Self-propelled combine corn harvester for harvesting spike or seed, collecting straws and juicing

A combine harvester, self-propelled technology, applied in harvesters, agricultural machinery and implements, applications, etc., can solve the problem of no self-propelled juice extraction, juice harvesting, slag extraction and packaging functions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

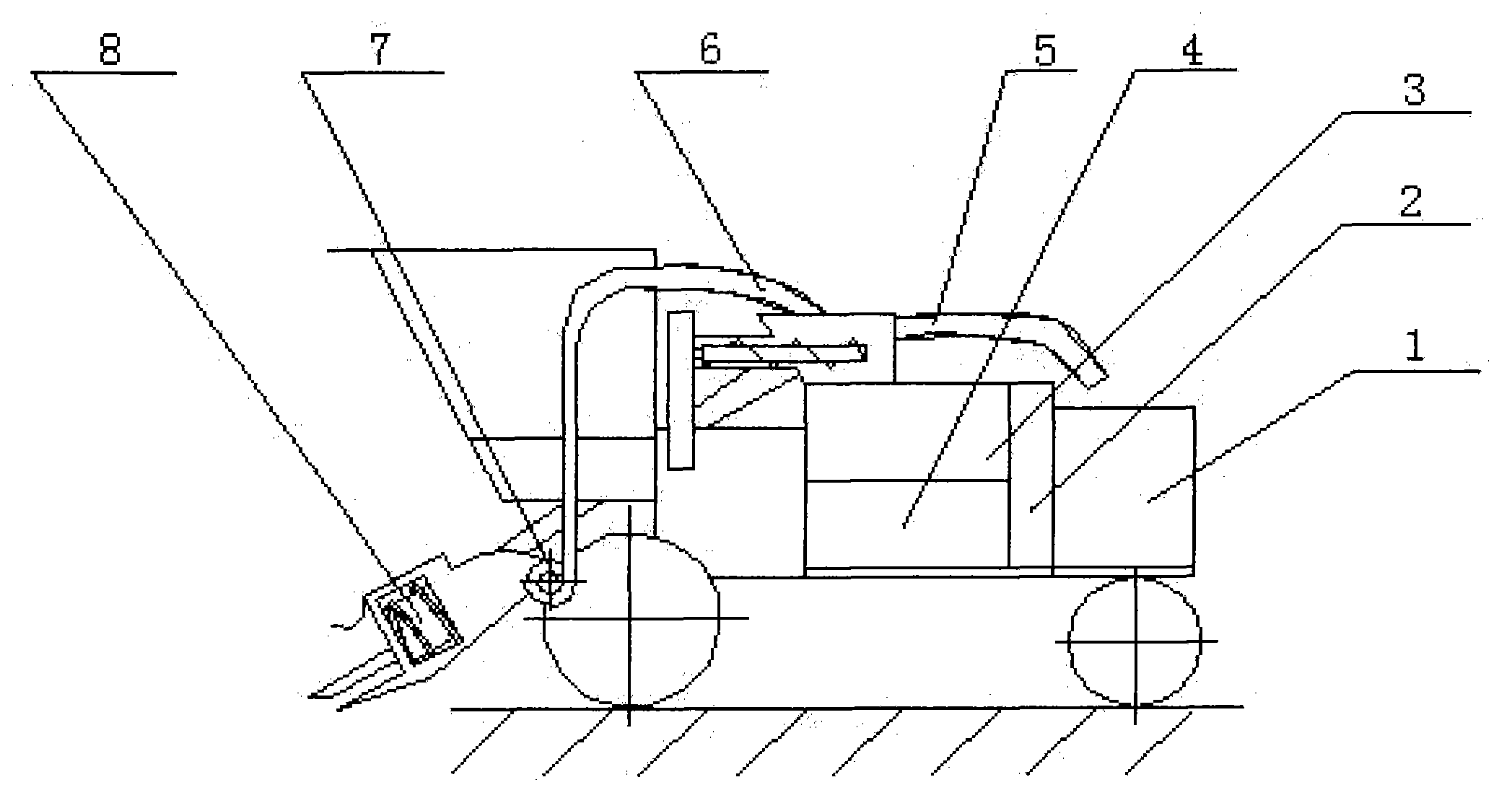

Embodiment 1

[0032] The structure of model 1 of the present invention is: integral machine power is a tractor head, and the ear collection box (1), slag pressing packing box (2), slag juice separation device (3), juice collection box ( 4), all power is provided by the tractor head. This machine harvests 7 mu of common corn per hour, collects dregs at 6 tons per hour, collects juice at 14 tons per hour, and collects corn ears at 7 tons per hour.

