Industrial part equipment transportation robot

A technology of robots and parts, applied in the field of industrial parts and equipment transportation robots, can solve the problems of time-consuming, labor-intensive, easy to lose, etc., and achieve the effect of convenient access, cost saving, and convenient long-distance transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

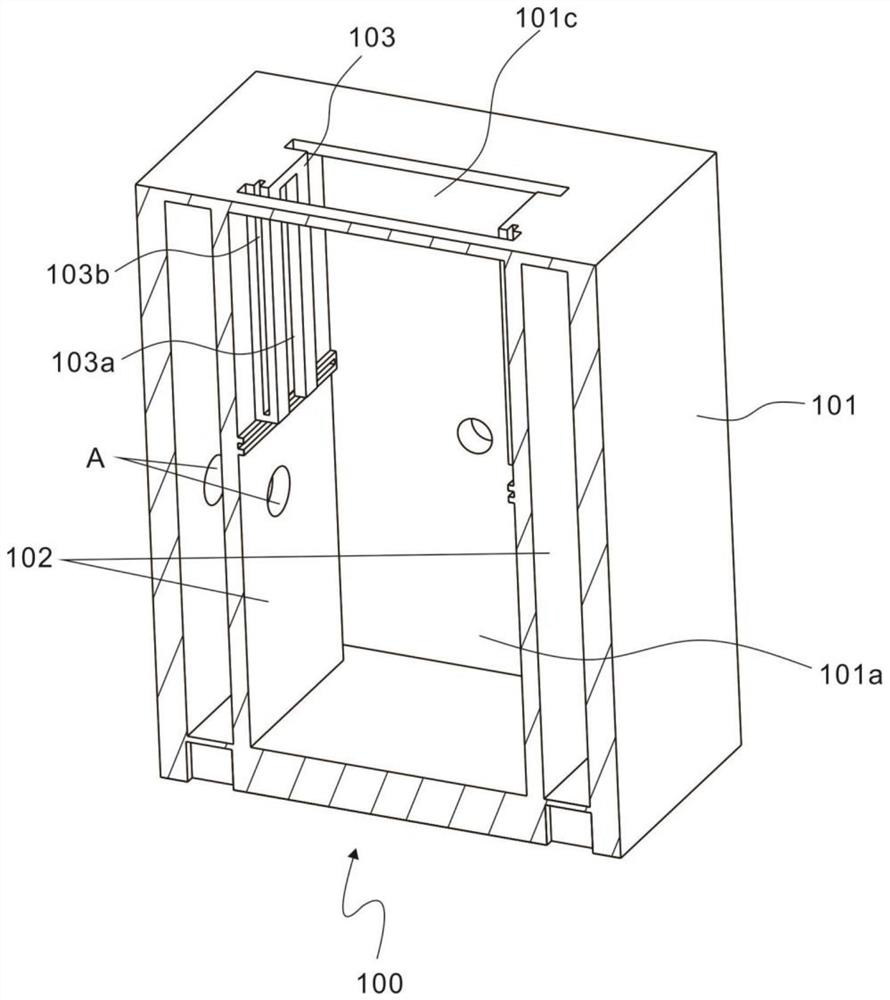

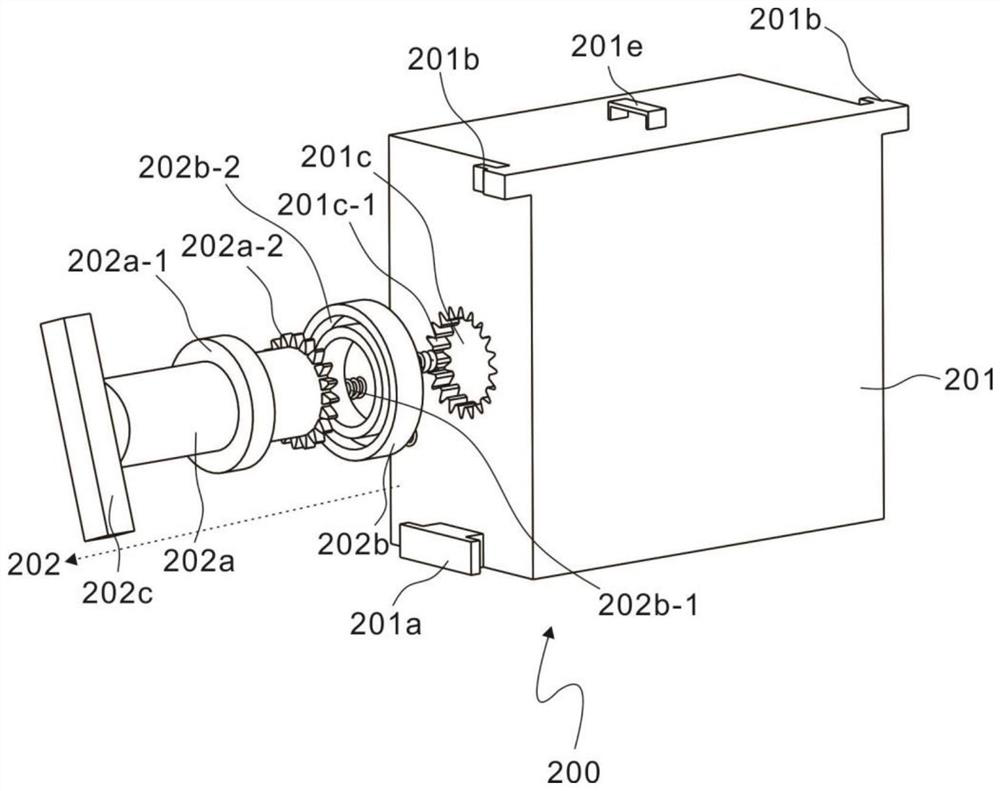

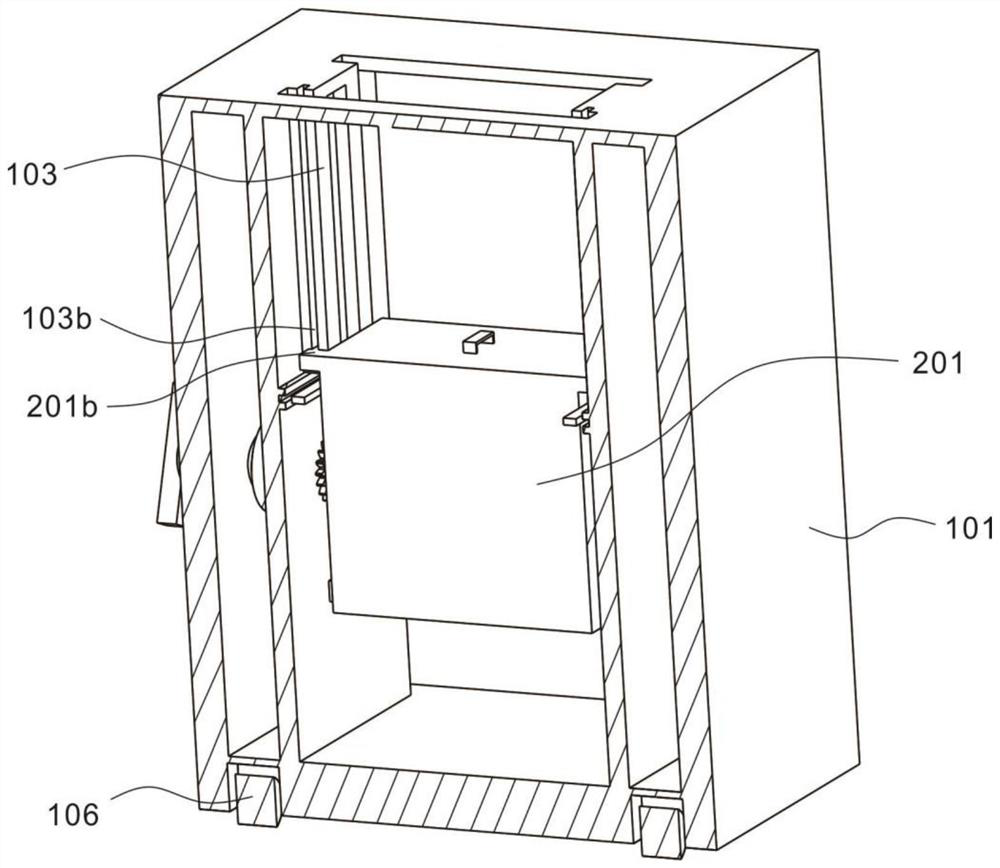

[0028] refer to Figure 1~3 , is the first embodiment of the present invention, which provides an industrial parts equipment transportation robot, which includes a moving module 100 and a storage module 200 for accessing parts and facilitating the storage and delivery of parts in restaurants.

[0029] The mobile module 100 includes a storage box 101, a grid baffle 102 and a slide bar 103. Specifically, a cavity 101a is arranged in the storage box 101, and there are two grid baffles 102, both of which are square plate-shaped structures, vertically and symmetrically arranged in the cavity. Inside the body 101a and the grid baffle 102 is connected from the bottom of the cavity 101a to the top of the cavity 101a, the board surface of the grid baffle 102 is opposite, and there are also two slide bars 103, which are respectively vertically arranged on the grid baffle 102 and opposite to each other. setting, each slide bar 103 has the same structure.

[0030] Further, a T-shaped slo...

Embodiment 2

[0037] refer to Figure 4~6 , is the second embodiment of the present invention, which is based on the previous embodiment, and the storage module 200 further includes a limiting plate 204 .

[0038] A concave bar 205 is horizontally arranged below the sliding bar 103 on the grid baffle plate 102, and the two ends of the limiting plate 204 extend into the concave bar 205 to limit the position so that the limiting plate 204 is horizontally erected between the two concave bars 205, Limiting groove 204a is arranged at the bottom of limiting plate 204, and limiting groove 204a is bent at ninety degrees, and block 201d is arranged on part rack 201, and locking block 201d is also curved at ninety degrees, and locking block 201d can cooperate with limiting groove 204a Limiting, when the part rack 201 rotates ninety degrees, the clamping block 201d can rotate and extend into the limiting groove 204a. At this time, the part rack 201 remains in an inclined state under the action of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com