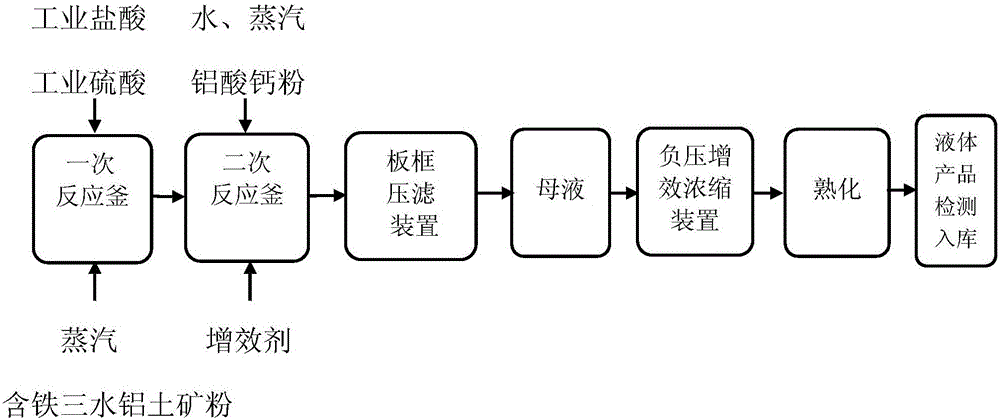

Production process of high-efficiency and high-concentration polyaluminum ferric chloride sulfate

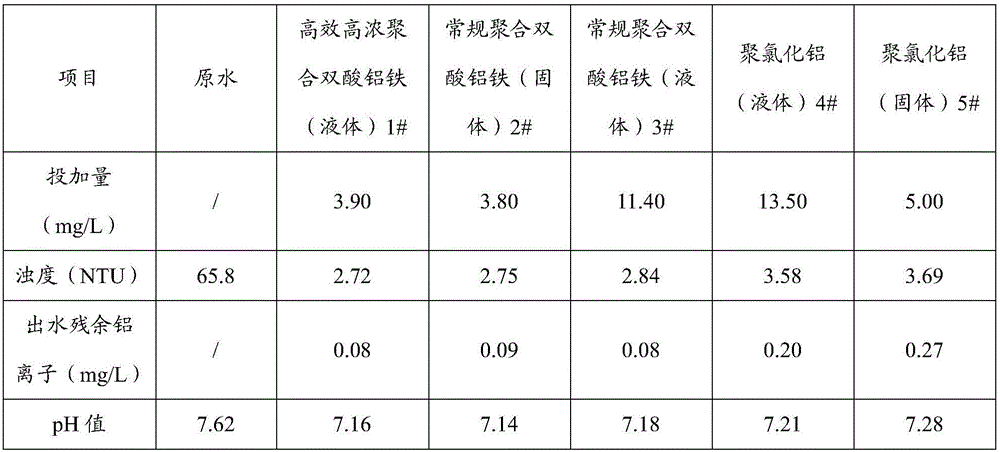

A technology for polymerizing aluminum-iron bis-acid and production process, which is applied in the fields of iron compounds, inorganic chemistry, water/sludge/sewage treatment, etc. It can solve the problems of high active ingredients and lack of promotion of liquid products, so as to improve the degree of polymerization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031]Step 1: Add an appropriate amount of water in an acid-resistant primary reaction kettle with a stirring device heated by steam, add 155 parts of industrial hydrochloric acid and 13 parts of 98% sulfuric acid according to the proportion under constant stirring, and add 56 parts of the hydrochloric acid solution at normal pressure and temperature. part of iron-containing bauxite powder, stirred until dissolved; then continue to heat up until the temperature of the reaction system is controlled at 105-125°C, and keep it under normal pressure for 5 hours; take samples for detection;

[0032] Step 2: Pump the primary feed liquid obtained in Step 1 into an acid-resistant polymerization secondary reaction kettle with a stirring device heated by steam, add an appropriate amount of water under constant stirring, and add 60 parts of calcium aluminate powder, and add During the process, the reaction self-heating is used to increase the temperature of the feed liquid. After the addit...

Embodiment 2

[0037] Step 1: Add an appropriate amount of water in an acid-resistant primary reaction kettle heated by steam with a stirring device, add 129 parts of industrial hydrochloric acid and 9 parts of 98% sulfuric acid according to the proportion under constant stirring, and add 40 parts of the hydrochloric acid solution at normal pressure and temperature. part of iron-containing bauxite powder, stirred until dissolved; then continue to heat up until the temperature of the reaction system is controlled at 105-125°C, and keep it under normal pressure for 4 hours; take samples for detection;

[0038] Step 2: Pump the primary feed liquid obtained in Step 1 into an acid-resistant polymerization secondary reaction kettle with a stirring device heated by steam, add an appropriate amount of water under constant stirring, and add 49 parts of calcium aluminate powder, and add During the process, the reaction self-heating is used to increase the temperature of the feed liquid. After the addit...

Embodiment 3

[0043] Step 1: Add an appropriate amount of water in an acid-resistant primary reaction kettle heated by steam with a stirring device, add 141 parts of industrial hydrochloric acid and 12 parts of 98% sulfuric acid according to the proportion under constant stirring, and add 47 parts of hydrochloric acid to the hydrochloric acid solution at normal pressure and temperature. part of iron-containing bauxite powder, stirred until dissolved; then continue to heat up until the temperature of the reaction system is controlled at 105-125°C, and keep it under normal pressure for 4.5 hours; sampling and testing;

[0044] Step 2: Pump the primary feed liquid obtained in Step 1 into an acid-resistant polymerization secondary reaction kettle with a stirring device heated by steam, add an appropriate amount of water under constant stirring, and add 56 parts of calcium aluminate powder, and add During the process, the reaction self-heating is used to increase the temperature of the feed liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com