Cloth bag dust removal type powdery magnesium sulfate long-distance conveying device

A long-distance transportation and bag dust removal technology, which is applied in the field of magnesium sulfate, can solve the problems that the transportation device does not have dust removal effect, a large amount of magnesium sulfate dust is easy to float, and affects the environment, so as to achieve convenient long-distance transportation, fast unloading and easy maintenance. The effect of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

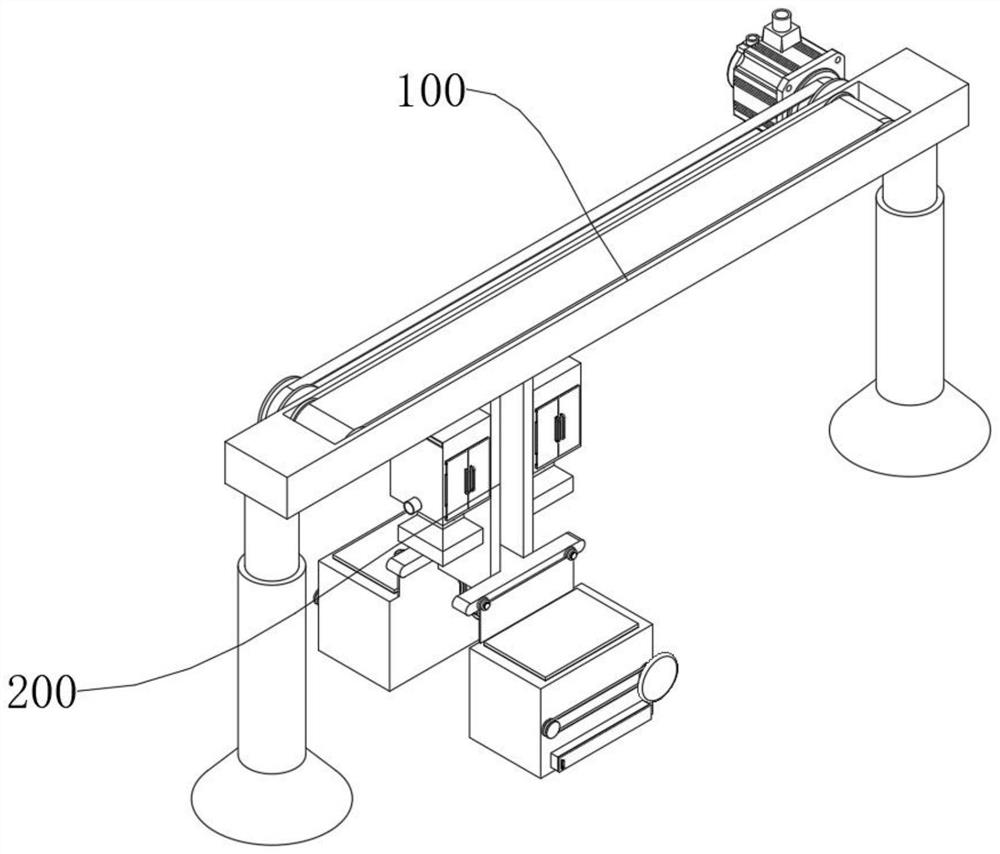

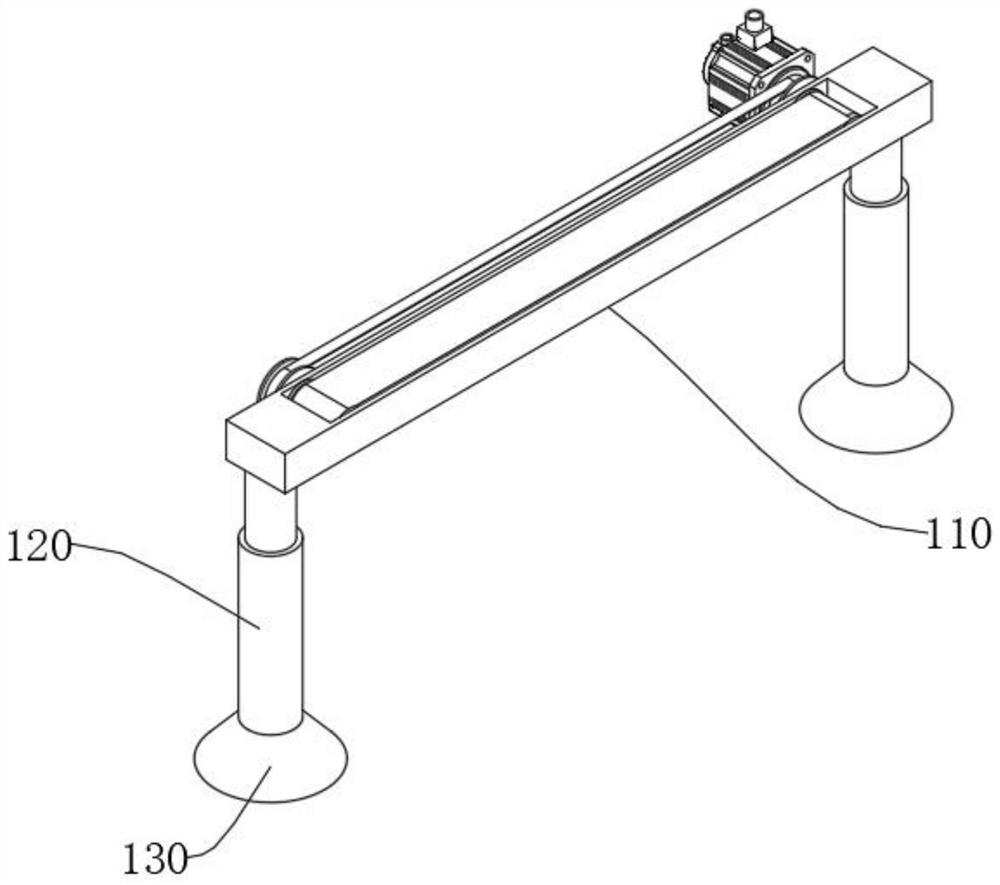

[0056] see Figure 1-Figure 13 As shown, this embodiment provides a bag dust removal type powdered magnesium sulfate long-distance conveying device, including a conveying frame 100 and a conveying mechanism 200 on the conveying frame 100, and the conveying frame 100 at least includes:

