Bulrush mower

A harvester and reed technology, applied in the field of crop harvesting equipment, can solve the problem of inputting large manpower, and achieve the effects of reducing labor intensity, reducing harvesting cost, and improving harvesting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

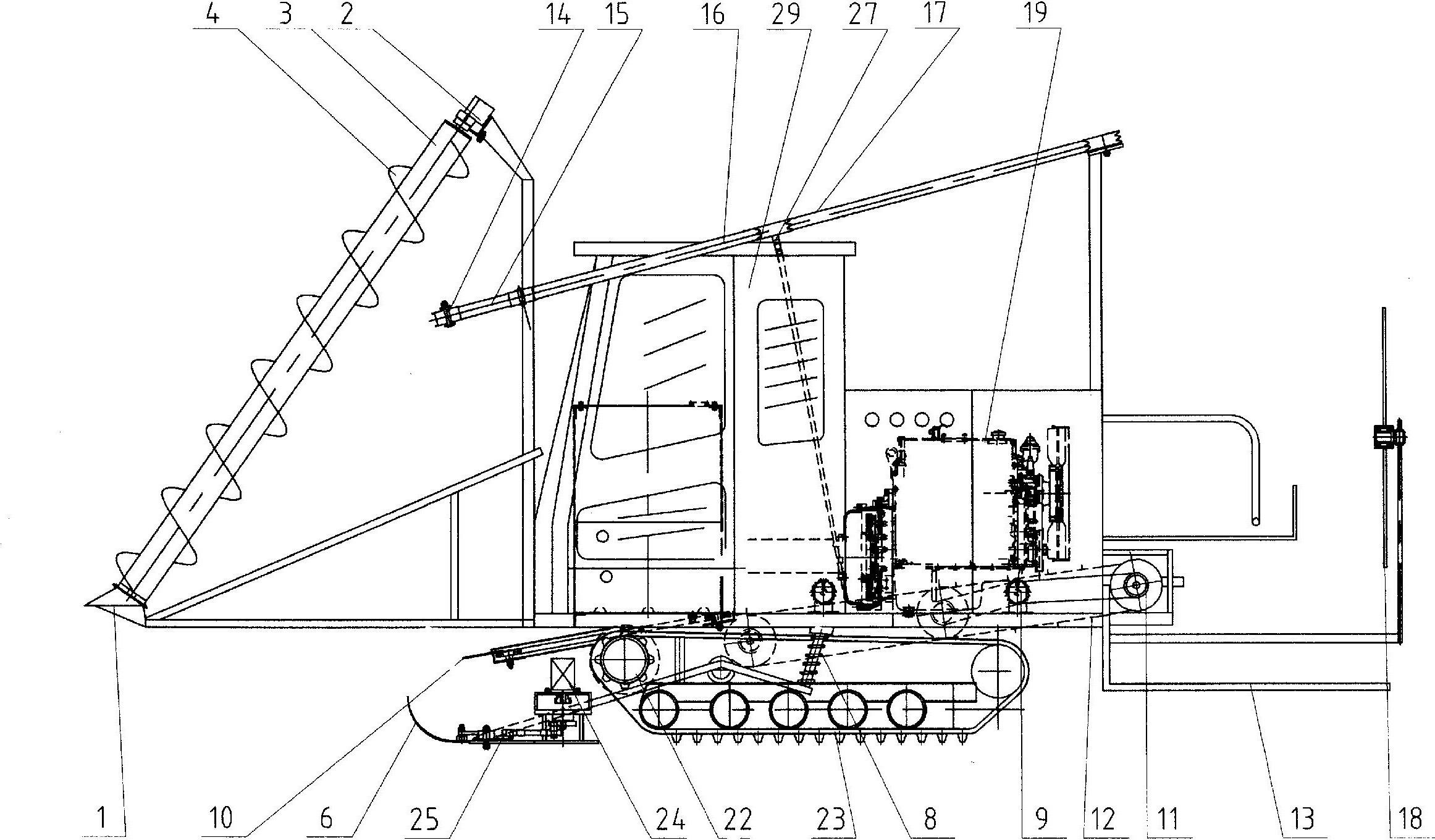

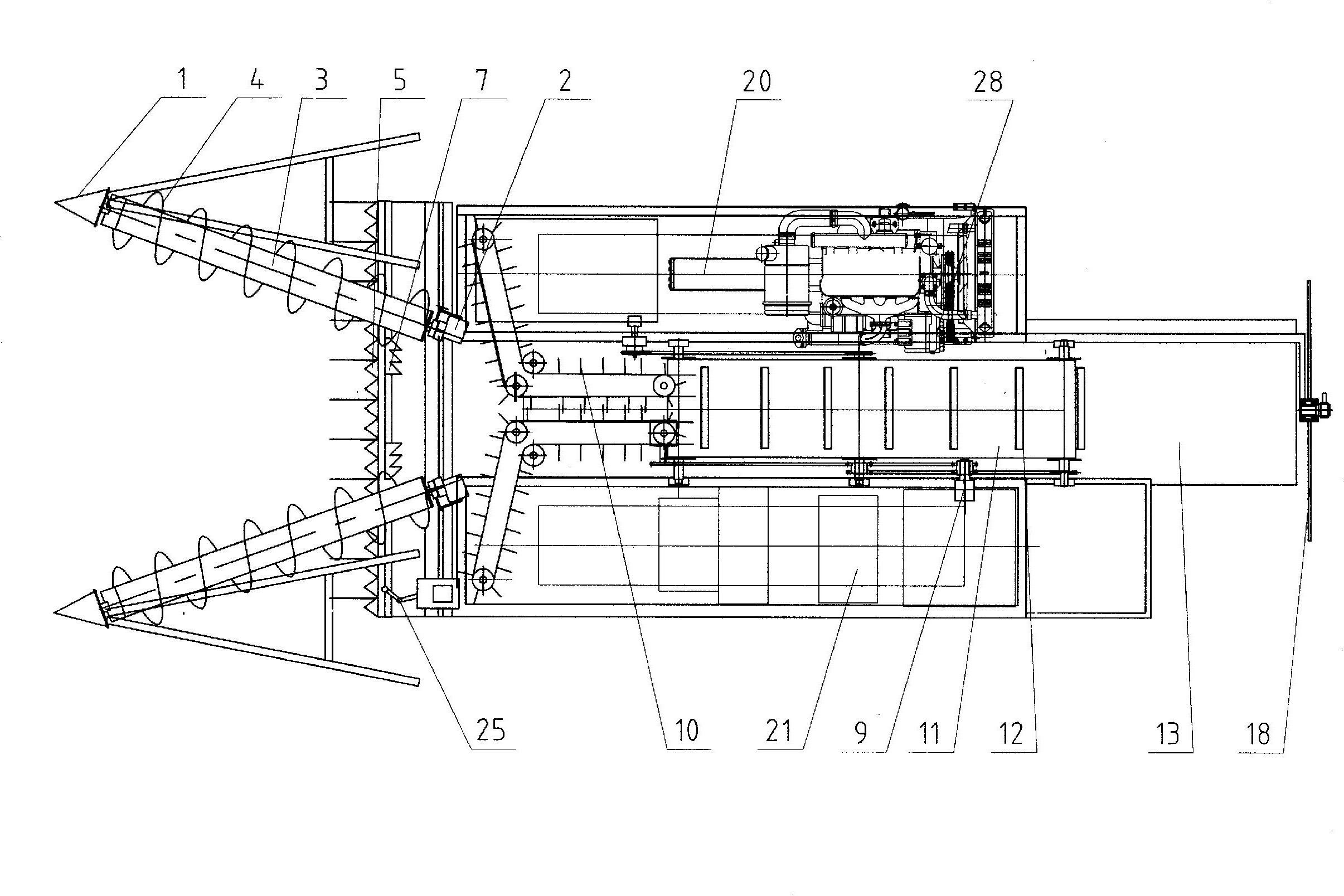

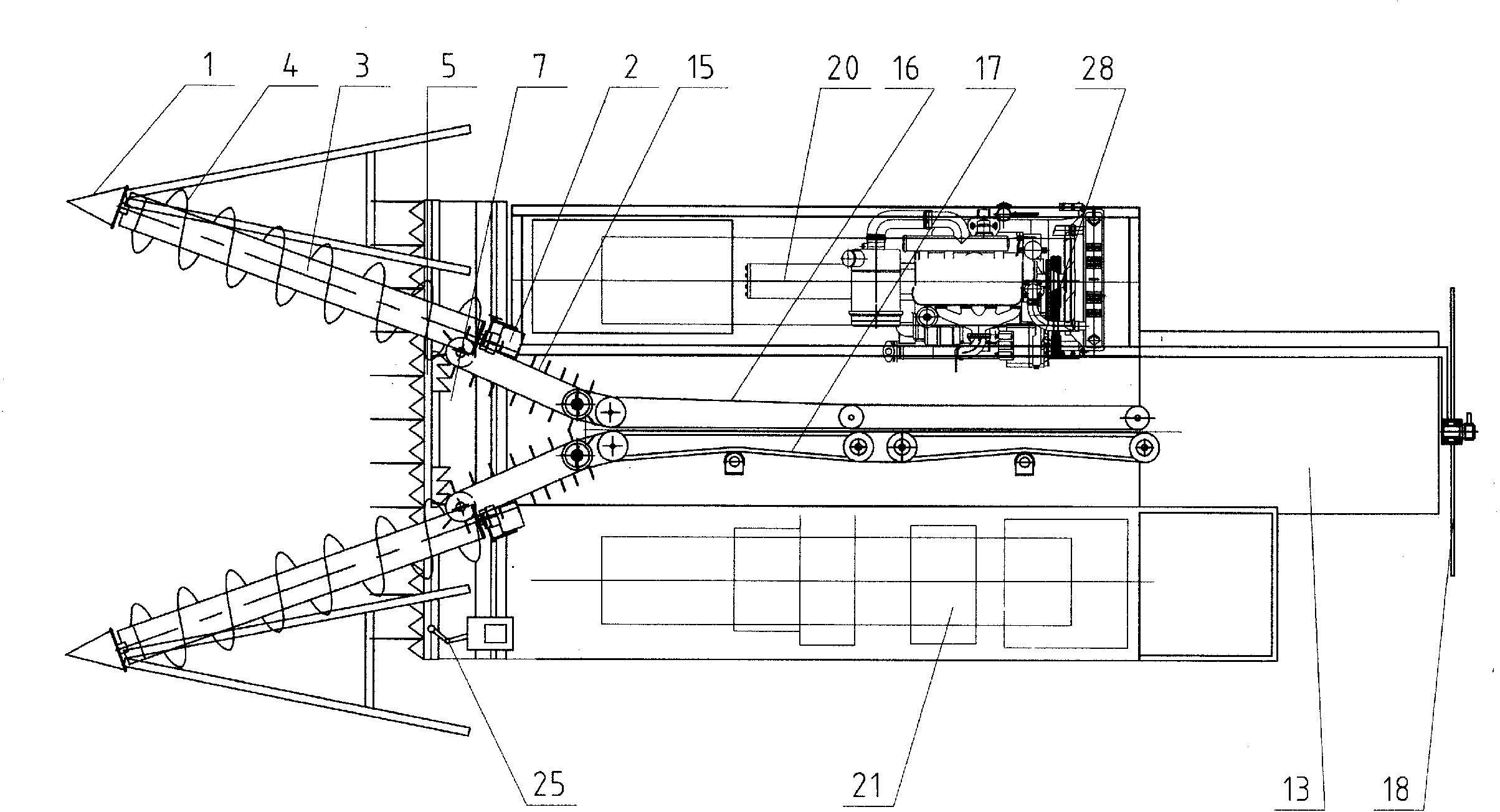

[0012] The invention includes a locomotive, a running mechanism and a cutting mechanism arranged at the lower part of the locomotive, a feeding mechanism arranged on the locomotive and a discharging mechanism arranged at the rear of the locomotive, wherein:

[0013] There are reed splitters 1 on both sides of the front of the locomotive, and reed splitters 1 are equipped with an electric drum device including a motor 2, a drum 3 and a screw blade 4, wherein the motor 2 and the drum 3 are connected by a coupling, and the screw blade 4 is set On the cylinder body of the drum 3; the electric drum device is two groups, which are respectively arranged on the reed splitter 1 on both sides, and the two groups of electric drum devices and the bottom guide rod of the reed splitter 1 form an inclined angle to the front end of the cab 29, and the two The spacing between the electric drum devices is set from top to bottom as a structure with a narrow top and a wide bottom;

[0014] The fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com