A long-distance conveying device for bag-type dust-removing powdered magnesium sulfate

A long-distance transportation and bag dust removal technology, which is applied in the field of magnesium sulfate, can solve the problems that the transportation device does not have dust removal effect, a large amount of magnesium sulfate dust is easy to float, and affects the environment, so as to achieve convenient long-distance transportation, fast unloading and easy maintenance. The effect of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

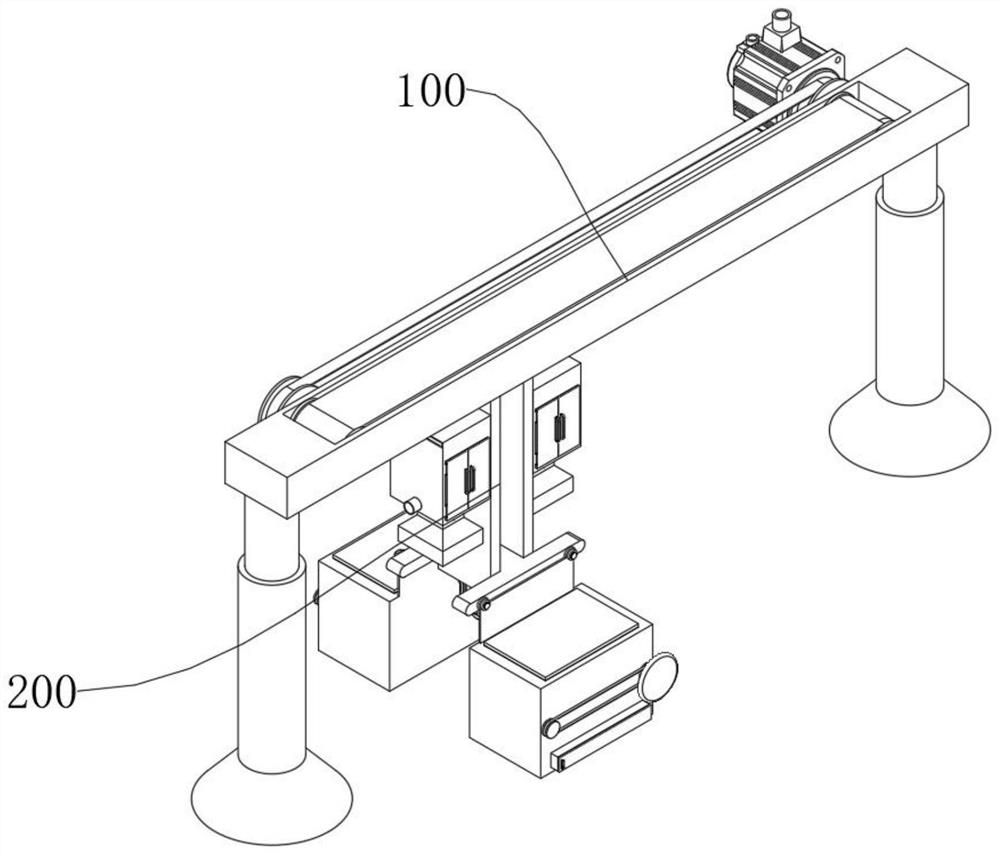

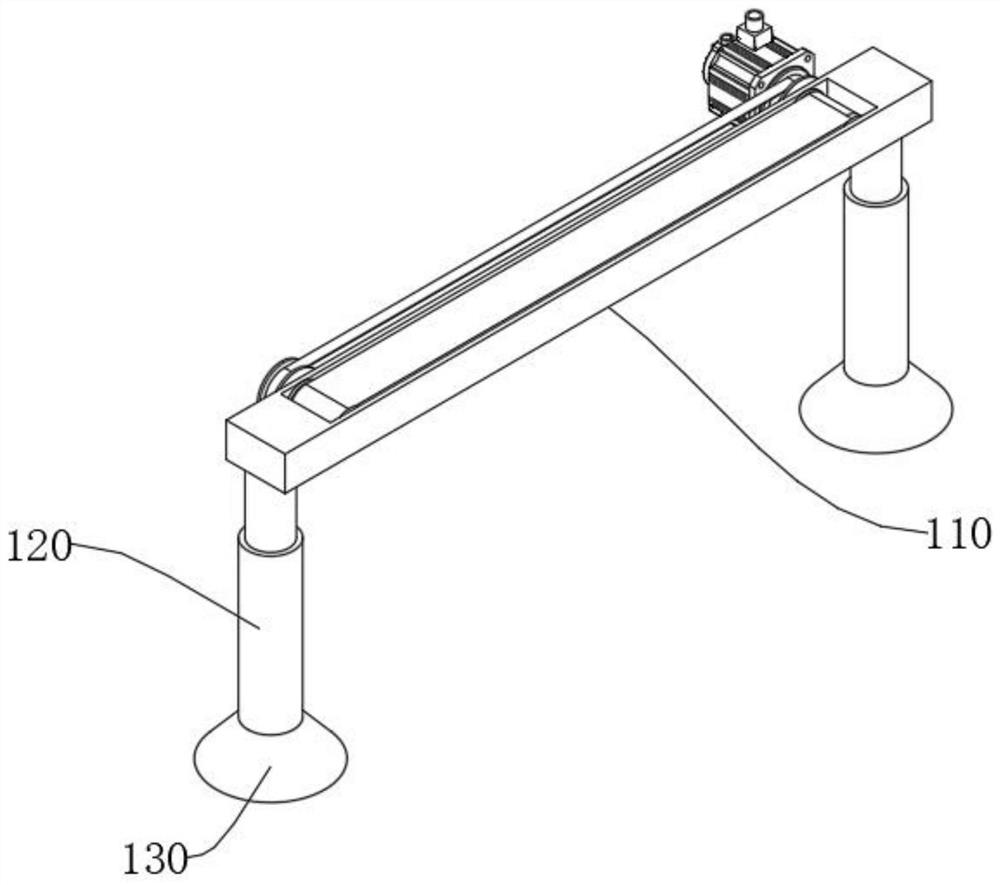

[0056] See Figure 1- Figure 13 As shown, the present embodiment provides a bag-shaped dust-shaped powder magnesium sulfate length distance conveying device including the conveying frame 100 and the conveying frame 100, and the conveying frame 100 includes:

