Touch powdery coating and preparation method thereof

A powder coating and tactile technology, applied in powder coatings, polyester coatings, epoxy resin coatings, etc., can solve the problems of low utilization rate, high production cost, and pollution of the environment by organic matter volatilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A preparation method for touch powder coating, comprising the following steps:

[0029] S1 Weigh the polyester resin, curing agent, whitening agent, leveling agent, degassing agent, accelerator, filler, and pigment by weight, pour it into the pre-mixing tank, and mix thoroughly at a speed of 1500 rpm for 3 -5 minutes, get the premixed material;

[0030] S2 The pre-mixed material is added to the twin-screw extruder for extrusion;

[0031] S3 Extruded materials are cooled by pressing rollers, pressed into tablets, ground, sieved and packaged.

[0032] In the step S2, the twin-screw extrusion temperature is set at 80-110°C, the screw speed is 38-48HZ, and the feeding speed is 10-20HZ. The average particle size of the powder after sieving in step S3 is 30-40UM.

Embodiment 1

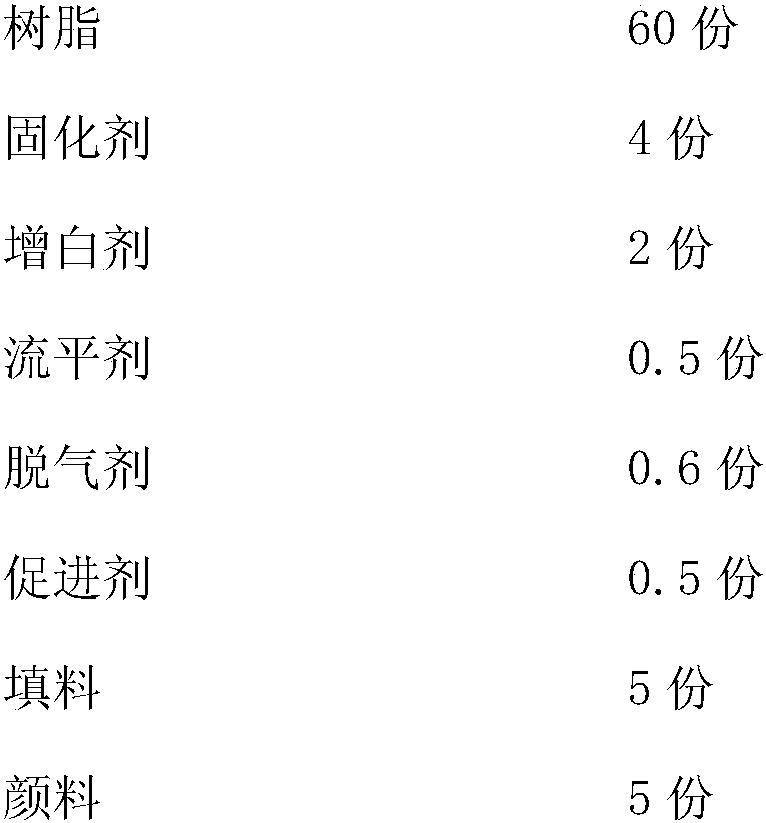

[0033] Embodiment 1, a kind of tactile powder coating, comprises the following components by weight:

[0034]

[0035] The resin is epoxy resin with a softening point of 88°C

[0036] The curing agent is an epoxy curing agent.

[0037] Process: The raw materials are weighed according to the formula, fully mixed by the pre-mixer at high speed, extruded by the extruder, cooled into pieces and crushed, then graded, ground and sieved by ACM.

