Carried-on-back lightweight combine harvester

A combine harvester and back-carrying technology, applied in the direction of harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of difficult field transfer, low harvesting efficiency, high labor intensity, etc., to simplify the complex transmission system, reduce the Labor intensity and the effect of reducing harvesting costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

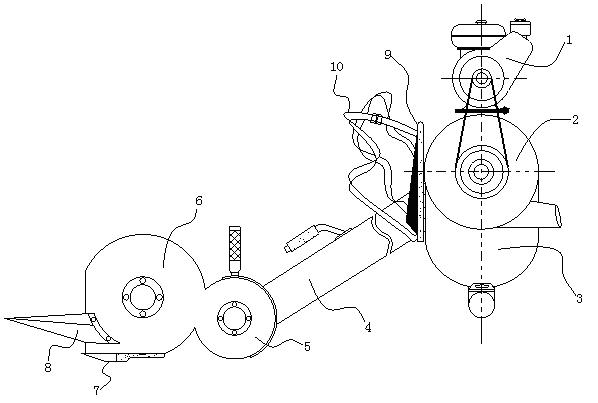

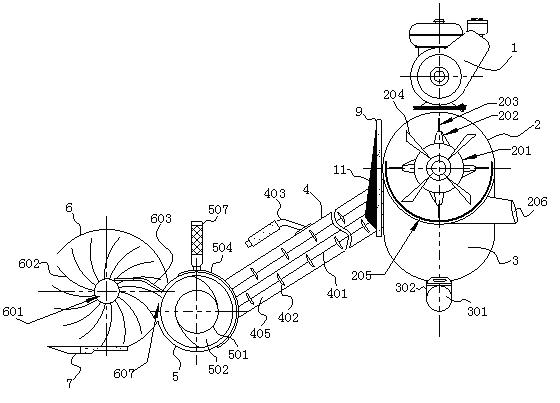

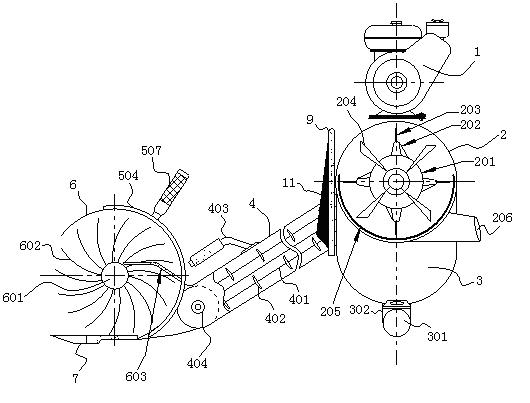

[0028] The following combination Figure 1 to Figure 9 The mechanism and structural arrangement of the embodiment of the present invention are described in detail.

[0029] As a preferred solution of the present invention, a lightweight carry-on combine harvester roughly mainly includes components that are connected by the engine (1) power source output shaft and the threshing drum (2), and the lower end of the threshing drum (2) is arranged for threshing The storage bin (3), on the outside of the barrel wall of the threshing drum (2) and the shell of the threshing storage bin (3), also includes a back plate (9), a back pad (11), and a strap (10), One end of the threshing drum (2) is connected to the conveying device (4), and the conveying device (4) is directly connected to the reeling device (6), or you can choose to add a screw auger device (5), and bordering to the reeling device ﹙6﹚, the main cutter﹙7﹚ is arranged at the front end of the reeling device﹙6﹚, or a pair of cutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com