Terminal actuator for picking tomato fruit clusters and picking method thereof

An end effector and fruit technology, applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problems of easily damaged fruit skin, low productivity, high cost, etc., and achieve the effect of compact device structure, reliable operation, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with drawings and embodiments. The technical features of the various implementations in the present invention can be combined accordingly on the premise that there is no conflict with each other.

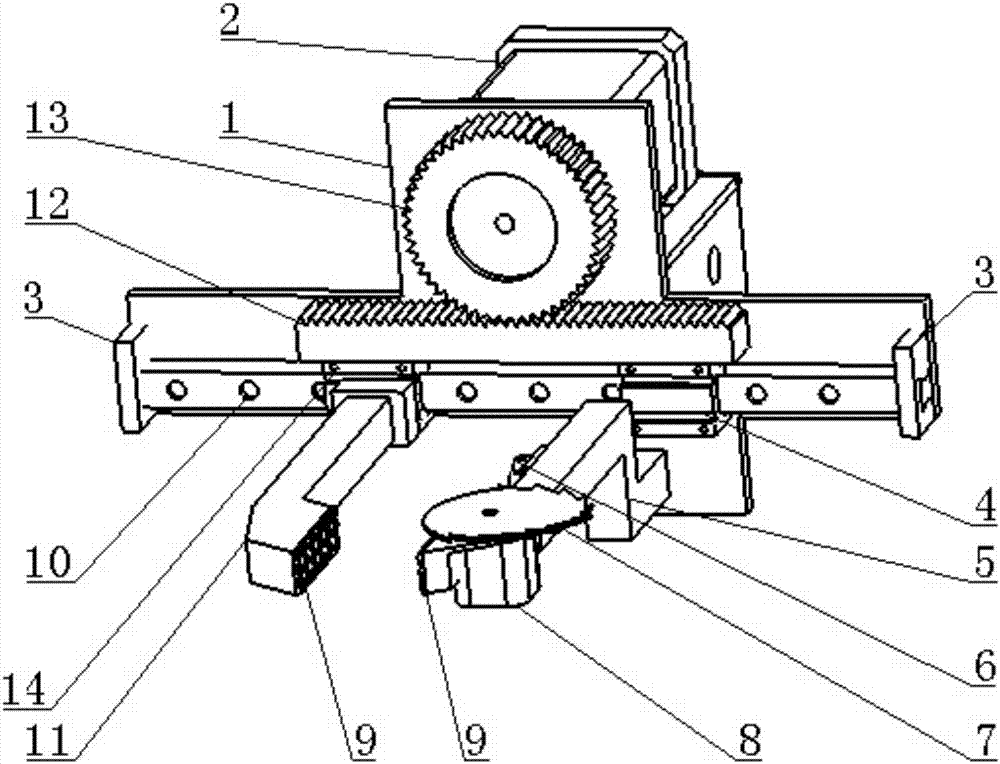

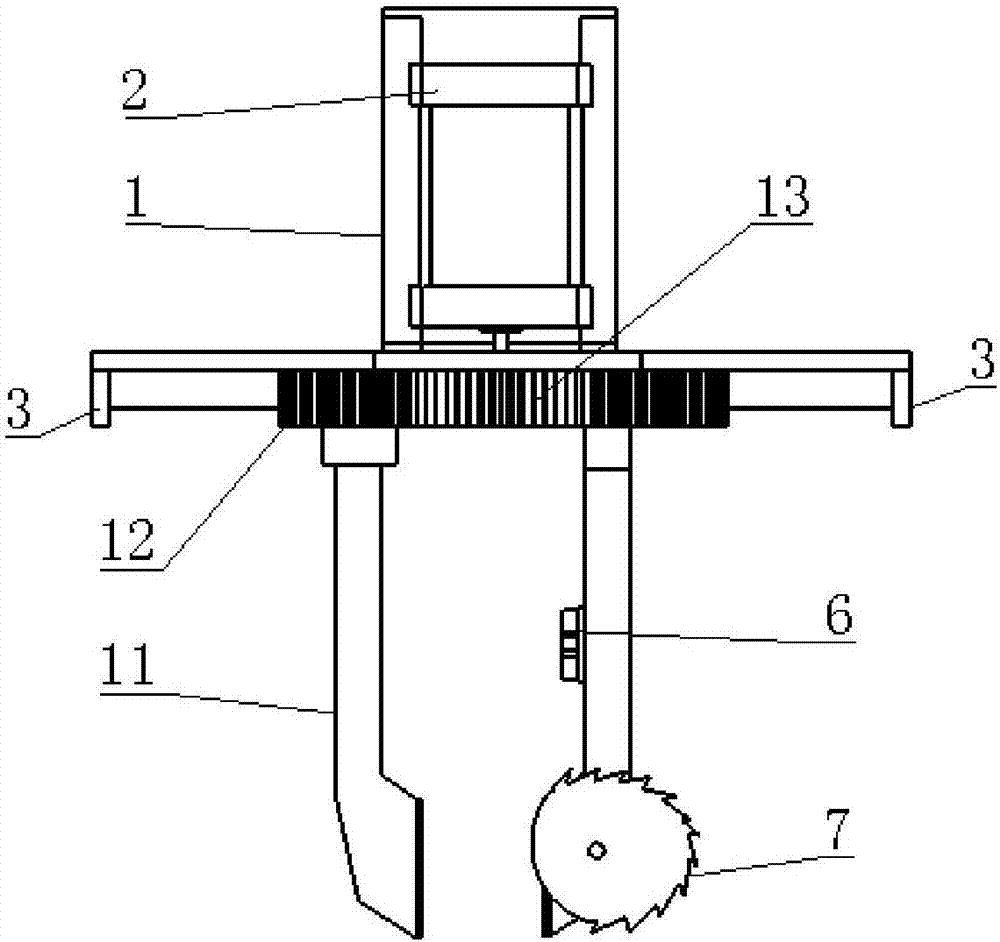

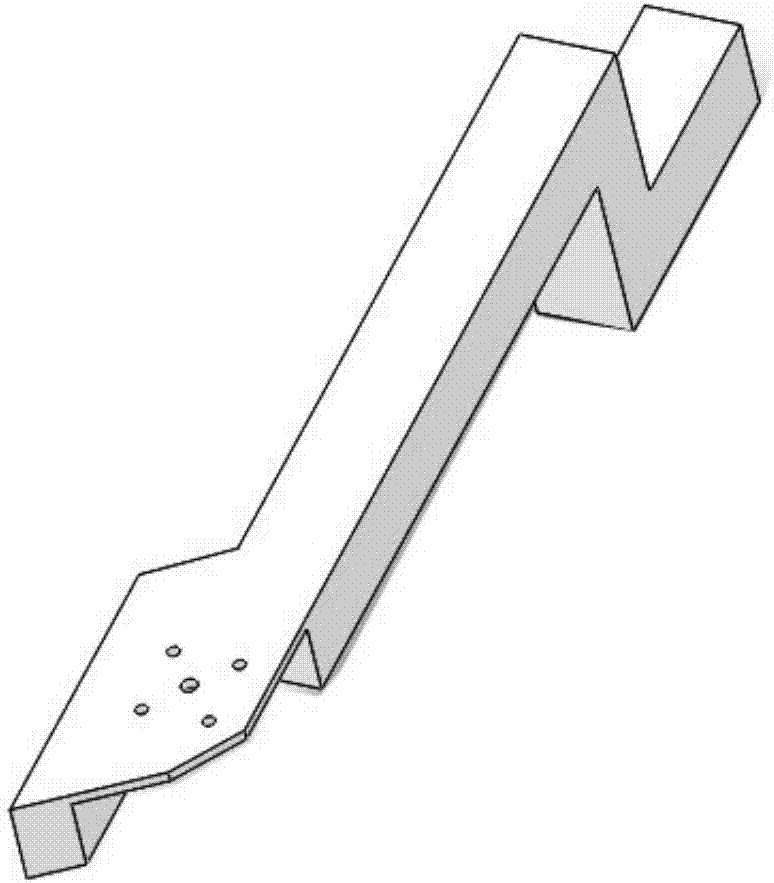

[0013] Such as figure 1 , figure 2 , image 3 As shown, the present invention includes a bracket 1, a clamping stepper motor 2, a support 3, a right slider 4, a fixed clamping arm 5, an ultrasonic distance measuring sensor 6, a cam serrated knife 7, a cutting stepper motor 8, and an elastic pad Sheet 9, slide rail 10, movable clamping arm 11, rack 12, gear 13, left slider 14, controller; The power output shaft passes through the frame 1 and is coaxially fixedly connected with the gear 13; the two supports 3 are respectively fixed on the two ends of the front side of the support 1, and the two ends of the slide rail 10 are respectively fixed on the two supports 3 on the support 1. Above, the left slider ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com