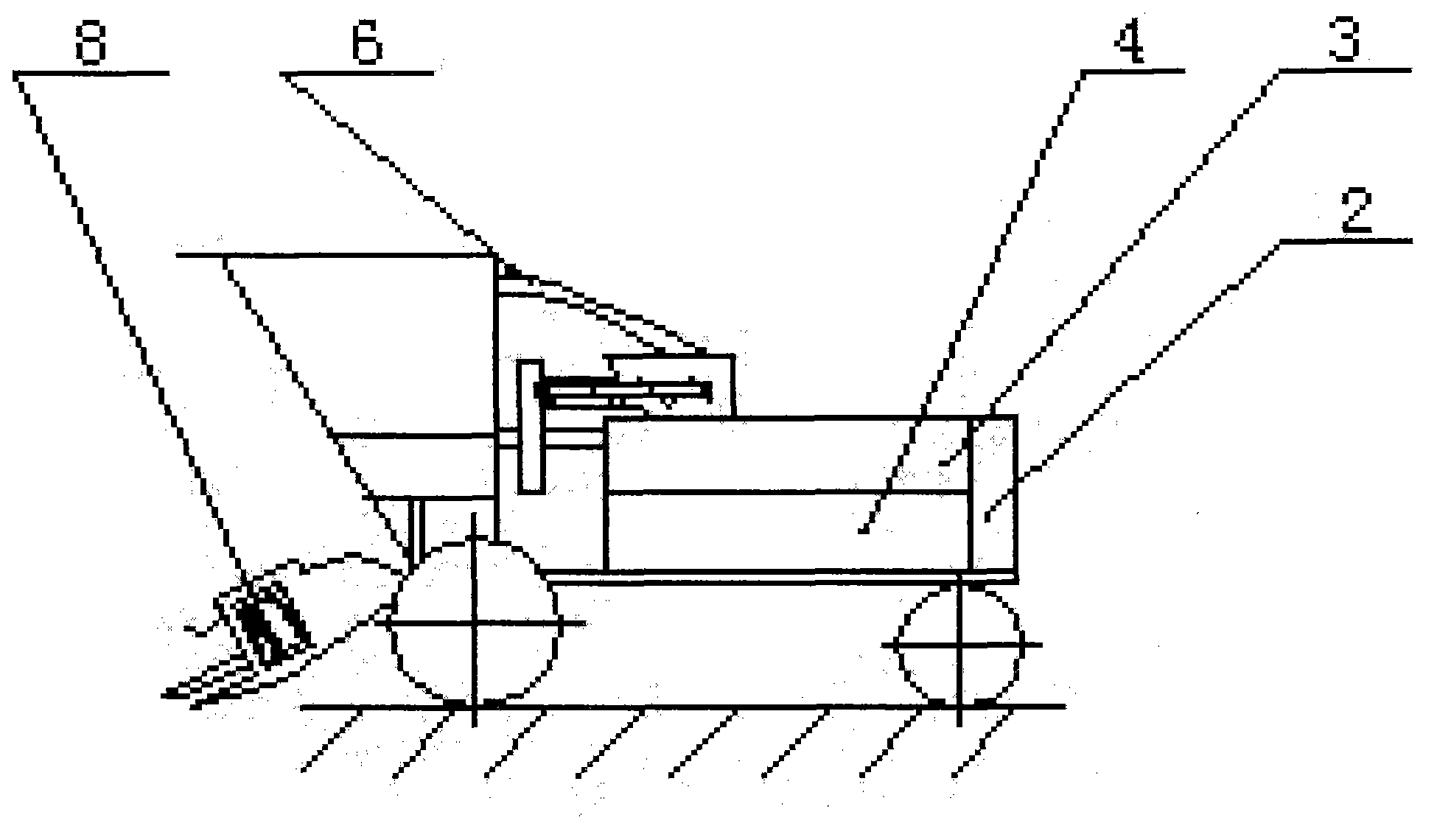

Embodiment 2

[0033] Embodiment 2: the structure of the model 2 of the present invention is: the integral motor force is a tractor head, and a rod picking device (8) is equipped with in front of the head, and the rod picking device (8) only receives the stalks and does not harvest the ears. , the tractor is dragged with slag squeezing packing box (2), slag juice separating device (3), and juice collecting box (4), and all power is provided by the tractor head. This machine harvests 10 mu of waxy corn stalks per hour, 9 tons of slag per hour, and 21 tons of juice per hour.