Embodiment 2

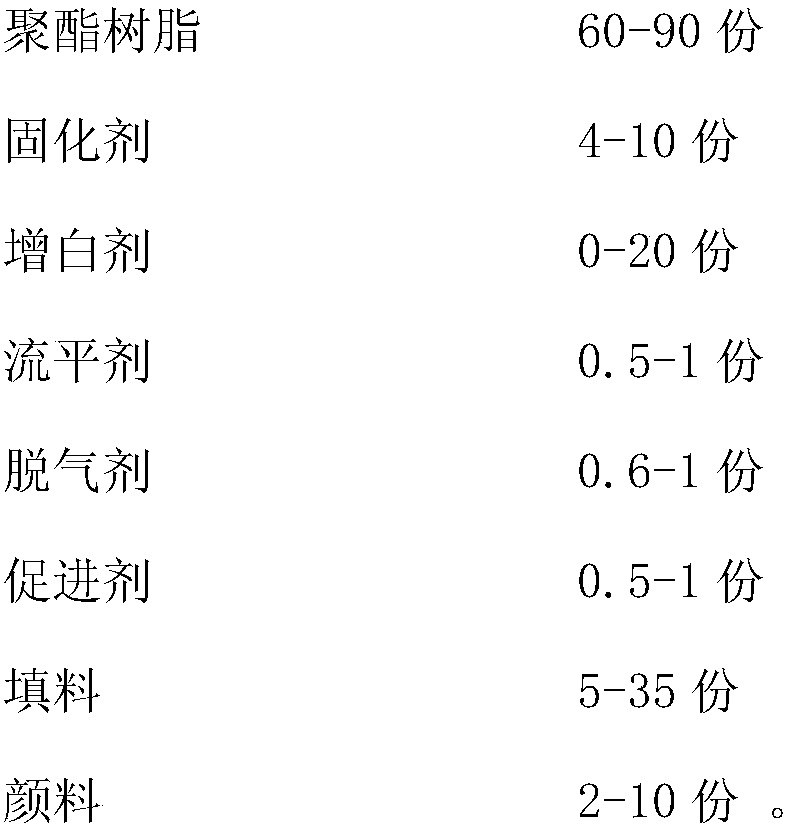

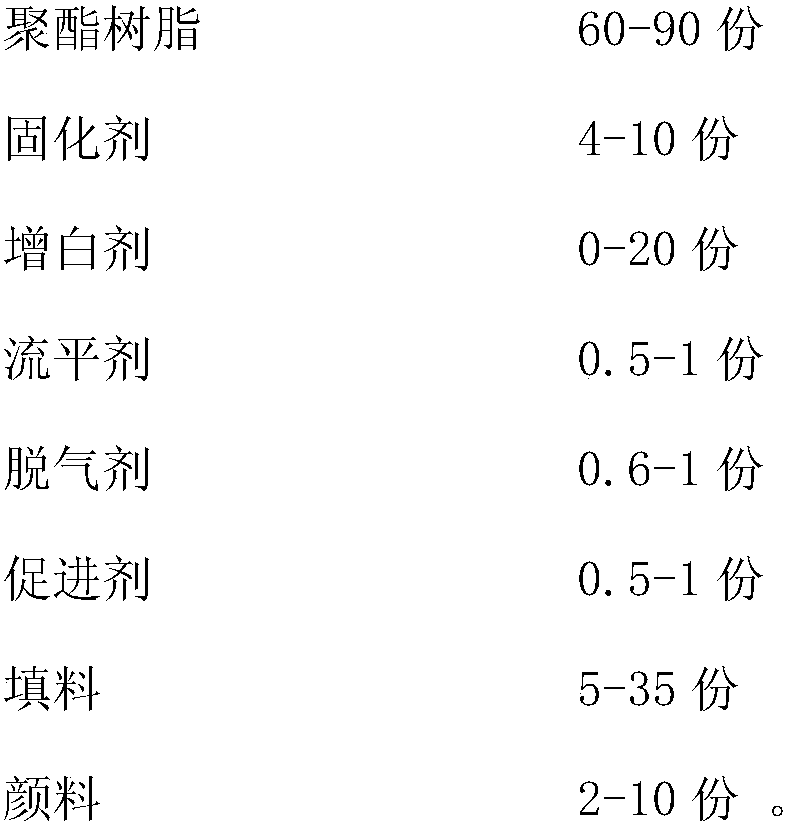

[0038] Embodiment 2, a kind of tactile powder coating, comprises the following components by weight:

[0039]

[0040] The resin is a carboxyl-terminated polyester resin with an acid value of 28-33mgKOH / g and a viscosity of 3000-4000mPa.s

[0041] The curing agent is an acrylic matting resin. Take the reaction ratio with resin 2.7-3.0.

[0042] Process: The raw materials are weighed according to the formula, fully mixed by the pre-mixer at high speed, extruded by the extruder, cooled into pieces and crushed, then graded, ground and sieved by ACM.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com