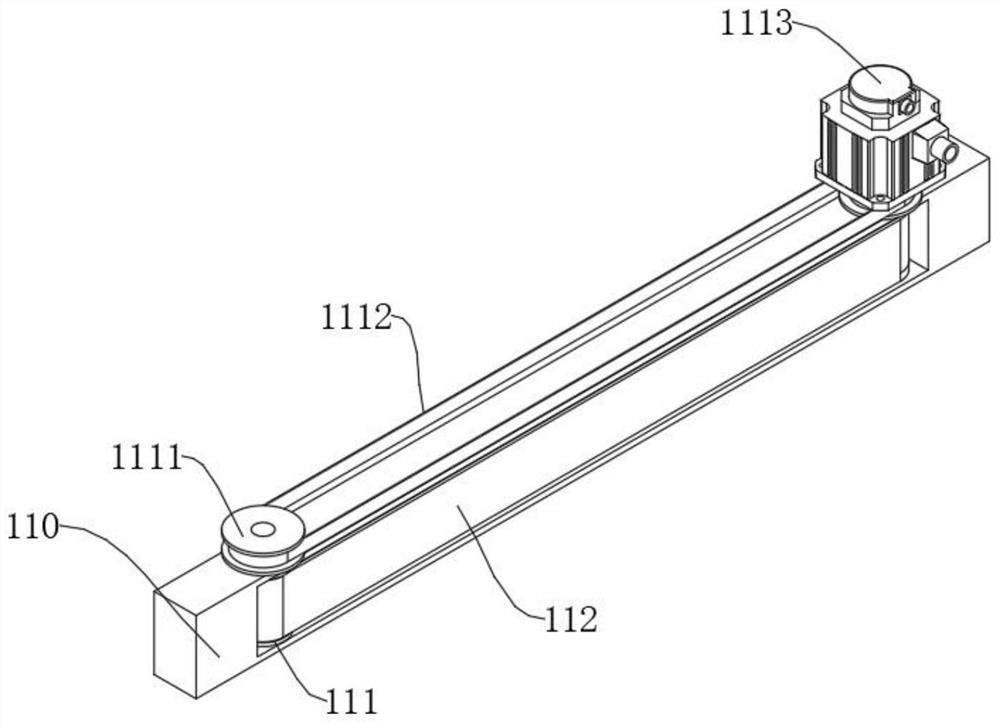

[0057] The fixed frame 110, two belt rollers 111 are rotatably arranged inside the fixed frame 110, the end of the belt roller 111 is provided with a conveying belt pulley 1111, and a conveying belt 1112 is disposed between the two conveying belt pulleys 1111, one of which is at the end of the conveying belt pulley 1111 The output shaft of the conveying motor 1113 is connected to the output shaft of the conveying motor 1113, and the conveying motor 1113 is powered on to make it work. The output shaft of the conveying motor 1113 drives one of the conveying belt pulleys 1111 to rotate. The operation is convenient, a conveyor belt 112 is arranged between the outer walls of the two belt rollers 111...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com