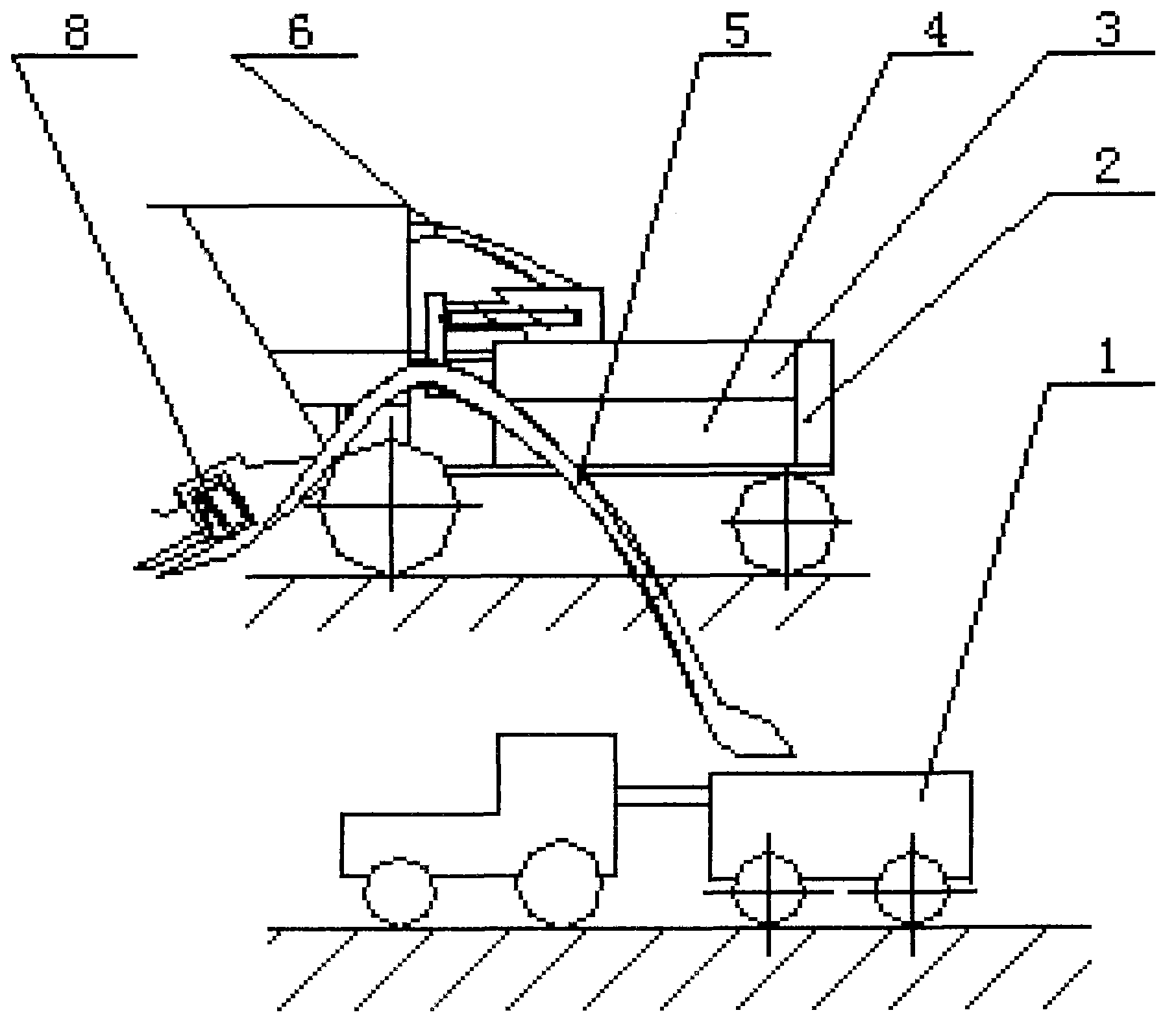

Embodiment 3

[0034] Embodiment 3: the structure of the model 3 of the present invention is: the split-type integral machine power is two tractor heads, and a tractor machine is dragged and is equipped with slag squeezing packing case (2), slag juice separation device (3), juice collecting box (4), the power is provided by the tractor head. The ear collection box (1) is housed on another auxiliary machine, and the power is provided by the auxiliary machine tractor. This machine harvests 15 mu of common corn per hour, collects dregs at 13.5 tons per hour, collects juice at 3105 tons per hour, and collects corn ears at 18 tons per hour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com