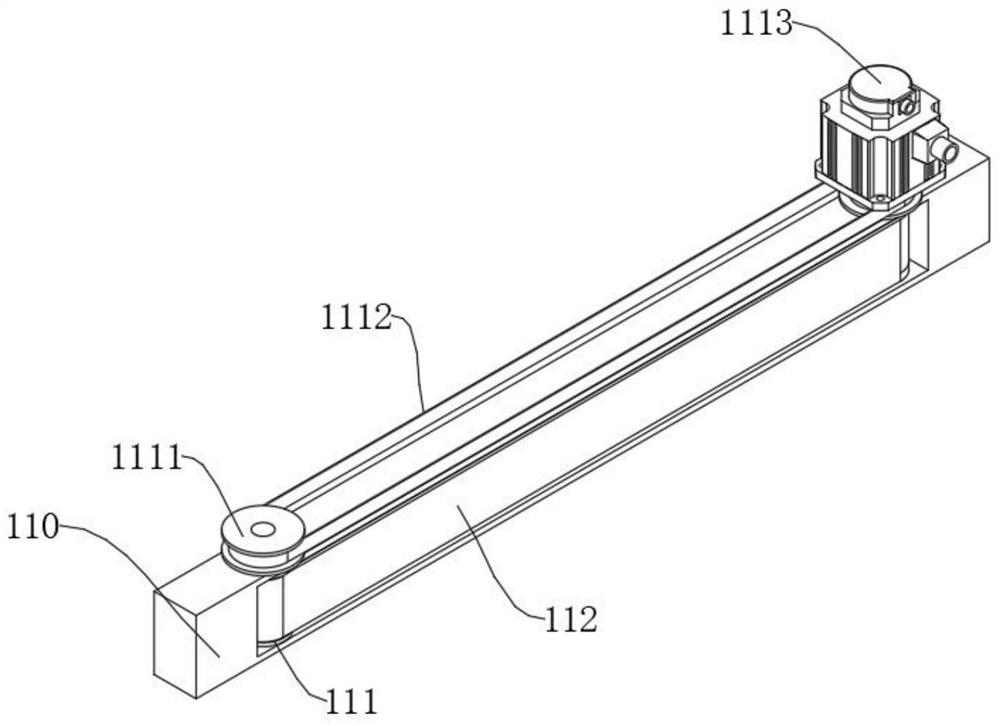

[0057] The mount 110, the inside of the mount 110 is rotated and provided having two belt roller 111, and the end of the belt roller 111 is provided with a conveying belt 1111, and the two conveying belt 1112 is provided with a conveying belt 1112, one of which transports the belt disk 1111 end. The portion is connected to the transmission motor 1113 output shaft, and the conveying motor 1113 is turned on, and the output shaft is output by the conveying motor 1113, and one of the transport belt 1112 can be rotated by the conveying belt 1112, and the two belt roller 111 can be rotated simultaneously. Easy, there is a conveyor belt 112 between the outer walls of the two belt roller 111, and as the rotation of the belt roller 111...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com