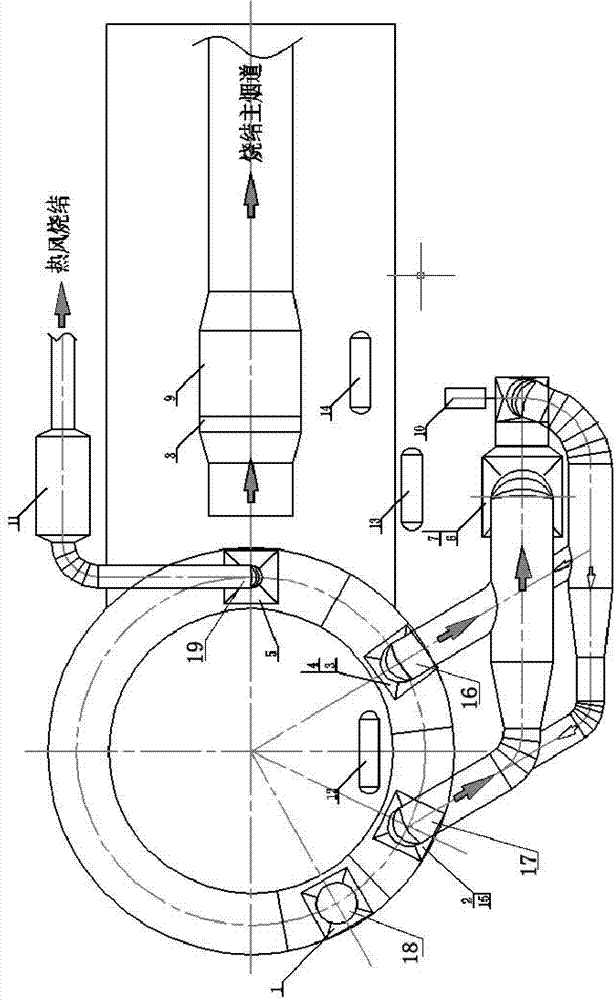

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

[0035] See figure 1 , a sintering waste heat comprehensive utilization device, including a flue waste heat utilization device, a medium-pressure superheater 3, a medium-pressure evaporator 4, a medium-pressure evaporator 2, a feed water preheater 1, a secondary superheater 5, and a low-pressure superheater Device 6, low-pressure evaporator 7, a flue waste heat utilization device is installed at the tail of the main flue to make full use of the waste heat flue gas with a temperature of 300-450°C in the main flue, reduce the inlet temperature of the main flue fan 10, and protect subsequent equipment;

[0036] Install medium-pressure superheater 3 and medium-pressure evaporator-4 at position 16 of section 1 of the cooler, make full use of the waste ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com